Trailboss QTHD774L User manual

Towbar Fitting Instructions

To Suit HOLDEN COMMODORE ZB CL4

Part Number QTHD774L

Rating 2100/90 kg

PLACE THESE INSTRUCTIONS IN THE VEHICLE’S GLOVEBOX AFTER INSTALLATION IS COMPLETED

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9898 3299

Email: info@cequent.com.au

Post: PO Box 4050, Dandenong South VIC 3175

Rev: A Page 1 Issue Date: 03-10-2018

FOR TRAILER TOWING PURPOSES ONLY

For towing capacity details please refer to vehicle owner’s

manual or to the manufacturer. Overloading can void your

warranties.

WARNING:

1. Do not, drill, cut, weld or otherwise modify the tow bar.

2. If you are using electric welding on a motor vehicle, always check that the vehicle is not equipped with electronic engine or

instrument management equipment. Failure to do so could destroy any onboard computers. If in doubt, check with the

vehicle's manufacturer.

3. The high tensile fasteners supplied with this product were used to achieve the specified rating. If replacement is required

ensure that fasteners of the same rating & quality are used. Contact an authorised Trailboss dealer if further information is

required.

4. If TBM is used in inverted position tow ball may make contact with rear tailgate when lowered, which could cause damage.

General:

1. Ensure all hardware items have been included refer to assembly diagram.

2. It is recommended that the instructions are read through and completely understood before making any attempt to fit this

product.

3. Be wary of any changes to vehicle designs or other accessories that may conflict with the installation of this product.

4. Before drilling ensure that the area is clear of fuel, electrical & other components.

5. All holes drilled into the body panels shall have all burrs & swarf removed then coated with a suitable rust preventative paint.

6. For vehicles that require the bumper to be cut. Ensure cut out area is in correct position on the vehicle prior to cutting the

bumper.

7. The high tensile fasteners supplied with this product were used to achieve the specified rating. If replacement is required

ensure that fasteners of the same rating & quality are used. Contact an authorized Trailboss dealer if further information is

required.

8. Ensure that all hardware is fastened to torque list below check fasteners on regular basis.

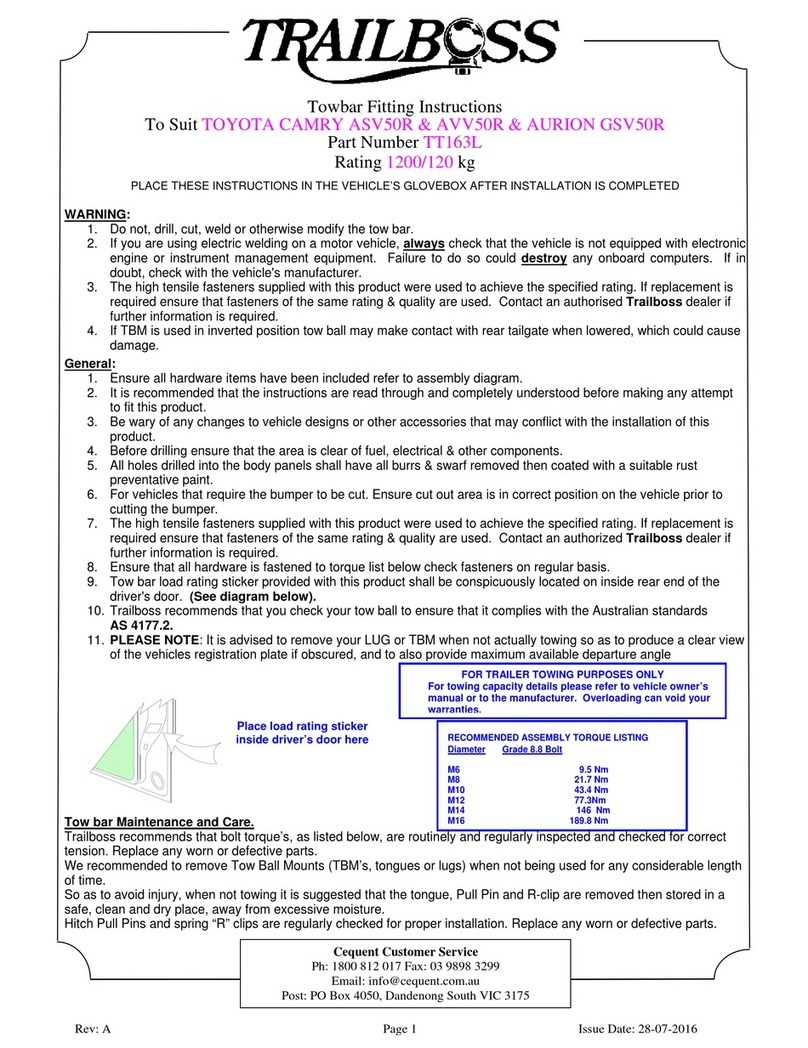

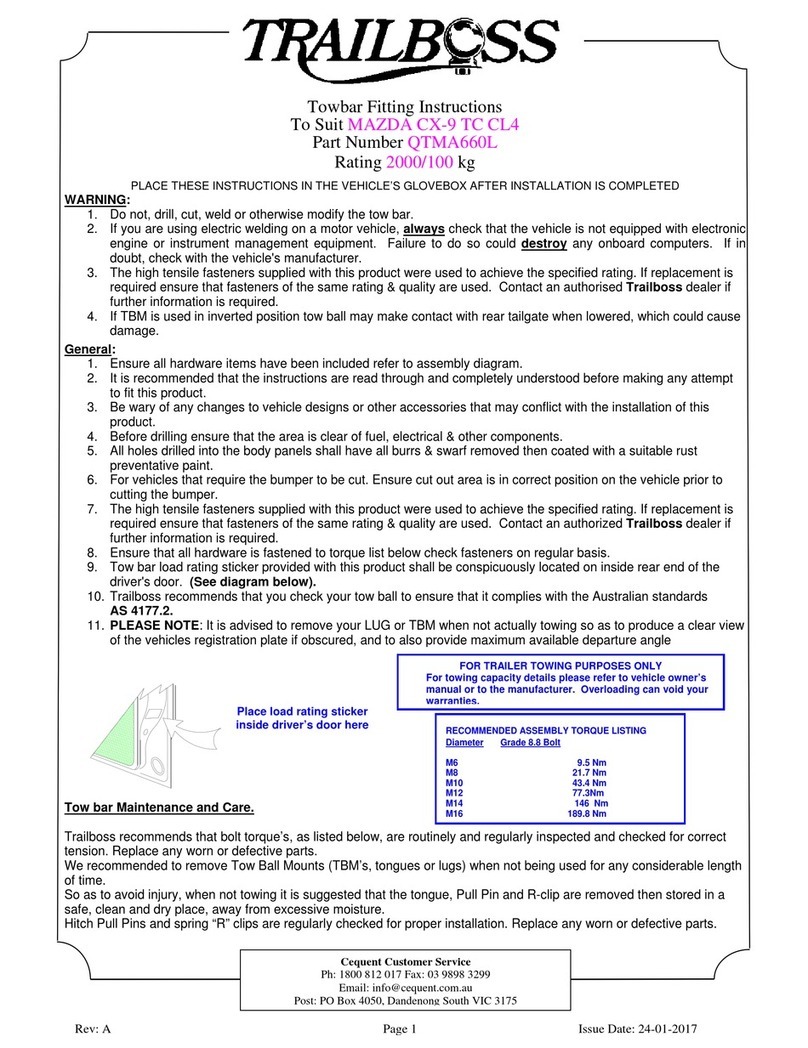

9. Tow bar load rating sticker provided with this product shall be conspicuously located on inside rear end of the driver's door.

(See diagram below).

10. Trailboss recommends that you check your tow ball to ensure that it complies with the Australian standards AS 4177.2.

11. PLEASE NOTE: It is advised to remove your LUG or TBM when not actually towing so as to produce a clear view of the

vehicles registration plate if obscured, and to also provide maximum available departure angle

Tow bar Maintenance and Care.

Trailboss recommends that bolt torque’s, as listed below, are routinely and regularly inspected and checked for correct tension. Replace

any worn or defective parts.

We recommended to remove Tow Ball Mounts (TBM’s, tongues or lugs) when not being used for any considerable length of time.

So as to avoid injury, when not towing it is suggested that the tongue, Pull Pin and R-clip are removed then stored in a safe, clean and

dry place, away from excessive moisture.

Hitch Pull Pins and spring “R” clips are regularly checked for proper installation. Replace any worn or defective parts.

Place load rating sticker

inside driver’s door here

RECOMMENDED ASSEMBLY TORQUE LISTING

Diameter Grade 8.8 Bolt

M6 9.5 Nm

M8 21.7 Nm

M10 43.4 Nm

M12 77.3Nm

M14 146 Nm

M16 189.8 Nm

Towbar Fitting Instructions

To Suit HOLDEN COMMODORE ZB CL4

Part Number QTHD774L

Rating 2100/90 kg

PLACE THESE INSTRUCTIONS IN THE VEHICLE’S GLOVEBOX AFTER INSTALLATION IS COMPLETED

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9898 3299

Email: info@cequent.com.au

Post: PO Box 4050, Dandenong South VIC 3175

Rev: A Page 2 Issue Date: 03-10-2018

ITEM

DESCRIPTION

QTY

1

HOLDEN WAGON WELDED ASSY

1

2

SIDE ARM ASSY RH

1

3

SIDE ARM ASSY LH

1

4

BUMPER TAB

2

5

TRAILER BALL MOUNT

1

6

NUT HEX HD M10 X 1.25P G8

8

7

WASHER PLAIN M10 X 25 X 3

28

8

BOLT HEX HD M10 X 40 X 1.25P G10.9

8

9

TEK SCREW 14-10 HEX HD 25MM

2

10

NUT M10 NYLOC

4

11

SETSCREW HXHD M10X30X1.5P G8.8

4

12

BOLT M10 - 1.5 x 55MM

4

ITEM

DESCRIPTION

QTY

13

SET SCREW M6 x 20 GR 8.8 Z/P

2

14

WASHER FLAT M6x18x1.5

2

15

NUT NYLON LOCK HEX HD M4X0.7P G8

2

16

CLIP NUT 6MM

2

17

VE PLUG BRACKET

1

18

HITCH BOX COLLAR COVER

1

19

"D" SHACKLE 10MM

2

20

TOWBALL 50MM

1

21

SILENT HITCH PIN –SILVER

1

22

ACRYLIC COMPLIANCE LABEL

1

23

WIRING LOOM

1

Towbar Fitting Instructions

To Suit HOLDEN COMMODORE ZB CL4

Part Number QTHD774L

Rating 2100/90 kg

PLACE THESE INSTRUCTIONS IN THE VEHICLE’S GLOVEBOX AFTER INSTALLATION IS COMPLETED

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9898 3299

Email: info@cequent.com.au

Post: PO Box 4050, Dandenong South VIC 3175

Rev: A Page 3 Issue Date: 03-10-2018

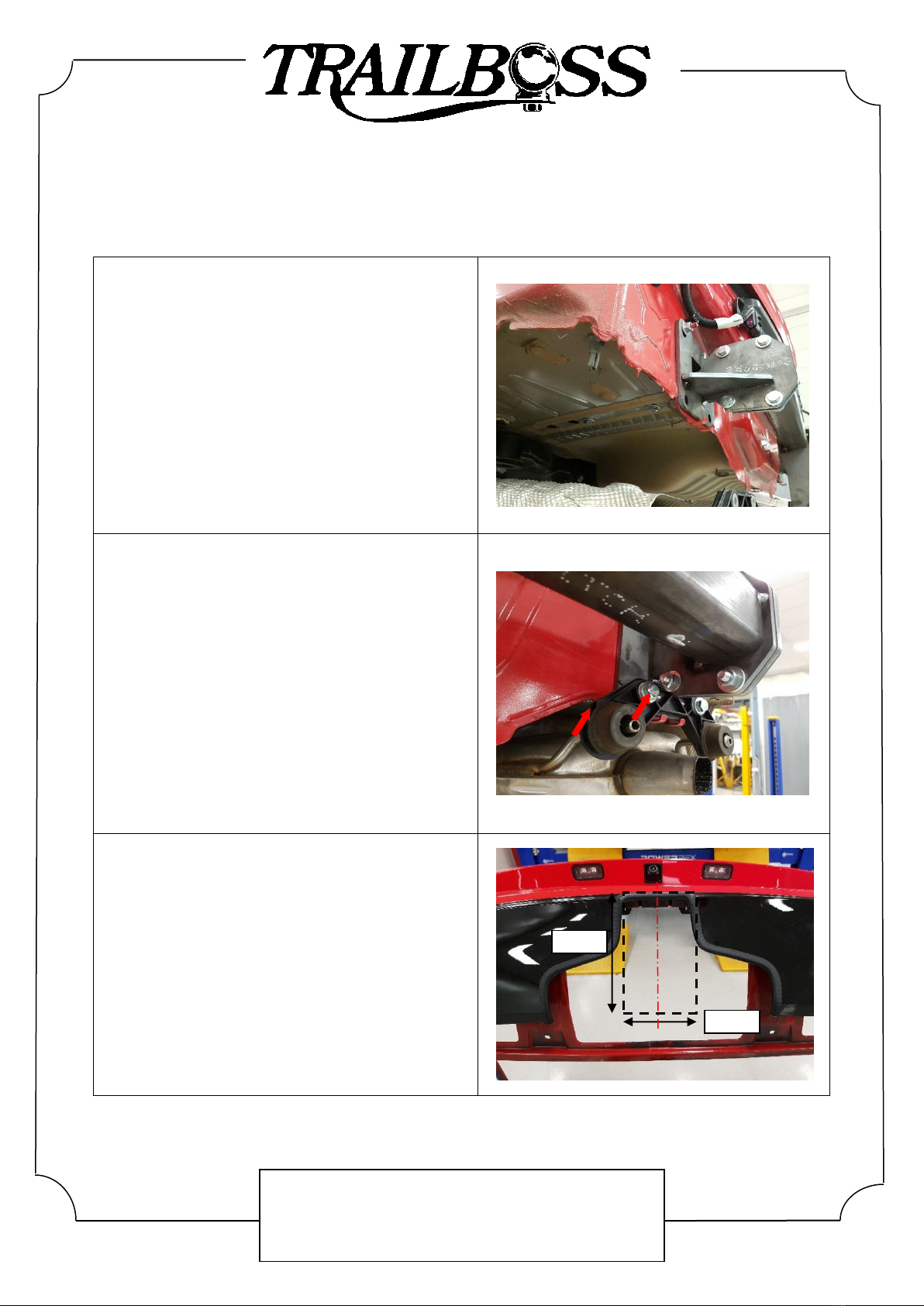

1. In wheel arch, remove 4 x Torx screws.

Repeat for other side

2. In the wheel arch peel back the trim and remove

the exposed 1 x Screw.

Repeat for other side.

3. Under bumper, remove 2 x screws.

Towbar Fitting Instructions

To Suit HOLDEN COMMODORE ZB CL4

Part Number QTHD774L

Rating 2100/90 kg

PLACE THESE INSTRUCTIONS IN THE VEHICLE’S GLOVEBOX AFTER INSTALLATION IS COMPLETED

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9898 3299

Email: info@cequent.com.au

Post: PO Box 4050, Dandenong South VIC 3175

Rev: A Page 4 Issue Date: 03-10-2018

4. Remove the Number Plate and remove the

exposed 2 x screws securing the bumper to the

back panel.

5. Peel away bumper from the sides and remove

from vehicle. Ensure to disconnect the electrical

harness (RH side).

Set bumper aside in a safe location.

6. Remove the 4 x Nuts on the top and 4 x Bolts on

the bottom that secure the impact beam and the

exhaust brackets.

Discard the impact beam along with the

fasteners.

Towbar Fitting Instructions

To Suit HOLDEN COMMODORE ZB CL4

Part Number QTHD774L

Rating 2100/90 kg

PLACE THESE INSTRUCTIONS IN THE VEHICLE’S GLOVEBOX AFTER INSTALLATION IS COMPLETED

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9898 3299

Email: info@cequent.com.au

Post: PO Box 4050, Dandenong South VIC 3175

Rev: A Page 5 Issue Date: 03-10-2018

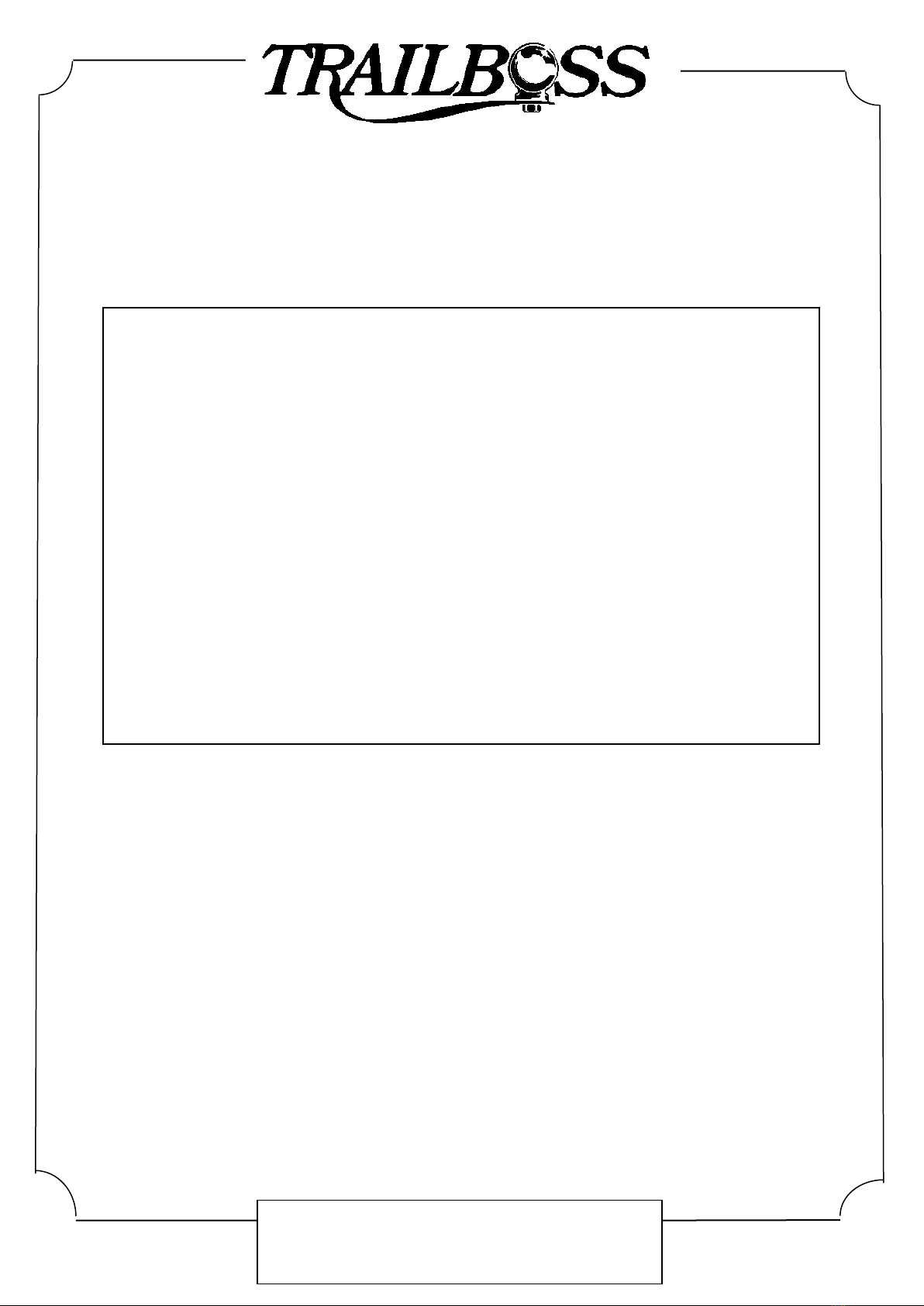

7. Lower the LH and RH mufflers.

8. Remove the LH and RH heat shields secured

with screw on retainers to gain access to the

chassis rails.

9. Insert the LH side arm assembly into the chassis

rail and loosely secure with 2 x M10 bolts

complete with 1 x washer per bolt.

10. Loosely secure (only) the top side arm mountings

with 2 x Nylocs complete with 1 x washer per

nyloc.

Repeat for other side.

11. Lift cross tube to the side arms and loosely

secure with 8 x M10 bolts complete with 2 x

washers and 1 x nut per bolt.

Towbar Fitting Instructions

To Suit HOLDEN COMMODORE ZB CL4

Part Number QTHD774L

Rating 2100/90 kg

PLACE THESE INSTRUCTIONS IN THE VEHICLE’S GLOVEBOX AFTER INSTALLATION IS COMPLETED

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9898 3299

Email: info@cequent.com.au

Post: PO Box 4050, Dandenong South VIC 3175

Rev: A Page 6 Issue Date: 03-10-2018

12. Tighten the 2 x M10 bottom fasteners.

Torque to 44Nm.

Repeat for other side.

13. Refit the 2 x heat shields removed in step 8.

14. Raise the muffler and loosely secure the muffler

brackets along with the bottom holes on the side

arm brackets with 2 x M10 bolts complete with 1

x washer per bolt to the back panel.

Repeat for other side.

15. Tighten all the fasteners to the torques as

specified:

Cross tube to side arms M10 (10.9) : 68Nm

M10 Nyloc : 44Nm

M10 Bolt to rear panel : 44Nm

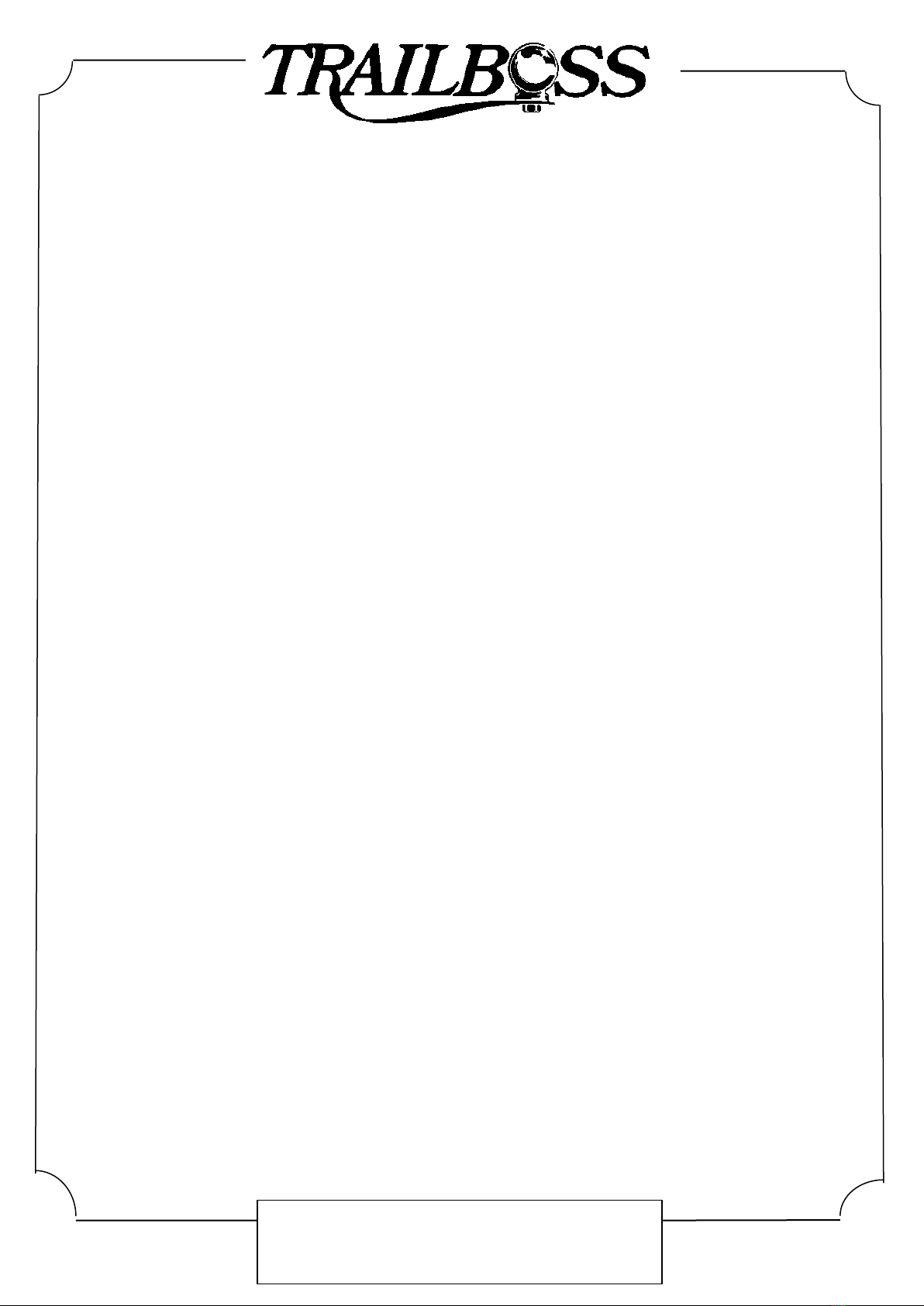

16. Working on the outside of the bumper panel,

locate the centre, mark off and cut out 100mm

wide and 160mm long as measured from the

edge of the bumper. (The cut should stop at the

first style line)

NOTE: The bumper has an inner skin panel that

requires some material removal.

100mm

160mm

Towbar Fitting Instructions

To Suit HOLDEN COMMODORE ZB CL4

Part Number QTHD774L

Rating 2100/90 kg

PLACE THESE INSTRUCTIONS IN THE VEHICLE’S GLOVEBOX AFTER INSTALLATION IS COMPLETED

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9898 3299

Email: info@cequent.com.au

Post: PO Box 4050, Dandenong South VIC 3175

Rev: A Page 7 Issue Date: 03-10-2018

17. Fit the clip nuts to the 2 x bumper brackets and

loosely secure to the inside of the bumper with 1x

M6 bolt complete with 1 x washer.

18. At an appropriate position on the bumper, mark

out and drill 2x ø5mm holes 69mm apart on

bumper skin to support plug bracket. Feed

bracket threads through drilled holes prior to

reinstalling bumper.

19. Refit the bumper to the vehicle.

20. Secure the bumper brackets to the cross tube

with 2 x tek screws.

21. Refit all removed fasteners following steps 1-4 in

reverse.

Wiring Loom Fitting Instructions

To Suit Holden Commodore ZB Wagon

Part Number 101996-WL

Page 1 of 3 Issue Date 17-09-18

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9797 3299

Post: PO Box 4050, Dandenong South VIC 3175

Wiring Loom Installation Instructions

Holden Commodore ZB Wagon

Part No: 101996-WL

ECU: 04839

Tail Harness Part No: WLT-019

RPA Disable: Near Transmission Lever

Electric Brake Input Location: Near Blue Connector

Wiring Loom Installation Time: Approx 15 Mins

Wiring Loom Fitting Instructions

To Suit Holden Commodore ZB Wagon

Part Number 101996-WL

Page 2 of 3 Issue Date 17-09-18

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9797 3299

Post: PO Box 4050, Dandenong South VIC 3175

1. In the boot, remove the LHS cover.

2. For V6 AWD variants: In the boot, disconnect the negative battery terminal.

3. For V6 AWD variants: In the LHS rear quarter panel in front of the battery towards

the tail light, locate the vehicle grey pre-wire connector.

4. For V6 AWD variants: Connect the trailer patch (101996-WL) 13-way grey connector

to the vehicle pre-wire connector.

5. For I4 FWD variant: In the engine bay, disconnect the negative battery terminal.

6. For I4 FWD variant: In the LHS rear quarter panel towards the tail light, locate the

vehicle grey pre-wire connector.

7. For I4 FWD variant: Connect the trailer patch (101996-WL) 13-way grey connector to

the vehicle pre-wire connector.

8. Using an alcohol wipe, clean a suitable area of the LHS inner sheet metal and the

underside of the ECU (04839).

9. Connect the trailer patch 22-way connector to the ECU.

10. Apply double sided tape to the ECU and secure it to the vehicle sheet metal.

Note: Mount the ECU, ensuring the connector is orientated downwards.

11. With the rear bumper removed, secure tail harness (Part No: WLT-019) to towbar.

12. Connect the tail harness 8-way connector to the trailer patch mating 8-way connector.

13. Cut-off, crimp and tail harness GREY and GREY/BLACK wires to the trailer patch

matching WHITE and GREY/BLACK wires.

14. Apply silicone grease (not supplied) to waterproof connector.

15. Under the vehicle LHS, locate the vehicle trailer harness pre-wire connector.

16. Remove the blanking plug sealing the connector and connect the black and purple

connector on the patch harness to the vehicle pre-wire connector.

17. Test the trailer patch function using a light board or multi-meter.

18. Secure all harness using supplied Cable Ties.

19. Re-fit all removed parts and secure all fasteners, ensuring there are no squeaks or

rattles.

Wiring Loom Fitting Instructions

To Suit Holden Commodore ZB Wagon

Part Number 101996-WL

Page 3 of 3 Issue Date 17-09-18

Cequent Customer Service

Ph: 1800 812 017 Fax: 03 9797 3299

Post: PO Box 4050, Dandenong South VIC 3175

20. The RPA function can be disabled via a switch next to the transmission lever.

21. Place the fitting instructions in the glove box after fitment.

Note: Keep harness routing clear of all sharp edges, moving parts and places

of extreme heat.

FITTING INSTRUCTIONS

Silent Anti-Rattle Hitch Pin (PRO001)

Pro Series

PO BOX 4050, Dandenong South, VIC 3164

[email protected] I 1800 812 017

www.pro-series.com.au

• These fitting instructions are supplied to ensure

understanding of how the HITCH PIN should be fitted and

used correctly.

•Once installed, we recommend ALL instructions are kept and

placed in the vehicle glove box.

NOTE: Routine maintenance and inspection of the towbar &

HITCH PIN is required. Regularly inspect for wear and check

the tightness of the Hitch Pin. Follow instructions below to

retighten the nut when necessary.

*Do not tow with your vehicle if the R CLIP or the HITCH PIN is

loose or missing. Replacement parts are available from your

Pro Series Distributor.

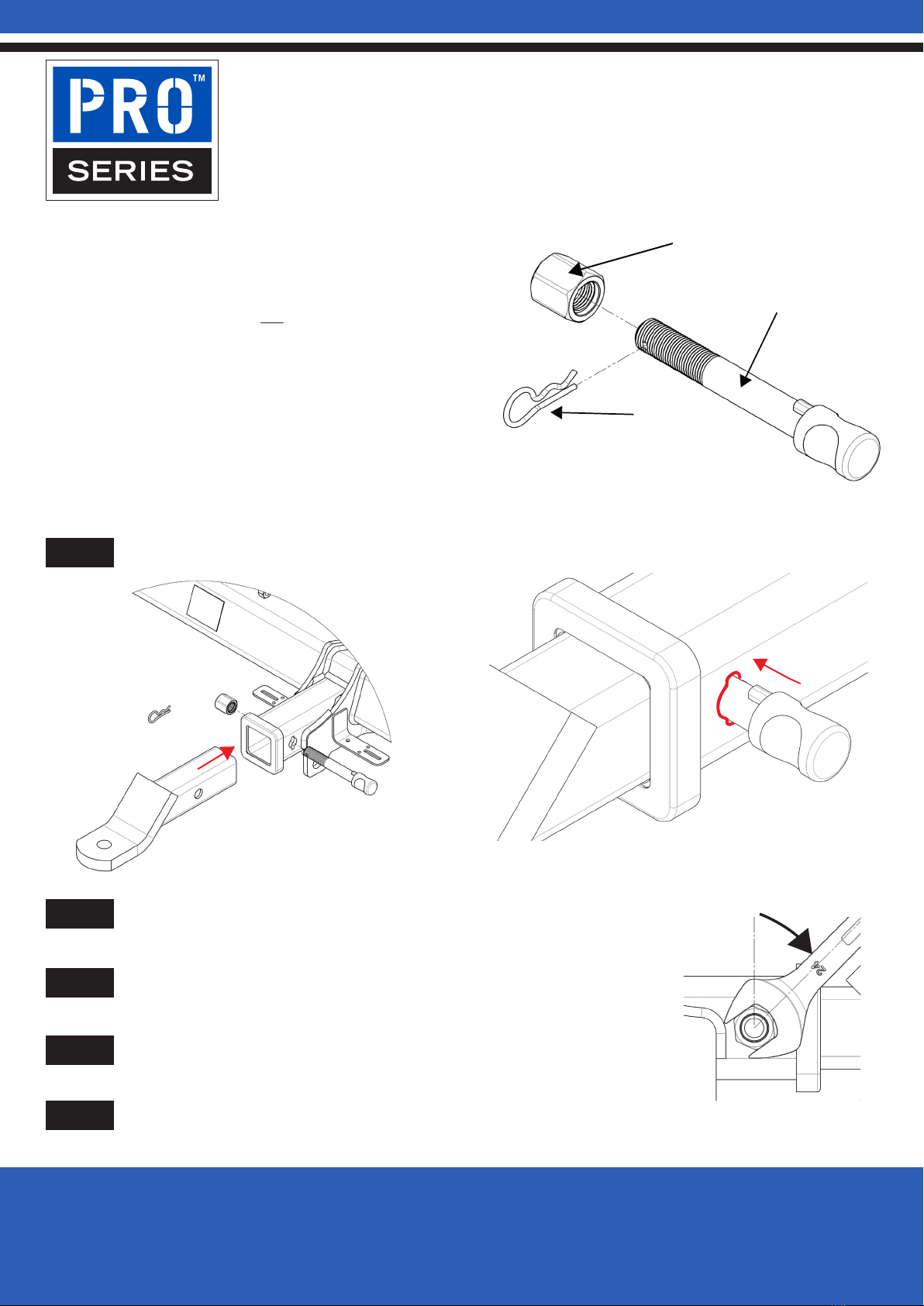

Hitch Pin Nut

R-Clip

Hitch Pin

Fig 1. Silent Anti-Rattle Hitch Pin assembly

Fig 2. Installation of Trailer Ball Mount Fig 3. Silent Anti-Rattle Hitch Pin orientation

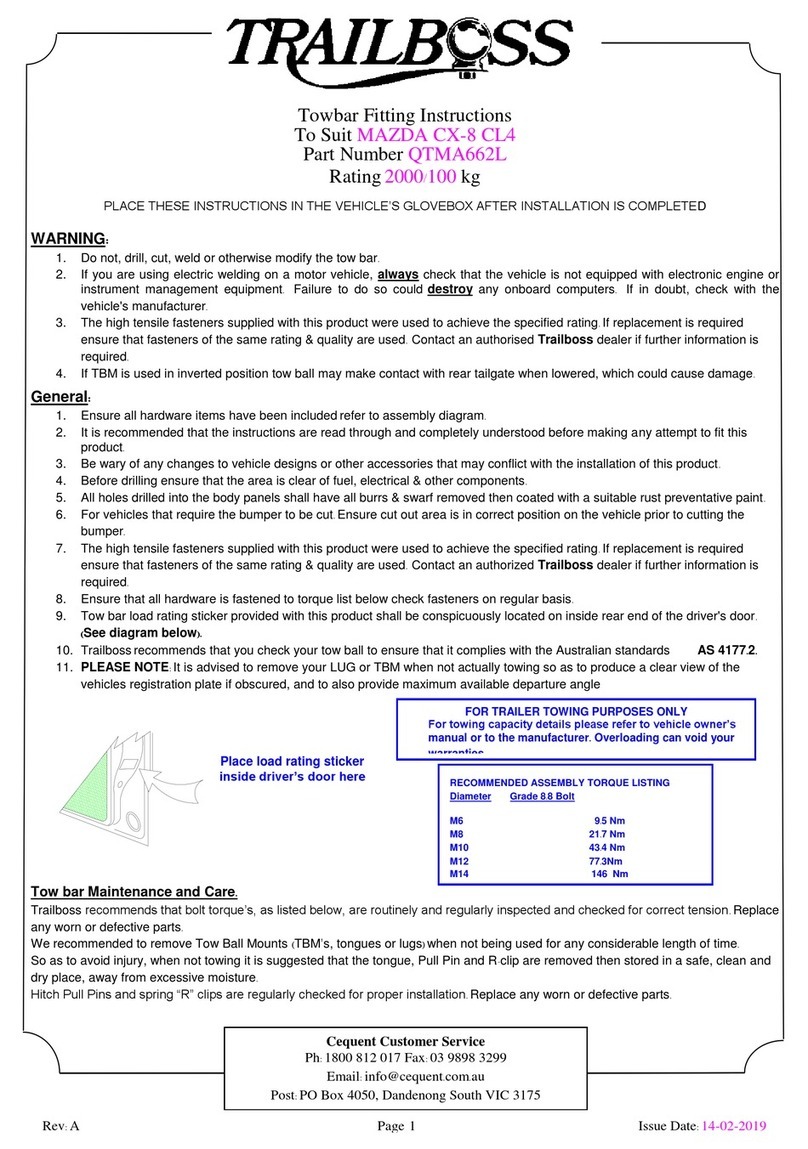

Insert Trailer Ball Mount (TBM) into towbar HITCHBOX, aligning hole in TBM SHANK with hole in HITCHBOX

(Fig 2).

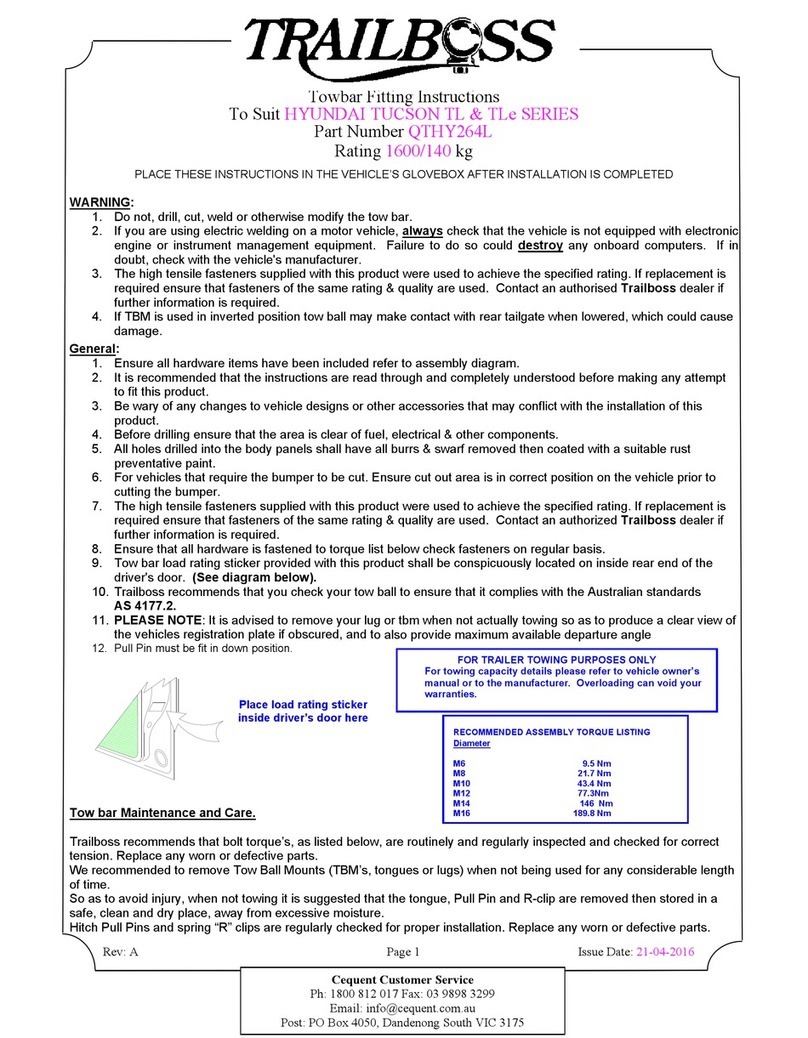

Insert HITCH PIN through hole in HITCHBOX and hole in TBM SHANK; ensure

the LOCATORS are inserted into the NOTCHES in the HITCHBOX (Fig. 3).

STEP 1

STEP 2

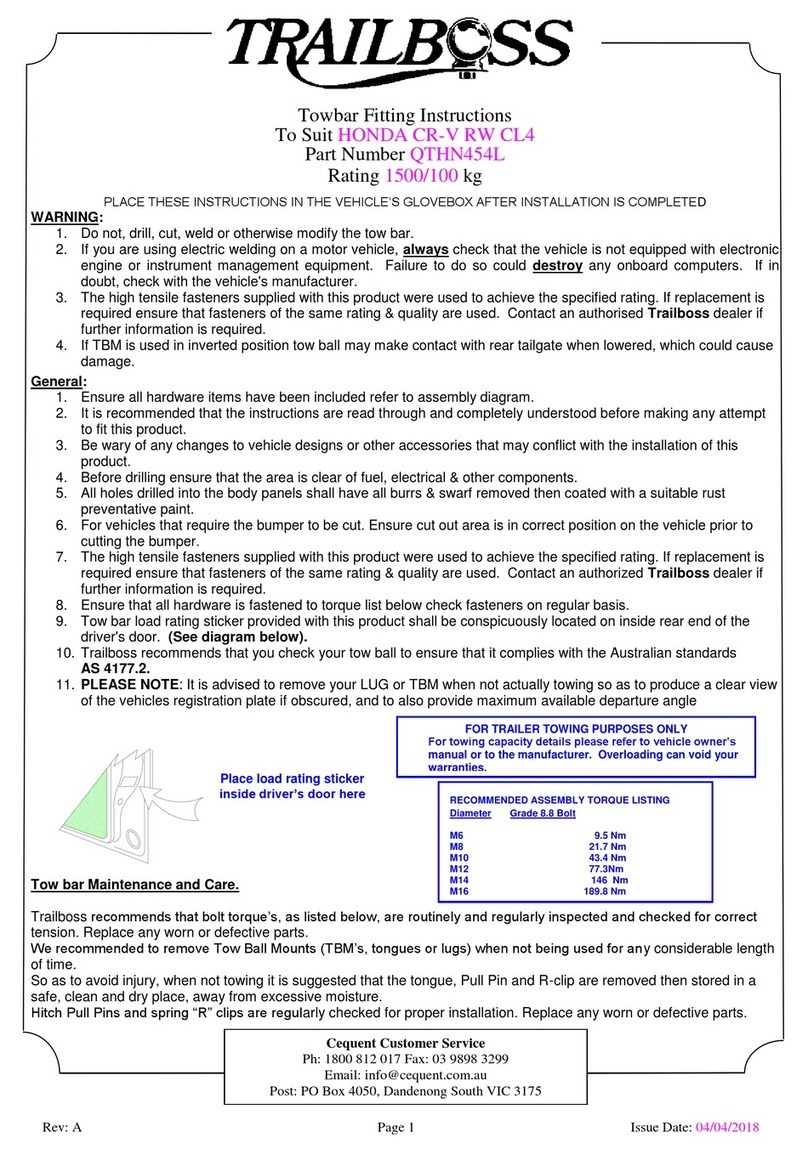

Screw HITCH PIN NUT onto HITCH PIN ; tighten HITCH PIN NUT until finger

STEPSTEP 3

3 tight, ensuring TBM is restrained from movement.

Tighten HITCH PIN NUT by turning nut a further 1/8th of a turn in the

clockwise direction using a 24mm spanner (Fig. 4).

STEP 4

Install HITCH PIN R CLIP through the hole on the HITCH PIN (Fig. 1).

STEP 5

Step 4

Fig 4. Tightening of Silent

Anti-Rattle Hitch Pin Nut

Notches

Locators

STEP 3

Table of contents

Other Trailboss Automobile Accessories manuals

Trailboss

Trailboss QTMA662L User manual

Trailboss

Trailboss HN72L User manual

Trailboss

Trailboss QTHY264L User manual

Trailboss

Trailboss QTHN454L User manual

Trailboss

Trailboss QTFD962L User manual

Trailboss

Trailboss QTBM115L User manual

Trailboss

Trailboss QTHY263L User manual

Trailboss

Trailboss QT1134L User manual

Trailboss

Trailboss QTSB318L User manual

Trailboss

Trailboss QTHD722L User manual

Popular Automobile Accessories manuals by other brands

Mont Blanc

Mont Blanc CFK36 Fitting instructions

BESAFE

BESAFE Baby Mirror XL2 quick start guide

Whispbar

Whispbar K611W Fitting instructions

Holley

Holley 0-80508S INSTALLATION, TUNING, AND ADJUSTMENT MANUAL

Cellink Technology

Cellink Technology BTHF-6200-L user manual

MVG

MVG 3134 F installation instructions