1. Before turning on the valet, make sure that the tracks and bottom of the valet are free from

obstruction.

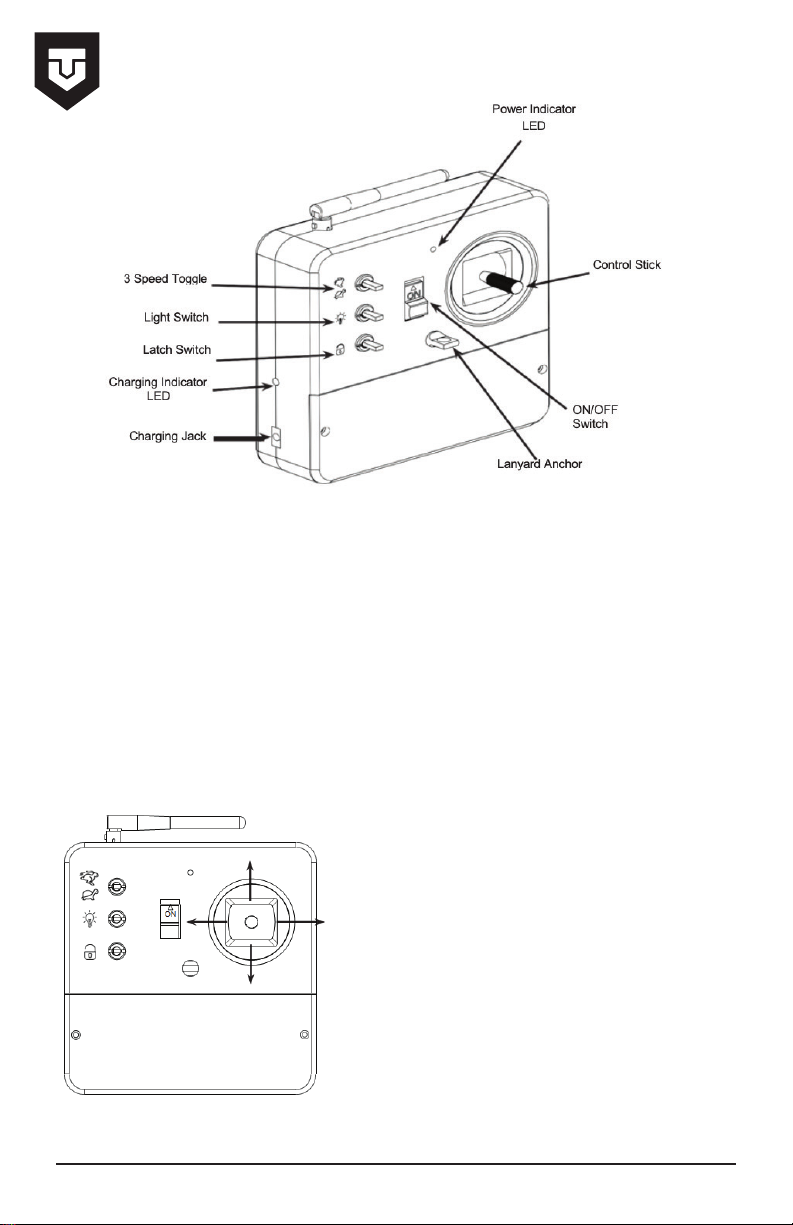

2. Turn the valet on using the ON/OFF button. There will be a short series of beeps and then

the power indicator LED around the Power button will illuminate to show the valet is on. The

Power Indicator LED may blink to indicate that the charge level of the battery is low.

3. Turn on the power switch on the radio controller and the power indicator LED will be green

and the transmit indicator LED will be red.

4. When towing, ALWAYS be cautious of the steering angle limitations of your trailer. Do not

over steer your trailer with the valet.

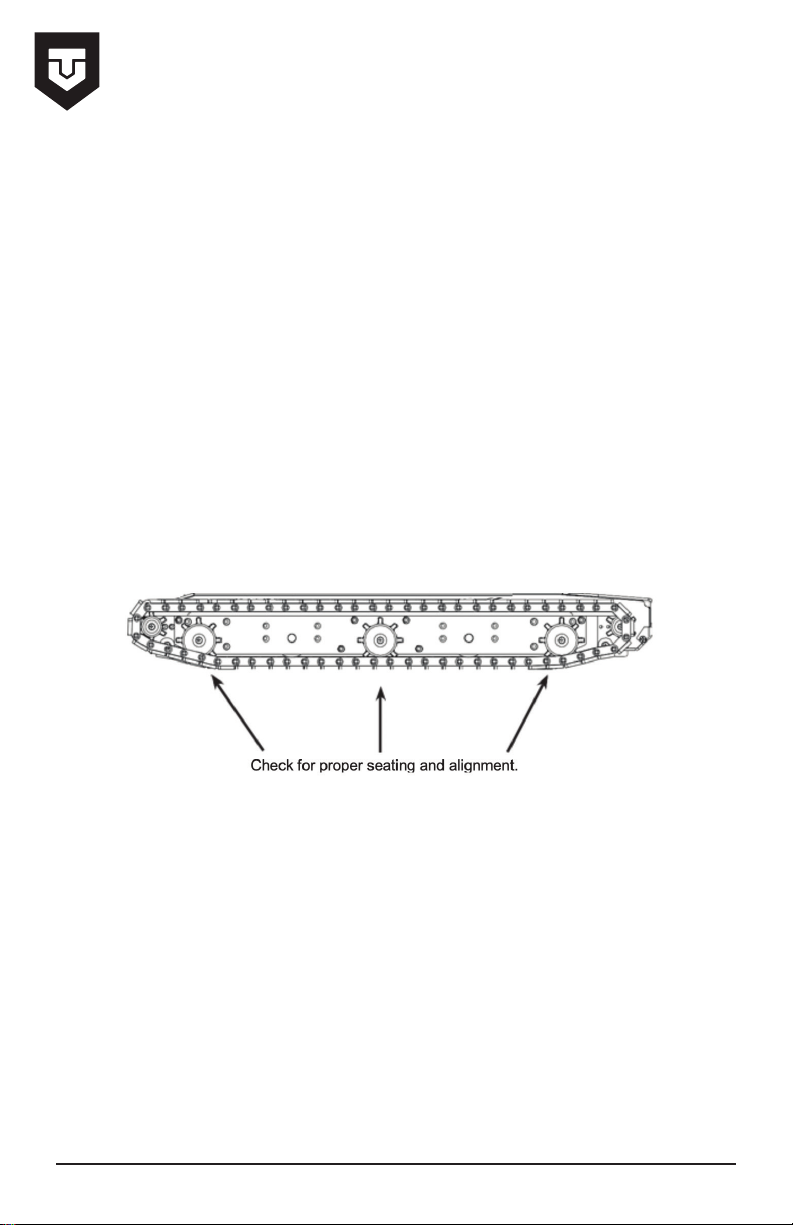

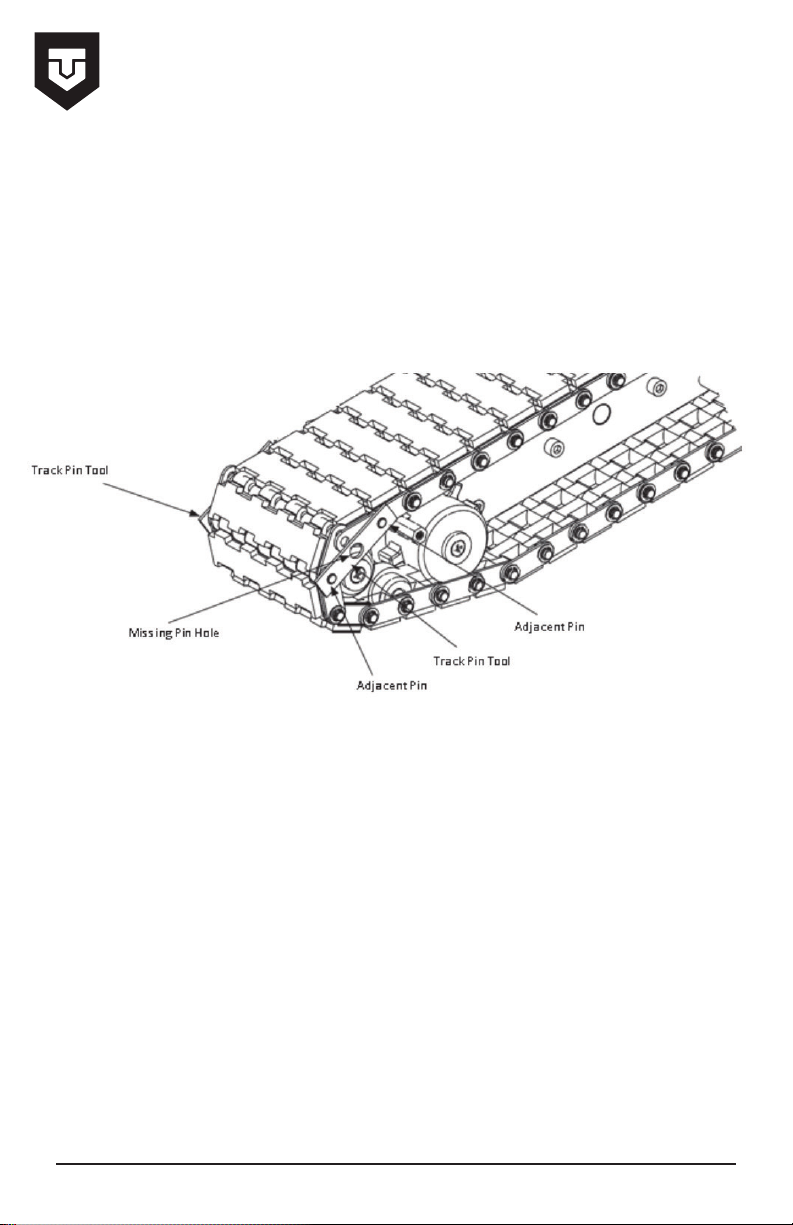

5. After lifting the valet o of the ground for any reason or taking it on and o of your trailer,

you must check to make sure that the sprockets are correctly seated on the tracks. If the

sprocket is not properly seated it could result in damage to the tracks.

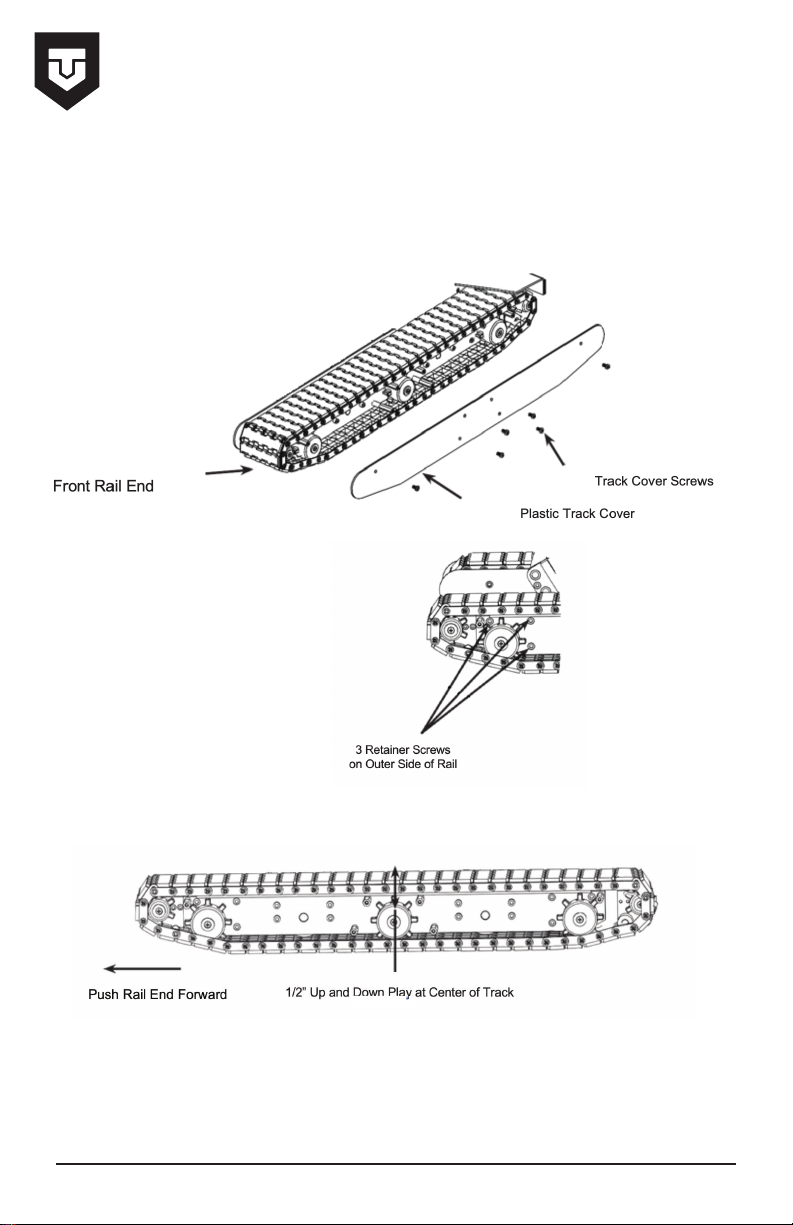

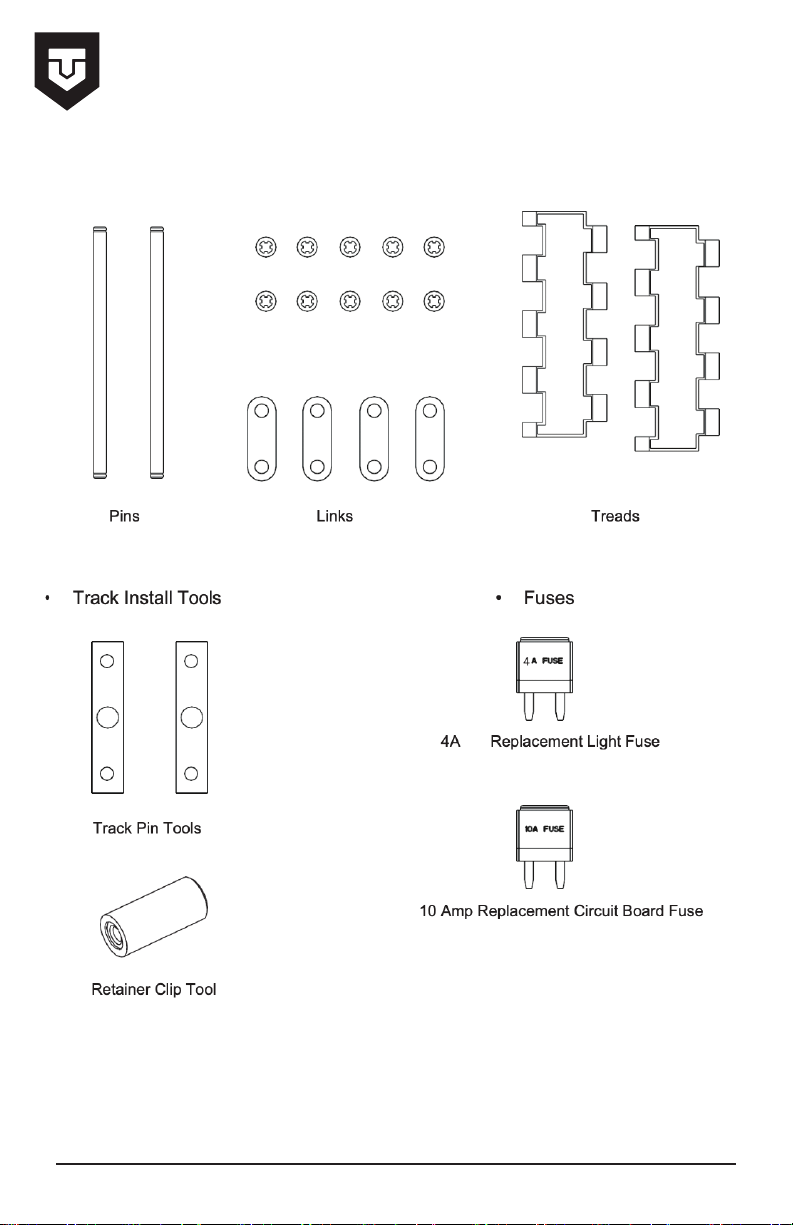

6. Visually check the tracks for wear on the treads and wear on the inner plastic surfaces.

Also inspect for damaged or missing rotoclips as a result of driving over small rocks. Damaged

treads should be replaced before operating the valet.

NOTE: The circuit breaker reset button will trip if the valet is overloaded. To reset

the circuit breaker open the top cover to push the reset button down. If the reset button pops

back up wait 1 minute then try again.

2

Operating the Valet