SAFETY WARNING

Only qualified personnel should install and service the equipment. The installation,

starting up, and servicing of heating, ventilating, and air-conditioning equipment can

be hazardous and requires specific knowledge and training. Improperly installed,

adjusted or altered equipment by an unqualified person could result in death or

serious injury. When working on the equipment, observe all precautions in the

literature and on the tags, stickers, and labels that are attached to the equipment.

132

4 5 6

© 2020 Trane

Installation Instructions

Tracer® VV551 VAV Controller

Ordering Numbers: 4020 1219 (without

actuator), 4020 1220 (with Belimo™

actuator), 4020 1221 (with Trane actuator)

The Tracer VV551 variable air volume (VAV) controller is a field-installed

controller for single -duct VAV boxes used in the following applications:

• Space temperature control

• Flow tracking

• Ventilation flow control

Warnings, Cautions, and Notices

Read this manual thoroughly before operating or servicing this unit. Safety

advisories appear throughout this manual as required. Your personal safety

and the proper operation of this machine depend upon the strict observance

of these precautions.

The three types of advisories are defined as follows:

WARNING Indicates a potentially hazardous situation which,

if not avoided, could result in death or serious

injury.

CAUTION Indicates a potentially hazardous situation which,

if not avoided, could result in minor or moderate

injury. It could also be used to alert against unsafe

NOTICE Indicates a situation that could result in

equipment or property-damage only accidents.

Agency Listing

UL and C-UL

listing UL-916-PAZX—energy management

CUL-C22.2—signal devices—Canada

Flammability

rating UL 94-5V (UL flammability rating for plenum

use)

FCC FCC Part 15, Class A

CE CE marked

Controller Shipment

Note: Visually inspect all parts for obvious defects or damage. All

components have been thoroughly inspected before leaving the factory.

Any claims for damage incurred during shipment should be filed

immediately with the carrier.

Shipment includes one each of:

• VV551 printed circuit board

• Sheet metal enclosure

• Airflow transducer

• Damper control actuator (optional)

• Actuator cable

Storage and Operating Specifications

Storage

Temperature: -40°F to 185°F (-40°C to 85°C)

Humidity: Between 5% to 95% (noncondensing)

Operating

Temperature: 32°F to 140°F (0°C to 60°C)

Humidity: Between 5% to 95% (noncondensing)

Power: 21-27 Vac, (24 Vac nominal), 50–60 Hz, maximum of 70

VA per controller (which includes output devices)

Mounting weight: •3.9 lbs. (1.77 kg.) without actuator

• 5.0 lbs. (2.27 kg.) with Belimo actuator

• 5.2 lbs. (2.36 kg.) with Trane actuator

Locating Recommendations

Mount the VV551 controller on the side of the VAV box (refer to Figure 1).

Place it over the damper shaft and secure it to the VAV box.

Figure 1. VV551 Dimensions and Configuration

9.5 in.

(24.2 cm)

9.6 in.

(24.4 cm)

4.6 in.

(11.7 cm)

Mounting the Controller

Note: Self-tapping sheet metal screws are not provided for mounting.

To mount the controller:

1. Remove the controller cover to access the wiring terminals and optional

damper control actuator.

2 With self-tapping sheet metal screws, mount the VV551 controller to the

VAV box using the mounting holes provided on the controller base (refer

to Figure 1).Note the following:

• If the VV551 assembly includes a damper control actuator, insert the

actuator shaft through the hole in the base and through the actuator shaft

coupling.

• If the VV551 assembly does not include a damper control actuator, a

locally supplied actuator can be mounted in the VV551 enclosure (after

removing the shelf, circuit board, and transducer); OR

The VV551 enclosure can be mounted in a location that provides access

for locally supplied actuator and wire leads. Secure the locally supplied

actuator to the damper shaft and the VAV box.

3. Next, manually rotate the damper control actuator 100% clockwise and

then manually rotate the damper shaft 100% clockwise until it is fully

closed.

4. Tighten the damper actuator coupling against the damper shaft.

Wiring

Prior to wiring, note the following guidelines:

• All wiring must comply with National Electrical Code™ (NEC) and local

codes.

• If providing a new transformer for power, use a UL-listed Class 2 power

transformer that supplies a nominal 24 Vac (21–27 Vac). The transformer

must be sized to provide adequate power to the VV551 controller (4 VA)

and output devices, including relays and actuators (a maximum of 12

VA per controller).

• Recommended wire size for AC power is 16 AWG copper wire.

• The VV5551 controller can use up to four binary outputs (maximum) at

any time.

WARNING

Hazardous voltage!

Disconnect all electric power, including remote disconnects, before servicing.

Follow proper lockout/tagout procedures to ensure the power cannot be

inadvertently energized. Failure to disconnect power before servicing could result

in death or serious injury.

CAUTION

Injury and Equipment Damage

Ensure t hat the 24Vac transformer is properly grounded. Failure to do so may

result in personal injury and/or damage to equipment.

Complete input/output wiring before applying power to the controller. Failure to

do so may cause damage to the controller or power transformer due to

inadvertent connections to power circuits. Do not share 24 Vac between

controllers. Failure to do so may cause controller damage.

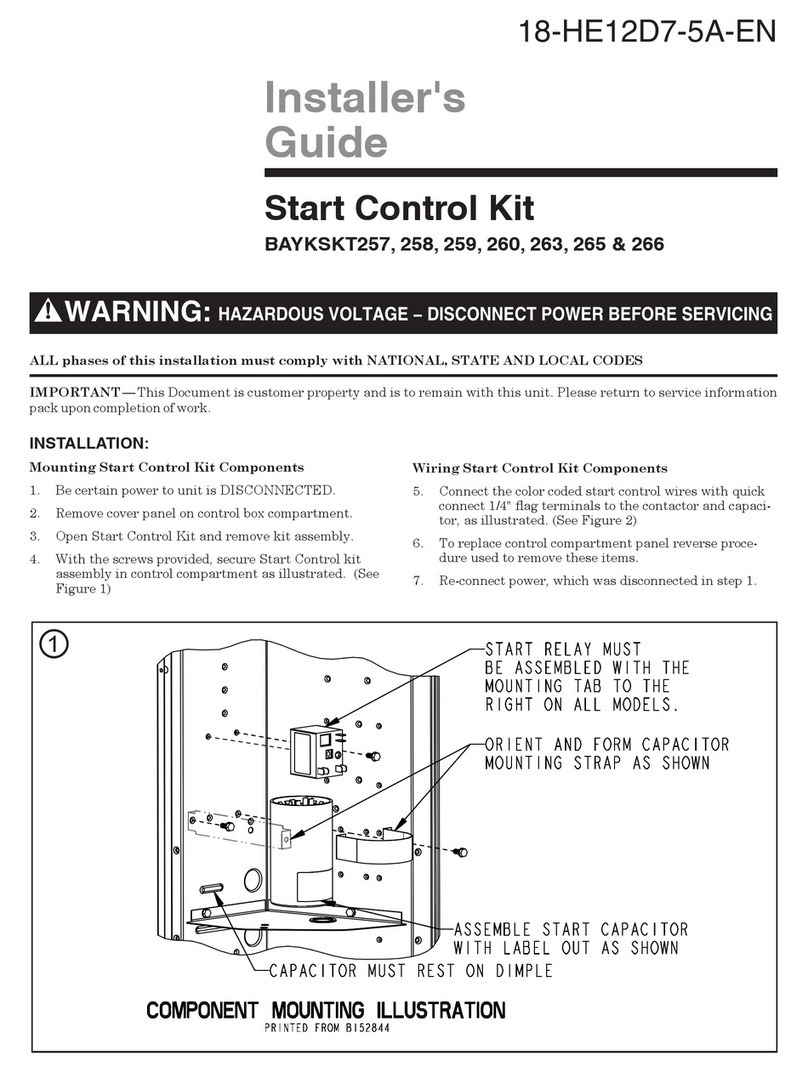

Wiring AC Power to the Controller

To connect AC power to the controller:

• Perform wiring as shown in Figure 2

Wiring the Actuator (Locally Supplied)

To wire the actuator:

1. Locate the supplied actuator cable.

2. Plug in the cable to the actuator 6-pin connector (J1) as shown in Figure 2

Note: Match receptacle 6 on the cable connector with pin 1 on the board

actuator J1 connector.

3. Attach the connectors on the actuator cable to the actuator as shown.

Note: The controller operates with floating (tri-state) control. If necessary,

the connectors that are attached to the actuator cable leads can be cut off

to enable direct connection to the locally supplied actuator wire leads.

Note: Refer to Figure 2 for wiring hot water and electric heat.

Figure 2. VV551 wiring diagram

1

4

5

3

2

.

J11, Heat 3

J9, Heat 1

J8, 24 volt

J11, Heat 3

J10, Open

J9, Close

J8, 24 volt

J11, Heat 3

J10, Stage 2

J9, Stage 1

J8, 24 volt

BI1

TB4_2

TB1_2

TB1_1

TB4_1

TB3_1

TB3_2

TB3_3

TB3_5

TB3_6

J2-3

J8

J9

J10

J11

J2-2

J2-1

TOOL IN OUT

COMM COMM COMM

FLOW

HEAT 1

HEAT 2

HEAT 3

ZONE GND SET GND

GND24V24V

AUX

1

2

3

4

5

6

ACTUATOR J1

Hot Water 2-

position

Hot Water

Proportional

Electric Heat

Staged/Pulse

Width

Modulation

(PWM)

Fan If Applicable

Fan If Applicable

Fan If Applicable

Proportional

Water Valve,

24 Vac

Heater Stage

Contactors,

24 Vac

24 V

Ground

24 Vac Transformer

AC Power Wiring Actuator Wiring

24 V

Air Valve Open (Counterclockwise)

Air Valve Closed (Clockwise)

Primary Air Temperature (Supply) or

Discharge Air Temperature

Note: Heat 3 represents fans in series or parallel fan powered VAV

boxes or Stage 3 local or remote heat in no fan situations.

Dry

Contacts

ON/OFF Water

Valve, 24 Vac

June 2020 BAS-SVN114G-EN

3270 3399