VAV-SVN04A-EN

©2002 American Standard, Inc. All rights reserved

These instructions do not cover all

variations in systems nor provide for

every possible contingency that may

arise at a jobsite installation.

INSPECTION:

Check carefully for any shipping

damage.This must be reported to and

claims made against the transportation

company immediately. Any missing

parts should be reported to your

supplier at once and replaced with

authorized parts only.

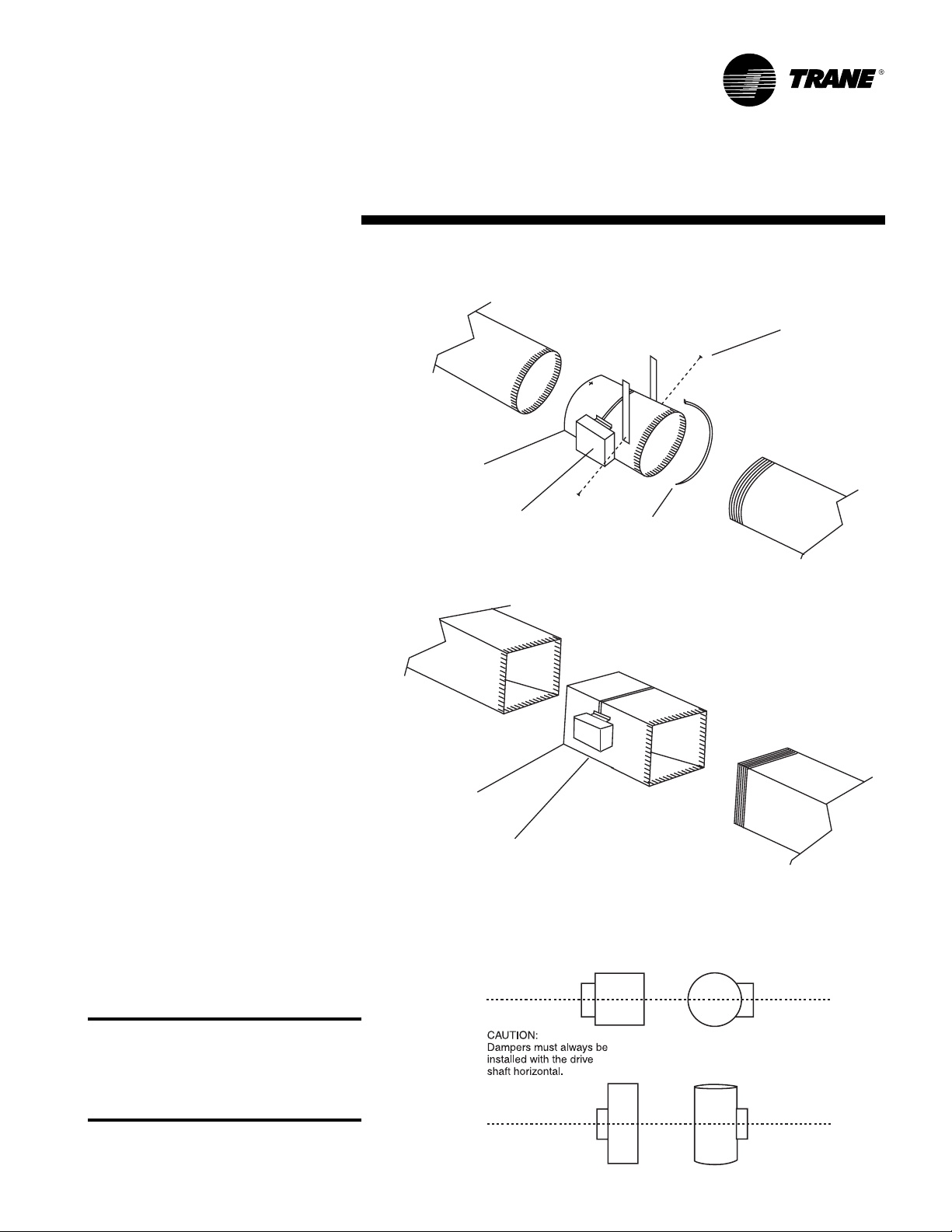

DAMPER DESCRIPTIONS

Round Dampers

Cylinder 18-gage galvanized–rolled

and seam welded

Damper 22-gage galvanized steel

Actuator Internal actuator w/

synchronous motor and

gear reduction is direct

coupled to the damper

shaft. It has a drive time of

57 seconds. Microswitches

stop the drive motor at the

full-open and full-closed

positions.

··

··

·Electrical Rating:

Power Supply—24 VAC (20

to 30 VAC) at 50/60 Hz

Transformer Sizing—2.0 VA

maximum at nominal

voltage, Class 2

Round Bypass Dampers

Size Shipping

Diameter (in.) Length (in.) Weight

6 12 11 lbs

8 12 12 lbs

10 16 17 lbs

12 16 18 lbs

Round Zone Dampers

Size Shipping

Diameter (in.) Length (in.) Weight

6 12 11 lbs

8 12 12 lbs

10 16 17 lbs

12 16 18 lbs

14 20 27 lbs

16 20 31 lbs

Rectangular Bypass Damper

Sheet metal box 24-gage galvanized

steel

Length 16"

Damper frame 13-gage galvanized

steel

Damper blades 16-gage galvanized

steel

Blade pin 3/8"

Rectangular Bypass Dampers

Size No. of Shipping

W" x H" Blades Weight

14 x 12 2 16 lbs

16 x 16 3 21 lbs

20 x 20 3 29 lbs

30 x 20 3 40 lbs

Rectangular Zone Damper

Sheet metal box 24-gage galvanized

steel

Length 16"

Damper frame 18-gage galvanized

steel

Damper blades 18-gage galvanized

steel

Gears ABS plastic

Blade pin 3/8"

Rectangular Zone Dampers

Size No. of Shipping

H" x W" Blades Weight

08 x 12 2 8 lbs

08 x 14 2 10 lbs

08 x 16 2 12 lbs

10 x 16 3 14 lbs

10 x 20 3 16 lbs

14 x 18 4 18 lbs

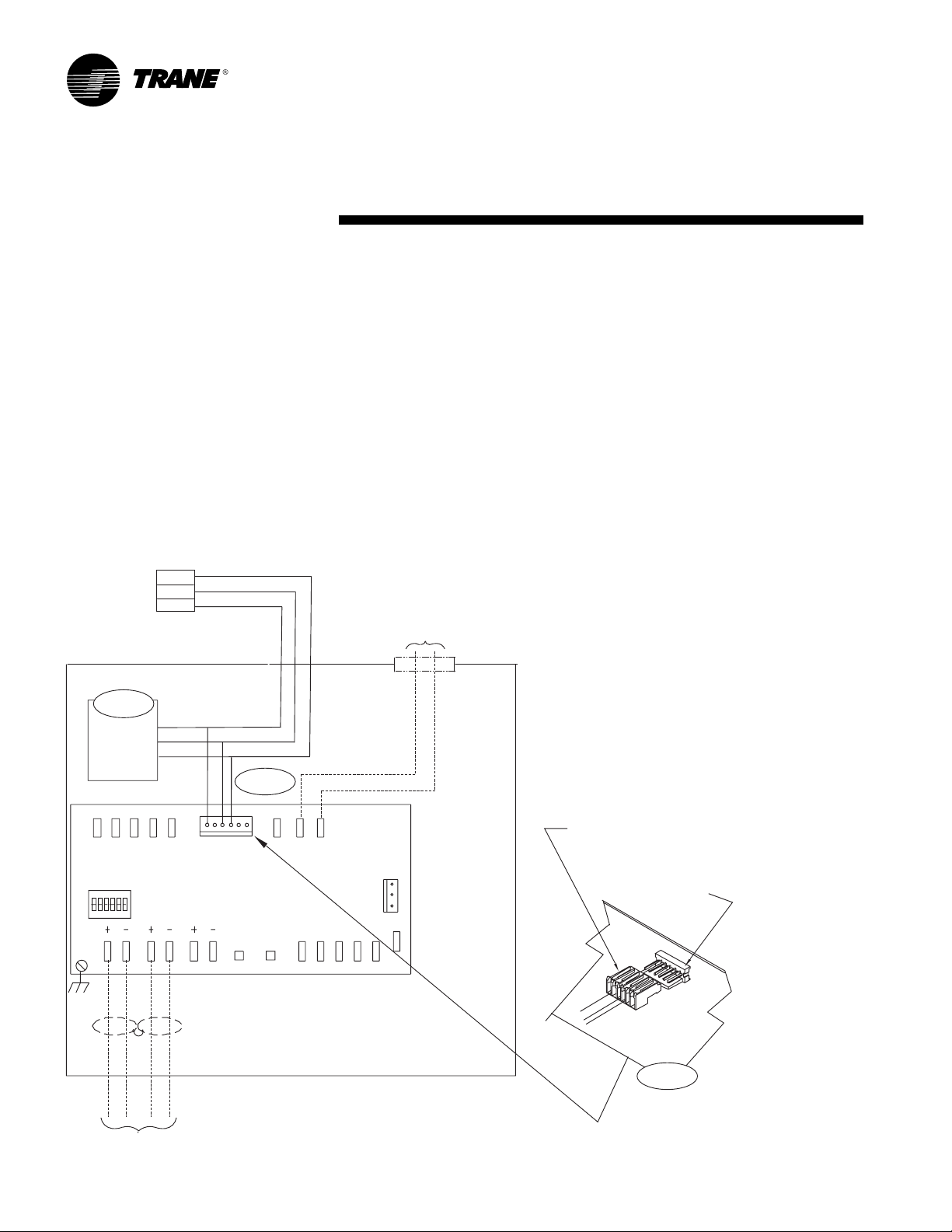

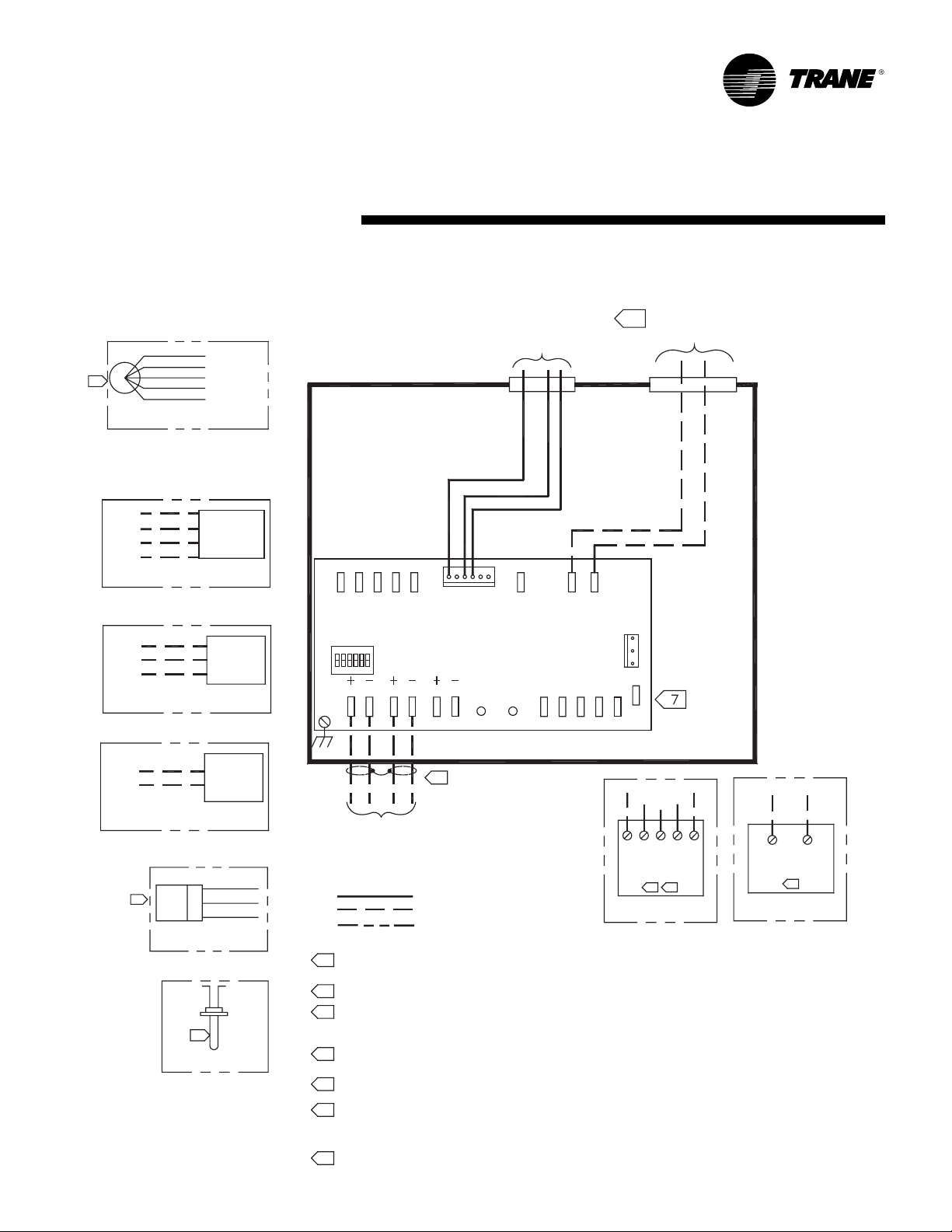

Rectangular Actuator

Specification:

··

··

·Actuator Design:

3 Wire 18 ga 24 VAC Floating Point

Control, Non-spring return

··

··

·Actuator Housing:

HousingType—NEMA 1, IP20

··

··

·Rotation Range:

Adjustable from 30°–90°, clockwise or

counterclockwise

··

··

·Electrical Rating:

Power Supply—24 VAC (20 to 30 VAC)

at 50/60 Hz

Transformer Sizing—2.5 VA maximum

at nominal voltage, Class 2

··

··

·Manual Override:

External release lever

··

··

·Humidity:

90% RH maximum, non-condensing

··

··

·Temperature Rating:

Ambient – 35°–125°F (2°–52°C)

Shipping and Storage: -20°–150°F

(-29°–66°C)

··

··

·To r qu e :

Running: 35 lb-in (4 N-m)

Breakaway: 35 lb-in (4 N-m) minimum

Stall: 40 lb-in (4.5 N-m)

minimum

··

··

·RunningTime for 90° Rotation:

60 seconds at 60 Hz nominal

72 seconds at 50 Hz nominal

··

··

·Weight:

1.5 lb (0.68 kg)

General