2

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

GENERAL PRECAUTIONS

• Always wear goggles or safety glasses.

Refrigerant liquid and battery acid can

permanently damage the eyes.

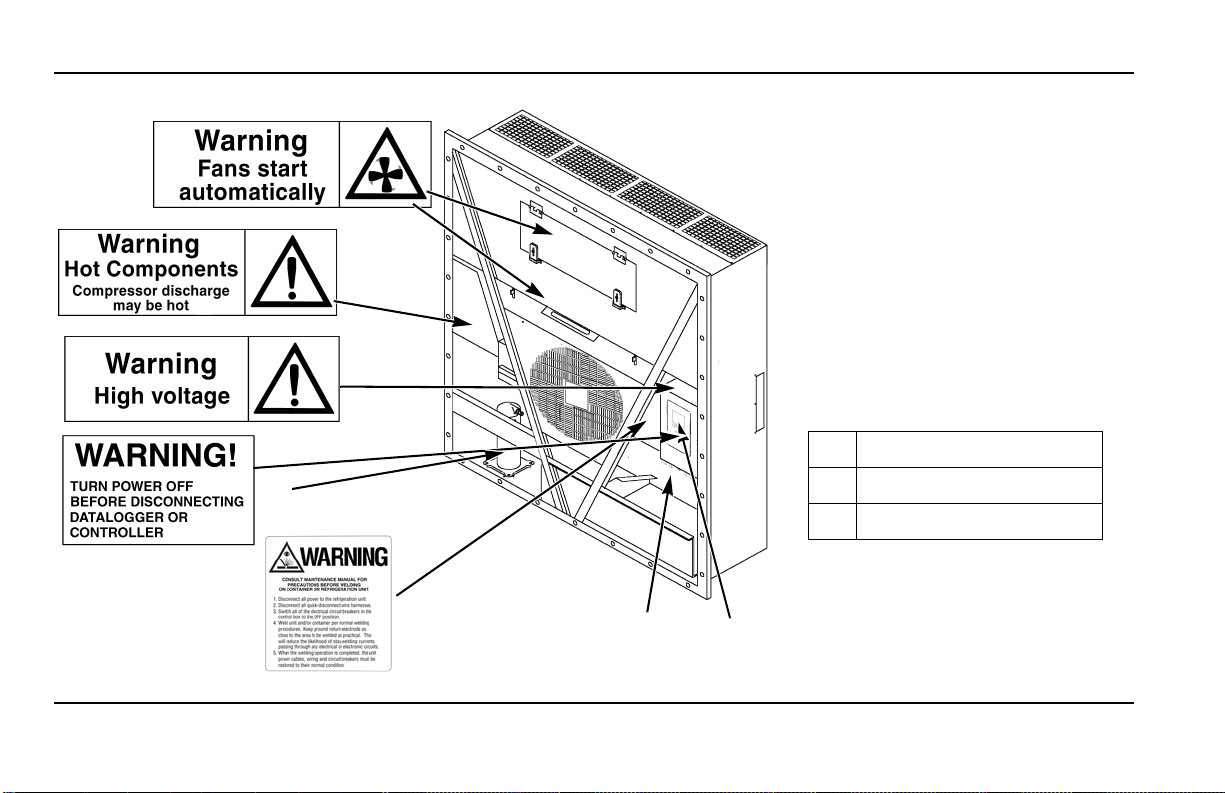

• Never operate the unit with the discharge

valve closed. Never close the compressor

discharge valve with the unit in operation.

• Keep your hands, clothing and tools clear of

the fans when the refrigeration unit is

running. If it is necessary to run the

refrigeration unit with covers removed, be

very careful with tools or meters being used

in the area.

• Never apply heat to a sealed refrigeration

system or container.

• Fluorocarbon refrigerants produce toxic

gases in the presence of an open flame or

electrical arc. The gases are severe

respiratory irritants capable of causing death.

• Firmly tighten all mounting bolts. Check

each bolt for correct length for their

particular application.

• Use caution when working around exposed

coil fins. The fins can cause painful

lacerations.

• Use caution when working with a refrigerant

or refrigeration system in any closed or

confined area with a limited air supply (for

example, a trailer, container or in the hold of

a ship). Refrigerant tends to displace air and

can cause oxygen depletion. This can result

in suffocation and possible death.

• Use caution and follow the manufacturer’s

suggested practices when using ladders or

scaffolds.

ELECTRICAL PRECAUTIONS

The possibility of serious or fatal injury from

electrical shock exists when servicing a

refrigeration unit. Extreme care must be used

when working with a refrigeration unit that is

connected to its power source. Extreme care

must be used even if the unit is not running.

Lethal voltage potentials can exist at the unit

power cord, inside the control box, inside any

high voltage junction box, at the motors and

within the wiring harnesses.

PRECAUTIONS

In general disconnect the units power cord

before repairing or changing any electrical

components.

Note that even though the controller is turned

off, one of the phases is still live and represents

a potential danger of electrocution

Where turning of the unit is not possible (for

example at voltage measuring or

troubleshooting), follow safety precautions

below.

• Turn the unit On/Off switch to Off before

connecting or disconnecting the unit power

plug. Never attempt to stop the unit by

disconnecting the power plug.

• Be certain the unit power plug is clean and

dry before connecting it to a power source.

• Use tools with insulated handles. Use tools

that are in good condition. Never hold metal

tools in your hand if exposed, energized

conductors are within reach.

• Do not make any rapid moves when working

with high voltage circuits. Do not grab a

falling tool or other object. People do not

contact high voltage wires on purpose. It

occurs from an unplanned movement.

• Treat all wires and connections as high

voltage until ammeter and wiring diagram

show otherwise.

• Never work alone on high voltage circuits on

the refrigeration unit. Another person should

always be standing by in the event of an

accident to shut off the refrigeration unit and

to aid a victim.

• Have electrically insulated gloves, cable

cutters and safety glasses available in the

immediate vicinity in the event of an

accident.