Transcat ThermCal130 User manual

The ThermCal130

Introduction

The ThermCal130 calibrator provides a safe, dry, constant temperature source for checking and calibrating a wide

range of temperature sensors, systems, indicators and thermometers. t is fast and economical and can be used

either on a bench top or as a portable field unit. The weight of the unit is only 17 pounds/7.7 kilograms. The unit

covers the temperature range from -20°C to +130°C in an ambient of 20°C using a machined aluminum block as

the heat transfer medium. The temperature control circuit is built into the unit.

Features include:

• Maximum temperature of 130°C/266°F

• Minimum temperature of -20°C/-4°F

• Up to eight setpoints can be stored & recalled

• insert well & ¼” diameter reference well

Even though the unit heats up and cools down rapidly, highly efficient insulation and an internal cooling fan

ensures that the case remains safe enough to handle even at maximum operating temperatures. The

ThermCal130 calibrator has been designed to comply with all relevant electromagnetic interference and electrical

safety regulations.

-1-

Specification

Figures quoted are at the base of the well at the time of calibration.

Temperature range: -20°C/-4°F to 130°C/266°F at an ambient of 20°C/68°F

NOTE: the typical minimum achievable temperature is 40°C/72°F below the room ambient temperature

Display resolution: 0.1°

Accuracy: ±0.4°C (-20 to 130°C)

±0.8°C (-4 to 266°F)

Stability (10 minutes): ±0.050°C

(10 minutes after reaching setpoint)

±0.060°C

Heat up time -20 to 130°C: 9 minutes

Heat up time 20 to 100°C: 4 minutes

Cool down 20 to -20°C: 9 minutes (ambient of +20°C)

Cool down 130 to 20°C: 4 minutes

mmersion Depth: 4" (101mm)

nsert well: ½” diameter x 4” depth

Reference well: ¼” diameter x 4” depth

Fan Cooling: Automatic

Weight: 17 lbs (7.7 Kg)

Dimensions* (H x W x D): 11 x 9 x 8 inches/279 x 229 x 203 mm

*excluding the carrying strap

Electrical supply

Voltage Cycles Power

230V 50/60Hz 150W

120V 50/60Hz 150W

Note: The above specifications are quoted for an ambient temperature range of 10°C/50°F to 30°C/86°F.

Outside this range, the quoted figures may deteriorate but the unit will still work safely.

NOTE: The

minimum achievable temperature is 40°C/72°F below the room ambient temperature.

-2-

Working environment

The calibrator units are designed to work safely under the following conditions:

Ambient temperature range: 5°C/9°F to 40°C/104°F

Humidity: Up to 95% relative humidity, non-condensing

Warning

Warning: H GH TEMPERATURES ARE DANGEROUS

Aviso: LAS TEMPERATURAS ELEVADAS SON PEL

H GH TEMPERATURES ARE DANGEROUS: They can cause serious burns to operators and ignite combustible

material. Accurate Thermal Systems has taken great care in the design of these units to protect operators from

hazards, but operators should pay attention to the following points:

• USE CARE AND WEAR PROTECT VE GLOVES TO PROTECT HANDS

• DO NOT put hot objects on or near combustible objects

• DO NOT operate the unit close to inflammable liquids or gases

• DO NOT place any liquid directly in your unit

• At all times USE COMMON SENSE

Operator Safety

All operators of Accurate Thermal Systems equipment must have available the relevant literature needed to

ensure their safety. t is important that only suitably trained personnel operate this equipment in accordance with

the instructions contained in this manual and with general safety standards and procedures. f the equipment is

used in a manner not specified by Accurate Thermal Systems, the protection provided by the equipment to the

operator may be impaired. All Accurate Thermal Systems units have been designed to conform to international

safety requirements. f a safety problem is encountered, switch off at the power socket and remove the plug

from the supply. Please use caution when removing probes and inserts as burns to the skin can occur if in

contact.

-3-

Installation

1. All Accurate Thermal Systems units are supplied with a power cable.

2. Before connecting the power supply, check the voltage against the rating plate. Connect the power

cable to a suitable plug according to the table below. Note that the unit must be earth grounded

to ensure proper electrical safety.

Electrical connections:

220V-240V 110V-120V

Live Brown Black

Neutral Blue White

Earth ground Green/yellow Green

The fused plug supplied with the power lead for use in the UK is fitted with the following value fuse to

protect the cable: 230V UK 4 AMP

The fuse in the unit protects the unit and the operator

Note that units marked 230V on the rating plate work at 220V; units marked 120V work at 110V. n

both cases, however, the heating rate will degrade by approximately 8%. The rating plate is on the

rear of the unit.

3. Plug the power cable into the socket on the rear of the unit.

4. Place the unit on a suitable bench or flat workspace, or in a fume cupboard if required, ensuring that

the air inlet vents on the underside are free from obstruction.

After use, when you have finished heating samples, remember that parts of the unit may be very hot.

Take the precautions listed earlier.

-4-

OPERATION

Preparation

1. The heater design, temperature sensor and control circuit give good temperature control and

uniformity, but make sure that there is a close fit of the probes in the block to allow efficient heat

transfer. Contact us about an insert that more closely fits your probe or device being calibrated.

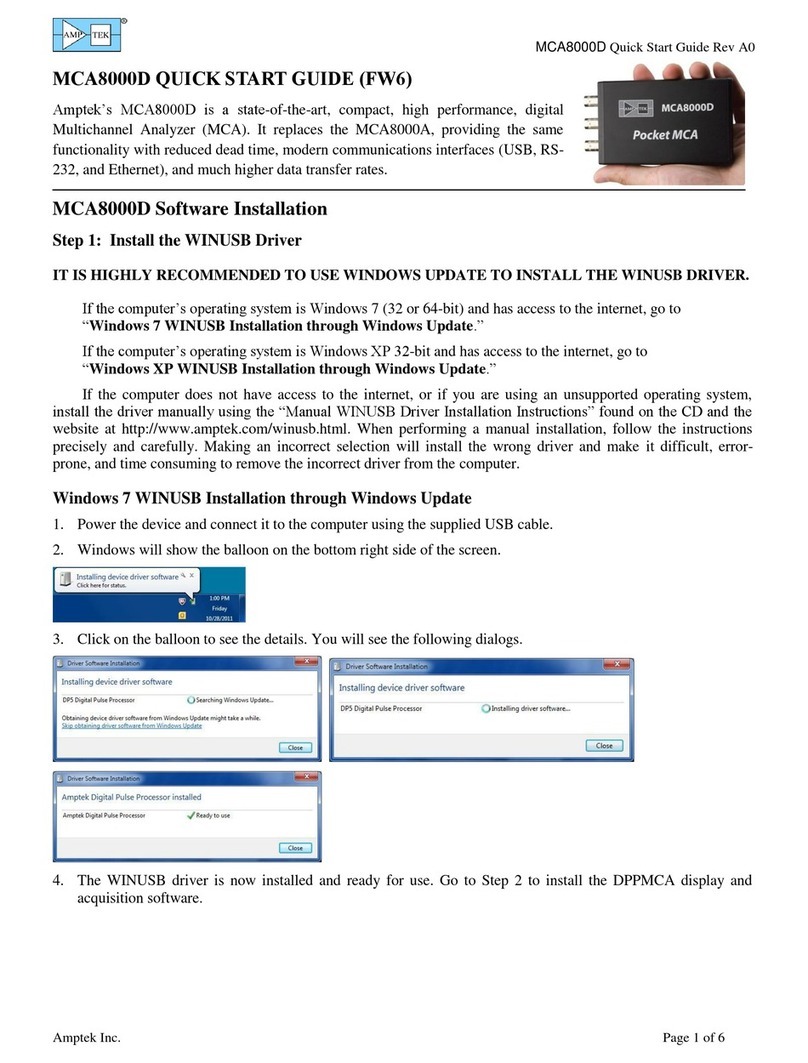

2. Plug the power cable into the socket in the back of the unit. Connect the power cable to the

electrical supply and switch the power on. 1 = power on, 0 = power off

Setting the operating temperature

1. To set the operating temperature required, press and hold either the up or down arrow button to

increment to the value required. Alternatively you can press the («PF) key to move over to

individual digits to set higher values much quicker. After 2 seconds your value will be set & retained.

2. When you have the correct set temperature displayed the unit will start to heat or cool to that

value.

3. Once the process value/actual temperature reaches the set point, allow the block to fully stabilize for

at least 10 minutes before performing a calibration.

4. When calibrating sensors and thermometers a best practice method is to start at higher

temperatures first and then work down to lower ones. This will allow devices to be removed safely.

Entering up to 8 setpoints for fast recall

1. To input up to 8 setpoints press the first button on the left and then the 2

nd

button from the left

until the top line displays SP-0. Here you can enter up to 8 values for fast future recall. Do not

change any of the settings or values after SP-7. When finished entering values press the button on

the left one time.

You’ll need to note which value is in which location for future recall.

2. To select one of the 8 setpoints for use from the main display press the 2

nd

button from the left so

the top line displays M-SP. Next use the up arrow key to select one of the 8 setpoint values. Press

the 1

st

key on the left twice for the value to be accepted.

-5-

Operation near ambient

For best results, to calibrate at a setpoint near ambient when cooling down from a higher temperature set

parameter (AL-1) 3 °C higher than you room ambient. When heating up from a lower temperature set (AL-1) 3 °C

lower than ambient. Access the AL-1 parameter by pressing the mode button (2

nd

from the left). Do not change

AL-2 which should be set at 1.0

Factory default control parameters

The parameters used in the controller have been developed by Accurate Thermal Systems to give the best unit

performance for most applications. f the need arises the “AT” autotune command can be run to further optimize

results based on the thermal block load and ambient conditions. Contact us for further support and details.

Switching the display from Degrees C to Degrees F and vice versa

To switch the display press and hold down the left key until the display indicates “CN-t”, next press the 2

nd

key

from the left one time and the top line will show “d-U” which is display units. Switch to either C or F. After setting

this value hold down the left most key so the controller resets and accepts the new value.

Next press the first button on the left and then the 2

nd

button from the left until the top line displays CN5.

Set CN5 to ____ for degrees F operation and ____ for degrees C. Unit S/N: _____________

When done press the button on the left one time.

-6-

Operator maintenance

NOTE THAT TH S EQU PMENT SHOULD ONLY BE D SMANTLED BY PROPERLY TRA NED PERSONNEL. REMOV NG

THE FRONT OR REAR PANELS EXPOSES POTENT ALLY LETHAL VOLTAGES. THERE ARE NO OPERATOR

MA NTA NABLE PARTS W TH N THE EQU PMENT.

n the unlikely event that you experience any problems with your unit which cannot easily be remedied, you

should contact your supplier and return the unit if necessary. Please include any details of the fault observed and

remember to return the unit in its original packing. Accurate Thermal Systems will accept no responsibility for any

damage to units that are improperly packed for shipment. f in doubt, contact your supplier.

1.

Cleaning: Before cleaning your unit, ALWAYS disconnect it from the power supply and allow it to

cool to 30° C. Your unit can be cleaned by wiping with a damp soapy cloth. Care should be

exercised to prevent water from running inside the unit. Do not use abrasive cleaners.

2.

Fuses: Your unit is protected by fuse. They should only be changed by suitably qualified

personnel. f the fuse blow persistently, a serious fault is indicated and you may need to return the

unit to your supplier for repair.

ADDITIONA INFORMATION

The controller is factory preset with all parameters and calibration data and therefore cannot be

calibrated or serviced in the field. Please contact Accurate Thermal Systems for arrangements to have

your unit calibrated or serviced.

-7-

Replacement Parts

The following parts may be obtained from Anville nstruments Ltd. if replacements or alternatives are required:

Part Number Description

4163 UK 240 volt power cable with 13amp UK plug (5 amp fuse)

4164 Euro style 240 volt power cable with R/A Schuko plug

4150 US style 120 volt power cable

4282 nstruction manual

4150 Unit carrying strap

4285 nsert extractor

ATS3074 insert for 1/8” diameter probes

ATS3075 nsert for 3/16” diameter probes

ATS3076 nsert for ¼” diameter probes

ATS3077 nsert for 5/16” diameter probes

ATS3078 nsert for 3/8” diameter probes

Spare Parts

Part Number Description

4224 Peltier

4174 Temperature controller

4147 PRT

4221 Solid state relay

4223 Power supply

4280 3 PDT power relay

4283 2 amp fuse, 5 x 20mm

-8-

Contact Information

Accurate Thermal Systems LLC

4106 Sylon Blvd

Hainesport, NJ 08036 USA

Ph: 609-326-3190

Fax: 609-479-5124

Email: [email protected]m

Website: www.accuthermal.com

GUARANTEE

The unit is guaranteed against any defects in material or workmanship for the period of 1 year. This period is

from the date of purchase, and within this period, all defective parts will be replaced free of charge provided that

the defect is not the result of misuse, accident or negligence. Servicing under this guarantee should be obtained

from the supplier. Not withstanding the description and specification(s) of the units contained in the Operator’s

Manual, Accurate Thermal Systems hereby reserves the right to make such changes as it sees fit to the units or

to any component of the units. This manual has been prepared solely for the convenience of Accurate Thermal

Systems customers and nothing in this nstruction Book shall be taken as a warranty, condition or representation

concerning the description, merchantability, fitness for purpose or otherwise of the units or components.

-9-

Table of contents

Other Transcat Measuring Instrument manuals