Transcat JOFRA ITC-155 A User manual

Service Manual

Temperature Calibrator

JOFRA ITC-155/320/650 A

Copyright 2002 AMETEK DENMARK A/S

2 21-08-2003

123313 02 21-08-2003 3

List of contents

1.0 General ......................................................................................4

1.1 Introduction ................................................................................... 4

1.2 Safety instructions ........................................................................ 6

2.0 Maintenance..............................................................................7

2.1 Adjusting and calibrating the instrument....................................... 7

2.2 Caring for the instrument after use ............................................. 14

3.0 Repairs ....................................................................................16

3.1 Trouble shooting ......................................................................... 16

3.2 Replacement of spare parts ....................................................... 22

3.3 Adjusting and testing PCBs ........................................................ 27

3.3.1 CONTROLLER PCB......................................................... 27

3.3.2 POWER PCB ITC-155 A .................................................. 28

3.3.3 POWER PCB ITC-320/650 A ........................................... 28

3.3.4 Testing the CONTROLLER PCB and keyboard............... 29

4.0 Spare parts and drawings .....................................................30

4.1 Spare parts ................................................................................. 30

4.2 Exploded view – ITC-155 A ........................................................ 34

4.3 Exploded view – ITC-320 A ........................................................ 35

4.4 Exploded view – ITC-650 A ........................................................ 36

4.5 Wiring diagram – ITC-155 A ....................................................... 37

4.6 Wiring diagram – ITC-320/650 A ................................................ 38

4 21-08-2003 123313 02

1.0 General

1.1 Introduction

This service manual applies to the following instruments:

• Jofra ITC-155 A

• Jofra ITC-320 A

• Jofra ITC-650 A

All calibrators are produced from quality components by skilled staff.

Each calibrator passes several tests during assembly and undergoes

a final inspection and test following a special calibration procedure

laid down by our technical staff.

Caution…

If you decide to check and/or re-calibrate the calibrator, you

must always use certified test equipment only and ensure

proper contact between the test probe and the well of the

calibrator.

Operating guidelines and technical specifications are outlined in

reference manual order no. 123312. Please note that this is only

available in English.

123313 02 21-08-2003 5

Technical assistance

The following information regarding testing and repair was

correct at the time of issue. Do not hesitate to contact our service

department or your local distributor, however, if you have further

queries.

Note…

Please note that we would be very interested in hearing

from you if you have any ideas or suggestions for changes

to our products.

AMETEK DENMARK A/S

Gydevang 32- 34

DK-3450 Allerød

Phone: +45 48 16 80 00

Fax: +45 48 16 80 80

6 21-08-2003 123313 02

1.2 Safety instructions

Read this manual carefully before doing

any maintenance on the instruments!

Please follow the instructions and procedures described in

this manual in order to maintain the instruments correctly

and to avoid any personal injuries and/or damage to the

instruments.

Warning

• The calibrator is designed for interior use only and

should not be used in risk-prone areas, where

vapour or gas leaks, etc. may constitute an explosives

hazard.

• Never use heat transfer fluids such as silicone, oil,

paste, etc. These fluids may penetrate the calibrator

and cause damage or create poisonous fumes.

Caution – Hot surface

This symbol is engraved in the grid plate.

• Do not touch the grid plate, the well or the insertion

tube as the calibrator is heating up – they may be very

hot.

• Do not touch the handle of the calibrator during use – it

may be very hot.

Note…

• The product liability only applies if the instrument is

subject to a manufacturing defect. This liability

becomes void if the service personnel fails to follow the

maintenance instructions set out in this manual or uses

unauthorised spare parts.

• The instrument must not be exposed to draughts.

123313 02 21-08-2003 7

2.0 Maintenance

2.1 Adjusting and calibrating the instrument

You are advised to return the calibrator to Ametek Denmark A/S or an

accredited laboratory at least once a year for calibration and

adjustment.

Alternatively, you can calibrate/adjust the calibrator yourself.

You will need a calibrated, traceable sensor and thermometer with an

accuracy better than ±0.1°C / ±0.18°F. Ensure that the ambient

temperature is 23°C±3°C / 73.4°F±5.4°F.

To calibrate/adjust the instrument five different temperatures are

needed. These are all preset in the various types of instruments.

The calibration temperatures are:

ITC-155 A 1. -23°C / -9.4°F

2. 20°C / 68°F

3. 60°C / 140°F

4. 100°C / 212°F

5. 155°C / 311°F

ITC-320 A 1. 50°C / 122°F

2. 120°C / 248°F

3. 180°C / 356°F

4. 250°C / 482°F

5. 320°C / 608°F

ITC-650 A 1. 50°C / 122°F

2. 200°C / 392°F

3. 350°C / 662°F

4. 500°C / 932°F

5. 650°C / 1202°F

Prepare to adjust/calibrate the instrument by doing the following (see

Fig. 1):

8 21-08-2003 123313 02

Caution…

• The well and the insertion tube must be clean before

use.

• The insertion tube must never be forced into the well.

The well could be damaged as a result, and the

insertion tube may get stuck.

• Do not touch the tip of the sensor when it is removed

from the insertion tube/well – it may be very hot.

Protect the sensor head from heat radiation from the well

by use of thermal protection shield (part no. 104216) or

similar.

Fig. 1

A

A

Thermal protection shield

CALIBRATI

ONINSTRUMENTS

Insertion tube

Reference sensor

Reference thermometer

Jofra DTI-1000

123313 02 21-08-2003 9

➀To enter service mode, switch on the instrument while

pressing the button.

➁Press or until Calib. Proc. is reached:

➂Press to accept.

The instrument will now heat up/cool down to reach the first

of the 5 calibration temperatures:

°C

°

C

➃Once the calibrator is stable, press or to enter the

true temperature found using the reference thermometer

(the calibration temperature is suggested as a reference

point):

°C

➄Press to accept the temperature.

Repeat this procedure for TEMP.2, TEMP.3, TEMP.4 and TEMP.5.

All five calibration temperatures and associated true temperatures

have now been entered.

The instrument will now check whether the true temperatures which

have been entered are within the permitted tolerances.

10 21-08-2003 123313 02

Permitted tolerances:

• ITC-155 A : ±0.10°C / 0.18°F

• ITC-320 A : ±0.15°C / 0.27°F

• ITC-650 A : ±0.20°C / 0.36°F

There are two possible outcomes:

If the instrument detects excessive deviations for one or more steps,

the display will read =ERR. at the in the top. A message reading AdJ.

will flash at the bottom of the display to indicate that an adjustment is

required:

If, on the other hand, the deviations are found to be within the

permitted tolerances, the instrument will display the text =OK at the

top of the display. The text Cont. will flash at the bottom of the display

to indicate that you may continue without adjustments:

If the calibration results in the message ERR. AdJ., the following

options are available:

- Press to cancel the function and return to service mode.

-

Press to go back and select between the calibration

temperatures if you want to repeat one of the steps.

-

Press to toggle between ERR. AdJ. and ERR. Cont.

123313 02 21-08-2003 11

-

Press when ERR. Cont. is displayed to accept the

calibration although the deviations are outside the permitted

tolerances.

-

Press when ERR. AdJ. is displayed to calculate new

coefficients.

If the coefficients deviate by more than 4% from the standard

values, the instrument will read ERROR 2 in the display. The

calculated coefficients will be ignored:

-

Press to cancel the function and return to service mode,

or press to repeat the calibration. If the coefficients

are within the permitted tolerances, the instrument will start a

calibration.

If the display reads OK Cont., the following options are available:

-

Press to toggle between OK Cont. and OK AdJ.

- Press to cancel OK Cont. or OK AdJ. and return to

service mode.

-

Press when the display reads OK Cont. to accept the

calibration. Next, enter a new calibration date.

12 21-08-2003 123313 02

-

Press when the display reads OK AdJ. to calculate

new coefficients even though the calibration was within the

permitted tolerances. A new calibration procedure will start.

➅Adjust the date by toggling through the available days,

months and years. Begin by selecting the required day as

shown below:

Press or to select the required day in the interval 1-

31.

➆Press to accept your selection.

➇Press or to select the required month from JAN /

FEB / MAR / APR / MAY / JUN / JUL / AUG / SEP /

OCT / NOV / DEC.

➈Press to accept your selection.

➉Press or to select a year between 2001–2025.

123313 02 21-08-2003 13

Press to accept your selection. The day will be

adjusted if necessary to ensure the legality of the date.

Finally, the day, month and year will flash:

Press to accept the date.

or

press to cancel the whole selection.

Switch the instrument off and on again using the power

control switch and cool down the instrument.

11

12

13

14 21-08-2003 123313 02

2.2 Caring for the instrument after use

➀The following routine must be observed before the insertion

tube is removed and the instrument switched off:

Over 100°C/212°F

If the calibrator has been heated up to temperatures above

100°C/212°F, you must wait until the instrument reaches a

temperature below 100°C/212°F before you switch it off.

Below 0°C/32°F (applies only to ITC-155 A models)

If the calibrator has reached a temperature below 0°C/32°F,

ice crystals may form on the insertion tube and the well.

This, in turn, may cause verdigris to form on the material.

To prevent this from happening, simply heat up the

calibrator to 50°C/122°F.

Fig. 2

CA

LIBR

A

TIONINST

R

UMEN

TS

123313 02 21-08-2003 15

➁Remove the insertion tube from the calibrator using the tool

for insertion tube as shown in Fig. 2.

➂Switch off the calibrator using the power control switch.

Caution…

• The insertion tube must always be removed from the

calibrator after use.

The humidity in the air may cause verdigris to form on the

insertion tube inside the instrument. There is a risk that

the insertion tube may become stuck if this is allowed to

happen.

• The insertion tube must be removed to avoid damage to

the instrument if the calibrator is to be transported long

distances.

Warning

Never leave hot insertion tubes which have been removed

from the calibrator unsupervised – they may constitute a fire

hazard.

If you intend to store the calibrator in the optional aluminium

carrying case after use, you must ensure that the instrument

has cooled to a temperature below 100°C/212°F before

placing it in the carrying case.

16 21-08-2003 123313 02

3.0 Repairs

Warning

The calibrator must be switched off before any attempt is

made to service the instrument.

Note…

Ametek Denmark’s liability ceases if:

• Parts are replaced/repaired using spare parts which are

not identical to those recommended by the manufacturer.

• non-original parts are used in any way when operating

the instrument.

Ametek Denmark’s liability is restricted to errors which

originated in the factory.

3.1 Trouble shooting

Error: No light in display

Likely cause: Solution:

Defective fuses:

Supply to CONTROLLER PCB:

Check fuses in the mains inlet.

Check fuses on the POWER PCB

inside the calibrator.

Check the supply – minimum 22V

on CN1 terminal 1(+) and CN1

terminal 2(-).

• If supply voltage is 22V or

higher, replace CONTROLLER

PCB and adjust and re-

calibrate the unit.

123313 02 21-08-2003 17

• If supply voltage is lower than

22V, replace POWER PCB and

adjust POWER PCB.

Error:

Likely cause: Solution:

The measured temperature is

out of range:

Check RTD sensor.

At 23°C the impedance should be

109 ohm ±3 ohm.

• If RTD sensor is OK, replace

CONTROLLER PCB and then

adjust and re-calibrate the unit.

• Otherwise, replace RTD sensor

and re-calibrate the unit.

Error:

Likely cause: Solution:

The new coefficients calculated

by the unit in the CALIB. Proc.

deviate by more than 4% from

the standard values. The

calculated coefficients will be

ignored:

Check the accuracy of the

reference thermometer used for

calibration and repeat the

calibration/adjustment procedure.

If the calibrator shows ERROR

0002 again, the internal RDT

sensor or the CONTROLLER PCB

is defective.

18 21-08-2003 123313 02

Error:

Likely cause: Solution:

Defective CONTROLLER PCB: Replace the CONTROLLER PCB

and then adjust and re-calibrate

the unit.

Error: Fan does not work.

Likely cause: Solution:

Fan obstructions:

Supply for fan:

Remove any obstructions.

ITC-155 A

Check the supply on CN2 terminal

1(+) and terminal 2(-) on the

POWER PCB.

• If supply voltage is 11-18V,

replace fan.

• If supply voltage is lower than

11V, replace and adjust

POWER PCB.

ITC-320 A, ITC-650 A

Check the supply on CN6 terminal

1(+) and terminal 2(-) on the

POWER PCB.

• If supply voltage is 11-18V,

replace fan.

• If supply voltage is lower than

11V, replace and adjust

POWER PCB.

123313 02 21-08-2003 19

Error: Switch test does not work.

Likely cause: Solution:

Defective I/O PCB: • Check signal from switch test

input. The voltage between

CN2 terminal 1(+) and CN2

terminal 2(-) on the

CONTROLLER PCB changes

from 0V to 5V when the switch

test input changes from closed

to open.

If the signal does not change

and the voltage between CN1

terminal 3 (+) and CN1 terminal

4(-) on the I/O PCB is 5V,

replace the I/O PCB.

• Otherwise, replace the

CONTROLLER PCB and

adjust and re-calibrate the unit.

Error: Calibrator does not cool or heat sufficiently (ITC-155 A

only).

Likely cause: Solution:

Defective well: • Set the SET temperature to

-40°C.

Measure the voltage between

CN6 terminal 1(+) and terminal

2(-) and the voltage between

CN3 terminal 1(+) and terminal

2(-).

If the voltage on CN3 is higher

than 26V, replace the well and

re-calibrate the unit.

20 21-08-2003 123313 02

Defective POWER PCB:

• If the voltage on CN6 is correct

and the calibrator does not cool

down sufficiently, replace the

well and re-calibrate the unit.

If the voltage on CN3 is less than

26V and the voltage on CN6 differs

from 0.330V ±0.005V, adjust R9

until the voltage is 0.330V ±0.005V.

If it is impossible to adjust the

voltage on CN6, replace the

POWER PCB.

Error: Calibrator does not heat (ITC-320 A, ITC-650 A).

Likely cause: Solution:

Defective POWER PCB: • Check impedance of the

heating elements (Approx. 23

ohm for ITC-320 A / ITC-650

A).

Turn on the instrument and set

the SET temperature to 320°C

(ITC-320 A) or 650°C (ITC-650

A).

Check that relay K1 has been

pulled.

If the relay has not been pulled,

check that the over-

temperature sensor (ITC-320

A/ITC-650 A) has been

mounted and is OK. If the

sensor is OK, change and

adjust the POWER PCB.

• If the 2 light diodes on the

POWER PCB are lit, change

and adjust the POWER PCB.

This manual suits for next models

2

Table of contents

Other Transcat Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

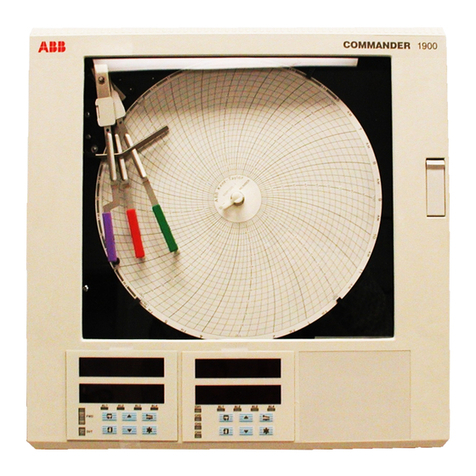

ABB

ABB COMMANDER 1900 Series Programming guide

Precision Digital Corporation

Precision Digital Corporation PD685 instruction manual

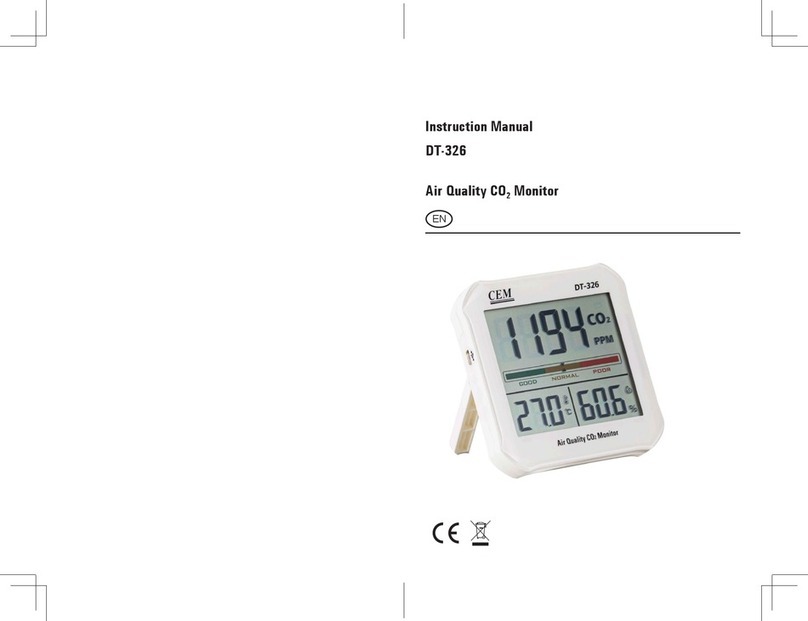

CEM

CEM DT-326 instruction manual

Emerson

Emerson Rosemount 8750WB quick start guide

ATAGO

ATAGO PAL-Easy ACID3 instruction manual

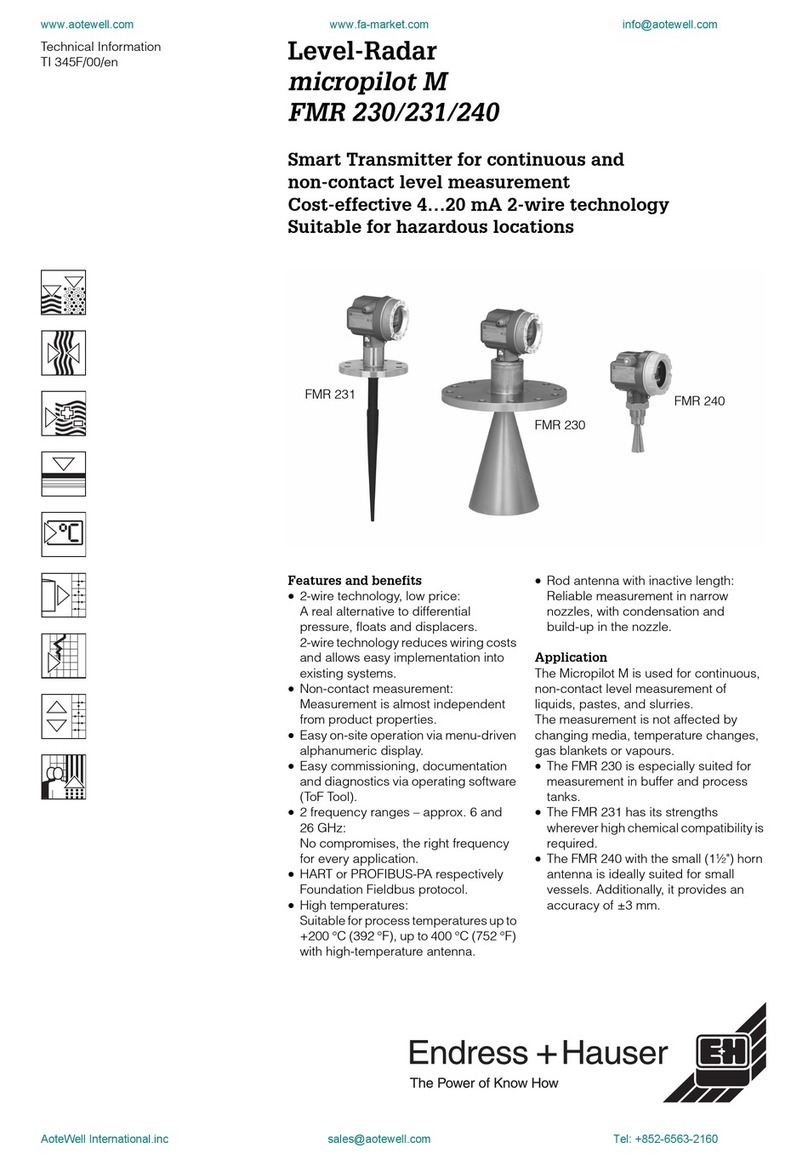

Endress+Hauser

Endress+Hauser micropilot M FMR 230 technical information