Transforming Technologies SCION IN1200 Series User manual

Model IN1200 Series

Instruction Manual

T R A N S F O R M I N G T E C H N O L O G I E S , L L C

O U T S T A N D I N G A L T E R N A T I V E S I N S T A T I C C O N T R O L

SCIONTM IN1200 - Ionizing Bar Operaon Manual

The SCIONTM IN1200 ionizing bar is an eecve tool to eliminate stac in

the electronics, plascs, chemicals, prinng, texle, opcal and other in-

dustries. Ulizing AC Square Wave Technology, the SCIONTM IN1200 deliv-

ers uniform streams of ionized air that quickly eliminates stac charge.

The ionizing bar features a unique aerodynamic design that ionizes a local

area without disrupon laminar ow. The IN1200 ionizing bar is designed

to reduce stac charge in mini-environments, laminar ow hoods and

wide are applicaons. Available in four dierent lengths.

Features

1. Aerodynamic bar design

2. AC Square Wave ionizing technology

3. Remote control operaon - Easily make adjustments

4. Fast decay mes with excellent ion balance

5. Equipped with an malfuncon Alarm

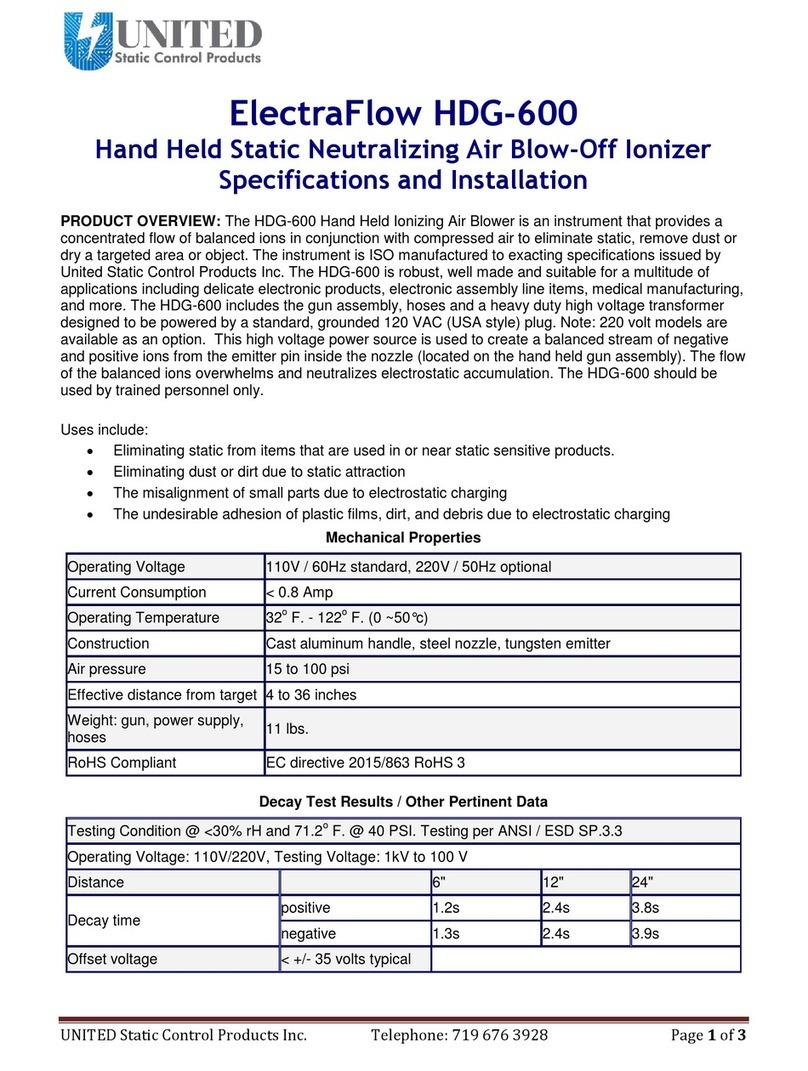

Specicaons

Model IN1200-12, IN1200-22, IN1200-44, IN1200-64

Output voltage DC±5.00 (KV)

Output frequency 5, 30(Hz)

Duty factor 10%-90%

Power 10W

Working distance 4in-40in

Ion balance ≤|±30V|(AVE)

Discharge time ≤2S at 18in with airflow

Working tempera- 32 - 122 Deg F

Working humidity <70%

Air pressure 70psi

Noce of Safety and Use

1. Read this manual carefully before use.

2. The device must be properly grounded when in use.

3. This device uses high voltage. Do not touch electrodes while in use. Do

not open bar without authorizaon. Internal maintenance and repair

must be carried out by professionals.

4. Do not use this device in an environment where the humidity is greater

than 75%

5. Do not use this device in combusble and explosive environments.

6. Electrodes must not come in contact with metal conductors.

7. Please contact Transforming Technologies Customer Service for repair

informaon.

Installaon

1. Choose opmal locaon for ionizaon and mount the bar and power

supply. Bar should be mounted perpendicular to the charged surface.

2. Slide the EZ mount clips onto the ionizer and twist. Tighten with an

Allen wrench to secure posion.

3. Insert the power cord in the port labels "Power".

4. Connect the air source to the bar via the quick release valve.

5. Turn on the power switch and adjust air pressure to proper levels with

needle valve.

Posioning

Air Assist

Aach the IN1200 to the gas line using the appropriate tubing. The

IN1200 comes with a 1/4” quick release connector. Adjust pressure as

required.

The me required to neutralize a stac charge on an item in this area de-

pends on two important factors: distance to the ionizer and air velocity

assist. With high air velocity, the ions travel further before they recom-

bine. Using assisted air with high speed results in coverage for the great-

est possible area.

Adjustments

There are two sengs on the ion bar that can be adjusted: Working Fre-

quency and Duty Rao. Adjustments are made to t your applicaon or

ion bar setup and are completed with the SCION remote control.

Working Frequency

The SCION uses an alternang current to produce ions. The Working Fre-

quency is the speed (measured in Hz) at which the ion bar makes a full

cycle from the posive current to the negave and back to posive. The

bar can be adjusted from 1Hz (slowest) to 50Hz (fastest). The Working

Frequency used depends on the distance the charge is from the bar and

the amount of airow assist used. A slower Working Frequency increases

the distance that the ions travel from the bar and works with lower air-

ow. A higher Working Frequency is used when the charge is close to the

bar and in high airow applicaons.

Duty Rao

Duty Rao is the balance of posive and negave ions the ion bar produc-

es. For most situaons, the ideal average balance should be as close to 0

as possible. This means the ion bar produces the same amount of posive

and negave ions. You can increase the amount of posive ions with

"IB+" and increase the negave ions with "IB+" on the SCION remote.

Duty Rao for Primarily One Charge Polarity

Situaons exist when you may need more of one ion polarity than the

other. If you are certain that the charge to be neutralized is primarily posi-

ve or negave, you can adjust the bar to produce the opposite charge.

For example, molded plasc components has a large primarily negave

charge so you would increase the posive ions produced by the bar.

You can set the ion bar to only posive or only negave with the "P" and

"N" on the remote. Cycle the bars power o and on to reset this.

Remote Control Operaon

"R/S": Run/Stop: Turns the bar on and o

"IB+": Increase duty rao

"IB-" Decrease duty rao

"P": Only posive voltage cycle

"N" Only negave voltage cycle

"Bar": Adjusts the ion bar working frequency.

"C": Rest

The bar can be set from 1hz (slowest) to 50hz

(fastest) by pressing "Bar" and then a number:

"Bar"+"1": Set ion bar working frequency 1Hz;

"Bar"+"2": Set ion bar working frequency 3Hz

"Bar"+"3": Set ion bar working frequency 5Hz;

"Bar"+"4": Set ion bar working frequency 10Hz

"Bar"+"5": Set ion bar working frequency 20Hz;

"Bar"+"6": Set ion bar working frequency 30Hz

"Bar"+"7": Set ion bar working frequency 50Hz; "

High Voltage Alarm

The ion bar will issue an alarm (Alarm 1) on the LED if a HV error occurs.

The error is a result of an issue with the high voltage current owing

through the bar. If an HV error occurs, turn of the ion bars power and con-

tact Transforming Technologies at 419-841-9552.

Maintenance

The electrodes must be regularly cleaned to maintain good ionizing per-

formance. Frequency of cleaning is dependent on the cleanliness of the

environment and requirements of the ESD program. At least once a

month is a suggested frequency. Note: Do not clean ionizer when pow-

ered on.

1. Power o the ion bar and let sit for 10 minutes.

2. Clean the electrode p, discharge pad and metal discharge body with

alcohol and a clean cloth.

3. Do not power on the ion bar unl the components are completely dry.

Calibraon

The SCION IN1200 ion output is inherently balanced by design, so there

are no calibraon adjustments. Periodic vericaon is recommended, per

ANSI/ESD SP3.3-2006 Periodic Vericaon of Air Ionizers. Vericaon fre-

quency may be set by the individual user, but is recommended to be not

less than one me per year.

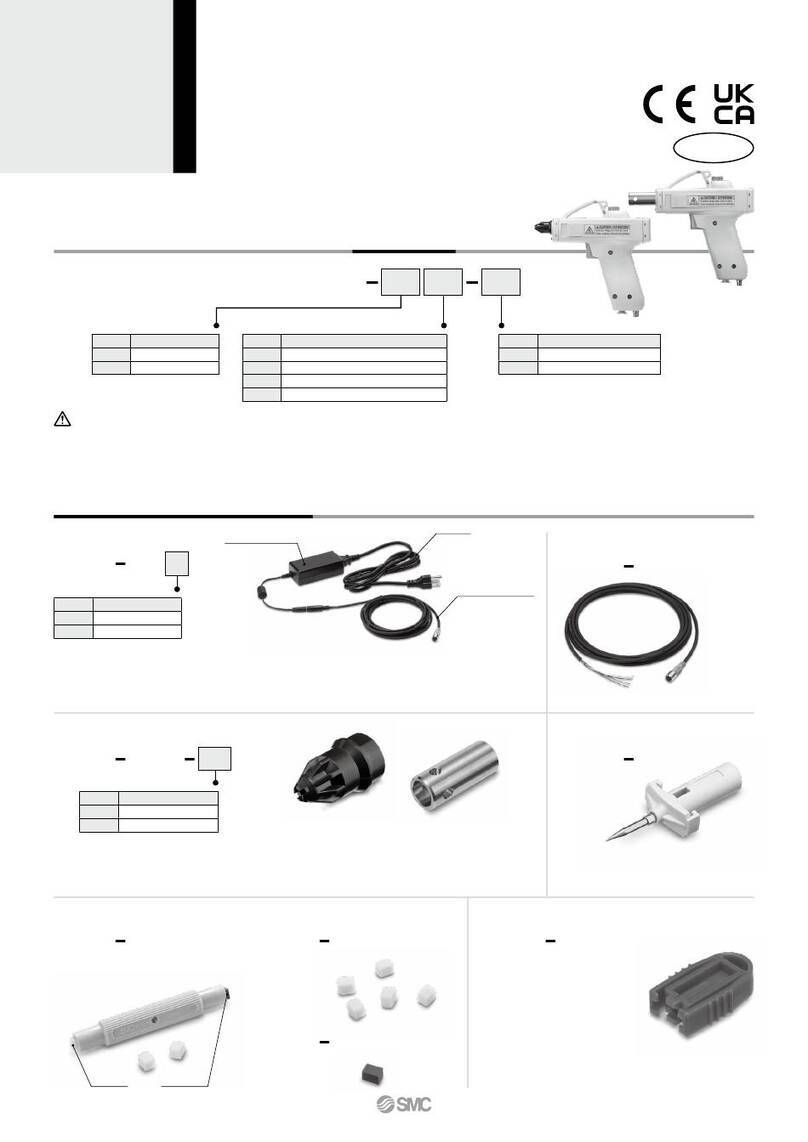

Equipment needed is a Charge Plate Monitor such as Transforming Tech-

nologies EFM51.CPS.SET or CPM74. Test the ionizer's ion output and bal-

ance according to the Charge Plate's instrucons.

Ion Output Check: Discharge mes should be 2 seconds (1000v-100v) at

18".

Ion Balance Check: Oset voltage should be measured and be within +30

volts.

EFM51.CPS.SET -

CPM74- Charge Plate

Service and Warranty

Transforming Technologies, LLC provides a limited warranty for the

IN1200 series Ionizers. All new products are guaranteed to be free from

defects in material and workmanship for a period of one (1) year from the

date of shipment. Liability is limited to servicing (aer evaluang, repairing

or replacing) any product returned to Transforming Technologies. The com-

pany does not warrant damage due to misuse, neglect, alteraon or acci-

dent. In no event shall Transforming Technologies be liable for collateral or

consequenal damages. To receive service under warranty, please contact

Transforming Technologies Technical Support.

About Transforming Technologies

Since 1998, Transforming Technologies has helped electronic man-

ufacturing facilies to protect their products and processes from the many

serious problems associated with stac electricity. Transforming Technolo-

gies oers a wide range of unique and outstanding products to detect, pro-

tect, eliminate and monitor electrostac charges. Our products are integral

components of an eecve stac control program.

3719 King Rd | Toledo, OH 43617 | P: 419-841-9552 | F: 419-841-3241 | info@transforming-technologies.com

This manual suits for next models

4

Table of contents

Other Transforming Technologies Air Ionizer manuals