Specifications

Parts Description

Description of LED Indicators

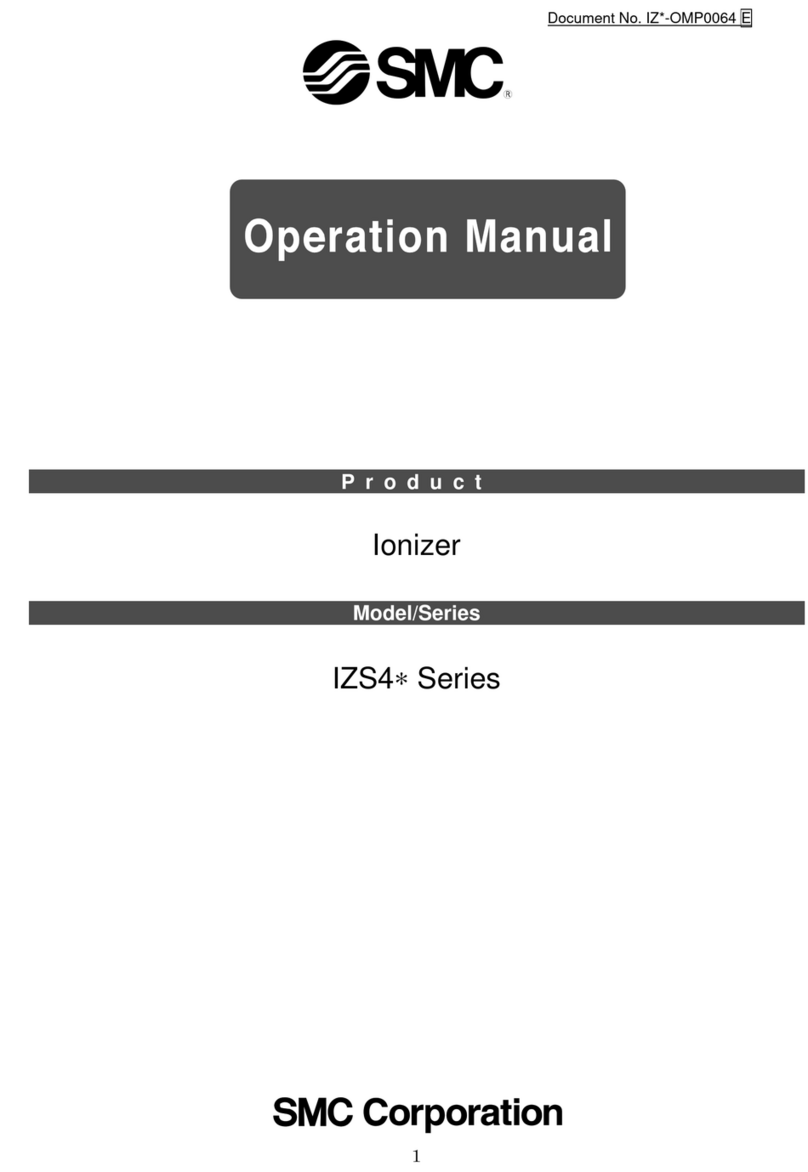

AC Adapter Specifications

Input voltage*4100 to 240 VAC

50/60 Hz

Output voltage 24 VDC ±5%

Output current 0.8 A max.

Ambient

temperature 0 to 40°C

Ambient humidity 20 to 80%RH

Safety standards IEC 62368-1

*4 An AC cord included with an AC adapter is only

for use in Japan. (Rated voltage 125 V, Plug

JIS C 8303, Inlet IEC 60320-C13)

LED Indicators

No. Display LED color Description Contents

qPWR Green Power supply

indicator

Green LED turns ON when power is supplied, and the LED

flashes when the voltage is outside of the specification range.

wION/

HV

Green/

Red

Static neutralization

operation/Incorrect

high voltage indicator

Green LED turns ON during static neutralization.

Red LED turns ON when a high voltage abnor-

mality is present.

eNDL Green Maintenance

indicator

Green LED turns ON when lowered static

neutralization performance due to the con-

tamination or wear of the emitter is detected.

wq e

w r

y

t

u

q

Ionizer model IZG10

Ion generation method Corona discharge type

Method of applying high voltage High frequency AC type

Applied voltage*1±2.5 kV

Offset voltage*2Within ±10 V

Air supply*3

Fluid Air (Clean, dry air)

Operating pressure 0.05 to 0.6 MPa

Connecting tube size ø8 (Metric), ø5/16" (Inch)

Power supply voltage 24 VDC ±10% (21.6 to 26.4 V)

Current consumption 90 mA (typ.)

Ambient temperature 0 to 40°C (No freezing)

Ambient humidity 35 to 65%RH (No condensation)

Material Case: PBT Emitter: Tungsten

Weight

(Body only)

Standard nozzle 200 g

Bypass nozzle 250 g

Standards/Directive CE (EMC directive, RoHS directive), UKCA

*1 Measured with a high pressure probe of 1000 MΩand 5 pF

*2 Measurement value based on a charged plate (Dimensions: 150 mm x 150 mm, Capacitance:

20 pF) as defined in the U.S. ANSI standards (ANSI/ESD STM3.1-2015)

When the distance between the charged plate and the ionizer is 150 mm, and the operating pressure is 0.2 MPa

*3 Static neutralization is not possible without supplying compressed air. Without compressed

air, ozone or nitrogen oxides generated by the ion generation process may accumulate and

adversely affect the product and peripheral equipment.

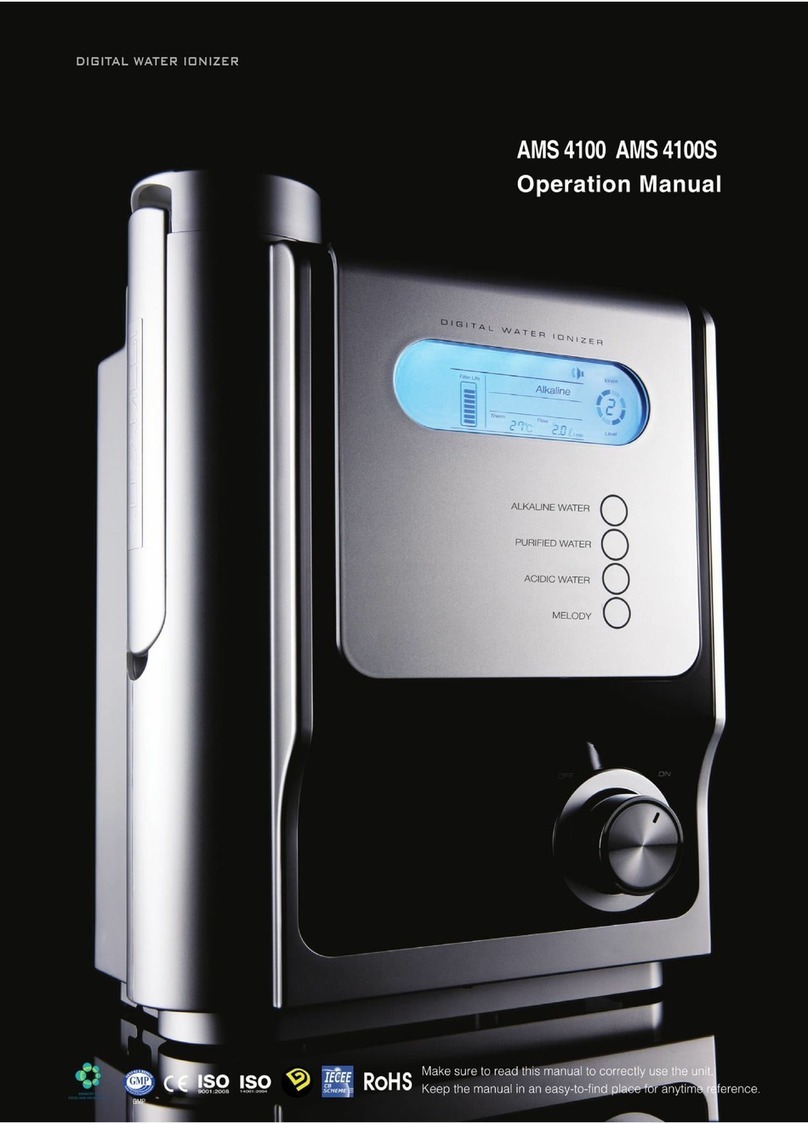

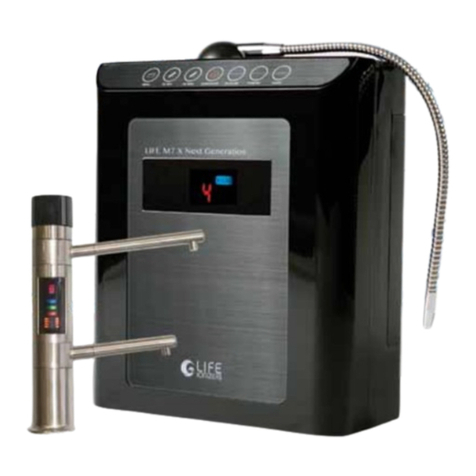

No. Description Contents

qNozzle Discharge ionized air

wSlide cover

Protective cover for the mode setting switch

eMode setting

switch

Switch for setting blow and trigger

(Default setting: Set no. 0)

r

Flow adjustment

knob (With indicator)

Turn the knob to adjust the flow rate.

Press the knob to lock the setting.

tTrigger

Switch to turn on and off static neutralization

yOne-touch fitting Supply port of compressed air

uPower supply

connector

Connector for power supply, F.G., and

external switch inputs

iLighting LED

Illuminate the object during static neutralization

LED indicator

i

*Inside of the slide cover

e

Alarm

The LEDs are used for notification of malfunctions.

Please note that ion generation may either continue or stop depending on the type of abnormality.

Alarm name Ion generation LED Description Action to reset

alarm

PWR ION/HV NDL

Power supply failure

Stop

Green (Flashing)

OFF OFF

Connected power supply voltage is outside of specification.

Supply power again.

Incorrect high voltage

Stop Green (ON) Red (ON) OFF The high voltage output has dropped.

Supply power again.

CPU failure Stop

Green (Flashing)

Red (Flashing)

Green (Flashing)

CPU error due to noise, etc.

Supply power again.

Maintenance

indication Continue Green (ON) — Green (ON)

When static neutralization performance is reduced

due to contamination, wear, or damage of the emitters

—

186

Gun Type Ionizer IZG10 Series

IZS40/41/42

IZT40/41(-L)/

42(-L)/43(-L)

IZN10EIZFIZG10ZVBIZD10/IZE11IZH10

Antistatic

Equipment