Installation, Operation & Maintenance Guide Matterhorn 1000/1002 6

1-888-MY-AIR11 CAG-06-21-003 AtmosAir.com

02 INSTALLATION

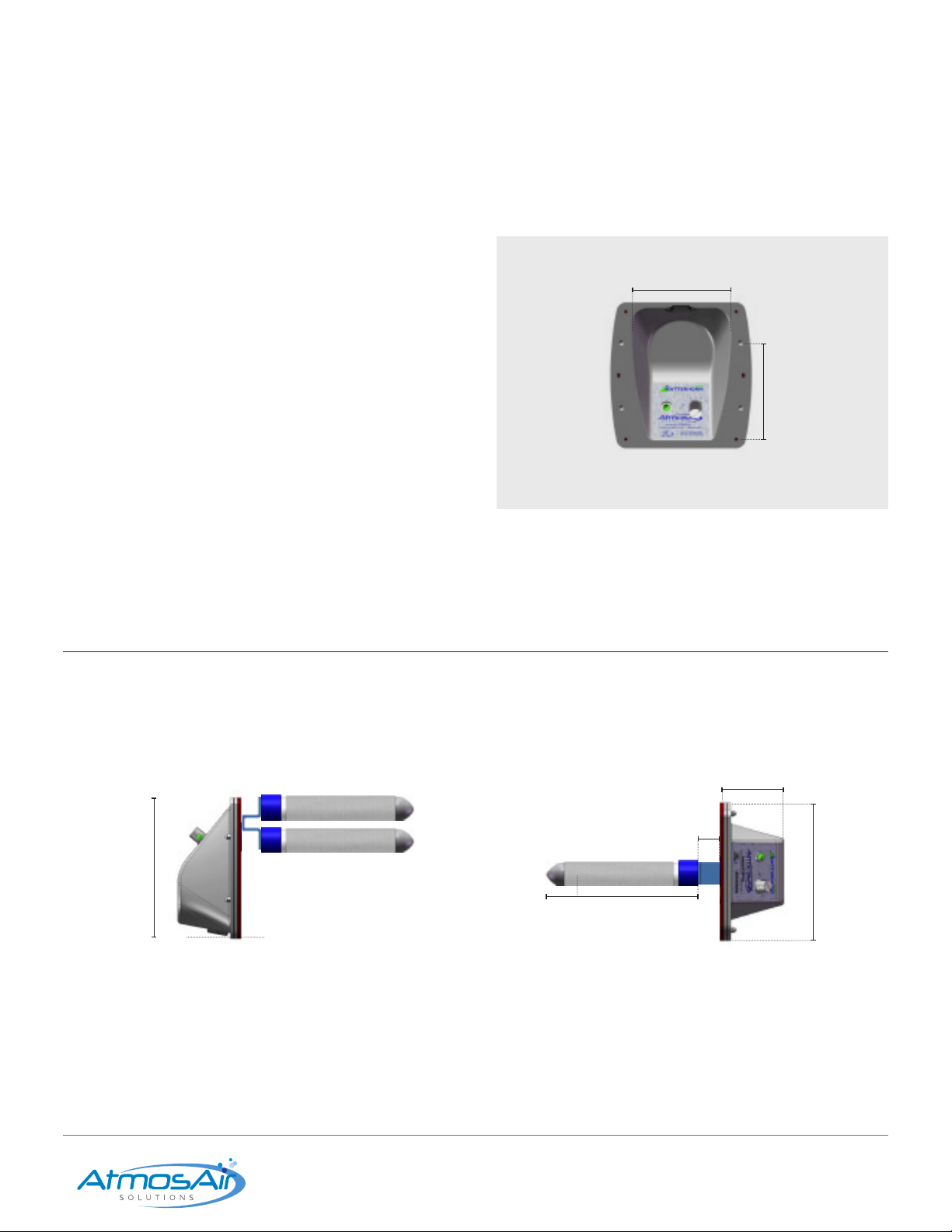

The Matterhorn 1000/1002 series equipment can be mounted

in-duct, using the faceplate mounting flange and its

weather-strip gasket, or inside a plenum using a semi-custom

mounting bracket. The units operate best when located after

all filters, coils, and fans. Various mounting arrangements are

possible; however, the available options may be limited due

to size and configuration restrictions. Use the Duct Cut-Out

and Quick-Change Plate Procedure for ideal placement of the

Matterhorn 1000/1002 models.

When mounted on the side of a duct or air handler wall, the

enclosure should not be exposed to moisture. If installing on

outdoor exposed ductwork, a weatherproof enclosure with an

access panel for servicing should be installed over the AtmosAir

equipment. Contact AtmosAir Sales for A.W.E. specifications.

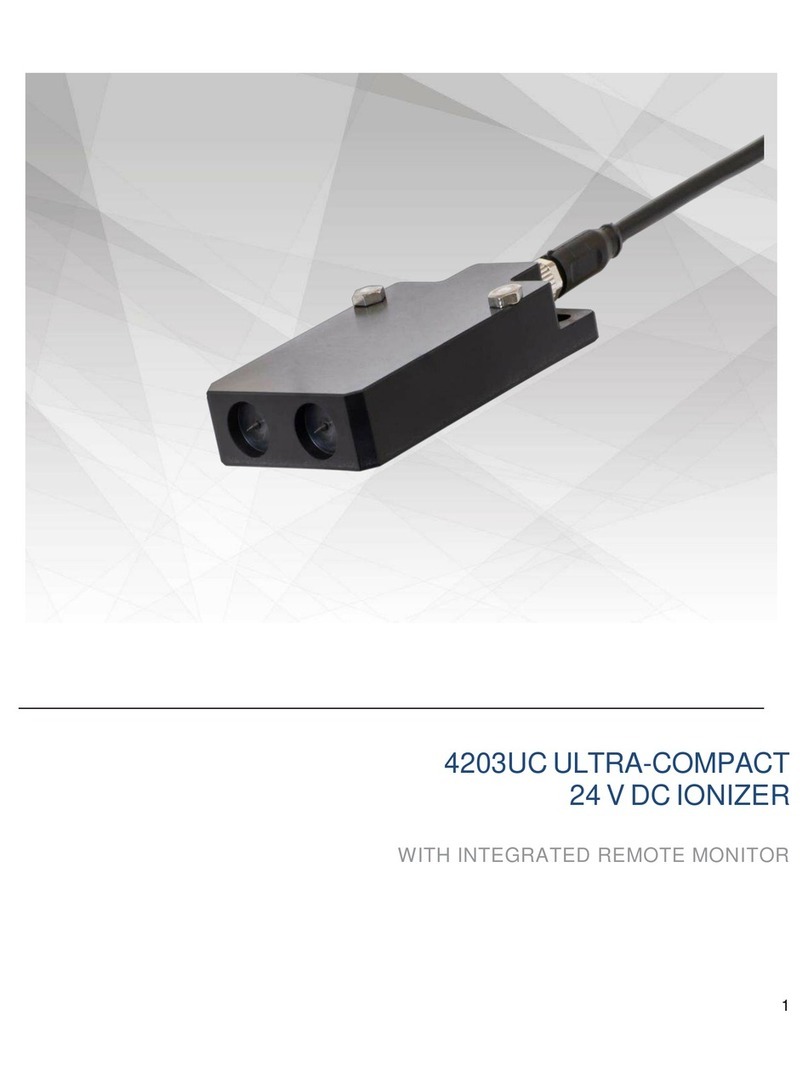

The AtmosAir Matterhorn 1000/1002 series operates on 120 VAC,

50/60 Hz. The tube and electrode contacts should not come into

contact with any conductive surface. A minimum 50.8mm (2”)

clearance around the tube is recommended.

Mechanical Installation

1. Carefully remove the equipment from its shipping

container. Inspect the main components, gasket, and

tube(s) for damage. Verify that the unit’s voltage rating is

the same as the available voltage, 120 VAC.

2. Install the ionization tube: Gently pull the conductor

strap back to allow the tube to turn freely; screw the end

screw of the tube into the tube holder hand-tight utilizing

the blue cap, DO NOT TWIST THE TUBE OR MOVE THE

EMITTER SCREEN. DO NOT OVER-TIGHTEN THE TUBE!

Once the tube is secure, return the conductor strap to its

normal position and ENSURE SOLID, FLAT CONTACT IS

MADE WITH THE TUBE’S OUTER MESH.

3. Location and Orientation: Install the unit downstream

of filters, coils, and fans with the ionization tubes vertical

whenever possible (When installing a dual F Tube setup,

the tubes MUST be mounted vertically, and ‘S’ clips are

recommended); If multiple units are installed in the same

duct, stagger the units in the airflow so they are not in the

same airflow path.

4. The standard Matterhorn 1000/1002 power cord is 3.05

meters (10’) long. Be sure to consider receptacle location in

your placement plan. The receptacle or junction box must

be within 2.44 meters (8’) of the M 1000/1002.

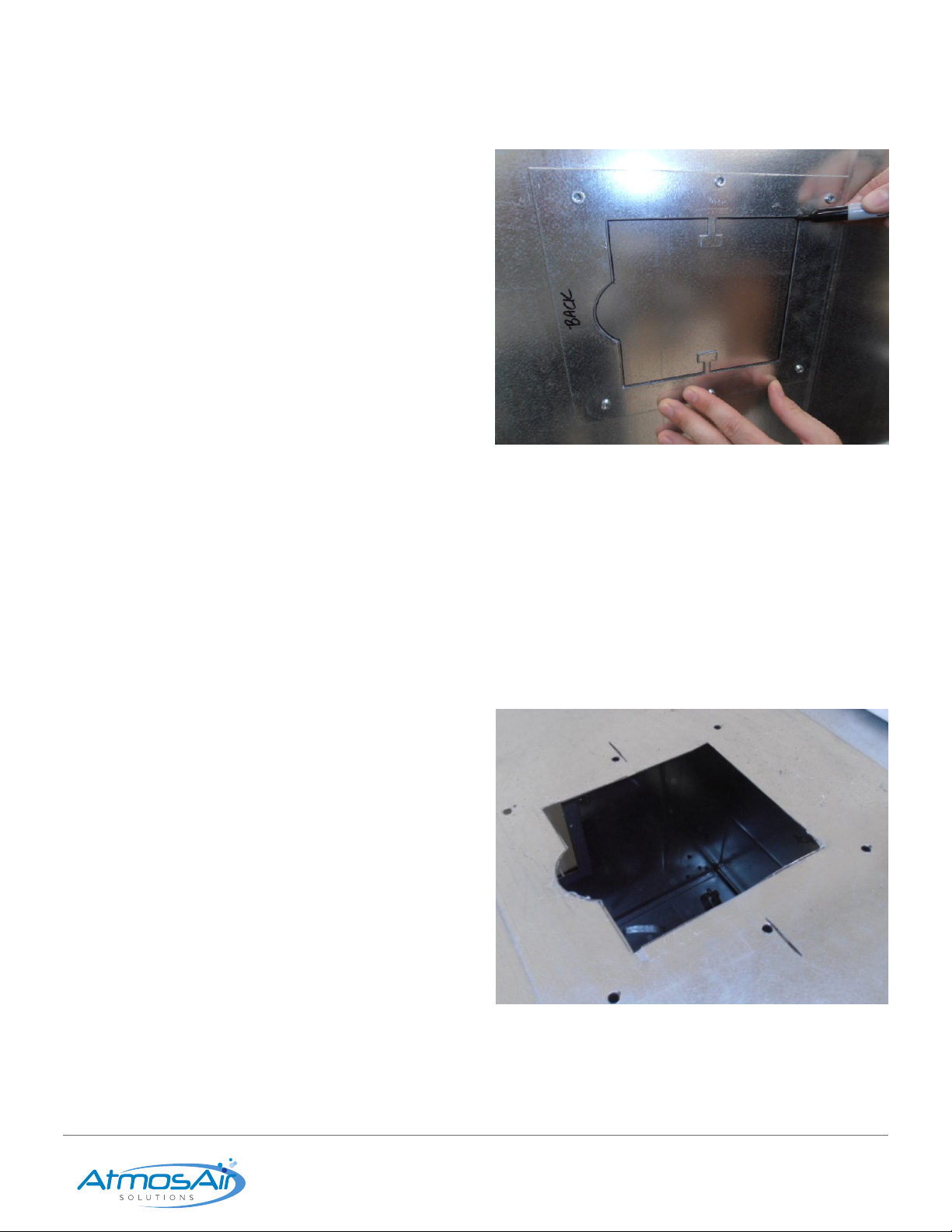

5. For in-duct installation: Verify the flange gasket is in

place and not damaged to ensure the unit seals properly.

When making a cut-out in the duct, ensure there is at

least 25.4mm (1”) clearance from the duct wall on all four

sides before cutting the 139.7 mm (5½”) high × 152.4mm

(6”) wide mounting cut-out. A galvanized steel template

is included for ease of installation; use the inner lines to

cut the cut-out hole, then trace the cut-out and mark

the locations of the mounting holes for the Matterhorn

1000/1002 series. The semi-circular cutout in the template

should be oriented upstream if possible.

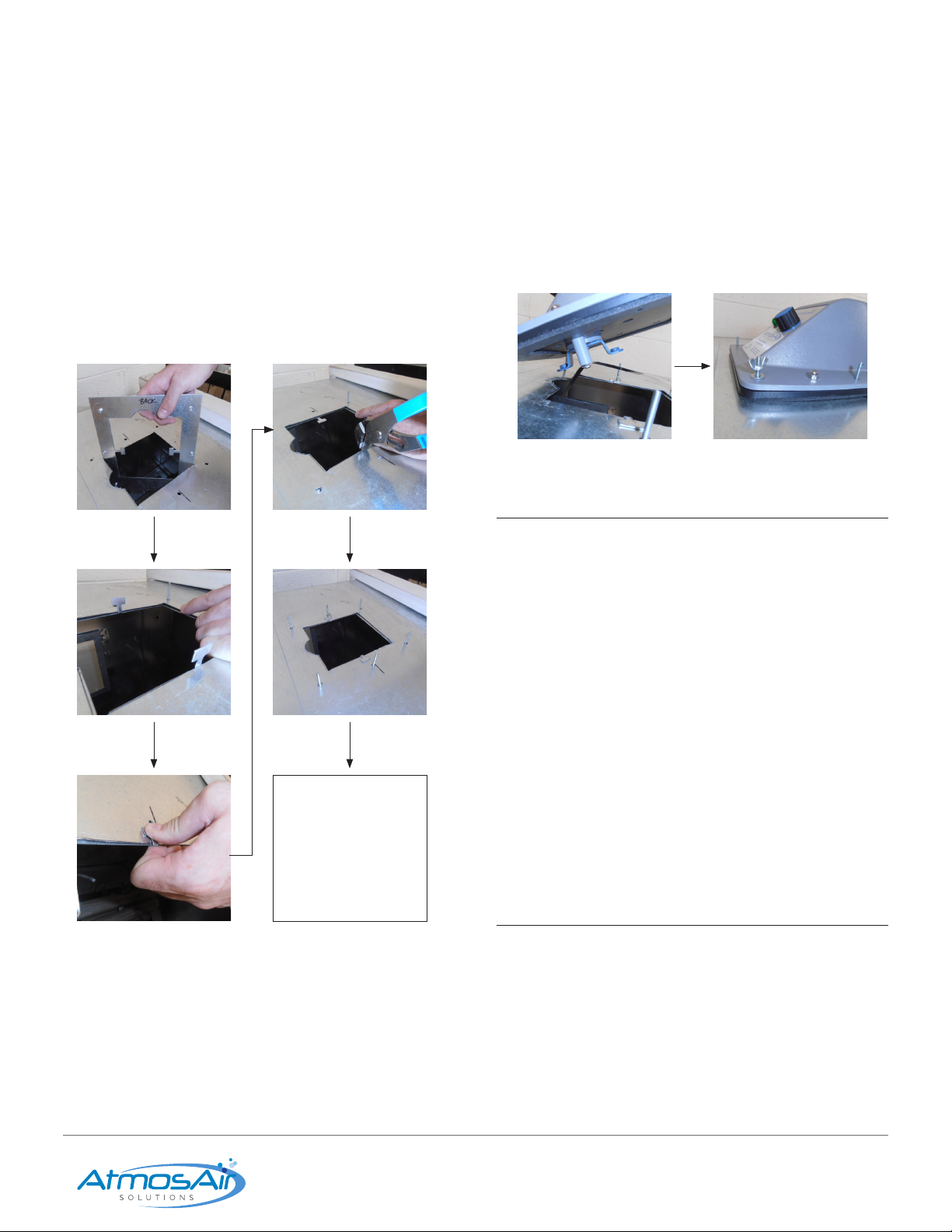

6. Using the marked holes from the backer-plate template,

affix the unit securely in the duct using self-tapping

screws (if not using backer-plate). Do not over-tighten,

this may strip the screw hole. The unit is self-sealing to the

duct, so no further sealing is needed.

Continue on Next page

Not Acceptable

Acceptable