Transforming Technologies BFN 803 User manual

BFN 803 Ionizing Blower

Instruction Manual

T R A N S F O R M I N G T E C H N O L O G I E S , L L C

O U T S T A N D I N G A L T E R N A T I V E S I N S T A T I C C O N T R O L

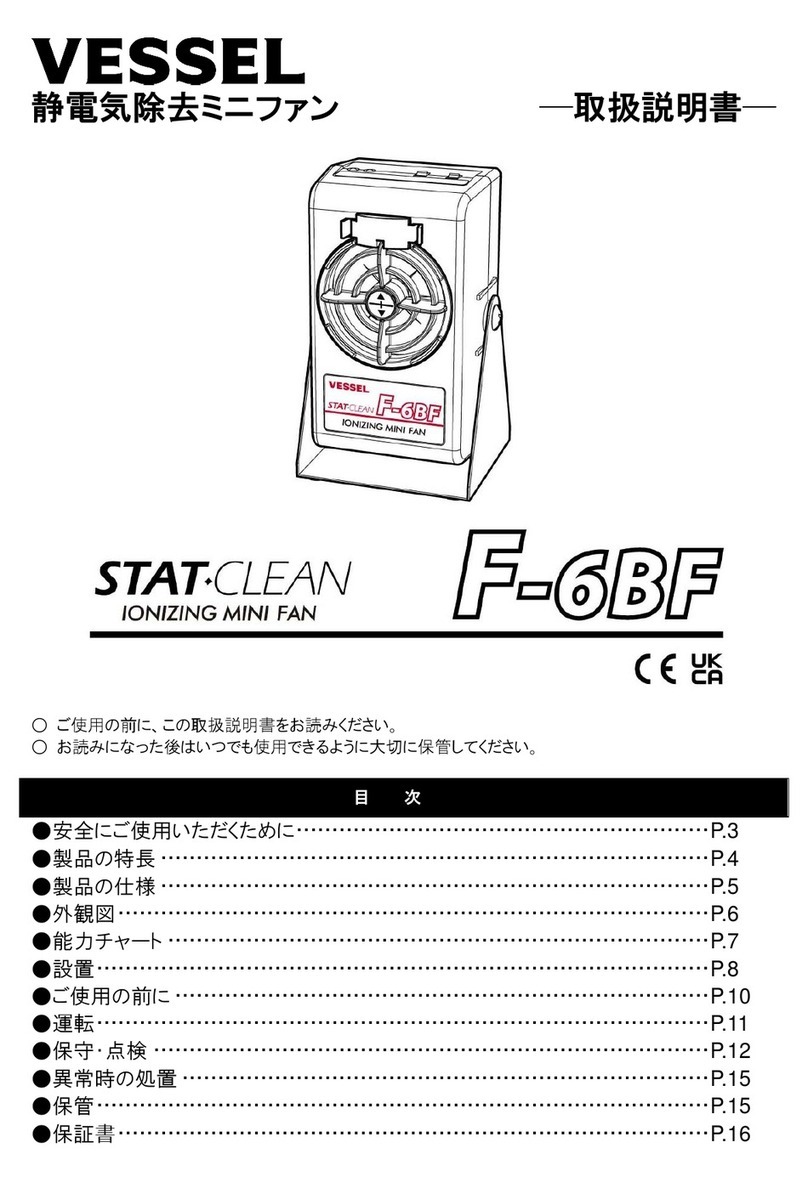

1. BFN 803

BFN Series 1

Description 2

Features 2

Specification 3

Operating Guide 4

Dis/Assembly 6

Periodic Verification 9

2. About

Service/ warranty 10

Transforming

Technologies 10

Contents

Description

BFN®Series Ionizers

Dependable, Balanced and Fast. BFN® AC ionizers, from

Transforming Technologies, are built to last. Reliable AC

ionization technology is combined with superior mechani-

cal design to assure years of optimal static neutralizing

performance.

A full 1 year warranty.

CE certification.

All BFN® AC ionizers use titanium alloy emitter points

for long life.

All BFN series AC ionizing blowers are designed for safe

operation under normal use. Safety switches under the

front and rear removable finger guards shut off the unit,

protecting the operator during maintenance.

Do not operate BFN series products in flammable

or explosive environments.

Do not insert foreign objects into the air inlet or

outlet.

Make certain the BFN ionizer is properly grounded

before operation.

Disconnect the BFN ionizer from any power source

before removing the finger guards.

Do not open or attempt to repair any BFN series

product. Breaking the manufacturing seal will void

warranty.

1

2

Description

Please read these operating instructions thoroughly be-

fore operating the BFN 803 unit. All BFN series devices

require a grounded power source for proper operation.

BFN series products are NOT suitable for use in flamma-

ble or explosive environments.

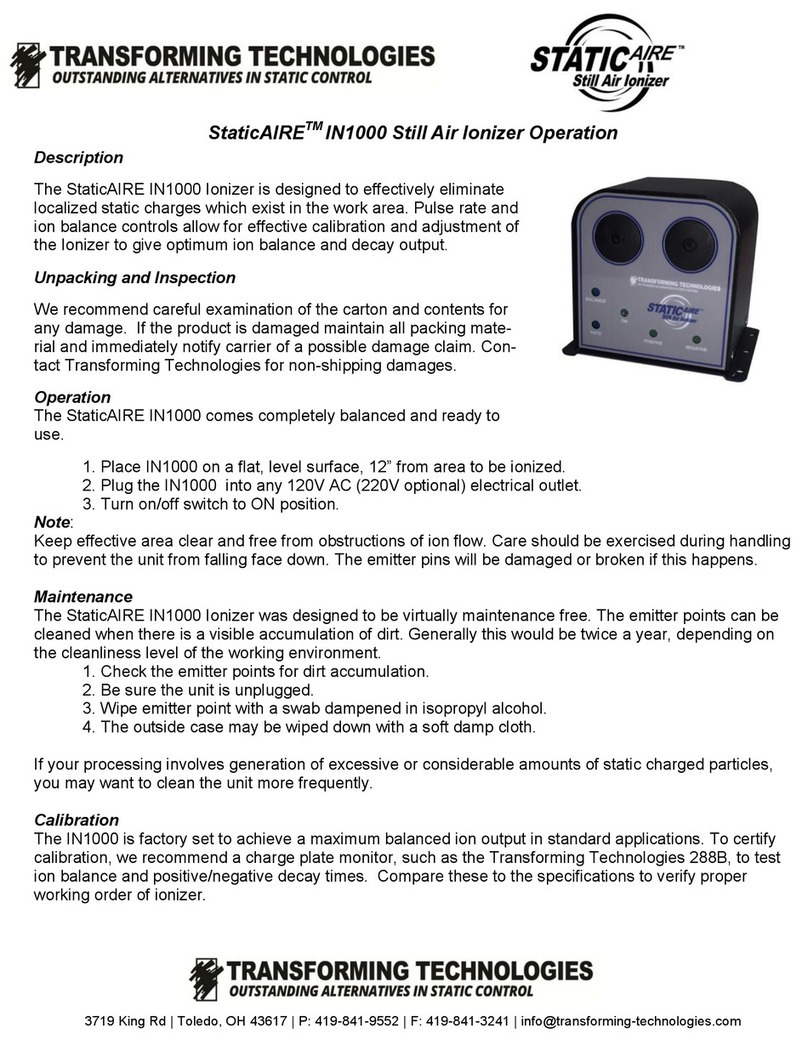

BFN 803: AC Overhead Blower Model

The BFN 803, 3 fan overhead ionizing blower, with AC

technology, provides excellent balance and stability for

secure workstation protection. This superior ionizer is

equipped with 2 LED task lights, integrated emitter

cleaners and safe, easy maintenance access.

BFN series AC ionizers from Transforming Technologies

create a dense and well-balanced ionization current.

They are unique in their ability to deliver fast decay

times with low offset voltages. Continuous balance and

decay protection is assured by the reliable AC design. An

integrated emitter point cleaner, removable front and

rear fan guards, safety switch combine to make the BFN

803 a user friendly ionizer.

Features

AC ionization output

2 LED Task Lights

Integrated emitter cleaning device

Variable fan speed control

Removable finger guards with auto shut-off sensor

3

Power Requirements

120 V AC, 60 Hz., 110W

220 V AC, 50Hz.

Dimensions

38.78” W x 6.75” H x 3.35” D

(58.5 W x 17.2 H x 8.5 D cm)

Weight

18.7 lb (8.5 kg)

Air Volume

150 CFM –300 CFM [low –

high]

Effective Coverage

2’ x 4’ area coverage

Balance

0+10 volts

Decay Time

< 3 seconds @ 18”, directly un-

der center of unit, 1000V-100V,

fan speed on high

Temperature

32-122° F (0-50° C)

RH operating range

20-60%, non-condensing

Ozone Production

< 0.003 ppm, 12” in front of

unit, EPA EQOA577019

Indicators

ON/OFF status light indicator,

detects presence of HV on

emitter points

Light Output

LED Lamp

Light Color Temperature

2500 K

Replacement Lamp

T4/5W fluorescent lamp

Audible Noise

52dB(A), (Distance 1 meter)

Enclosure

Steel

Finish

Powder coat, off white

Approvals

CE

Product Specifications

Packing list:

BFN 803 ionizing blower

Power cord

Instruction manual

Certificate of Conformance

Mounting Brackets

4

Tested in accord with ANSI/ESD STM3.1-2006

BFN 803 Performance

Discharge time

in seconds

(1000 volts to

100volts) de-

termined per

EOS/ESD Asso-

ciation Stan-

dard NO.3; unit

at 18” above

test plate, fans

at high speed.

Discharge

times are

slightly loner

for 230VAC,

50Hz unit.

Operating Guide

1. Power Connection

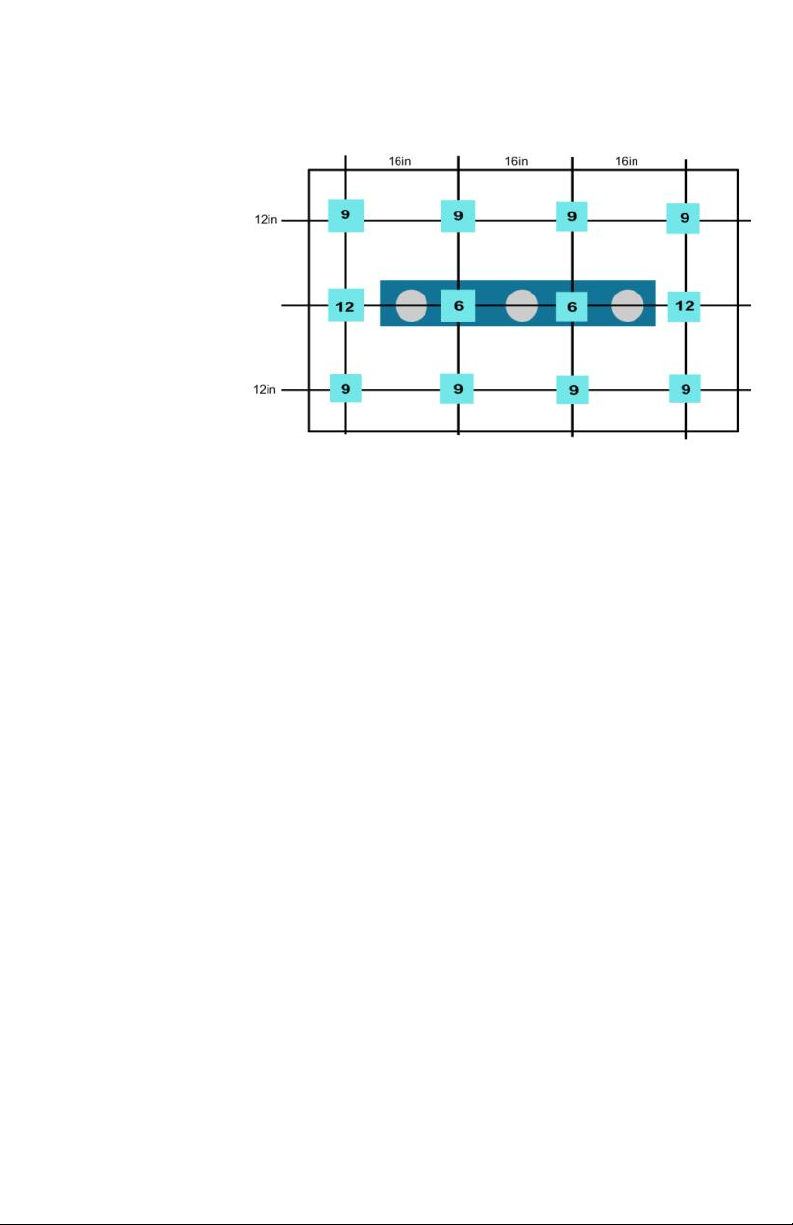

Properly locate and install the ionizer into the proper po-

sition and connect the power cord. Mounting brackets lo-

cated on the back right and left are used hang the ionizer

from the ceiling. Rotate the on/off, fan speed knob clock-

wise to turn on the unit. Continue rotating the knob to

achieve the desired fan speed.

Note: Do not insert any object into the air inlet or outlet.

Note: Unit must be properly grounded before operating.

5

2. Periodic Maintenance

The only maintenance required for BFN series ionizers is

the periodic cleaning of the emitter points, inlet and out-

let finger guards and the fan assembly. Emitter point

cleaning affects the static decay ability of the ionizer and

is important for maintaining its optimal performance.

Emitter point cleaning: All BFN series ionizing blow-

ers include an integrated emitter point cleaning brush on

the inlet fan guards. Turn the emitter point cleaners

clockwise, then counter clockwise several times, until

points are clean. When finished, return the point cleaning

brush to its resting position. CAUTION: Brushes do not

spin 360 degrees. Stopping point is on the bottom

right of fan guard. Do Not Force.

Internal fan cleaning: All BFN series ionizing blowers

offer convenient cleaning of the internal fan assembly.

Use the following procedure to maintain cleanliness.

Note: Always disconnect the ionizer from the power

source prior to internal cleaning.

Air Outlet Disassembly

A. Press the button on the bottom of the plastic front

cover upwards and make the lower portion of the fan

Operating Guide Cont.

6

B. Lightly pull the front cover downwards until it

separates from the blower.

C. Completely remove cover and set aside.

CBA

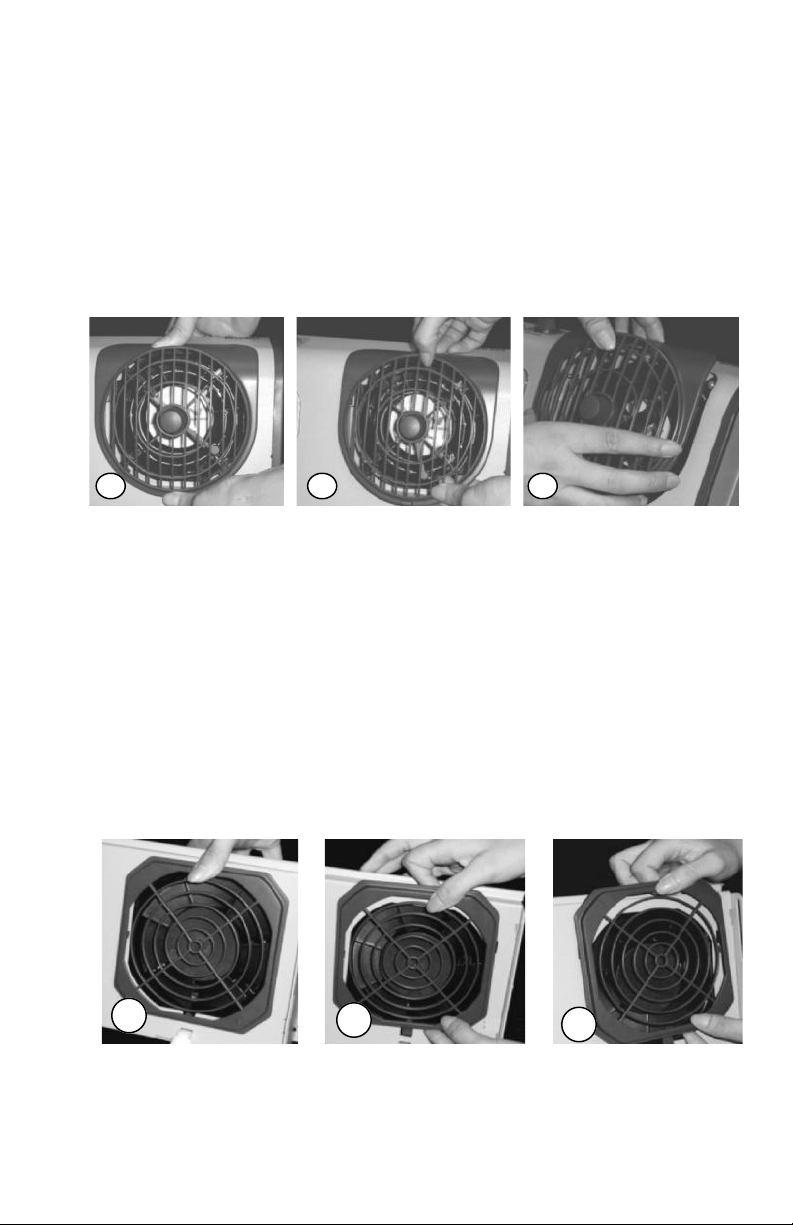

Air Inlet Disassembly

A. Press the recessed release point on the bottom of

the plastic rear cover using a flat blade screw-

driver.

B. Gently push the cover upwards.

C. Lift the rear cover up and away from the metal

casing.

A B C

Air Outlet Disassembly Cont.

7

Internal Fan Cleaning

After removing both front and rear fan guards, the emit-

ter points and fan assembly will be unobstructed, for easy

deep cleaning. Use a soft brush, Isopropyl Alcohol and

compressed air to remove any foreign matter.

Note: The frequency of cleaning required for optimal per-

formance from BFN ionizers depends on the environment

in which the BFN series ionizer operates.

When finished cleaning, replace both front and rear fan

guards.

Air Outlet Assembly

A. Slide the slot on the upper back side of the front fan

guard onto the metal case.

B. Push upward from the bottom of the front fan and

gently press into the metal casing, until attached.

C. Press the sides of the cover in to make sure cover is

securely attached.

A B C

8

Caution: BFN series products have safety re-

lay switches where the front and rear fan

guards attach to the unit. These relays dis-

able the fan/ionizer operation when either

fan guard is removed. Take care when attach-

ing the fan guards to assure proper function-

ing of the product.

Periodic Verification:

BFN ionizer have no user serviceable parts and the

technology requires no calibration because of the in-

herently stable ionization output from the AC emis-

sion. Periodic verification is recommended, per ANSI/

ESD SP3.3-2006 Periodic Verification of Air Ionizers.

Verification frequency may be set by the individual

user, but is recommended to be not less than one

time per year. Equipment needed is a Charge Plate

Monitor.

9

Service and Warranty

Transforming Technologies, LLC provides a limited war-

ranty for the BFN Series Ionizers. All new products are

guaranteed to be free from defects in material and work-

manship for a period of one (1) year from the date of ship-

ment. Liability is limited to servicing (after evaluating, re-

pairing or replacing) any product returned to Transforming

Technologies. The company does not warrant damage due

to misuse, neglect, alteration or accident. In no event shall

Transforming Technologies be liable for collateral or conse-

quential damages. To receive service under warranty,

please contact Transforming Technologies Technical Sup-

port.

About Transforming Technologies

Since 1998, Transforming Technologies has helped elec-

tronic manufacturing facilities to protect their products and

processes from the many serious problems associated with

static electricity.

Transforming Technologies offers a wide range of

unique and outstanding products to detect, protect, elimi-

nate and monitor electrostatic charges. Our products are

integral components of an effective static control program.

3719 King Rd | Toledo, OH 43617 | P: 419-841-9552 | F: 419-841-3241 | info@transforming-technologies.com

Table of contents

Other Transforming Technologies Air Ionizer manuals