Table of contents4

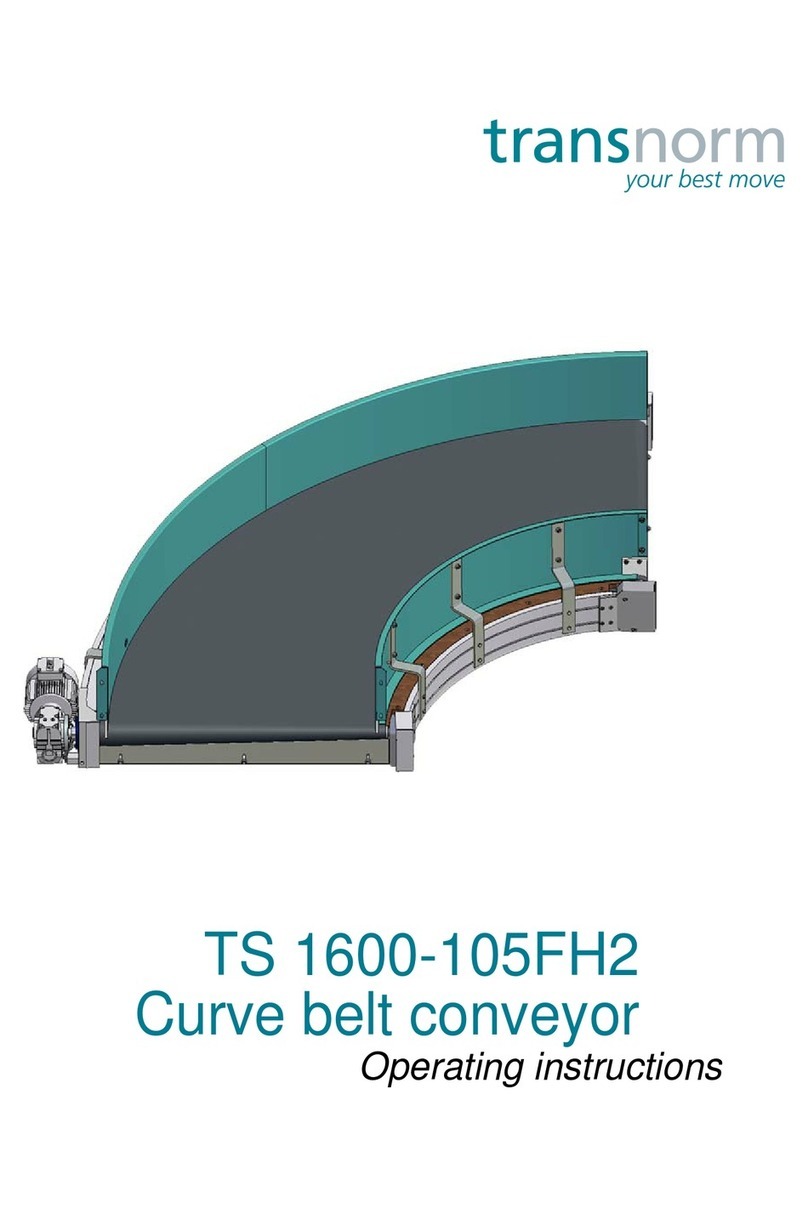

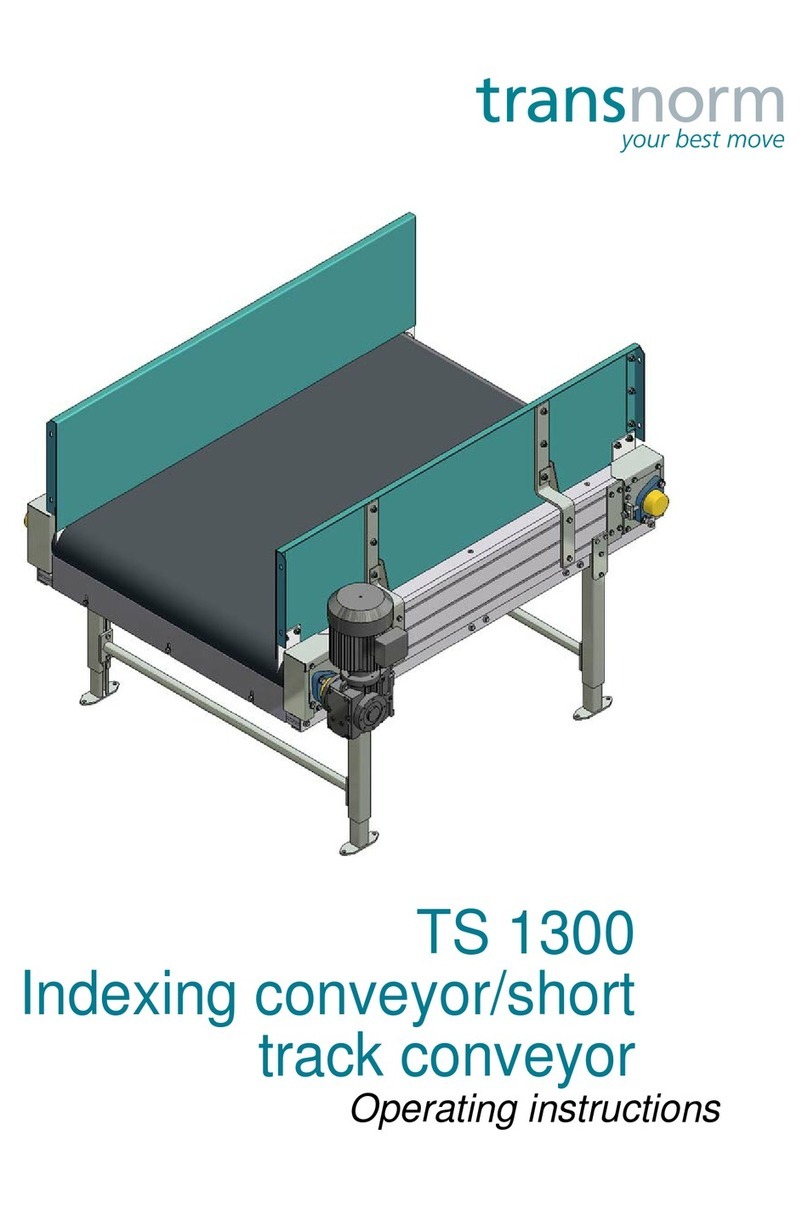

Operating instructions: Outfeed conveyor TS 4800

Version 3.6ENG, 27.01.2020

In-company transportation..................................................................................................................37

Auxiliary equipment ......................................................................................................................38

Transport with industrial truck or crane...............................................................................................40

Final assembly on site ........................................................................................................................41

Installation ....................................................................................................................................41

To carry out the assembly.............................................................................................................42

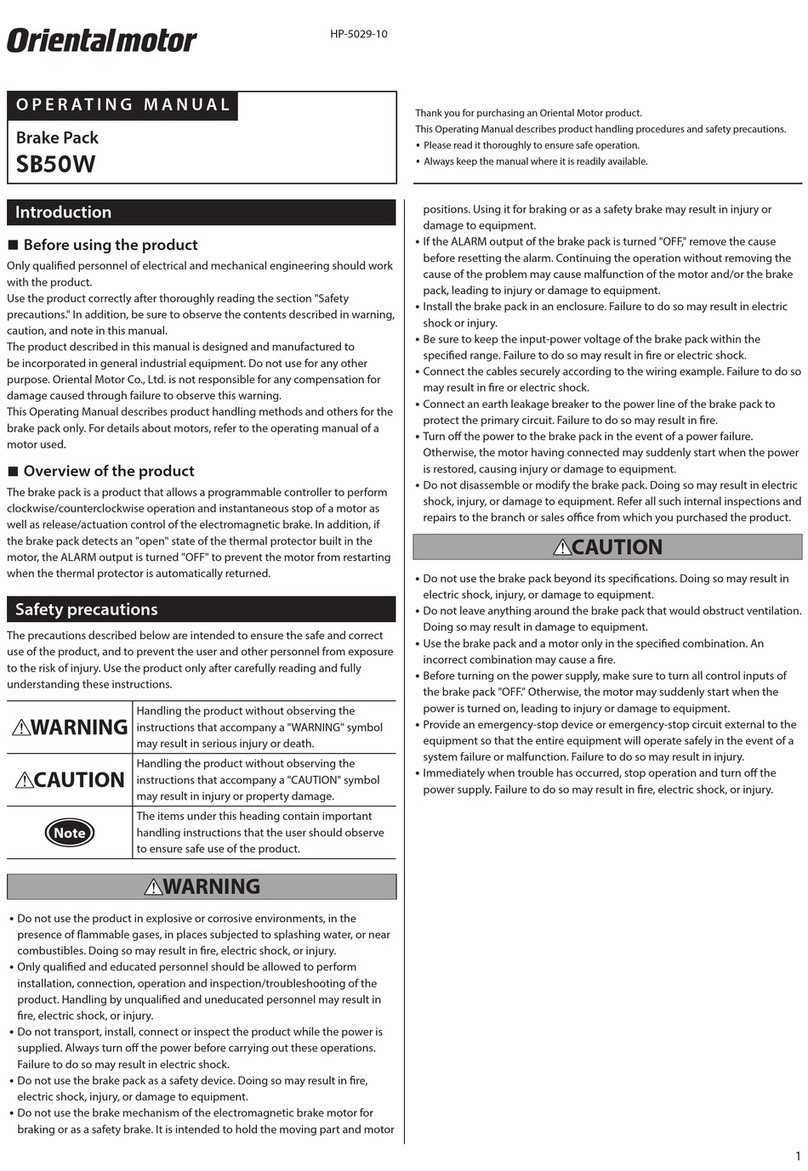

Electrical connection.....................................................................................................................45

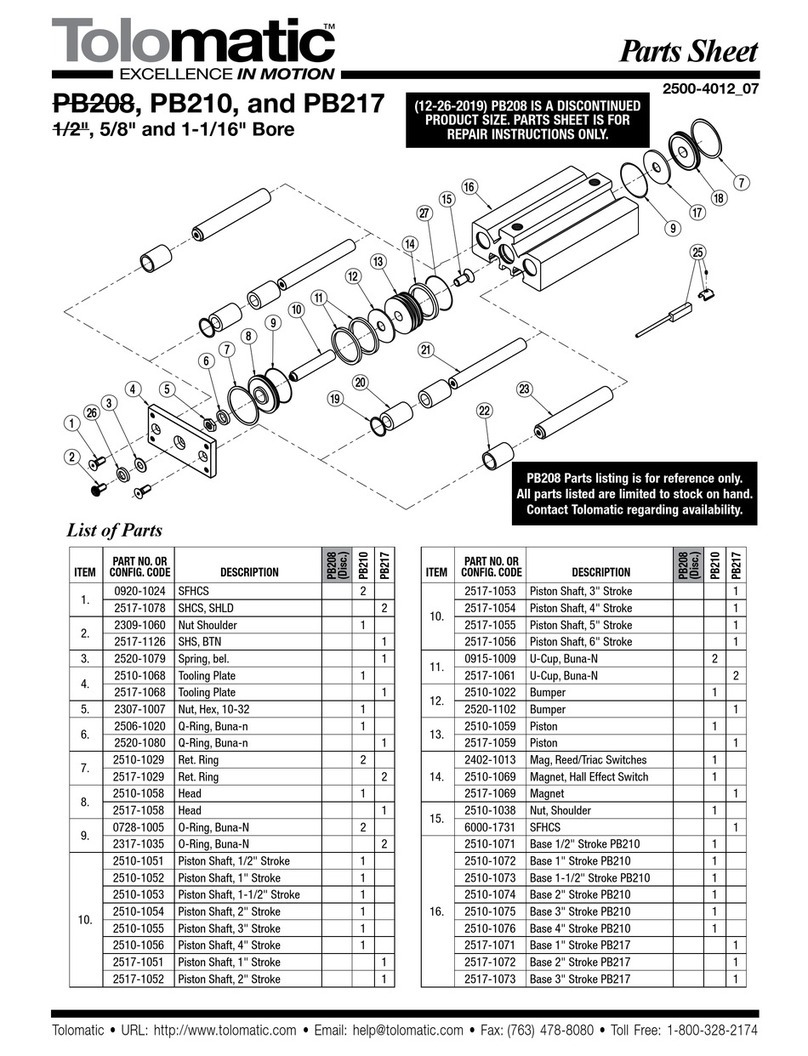

Pneumatic block diagram ...................................................................................................................46

Operation .......................................................................................................................................49

Commissioning ...................................................................................................................................49

Commissioning and start-up after service and maintenance works ...................................................49

Normal operation ................................................................................................................................52

Shutdown............................................................................................................................................52

Maintenance and care...............................................................................................................53

Maintenance works.............................................................................................................................53

Motor maintenance.......................................................................................................................53

Gear unit maintenance .................................................................................................................53

Lubricants ...........................................................................................................................................54

Maintenance plan ...............................................................................................................................54

Cleaning and care...............................................................................................................................56

Maintenance and repair............................................................................................................57

Spare part purchasing ........................................................................................................................57

Tools, equipment and supplies ...........................................................................................................57

Tightening torques ..............................................................................................................................58

Guards ................................................................................................................................................59

Replacing the tubular side guide ........................................................................................................60

Replacing the idler rollers ...................................................................................................................61

Replacing the tail pulley......................................................................................................................62

Replacing the finger guard..................................................................................................................63

Replacing the pressure roller..............................................................................................................64

Replacing the drive belt ......................................................................................................................65

Drive belt, non-endless joint .........................................................................................................65

Drive belt, endless joint ................................................................................................................67

Loosening/tensioning/adjusting the drive belt.....................................................................................71

Tensioning unit..............................................................................................................................71

Tail pulley......................................................................................................................................74

Replacing the gear motor ...................................................................................................................77

Gear motor, motor position M3 .....................................................................................................77

Shaft-mounted worm gear ............................................................................................................81

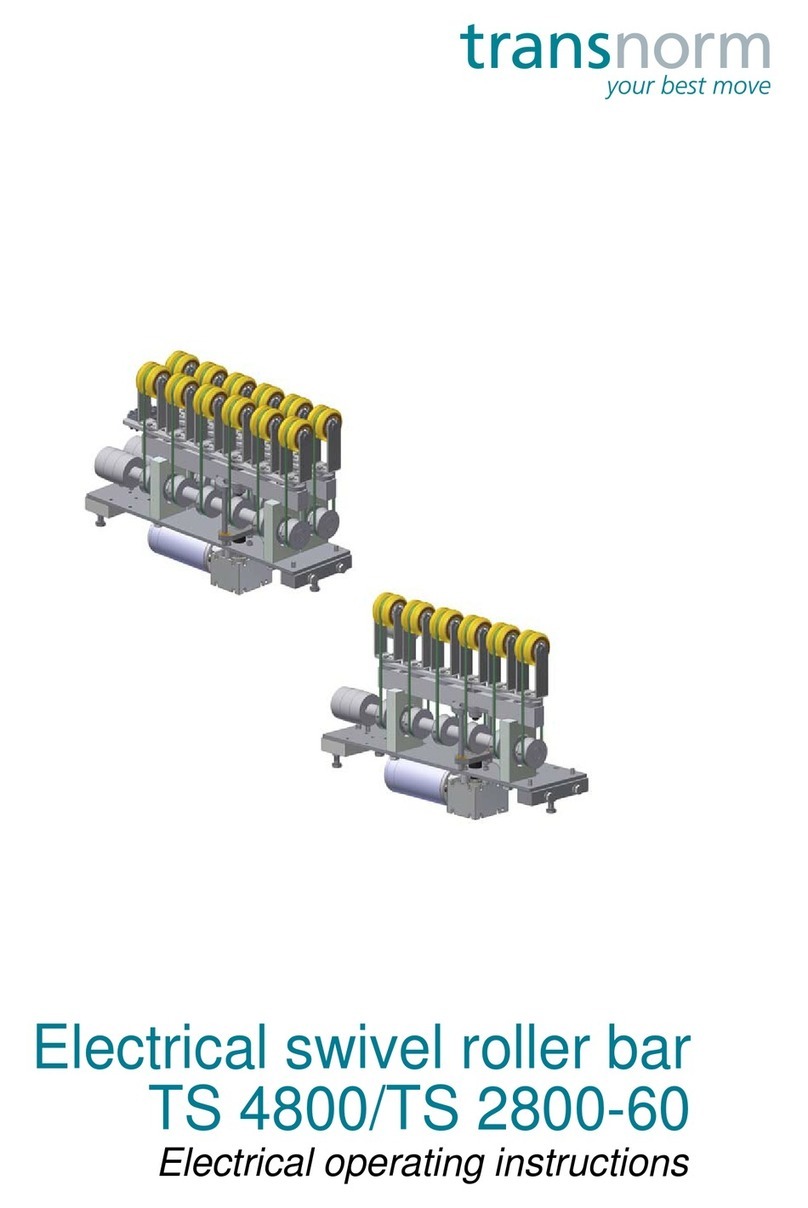

Replacing the swivel roller assembly..................................................................................................83

Servicing the swivel roller assembly ...................................................................................................87

Pneumatic block diagrams..................................................................................................................94