T

olomatic

•

URL:

http://www

.tolomatic.com

•

Email:

[email protected] •

Fax:

(763)

478-8080

•

T

oll

Fr

ee:

1-800-328-2174

Disassembly and Assembly Instructions

POWER-BLOCK2 DISASSEMBLY

1. To remove the Tooling Plate (#4) and Shafts (#21 or #23) first remove

the Button Head Screw (#2). Note, for later reassembly, that the cupped

surface of the Belleville Spring (#3) faces toward the Tooling Plate. Pull

on the Tooling Plate (#5). The Tooling Plate and Shafts (#21 or #23) will

slide out of the assembly.

2. Push Head (#8) into bore to expose a gap between Head and Retaining

Ring (#7). To remove the Head use a screwdriver to remove the

Retaining Ring. The Head is now free to be removed.

3. Remove the Piston/Piston Shaft Assembly from the Base (#16). Loosen

Socket Flat Head Screw (#15) to remove the Piston Shaft (#10) from the

Piston (#13). When removing the two U-Cups (#11) from the Piston

note that the flare of the U-Cups face away from each other. In looking

at the piston from the side view the two U-Cups form a “V” shape.

4. Push Cap (#18) into bore to expose a gap between Cap and Retaining

Ring (#7). Using a screwdriver remove the Retaining Ring from the Cap

side of the Base (#16). Remove the Cap from the Base.

5. To remove the Linear Bearings (#20) or the Composite Bearings (#22)

use a screwdriver to remove the two Retaining Rings (#19) from the

shaft bores of the Base (#16). The Bearings (#20 or #22) may now be

pushed out, with a screwdriver.

POWER-BLOCK2 ASSEMBLY PROCEDURE

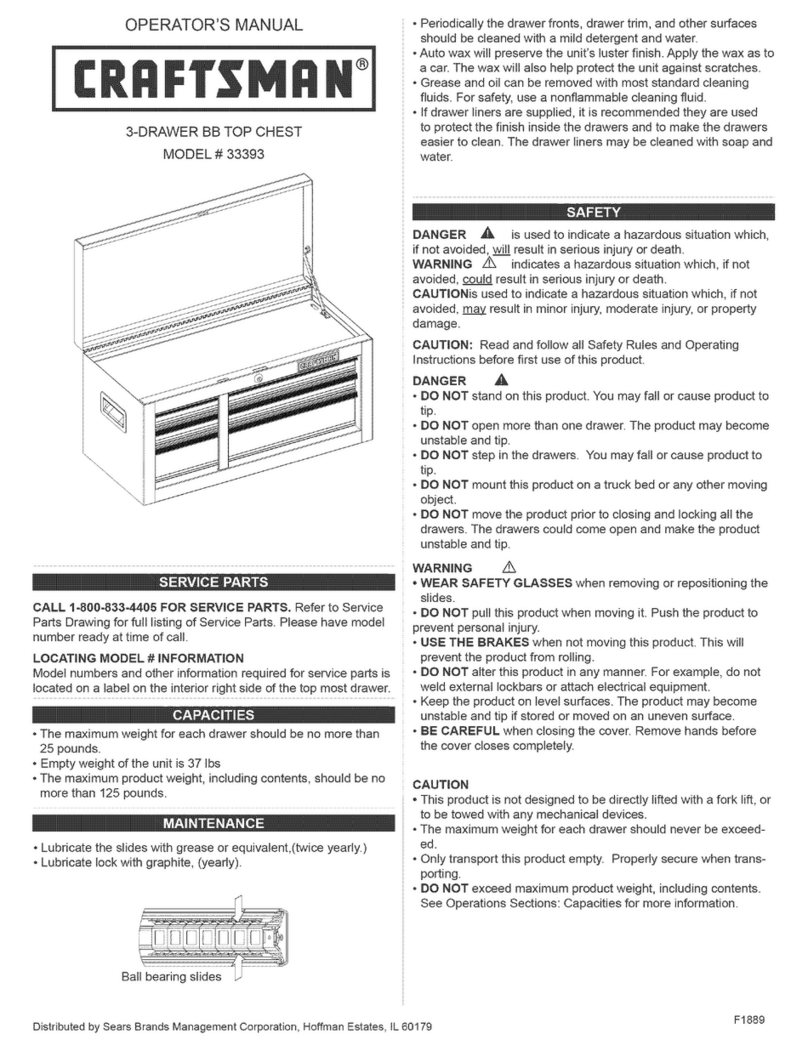

Clean work bench and area, check that all parts are there and without any

visual damage or defects.

1. Base Assembly

PB208 and PB210 Models

(Composite and Linear Bearings) By hand press new Composite

Bearing (#22) or Linear Bearing (#20), outside chamfered side down,

into each of the two bearing bores in the Base (#16). Press an addition-

al Bearing (#22) or (#20) outside chamfered side down, into the same

two bearing holes in the Base. Bearing must be recessed to allow for

retaining ring. Using a ring spreader insert two Retaining Rings (#19) to

retain the Bearings.

PB217 Models

(Composite Bearings) Press new Composite Bearing (#22), outside

chamfered side down, into each of the two bearing bores in the Base

(#16). Press an additional Bearing (#22) outside chamfered side down,

into the same two bearing holes in the Base with an arbor press until

the bearing is flush with the front surface of the base.

(Linear Bearings) Place new Linear Bearing (#20) into each of the bear-

ing bore holes in the Base (#16). Place second Linear Bearing into each

of the bearing bore holes. Install the Retaining Rings (#19) into the

grooves in the bores to hold the Bearings in place.

2. Cap Assembly

a. Thoroughly lubricate the center bore of the base.

b. Apply Loctite #495 to the recess in the Cap (#18) then press in the

Bumper (#17) with the grooves in the Bumper facing away from the

Cap.

c. Install an O-Ring (#9) into the cap. Place a thin coat of Magnalube

®

-G

over the O-Ring. Push the Cap (#18); Bumper side in, into the counter-

bore on the back side of the Base (#16). (Note: the mounting holes on

the base are closest to the front side.)

d. Install a Retaining Ring (#7) in the groove behind the Cap (#18).

3. Piston Assembly

PB208, PB210 and PB217 Models

a. Install the two U-Cups (#11) into the two grooves on the Piston (#13)

with the flares of each U-Cup facing away from each other.

b. Apply Loctite #271 to the Piston Shaft (#10) threads and screw Shaft

into the end of the Piston (#13) which is counterbored. Hand tighten.

c. Apply Loctite #271 to the Socket Head Flat Screw (#15) and attach the

Magnet to the Piston (#13) with secured Shaft and tighten nut with the

appropriate hand wrench. DO NOT OVERTIGHTEN.

d. Place a Bumper (#12) over the Piston Shaft (#10) so that the flat side is

against the Piston.

e. Place a thin coat of Magnalube

®

-G on the Piston Shaft (#10) and

U-Cups (#11).

f. Push the Piston Rod assembly, Piston first, into the front side of the

center bore on the Base (#16).

PB220 Models

a. Apply Loctite #271 to the Socket Flat Head Screw (#15) and attach the

Piston (#13) to the flat end of the Piston Shaft (#10).

b. Install the two U-Cups (#11) into the two remaining grooves in the

Piston (#13) note that the flare of the U-Cups must face away from

each other. In looking at the piston from the side view the two U-Cups

form a “V” shape.

c. Place a Bumper (#12) over the Piston Shaft (#10) so that the flat side is

against the Piston (#13)

d. Place a thin coat of Magnalube

®

-G on the Piston Shaft (#10) and the

U-Cups (#11).

e. Push the Piston/Piston Shaft Assembly, Piston first, into the front side of

the center bore of the Base (#16).

4. Head Assembly

a. Lubricate the Quad Ring (#6) with Magnalube

®

-G and insert into the

center of the Head (#8).

b. Press the Retaining Ring (#7) flush into the center of the Head (#8).

c. Install an O-Ring (#9) onto the Head. Place a thin coat of

Magnalube

®

-G over the O-Ring and Quad Ring (#6). Guide the Head

over the Piston Shaft (#10) and push the Head (#8), flat surface in, into

the counterbore on the front side of the Base (#16).

d. Install a Retaining Ring in the groove in the counterbore in front of the

Head (#8).

5. Tooling Plate and Bearing Rod Installation

PB208 and PB210 Models

a. Clean the Hex Nut (#5) and Socket Head Flat Screw (#15) and apply

Loctite #242 to the Piston Shaft (#10) threads

b. Attach the Tooling Plate (#4) to the Piston Shaft (#10) with the Hex Nut

and Shoulder Nut. The Shoulder Nut goes on the outside of the Tooling

Plate. Adjust the position so that the end of the piston shaft is flush with

the outer surface of the Hex Nut. Tighten with the appropriate wrench-

es.

PB217 Models

a. On units with Composite Bearings only, apply a small amount of

Magnalube

®

-G into the bearings on the base. No additional lubricant is

needed with the Linear Bearings. Insert the Guide Shafts (#21 or #23)

with the drilled and tapped holes towards the Tooling Plate (#4) through

the bearings. Apply Loctite #271 to the threads of the two SHCS (#1)

and attach the Tooling Plate to the Guide Shafts (#21 or #23).

b. Apply Loctite #242 to the threads of the Button Head Screw (#2).

Attach the Tooling Plate (#4) to the Piston Shaft (#10) with the Button

Head Screw and Belleville Spring (#3). Note that the cupped surface of

the Belleville Spring (#3) faces toward the Tooling Plate. Tighten all

screws.

c. Cycle the assembly back and forth by hand to seat the Bumpers, End

Cap and Head.

6. Switch Option

Clamp for switch will fit in either of the two grooves on the top (porting)

side of the Base (#16). Secure Switch to the Base with Clamp and Set

Screw. Note the scored surface of the Switch housing should face the

base of the Power-Block2.

NOTE: Form A Reed Switches should not be used in TTL logic cir-

Parts Sheet #2500-4012_07_PB208_10_17ps

PB208, PB210, PB217 Instructions – 3

Parts Sheet #2500-4012_07_PB208_10_17ps