New lift CBM User manual

Contactorless Brake Module

Manual

______________________________________________________________________

2 Handbuch CBM

Manufacturer

NEW LIFT Service Center GmbH

Ruwerstraße 16

54427 Kell am See

Tel: +49 6589 –919 540

Fax: +49 6589 –919 540 300

Mail: info@newlift-sc.de

www.newlift.de

Service line

Tel: +49 6589 –919 540

Mail: service@newlift-sc.de

First edition

30.10.2018

Author

JW

Last change

23.11.2018

Release

Hardware version

EF336.9, EF337.5, EF341.1

Software version

V1.7.0.0

Doc. No.

hb_cbm_2018-10_en_v1.2

Copyright

© NEW LIFT Service Center GmbH, 2018.

This manual is protected by copyright. All rights, including those of copying, of

reproduction, of translation and of modification, in whole or in part, are reserved by the

publisher.

No part of this description may be reproduced in any form or copied with an electronic

replication system without written permission.

Although great care has been taken in the production of texts and figures, we cannot be

held legally liable for possible mistakes and their consequences.

_________________________________________________________________

Handbuch CBM 3

Content

1. About this manual.............................................................................................................................................5

1.1 General.............................................................................................................................................................5

1.2 Abbreviations, characters and symbols used...................................................................................................5

1.3 Further information...........................................................................................................................................5

1.4 How to contact us.............................................................................................................................................5

2. General safety regulations................................................................................................................................6

2.1 Qualifications of the installing engineer............................................................................................................6

2.2 Residual dangers .............................................................................................................................................7

2.3 Safety regulations.............................................................................................................................................8

3. Terminals........................................................................................................................................................10

3.1 Pinout.............................................................................................................................................................11

4. I/O-Modus.......................................................................................................................................................12

4.1 Configuration with dip switches......................................................................................................................12

4.2 Brake coils with different voltages ..................................................................................................................13

4.3 Explanation of inputs......................................................................................................................................14

4.3.1 DRIVE-Signal.........................................................................................................................................14

4.3.2 BRAKE-Signal .......................................................................................................................................14

4.3.3 EVAK-Signal..........................................................................................................................................14

4.3.4 Test-Signal.............................................................................................................................................14

4.4 Explanation of Outputs...................................................................................................................................14

4.4.1 OK-Signal ..............................................................................................................................................14

4.4.2 Open-Signal...........................................................................................................................................14

4.4.3 Test-Signal.............................................................................................................................................14

4.5 Sequence of the control..................................................................................................................................15

4.5.1 Normal ride............................................................................................................................................15

4.5.2 Emergency stop.....................................................................................................................................15

4.5.3 Brake test ..............................................................................................................................................15

4.5.4 Evacuation.............................................................................................................................................15

5. CANopen-Mode..............................................................................................................................................16

6. LEDs...............................................................................................................................................................17

6.1 Voltage setting................................................................................................................................................17

6.2 Status-LEDs...................................................................................................................................................18

6.2.1 Status Monitoring...................................................................................................................................18

6.2.2 Status Controlling ..................................................................................................................................18

7. Technical data................................................................................................................................................20

______________________________________________________________________

4 Handbuch CBM

Version History:

Version

Date

Remarks

1.0

31.10.2018

First version

1.1

06.11.2018

09.11.2018

5 Changed CANopen chapter

6.2.1 Error list extended by monitor CPU

1.2

23.11.2018

4.1 times for evacuation changed

4.3 Explanation of Inputs revised

4.4 Explanation of Outputs revised

4.5 Sequence of the control revised

4.6 EEPROM inserted

_________________________________________________________________

Handbuch CBM 5

1. About this manual

1.1 General

The CBM Handbook is a comprehensive reference work for the experienced elevator expert.

Objectives of this manual:

➢Describe the technical data of the CBM

➢Describe the operation of the CBM

➢Describe the configuration of the CBM

➢Describe the messages of the CBM

The CBM is a module that can control brake coils of all voltages (40-200VDC) and currents (up to 4A) up to a power

of 240VA without protection. It is type-tested according to DIN EN81-20. In addition, it can perform brake test and

evacuation (for machine roomless systems). In addition, other functions are available, such as the connection of a

motor PTC or brake monitoring. The function of the brake circuits is monitored by a continuous current measurement.

1.2 Abbreviations, characters and symbols used

CBM

Contactorless Brake Module for elevators

DRIVE

Driving signal from the end of the safety chain

BRAKE

Brake signal to open the brake

EVAK

Evacuation signal for evacuation in the event of a fault in the system

TEST

Test signals for brake test

CANopen

CAN interface with CANopen protocol according to CiA Standard Draft 301

1.3 Further information

For integration with FST see the manual of the FST.

1.4 How to contact us

If, after referring to this manual, you still require assistance, our service line is there for you:

Tel: +49 6589 919 540

Mail: [email protected]

Mon-Thurs: 8:00 a.m. –12:00 p.m. and 1:00 p.m. –5:00 p.m.

Fr: 8:00 a.m. –3:00 p.m.

______________________________________________________________________

6 Handbuch CBM

2. General safety regulations

All important safety regulations are summarized in this chapter. These safety instructions must always be adhered to

during all work on the installation.

All persons performing installation and commissioning work on the FST controller must read this chapter and follow

its regulations.

Laws, regulations, guidelines and standards that apply in the country of operation must be followed in addition to the

safety regulations mentioned in this manual.

2.1 Qualifications of the installing engineer

The installing engineer must:

➢be over 18 years of age (exception: apprentices who are over 16 years of age and are permanently

supervised by an engineer qualified for training apprentices).

➢have first aid training,

➢have theoretical and practical knowledge of regulations and measures for the prevention of fre and

explosions in his work area,

➢be able to identify, avoid and rectify all dangers that might occur during his work in the shaft and in the

operating rooms,

➢be able to identify and rectify all irregularities and faults that might occur during installation and operation of

a lift systems,

➢have theoretical and practical knowledge of operating principles and requirements of electric controls and

drive systems.

All installation and commissioning work on electric and electronic components of the FST controller must be

performed by or supervised by a qualified electrician.

A qualified electrician has appropriate training and knowledge of regulations that allow him to judge the quality

of the work performed and identify possible dangers (DGUV instruction 3).

_________________________________________________________________

Handbuch CBM 7

2.2 Residual dangers

Danger for persons

The following shall always apply during all work on the installation:

Danger to life! Do not touch live parts while working on electrical equipment.

➢Before starting work, make sure the system is off circuit.

➢Only carry out any installation work on electrical components when these are switched off and in an

unpowered state.

➢Only use insulated tools when working on electrical system components.

Risk of injury when lifting or moving the control cabinet if it falls down or tips over.

➢Only transport and lift the control cabinet with suitable equipment (lift truck, hoisting gear etc.).

➢All workers must be trained in using these aids and must observe all applicable special regulations to avoid

accidents.

Falling parts or parts protruding into the shaft. Risk of serious injury or death.

➢Block the shaft access points.

➢Before beginning installation work, remove all foreign parts and assembly aids that are not required from the

shaft.

Electrical hazard, leaking gas or water due to pierced supply lines. Risk of serious injury or death.

➢Make sure no supply lines are in the installation location before starting any installation work.

Danger of falling! Installing engineers and unauthorized persons can fall down the shaft. Risk of serious injury or

death.

➢Block the shaft access points.

➢Use suitable protection (e.g. safety harnesses, scaffoldings) when working on or in the shaft.

Danger of crushing due to intentional or accidental car movement. Risk of serious injury or death.

➢Block the shaft access points.

______________________________________________________________________

8 Handbuch CBM

➢Before starting any work, make sure that there are no persons in the shaft or in the vicinity of moving parts

of the drive.

➢Prevent unauthorized operation of the controller.

Risk of material damage

The following shall always apply during all work on the installation:

Electrostatic charging

➢Keep the electronic assembly in its original packaging until installation.

➢Before opening the original packaging, a static discharge must be performed. To do this, touch a grounded

piece of metal.

➢During work on electronic assemblies, periodically perform this discharge procedure.

Electronic assemblies are destroyed by defective, interchanged or incorrectly mounted connectors, short-circuiting or

excess voltage.

➢Check plugs for mechanical damage.

➢Never change pre-assembled connectors or cables.

➢Only connect loose or torn off wires according to circuit diagram details if this is possible on site (suitable

material and tools must be available.

➢Pay attention to coding pins and latch lugs.

2.3 Safety regulations

General

➢The instructions of the lift manufacturer and the instructions in this manual must be followed during

installation and commissioning of the lift system.

➢The shaft must be secured against unauthorized trespassing during installation and commissioning.

➢Assemblies, devices and cables must be installed and fastened securely and permanently.

➢Loads must be moved with suitable aids (lift trucks, hoisting gear etc.).

➢Sharp and pointed tools or other potentially dangerous objects may only be carried along in clothing if

suitable protective measures have been taken to rule out any danger.

➢Alcohol and drugs must not be consumed before and during installation and commissioning.

Documentation

➢A copy of the installation and commissioning manual must be available to the installing engineer at the time

of installing and commissioning the FST controller and its components.

➢A copy of the installation and commissioning manual and the wiring diagrams must be kept in the control

cabinet at all times after.

➢The wiring diagrams supplied with the FST controller are binding. Changes must only be made after

consulting NEW LIFT and must be documented in writing on the system.

➢The factory test logs of the FST controller remain with NEW LIFT.

Electricity

➢Regulations for installing and operating electrical equipment (VDE 0100) and regulations of local utilities

must be followed.

➢The specified distances between different electrical assemblies must be controlled and maintained.

➢All installation work must be carried out with the system shut down and off circuit.

➢All cables and wires must be installed with sufficient strain relief.

➢The neutral and ground wires must be routed separately.

➢The control cabinet must be supplied with a clockwise rotary field.

Working in the shaft

_________________________________________________________________

Handbuch CBM 9

➢Any work in the shaft requires perfect and permanent communication between the supervisor on the FST

controller in the motor room and the workers in the shaft.

➢Components in the shaft must be arranged or secured in such a way that persons accessing the shaft for

inspection, maintenance or repair purposes are not in danger.

➢The maximum load of the lift system must not be exceeded.

➢The specified overruns of the emergency end switches in relation to the speed must be observed.

➢The emergency installations must not be activated during normal operation.

➢All emergency installations and braking systems must be checked for trouble-free operation and all shaft

entrances closed off before beginning work.

➢Installation and operation are prohibited if other persons could be in danger.

➢Workers must be secured against falling.

➢In case of any work interruptions, the car must be moved to the lowest stop position, the control system

switched off and the power supply (e.g. UPS) permanently disconnected.

Personal safety equipment of the installing engineer

➢Eye protection

➢Safety boots

➢Protective helmet

➢Safety harness

➢Clothing suitable to the ambient conditions of the installation location

➢Jeweler, watches and similar items may not be worn; a hair net must be used if applicable.

Handling electronic assemblies

➢Leave electronic assemblies in their original packaging until installation.

➢Touch a grounded piece of metal prior to opening the original packaging to prevent damage from static

charges.

Waste disposal

➢All packaging material must be disposed of in an environmentally acceptable manner; paper, plastic, metal,

electronic assemblies etc. must be recycled.

______________________________________________________________________

10 Handbuch CBM

3. Terminals

X6: Brake coils

B1+, B1-, B2+, B2-, B3+, B3-

X5: Brake monitoring, Motor-PTC

BM1, BM2, BM3, +24V, PTC, PTC

X4: CAN-Open

GND, CANL, CANH

X3: Outputs

GND, Test, OK, Open, +24V

X2: Inputs

+24V, Brake, T3, T2, T1, Evac

X1: Power, Overvoltage -Test, SHK (Drive)

L, N, OV-Test, OV-Test, Drive, Drive

_________________________________________________________________

Handbuch CBM 11

3.1 Pinout

Clip

Name

Description

X1.1

L

Power Supply –230VAC

X1.2

N

Power Supply –230VAC

X1.3

Test

Test Switch to simulate Overvoltage spark

X1.4

Test

Test Switch to simulate Overvoltage spark

X1.5

D

Drive-Signal –48-230VUC

X1.6

D

Drive-Signal –48-230VUC

X2.1

+24V

Common pin for inputs on X2

X2.2

Brake

Brake Switch (opens brake)

X2.3

Test 3

Test Switch for Brake 3

X2.4

Test 2

Test Switch for Brake 2

X2.5

Test 1

Test Switch for Brake 1

X2.6

Evac

Evacuation Switch

X3.1

0V

0V –Power Supply for In/Outputs

X3.2

Test

Test active Output (open collector)

X3.3

OK

CBM OK Output (open collector)

X3.4

Open

Brake open Output (open collector)

X3.5

+24V

+24V –Power Supply for In/Outputs

X4.1

GND

GND for CAN

X4.2

CAN-L

CAN-L (CANopen)

X4.3

CAN-H

CAN-H (CANopen)

X5.1

BM1

Brake 1 Monitor Input

X5.2

BM2

Brake 2 Monitor Input

X5.3

BM3

Brake 3 Monitor Input

X5.4

+24V

Common pin for Brake Monitor Inputs

X5.5

PTC

Motor PTC

X5.6

PTC

Motor PTC

X6.1

B1+

Brake 1 Coil +

X6.2

B1-

Brake 1 Coil -

X6.3

B2+

Brake 2 Coil +

X6.4

B2-

Brake 2 Coil -

X6.5

B3+

Brake 3 Coil +

X6.6

B3-

Brake 3 Coil -

______________________________________________________________________

12 Handbuch CBM

4. I/O-Modus

In I/O-Mode the configuration is done by 16 dip switches inside CBM. Controlling is done over the inputs on X2.

4.1 Configuration with dip switches

Inside the housing you can find 2 8-pole dip switches S1 and S2. Following you find the meaning of the individual

switches:

S1:

DIP1-3: Voltage Brake 3

000 - AUS

001 - 40VDC (max. 160VA)

010 - 80VDC (max. 240VA)

011 - 120VDC (max. 240VA)

100 - 160VDC (max. 240VA)

101 - 200VDC (max. 240VA)

110 - reserved

111 - Only Brake 2 is connected. Mode for single-circuit brakes!

DIP4-6: Voltage Brake 1 and 2

000 - AUS

001 - 40VDC (max. 160VA)

010 - 80VDC (max. 240VA)

011 - 120VDC (max. 240VA)

100 - 160VDC (max. 240VA)

101 - 200VDC (max. 240VA)

110 - reserved

111 - reserved

DIP7-8: Power Reduction Level %

00 - 50%

01 - 62.5%

10 - 75%

11 - 87.5%

S2:

DIP1-2: Power Reduction Time

00 - directly

01 - 3s

10 - 5s

11 - never

DIP3-4: Evacuation Mode

00 - 3000ms open –6000ms closed

01 - 5000ms open –8000ms closed

10 - 7000ms open –10000ms closed

11 - permanent open

DIP5: Brake Monitoring

0 - OFF

1 - ON

DIP6: Brake Monitoring Contact Type

0 - NO

1 - NC

DIP7: Voltage Ramping

0 - slow: 100V/s

1 - fast: 200V/s

DIP8: Motor PTC Function

0 - OFF

1 - ON

_________________________________________________________________

Handbuch CBM 13

4.2 Brake coils with different voltages

By selecting the Power Reduction Time to “directly” and choose a Power Reduction Level, some other voltages can

by generated. In that case you must disclaim Power Reduction!

Adjusted Voltage [VDC]

Adjusted Power Reduction

Resulting Voltage [VDC]

200

87.5%

175

200

75%

150

160

87.5%

140

200

62.5%

125

120

87.5%

105

200

50%

100

120

75%

90

120

62.5%

75

80

87.5%

70

80

75%

60

80

62.5%

50

Voltages smaller than 40VDC are not possible. Therefore, power reduction selected with 40VDC will have no effect.

______________________________________________________________________

14 Handbuch CBM

4.3 Explanation of inputs

4.3.1 DRIVE-Signal

The DRIVE-Input can handle voltages from 48-230VUC. As a result, all common safety circuits can be connected

here. This signal opens two safety contacts in front of and behind the brake and thus prepares the power supply of

the brake coil. If brake coil 3 is connected, which is intended for the transmission of the elevator motor, then this is

also opened directly with the DRIVE signal.

4.3.2 BRAKE-Signal

The BRAKE signal opens brake 1 and 2 if both are activated. These two brake coils are mounted on the traction

motor.

4.3.3 EVAK-Signal

The EVAK signal is used for evacuation in the event of a fault. It activates a different measurement of the input

voltage, since the evacuation can also be carried out with a UPS as power supply. When the EVAK signal is

activated, normal driving is not possible!

4.3.4 Test-Signal

With the test signals 1-3, either the brake test or the evacuation can be performed.

In addition, by pressing T1 and T2 during the boot process, the EEPROM can be reinitialized with the default values.

For details, see section 4.6.

A detailed description of the signal sequences can be found in Section 4.5

4.4 Explanation of Outputs

4.4.1 OK-Signal

The OK output signals that the CBM is active and has no error. This output is only active if both processors (control

and monitor CPU) release them.

4.4.2 Open-Signal

The open output signals an open brake.

4.4.3 Test-Signal

The test output signals an active brake test.

_________________________________________________________________

Handbuch CBM 15

4.5 Sequence of the control

4.5.1 Normal ride

During normal driving, only the DRIVE and the BRAKE input are activated. DRIVE must be applied first. In this case,

if connected, the brake 3 is opened. Then BRAKE is applied. This opens brake 1 and 2. After the ride BRAKE is

deactivated again. Then first brake 1 and 2 close. Thereafter, brake 3 is closed. Now DRIVE must be deactivated

again. The inputs DRIVE and BRAKE are checked with an ABC circuit. This means that DRIVE must be

activated before BRAKE and both signals must be deactivated before reactivation!

4.5.2 Emergency stop

During emergency stop, the DRIVE signal is deactivated first. As a result, all brakes are immediately closed! In this

case, no voltage ramp is driven!

4.5.3 Brake test

In the brake test, a normal ride is first initiated. By activating the respective test signal, the corresponding brake is

closed immediately. The other brakes remain open. The brake test is signaled directly via the test output to the

controller of the lift. This must now ensure that the torque is removed from the frequency converter. As a result, it will

disable the BRAKE signal. This is allowed for the brake test. The other brakes remain open anyway. The other

brakes only close when the DRIVE signal is deactivated.

4.5.4 Evacuation

To perform an evacuation, the EVAK signal must first be activated. This changes the internal control of the brakes,

since the evacuation can also be performed with a UPS. Since it is also possible to use UPSs that do not generate a

pure sine wave voltage (VI-SY-333 or better), the phase control must be adjusted. Now the brakes are controlled by

the previously stored operating current.

Now the DRIVE signal can be activated. As a result, brake 3 already opens when it is connected. By activating the

signals Test 1 and Test 2 the evacuation can be activated. This is carried out in the mode set via the dip switches

(pulse and period duration). If you deactivate the signals again, the brakes come back in.

4.6 EEPROM

The EEPROM mainly stores data required for the CANopen functionality. For details, see the CANopen manual.

In addition, the operating currents of the individual brake coils are stored here. These are necessary to perform an

evacuation. The default value for all brakes is the equivalent to 0.4A. If this value is still in the EEPROM and a normal

ride is triggered, the current values of this normal travel are stored and used in the following. Thus, an evacuation

with a CBM in factory settings without prior normal drive would have a current control to 0.4A per brake result. After a

single normal ride a correct evacuation is possible!

______________________________________________________________________

16 Handbuch CBM

CANopen-Mode

This chapter will be adapted after integration into the FST control. There is a CANopen manual for integrating the

module into a CANopen network.

_________________________________________________________________

Handbuch CBM 17

5. LEDs

5.1 Voltage setting

The set voltage of each brake can be read via 3 LEDs each. Their meaning is the same with the voltage set via the

dip switches S1.1-6!

Table 1 - LEDs for Brake 1/2

○

○

○

Deactivated

○

○

●

40VDC

○

●

○

80VDC

○

●

●

120VDC

●

○

○

160VDC

●

○

●

200VDC

●

●

○

Deactivated

●

●

●

Deactivated

Table 2 - LEDs for Brake 3

○

○

○

Deactivated

○

○

●

40VDC

○

●

○

80VDC

○

●

●

120VDC

●

○

○

160VDC

●

○

●

200VDC

●

●

○

Deactivated

●

●

●

Only Brake 2 connected (single-circuit brake)

______________________________________________________________________

18 Handbuch CBM

5.2 Status-LEDs

Each of the two integrated controllers has a 2-color LED (blue / red). The meaning of the states is different.

5.2.1 Status Monitoring

Blue LED:

•On: Monitoring OK

•Off: Monitoring not OK

Red LED:

The red LED indicates a fault condition. It can show a 5-digit error code by flashing. The duration of a job is 1000ms.

A logical 1 has an on time of 500ms while a logical 0 only has an on time of 100ms. To find the beginning of the 5-

digit code, there is a break of 2000ms between the end and the beginning.

Fehler

B0

B1

B2

B3

B4

Beschreibung

0x00

0

0

0

0

0

No Error

0x01

1

0

0

0

0

Inputs during booting not in initial position

0x02

0

1

0

0

0

ABC Error of inputs DRIVE and BRAKE

0x03

1

1

0

0

0

Internal DRIVE signals are not the same

0x04

0

0

1

0

0

BRAKE signal active before DRIVE signal

0x05

1

0

1

0

0

Trigger-Signal from Monitor-CPU not detected

0x06

0

1

1

0

0

Short-circuit tests of MOSFETs in MAIN-CPU unsuccessful

5.2.2 Status Controlling

Blue LED:

•On: Controlling OK

•Flashing with 400ms/1000ms: Brake open

•Flashing with 100ms/1000ms: Evacuation active

•Off: Controlling not OK

Red LED:

The red LED indicates a fault condition. It can show a 5-digit error code by flashing. The duration of a job is 1000ms.

A logical 1 has an on time of 500ms while a logical 0 only has an on time of 100ms. To find the beginning of the 5-

digit code, there is a break of 2000ms between the end and the beginning.

Error

B0

B1

B2

B3

B4

Description

0x00

0

0

0

0

0

No Error

0x01

1

0

0

0

0

Inputs during booting not in initial position

0x02

0

1

0

0

0

ABC Error of inputs DRIVE and BRAKE

0x03

1

1

0

0

0

Internal DRIVE signals are not the same

0x04

0

0

1

0

0

BRAKE signal active before DRIVE signal

0x05

1

0

1

0

0

Trigger-Signal from Monitor-CPU not detected

0x06

0

1

1

0

0

Overtemperature (>85°C) on PCB

0x07

1

1

1

0

0

Overtemperature in Motor

0x08

0

0

0

1

0

Overcurrent in brake circuit 1

0x09

1

0

0

1

0

Overcurrent in brake circuit 2

0x0A

0

1

0

1

0

Overcurrent in brake circuit 3

0x0B

1

1

0

1

0

Undercurrent in brake circuit 1

0x0C

0

0

1

1

0

Undercurrent in brake circuit 2

0x0D

1

0

1

1

0

Undercurrent in brake circuit 3

0x0E

0

1

1

1

0

Error in Thyristor in brake circuit 1

0x0F

1

1

1

1

0

Error in High-Side-MosFET in brake circuit 1

0x10

0

0

0

0

1

Error in High-Side-MosFET in brake circuit 1

0x11

1

0

0

0

1

Error in Thyristor in brake circuit 2

0x12

0

1

0

0

1

Error in High-Side-MosFET in brake circuit 2

0x13

1

1

0

0

1

Error in High-Side-MosFET in brake circuit 2

0x14

0

0

1

0

1

Error in Thyristor in brake circuit 3

0x15

1

0

1

0

1

Error in High-Side-MosFET in brake circuit 3

0x16

0

1

1

0

1

Error in High-Side-MosFET in brake circuit 3

0x17

1

1

1

0

1

Internal 12V power supply faulty

0x18

0

0

0

1

1

Diagnostic inputs incorrect during boot process

_________________________________________________________________

Handbuch CBM 19

0x19

1

0

0

1

1

Brake monitoring faulty

0x1A

0

1

0

1

1

Diagnostic-Error

______________________________________________________________________

20 Handbuch CBM

6. Technical data

Description

Value

Supply Voltage

230V AC ±5%

Typical power consumption

Brake inactive –160mA

(with active brakes depending on connected brakes)

Internal Fuse

5A T –1500A safe switch off capability

Temperature range

Storage: -20 - +70°C

Operation: 0 - +60°C

Relative humidity

(not condensing)

Storage/Transport: +5 - +95%

Operation: +15 - +85%

Length x width x depth

319mm x 59mm x 167mm

Mass

2600g

Other manuals for CBM

1

Table of contents

Other New lift Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

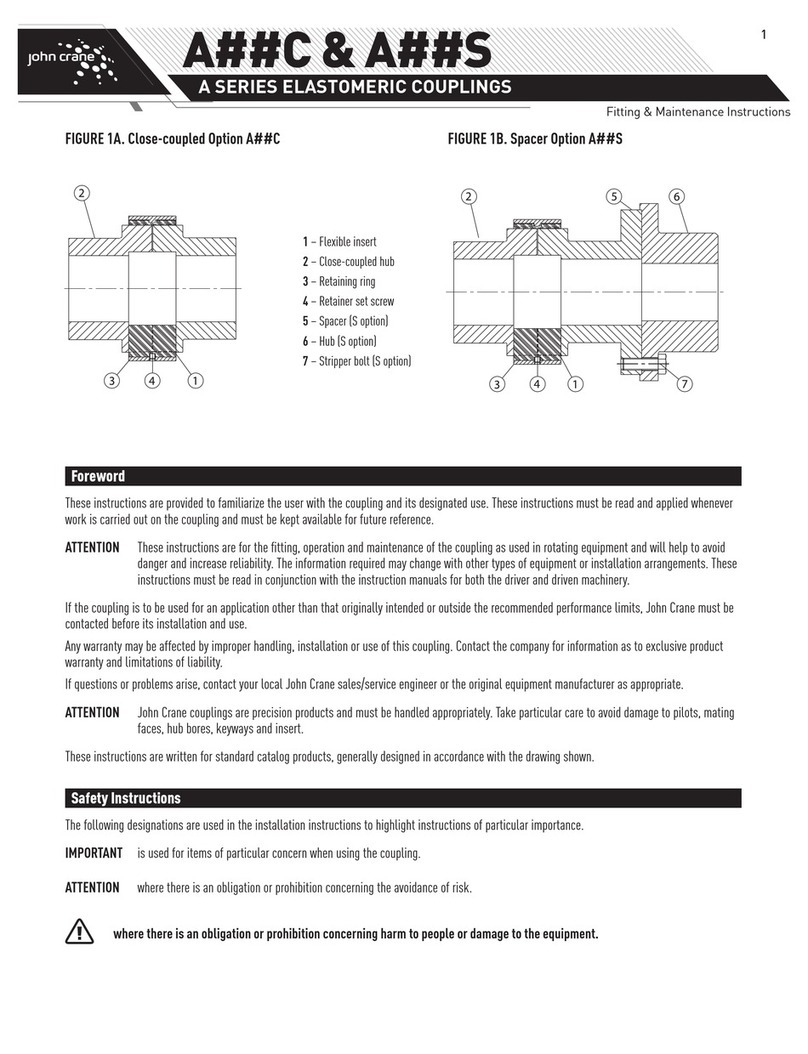

John Crane

John Crane A Series Fitting & Maintenance Instructions

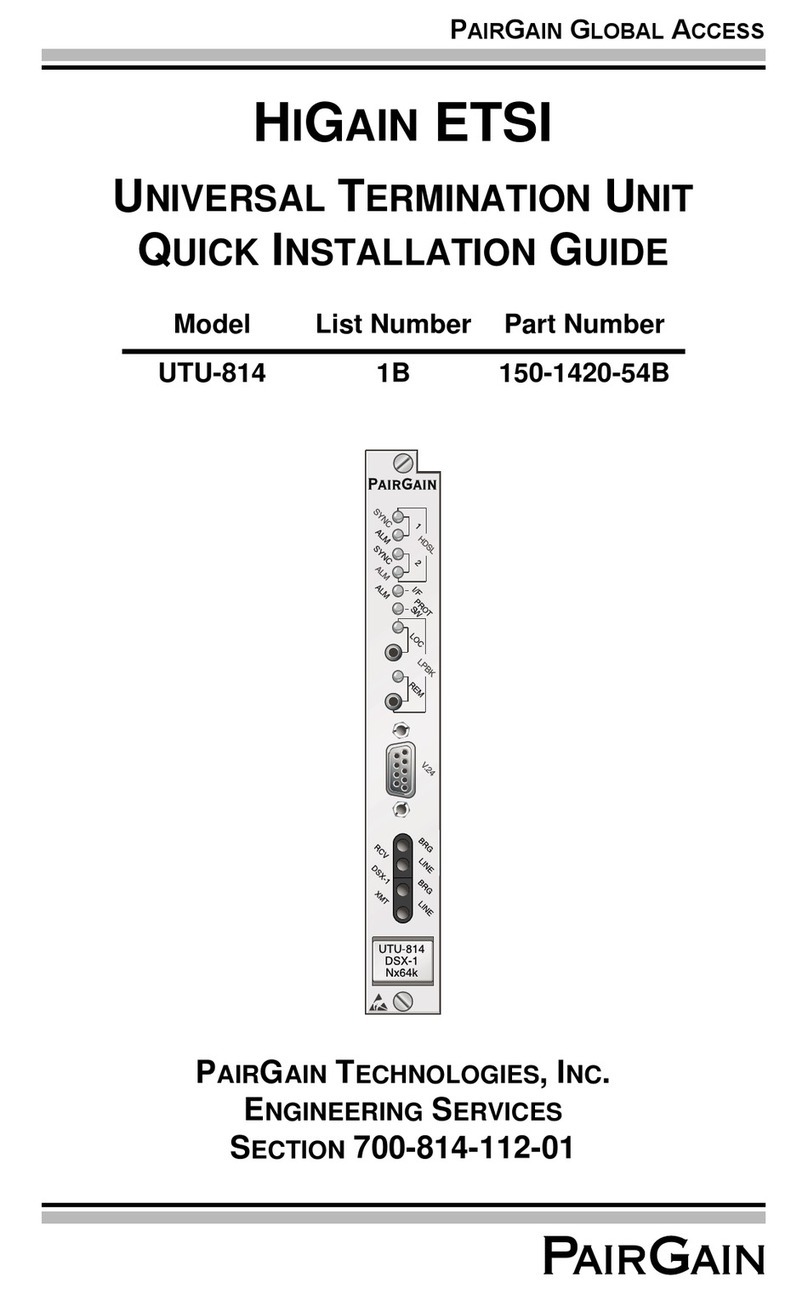

PairGain

PairGain HiGain ETSI UTU-814 Quick installation guide

DX Engineering

DX Engineering DXE-RT-4500HD unpacking instructions

Berthold

Berthold 40876-01 operating manual

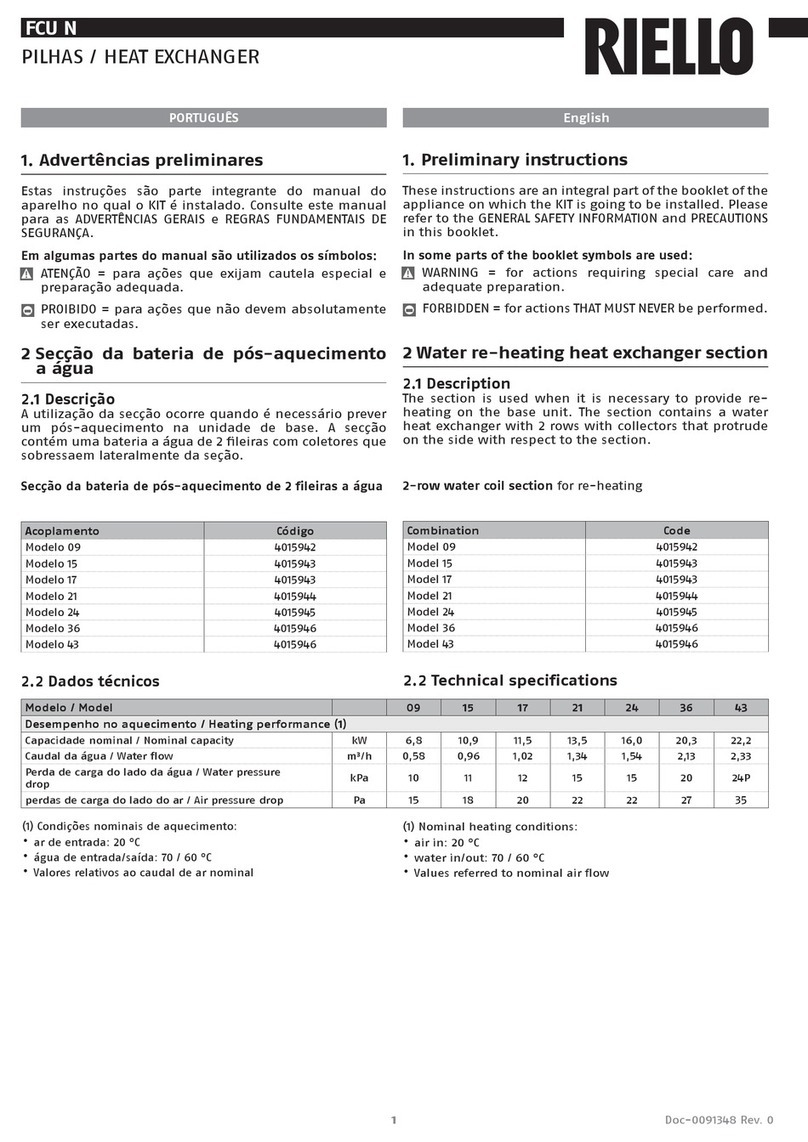

Riello

Riello FCU 09 N manual

Rivenco

Rivenco Ultraseal PF-200 operating instructions