IMPORTANT!

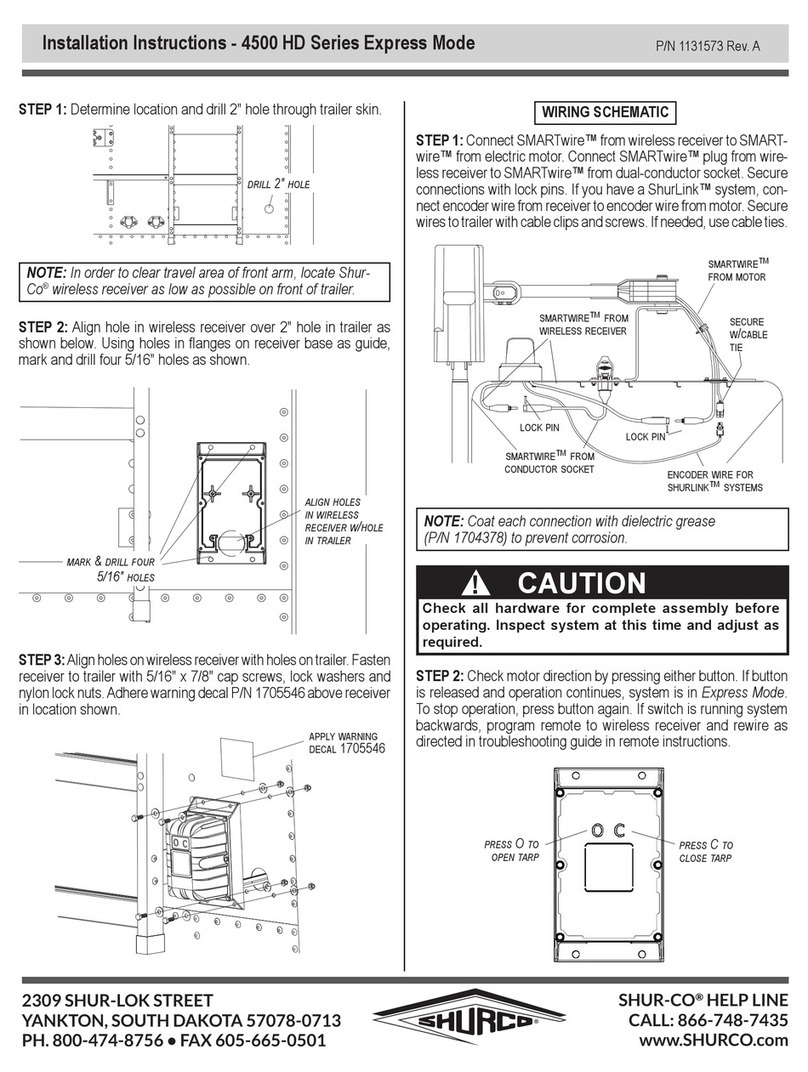

12-Volt Electrical Requirements

A TarpStretcher®* must be used in conjunction with the following

Shur-Co®parts:

• Shur-Co®-Supplied Circuit Breaker

• Momentary Rocker Switch / Shur-Co® SMARTransmitter®

• 6-Ga. Dual-Conductor Wire

• 14-Ga. 3-Conductor Wire

Use of unauthorized parts or improper installation may lead to

premature component failure and may void the warranty.

See Electrical Diagram for installation details or call Shur-Co®

Customer Service at 1-866-748-7435.

*TarpStretcher®is a Registered Trademark of Roll-Rite®

Shur-Co®

P.O. Box 713, 2309 Shur-Lok Street, Yankton, South Dakota 57078-0713

Phone: 1-866-748-7435 Fax: 1-605-665-0501 Web Site: www.shurco.com

To ensure full warranty coverage, please follow the wiring specifications shown in the Tarp-

Stretcher®* P/N 1703135 motor Owner’s Manual. Warranty is good for original owner only.

We warrant the TarpStretcher

®

* P/N 1703135 motor against manufacturing defects for a

pe

riod of five (5) years. Warranty begins three (3) months from time of factory shipment. The

TarpStretcher®motor can only be used in conjunction with the 3500 Series Electric system.

Use of the TarpStretcher®motor in applications other than the 3500 Series Electric voids

the product warranty, unless the use is specifically approved in writing by Shur-Co®,LLC

engineering management. The warranty period in these approved applications will be one (1)

year, beginning from time of factory shipment. There are no warranties for used TarpStretch-

er®motors or TarpStretcher®motors that have been repaired, altered, modified or subjected

to misuse, negligence or accident. We will not repair or replace a product that fails or malfunc-

tions due to ordinary wear and tear. The use of non-Shur-Co®, LLC parts in conjunction with

the TarpStretcher®motor will void this product warranty.

Returns of a TarpStretcher®motor for warranty must be accompanied by a Return Merchan-

dise Authorization number (RMA#), which can be obtained by calling Customer Service at

866-748-7435, and sent, with freight paid by us, to Shur-Co®, LLC, 2309 Shur-Lok Street,

P.O. Box 713, Yankton, SD 57078 USA. All products returned without an RMA# will be re-

fused. When we issue the RMA#, we will also issue a call tag to have UPS (or other freight

company), pick up the product. C.O.D. warranty returns will not be accepted. We will pay no

storage charges for a warranty product return prior to pickup by us or the freight company. If

a warranty product return is scheduled to be picked up by us, we will pick up the product at

our earliest convenience.

If the TarpStretcher®motor returned is found, in our judgement, to have a manufacturing de-

fect, our obligation under this warranty is limited to the repair or replacement of the product,

which will be made by us. Repair or replacement will be at our discretion, with replacements

being made using current models or parts performing in the equivalent function. Labor charg-

es, other than those incurred at our factory, including, but not limited to, any labor to install a

repaired or replacement product, are not covered under this warranty. All expenses associ-

ated with delivering defective products to our factory and delivering repaired or replacement

products from our factory to the owner will be paid by us.

If the product returned is found, in our judgement, to be non-warrantable, the owner will be

contacted to authorize repair work, the purchase of a replacement product or return of the

product, all of which will be at the owner’s expense. Payment authorization must be received

by us before any non-warrantable product is repaired, replaced or returned. All expenses as-

sociated with delivering the repaired non-warrantable product, a replacement product or the

non-warrantable product from our factory to the owner will be paid by the owner.

This limited warranty excludes all other warranties, express or implied, including, but not lim-

ited to, warranties of merchantability or fitness for a particular use. In no event will we be liable

for any damages of any kind or nature to person, product or property, including, but not limited

to, indirect, incidental, special, consequential or punitive damages of any kind, or damages for

loss of profits or revenue, even if we have been advised of the possibility of such damages.

In the event of a conflict between this product-specific warranty and any general warrant, this

product-specific warranty will govern.

*TarpStretcher®is a Registered Trademark of Roll-Rite®

®

WARRANTY

1119116 Rev. B