TTi’s OnDeck™HandBook

8Call 1800 816 277www.tti.com.au 8

Spray Maintenance

Maintenance should be carried our regularly.

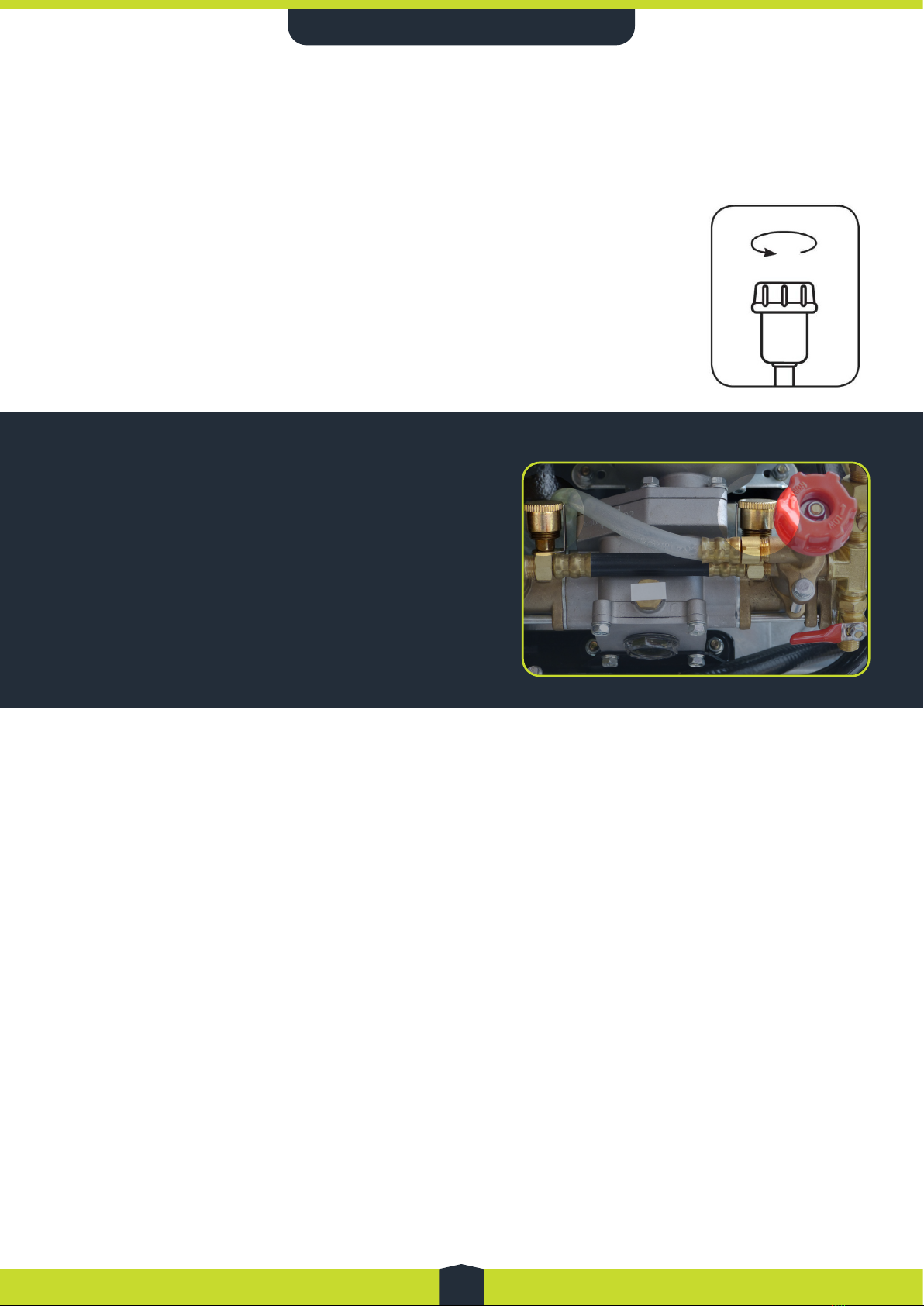

Pump Maintenance

• Check to make sure that all screws are tightened and that no parts are

missing.

• Check to make sure ther are no loose connections on

hoses, nozzle, lance or valves.

• Thoroughly clean the nozzle and filter (suction). Take

the cap off the filter housing and remove filter screen

for screening. Ensure screen is properly located before

screwing cap back on.

• Water rinse and dry the tips before storing.

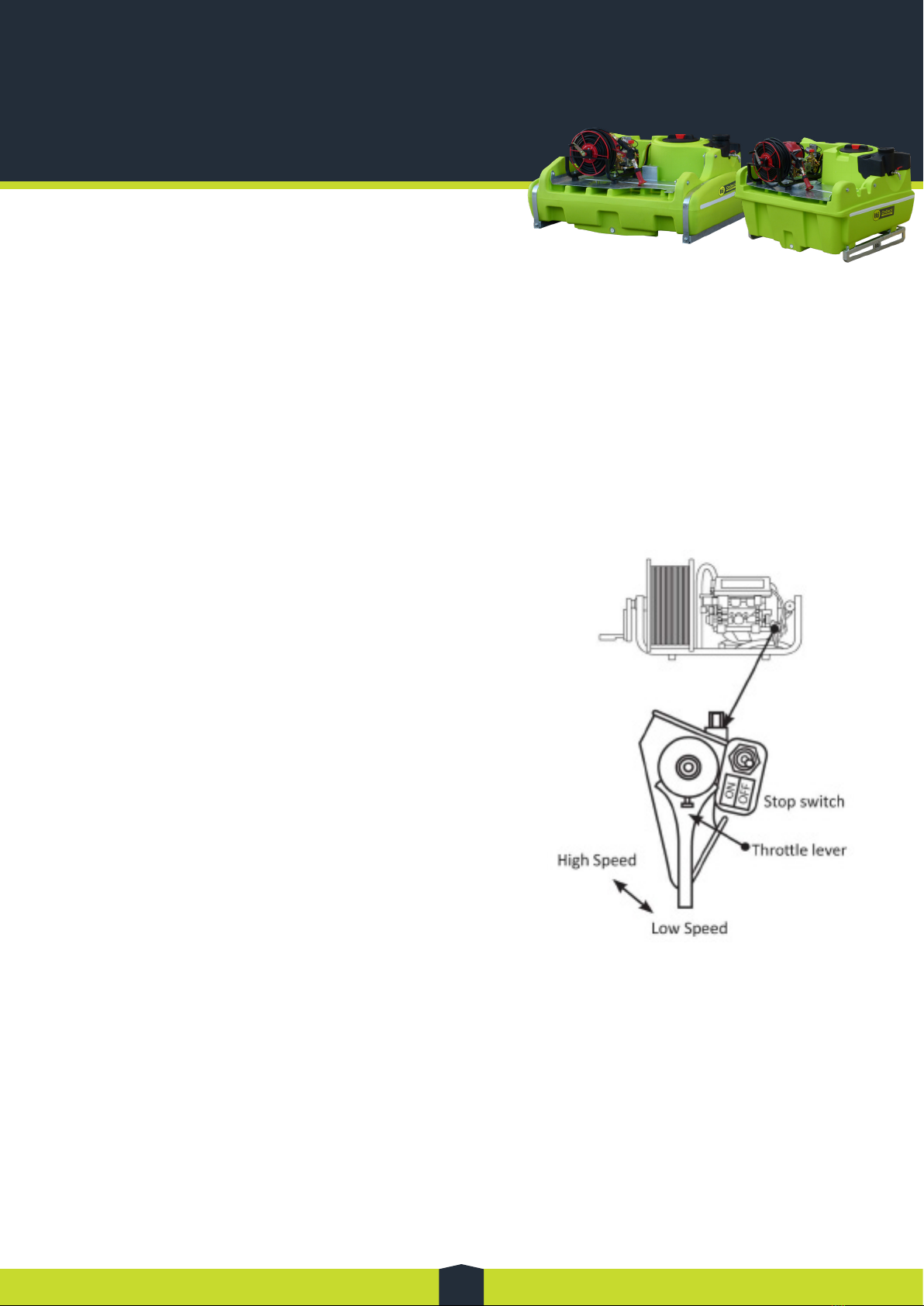

INSPECT THE ENGINE

• Check to make sure there are no loose or missing screws in any part of the

engine.

• Clean the air filter regularly - particularly if working in a dusty environment.

• Clean and adjust the spark plug as necessary.

• Clean the cooling far, air intake opening and parts around the muffler.

• Check the engine oil and change it as necessary.

• Inspect the fuel line filter, check for fuel leaks.

LONG TERM CLEANING AND STORING

When storing the sprayer, ensure that it is clean and dry and kept in a ventilated

place where it will not be subjected to freezing temperatures.

• Complete drian any water for the pump

• Pull the recoil starter handle slowly until there is resistance

• After removing fuel from the tank, push the priming pump until fuel in the

line runs out. Remove fuel from the tank once more

• Check the engine oil and change it if necessary

• Set the throttle level in the low speed position

• Wipe away any dirt or dust

Lubrication

• There are two grease cups (marked

with “ “ on the back of the pump)

• Always ensure grease cups are filled

with grease. Screw grease cups 2-3

turns every 2 hours of operation.

• Once caps reached the end of

thread, undo, top up with GP grease

and screw caps back down until firm.