TransTank ReelStrike Service manual

Manufacturer of The Safest Tanks in Motion

www.tti.com.au

ReelStrike™

HANDBOOK

OPERATOR’S

Operational · Efficient · Effective

TTi’s ReelStrike™HandBook

2Call 1800 816 277www.tti.com.au 2

Table of Contents

Introduction 3

Risk Assesment 4

Mixing and Filling 5

Calibration Procedure 6

Maintenance 7

Spray Lance 8

Pump Data 9

Hose Reel 10

Warranty 11

Warranty Limitations 12

Warranty Registration Card 13

TTi’s ReelStrike™HandBook

3Call 1800 816 277www.tti.com.au 3

Introduction

Congratulations on your purchase of a TTi ReelStrike, which has been designed for

effortless spraying of herbicides and pesticides. The design of the tank enables the

unit to be mounted onto the cargo rack of an ATV or on the back of a utility vehicle

or trailer.

Your Safety

1. When mounting to any vehicle ensure that you have read the Vehicle Owner’s

Manual and that you comply with all the weight restrictions as specified by the

vehicle manufacturer, as overloading can cause injury or death. Remember that

1 litre of water weighs 1 kilogram.

2. To ensure your own safety and that of your employees (if applicable) you must

comply with all relevant environmental, work place health and safety legislation

and codes of practice.

3. Care should be taken when spraying in windy conditions as spray drift may

contaminate the air and may affect the operator or damage adjacent non-

target vegetation.

4. Select and wear appropriate Personal Protection Equipment in accordance with

the label of the product you intend using and your own safe work practices.

5. Improper or careless use of this sprayer can cause serious injury. Minors should

never be allowed to use this sprayer. This sprayer should not be used when

bystanders or animals are in the area. This sprayer should never be used while

children are in the area

6. Once the spraying operation has been completed, decontaminate the spray tank

and spray accessories. Store any remaining chemicals in a safe place in a sealed

container. Dispose of tank rinsings in compliance with current environmental,

work place health and safety regulations.

7. Personal Protection Equipment must still be worn while decontaminating your

sprayer as per warning at 4 above.

8. Never leave the sprayer unattended without turning off the engine and relieving

the line pressure, and flushing the sprayer of any harmful chemicals

TTi’s ReelStrike™HandBook

4Call 1800 816 277www.tti.com.au 4

Risk Assesment

Product Information Risk Assessment Sheet

TTi - ReelStrike

TASK HAZARDS RISK CONTROL MEASURES

Partially fill the tank

with water, start the

motor & test the spray

unit

Manual

handling; slips,

trips or falls;

petrol; fumes;

fingers jammed;

electric shock

or Electricity.

Medium

Concentrate on task; follow safe

manual handling techniques:

• Don’t lift on your own if > 20kg, bend

knees & keep back straight;

• Keep fingers clear; keep unit at least

8m away from overhead powerlines;

• Ensure AS 3760: 2001 Testing

Electrical Equipment applies;

• Water away from electrical sources.

Check weather

conditions &

select the ppropriate

PPE to suit the

chemicals to be used

Manual

handling; slips,

trips or falls

Low

• Put on PPE as per the chemical

requirements in the Material Safety

Data Sheet-coveralls, gloves, safety

footwear, glasses & respirator;

• Follow safe manual handling

techniques:

• Don’t lift on your own if >20kg

• Bend knees & keep back straight.

Mix chemicals (if

applicable)

& fill spray tank

As above; spray

drift, chemical

spillage,

emission

of vapors or

flammability;

weather;

untrained

visitors

Medium

• As above; user trained in the state’s

chemical mixing & administration

course eg Chem. Cert;

• Follow the relevant Environment

Protection Authority requirements;

• Fire extinguisher present;

• Keep visitors away from the job

unless wearing full PPE.

Check the Spray Unit

& carry vehicle is safe

before use, i.e. where

applicable: - wheel

nuts, ture pressure,

bearings, toe hitch,

etc. Use spray unit

as per instructions in

manual & thereon

As above; loss

of load; heat

& cold; noise;

exceed

load limit of

vehicle; hose

entanglement;

exhaust fumes;

terrain & slopes;

High

• As above; wear clothes to suit heat

& cold;

• Wear hearing protection if noise > 85 dBa;

• Follow the manufacturer’s safe

operation instruction for the vehicle

and the spray unit;

• Don’t overload - water weighs 1kg

for every 1 litre;

• Secure load to vehicle;

• Keep hose tidy.

TTi’s ReelStrike™HandBook

5Call 1800 816 277www.tti.com.au 5

Mixing and Filling

The following steps are given as a guide for mixing and filling the

sprayer:

1. Read the product label and follow the instructions carefully, taking special note

with regard to the order in which the products are added to the tank.

2. Half-fill the spray tank with water only and commence agitation by following

these steps:

• Pressure control lever must be in the “bypass position”. Turn regulator valve knob

in anticlock wise direction to reduce pressure to “O” bar.

• Measure the correct quantity of pesticides, using clean measuring jugs used

only for this purpose and add to the spray tank while still agitating.

• Rinse out the measuring jugs and empty containers and pour all rinsings into the

spray tank.

• Top up the spray tank with clean water to the required level.

• Your spray tank has now been correctly filled and the product thoroughly mixed.

Spraying can now commence.

3. To commence spraying, turn on pump. Open the spray gun or boom and start

spraying.

Calibration

Accurate calibration is an essential element of any spraying function as it ensures

that the pesticide is applied at the rate on the product label. Application in excess

of the recommended rate is prohibited, can damage crops and is uneconomical.

Calibration must always be carried out:

• When spraying for the first time with new spray equipment

• At the beginning of each season

• After changes of nozzle tips, spraying pressure or speed

• After every 100 hectares of spraying

When calibrating a sprayer, a minimum of coverall, gloves and boots must be worn.

A face shield and PVC apron may be included depending on the task and the

cleanliness of the sprayer.

TTi’s ReelStrike™HandBook

6Call 1800 816 277www.tti.com.au 6

Calibration Procedure

The following table gives a step-by-step guidance on the standard method of

sprayer calibration

BOOM SPRAYERS HYDRAULIC NOZZLES EXAMPLE

Read the LABEL Spray VOLUME Product Dose Spray

QUALITY

200 Litres/hectare

50 Litres/hectare

Medium

Measure TIME per

100 Metres

Measure time in seconds over land

similar to that to be sprayed 41.9 seconds

Calculate SPEED SPEED = 360 divided by TIME

(km/h) / sec 360/41.9 = 8.6km/h

Measure nozzle

SPACING

Normally

.5 metres

(50cm)

.5 metre

Measure TIME per 100

Metres

OUTPUT = VOLUME x SPEED

x SPACE / 600

(Litres/min) x (Litres/hectare) x

(km/h) x (metre)

200 x 8.6 x 0.5 / 600

Select NOZZLE

Refer to nozzle manufacturers

data charts or other sources and

select the size and type of nozzle

that will produce the calculated

OUTPUT and required spray

QUALITY

41.9 seconds

Now, check the calibration on the sprayer

Check NOZZLE OUTPUT

With water, check outputs of 4 or

more nozzles using a calibrated

jug or flow meter. Check all

nozzles are aligned correctly and

spray patterns

Average output

=

41.9 seconds

Calibrate SPRAYER SPEED = 360 divided by TIME

(km/h) / sec 1.4 x 600 / 0.5 / 8.6

As the nozzle output and therefore the spray volume are less than target figures, increase the

pressure to, say 2.5 bar and repeat the calibration to achieve 200 Litres / hectare

Now, record the details as calculated

Nozzle Fitted 11004 - red

Spray Volume 200 Litres/hectare

Spray Pressure 2.5 bar

Spray Quality Medium

Forward Speed 8.6 km/h

TTi’s ReelStrike™HandBook

7Call 1800 816 277www.tti.com.au 7

Maintenance

The following steps are given as a guide to maintain your spot sprayer.

• After use, the sprayer must be thoroughly decontaminated including tank, pump,

hoses and hand lance to avoid damage to crops from harmful spray residue and

to the sprayer from corrosion or abrasion.

• After spraying, flush the tank, hose and hand lance by running it with clean

water plus a recommended cleaning fluid. It is best to clean sprayer in the field

or area just treated.

• The suction strainer attached to the pump suction line should be cleaned

periodically. Lift the strainer from the base of the tank and brush off with a soft

brush.

• Nozzle filters (if fitted), nozzle tips, nozzle caps and gaskets should be cleaned

by soaking in water, brushing with a nozzle brush and allowed to dry. Never blow

through nozzles with your mouth, nor use wire or pins to clear any blockages.

• Unscrew the hand lance grip and remove the filter screen and clean in the same

way as described for the suction strainer. Ensure that the o-rings do not become

displaced during cleaning. Reassemble the hand lance correctly.

• Align the filter screen in the handle body before the hand lance grip is screwed

back.

• When storing your spot sprayer ensure that it is clean and dry and kept in a well

ventilated place.

TTi’s ReelStrike™HandBook

8Call 1800 816 277www.tti.com.au 8

Spray Lance

OPERATORS HANDBOOK 8

SPRAY LANCE

Spray Lance

OPERATOR HANDBOOK 7

www.tti.com.au

Call 1800 816 277

S Lance

8www.tti.com.au | Call 1800 816 277

TTi - Operators Handbook

TTi’s ReelStrike™HandBook

9Call 1800 816 277www.tti.com.au 9

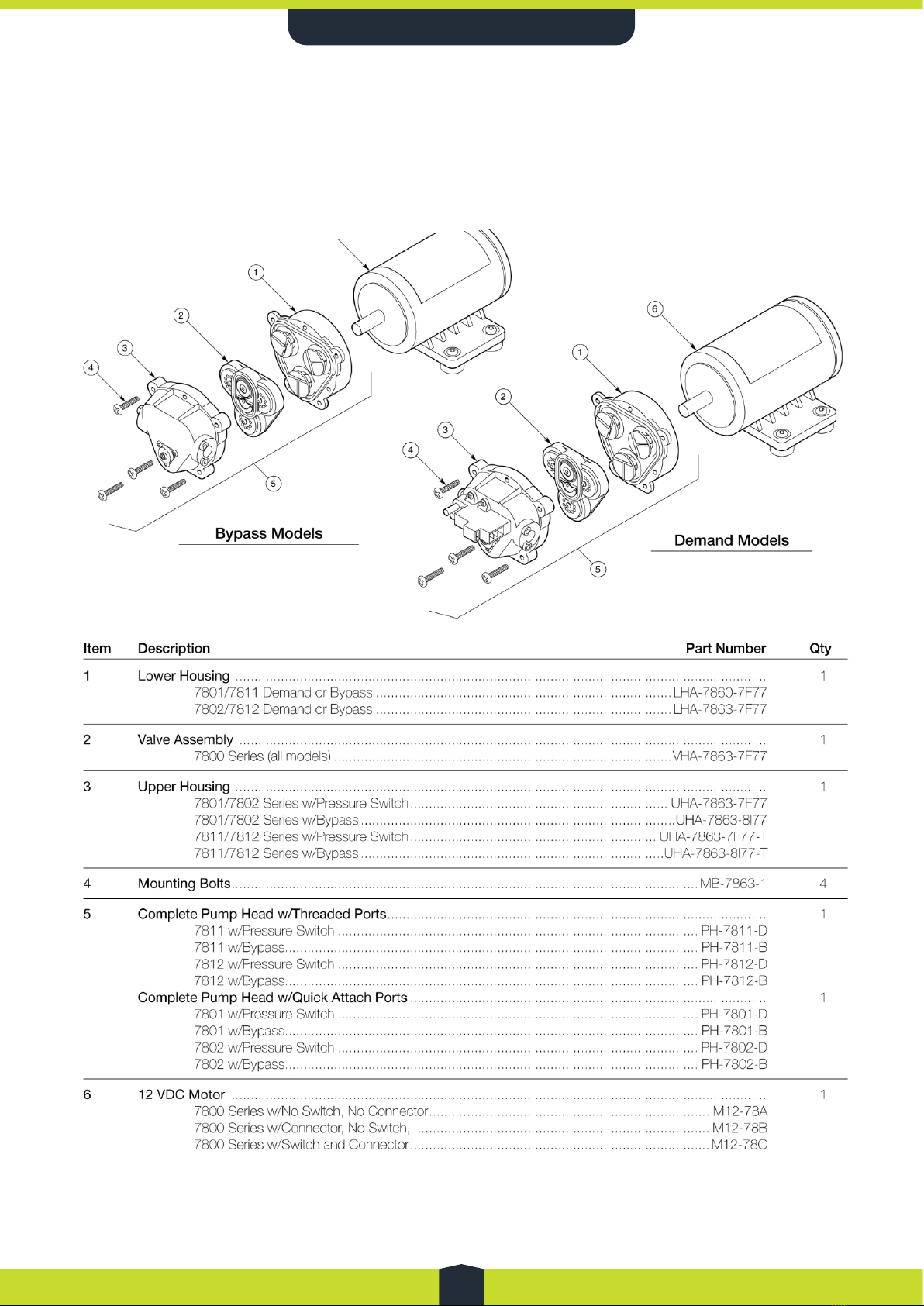

Pump Data

Replacement PowerFlo Models 7801/7811 & 7802/7812

Parts

OPERATORS HANDBOOK 8

SPRAY LANCE

Spray Lance

OPERATOR HANDBOOK 7

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 9

PUMP DATA

Pump Data

OPERATOR HANDBOOK 8

www.tti.com.au

Call 1800 816 277

S L P D

Replacement

Parts

PowerFlo Models 7801/7811 & 7802/7812

9www.tti.com.au | Call 1800 816 277

TTi - Operators Handbook

TTi’s ReelStrike™HandBook

10 Call 1800 816 277www.tti.com.au 10

Hose Reel

REEL

AHTW03B030M10G

HOSE

CUY58010MM

SWIVEL

CFSPB12F12M

NUT x 10mm TAIL

ATPXM1210S 1/2”

TTi’s ReelStrike™HandBook

11 Call 1800 816 277www.tti.com.au 11

Warranty

Warranty Policy

Your Sprayer is guaranteed free from defect in materials, workmanship or manufacture

for 12 months from the date of purchase. Any parts which appear to us to be

defective either in material or workmanship will be replaced or repaired at no cost

to the purchaser, subject to the following conditions:

1. The registration card enclosed in this handbook must be returned to us within 7

days of purchase.

2. The guidelines in this handbook have been adhered to in every respect.

3. In the unlikely event of sprayer failure this should be reported to your dealer who

will act on your behalf to resolve the issue to your satisfaction.

4. Any defective parts will be returned by your dealer within 7 days of failure,

together with a report describing the failure and conditions in which the failure

occurred.

5. The following are specifically excluded from the terms of warranty:

• Fair wear and tear to pump moving parts and diaphragms

• Fair wear and tear to nozzles and nozzle bodies

• Damage caused by neglect or lack of lubrication

• Damage caused by misuse or abuse

• Damage caused while the sprayer is in transit

TTi’s ReelStrike™HandBook

12 Call 1800 816 277www.tti.com.au 12

Warranty Limitations

a] There is no other express warranty. Any warranty that may be implied from this

purchase including merchantibility and finess for a particular purpose is hereby

limited to the duration of this warranty and to the extent permitted by law. Any

and all implied warranties are excluded.

b] TTI will not be liable for any incidental, consequential or special damages and/

or expenses in connection with the purchase or use of this equipment, to the

extent permitted by law.

c] Only the warranty expressed in this limited warranty shall apply and no dealer,

distributor, or individual is authorized to amend, modify, or extend this warranty

in any way. Accordingly, additional statements, whether oral or written, do not

constitute warranties by TTi, and should not be relied upon.

Whilst every care has been taken in the preparation of these instructions, no liabilities

can be accepted with regard to errors or omissions. Product specifications are

subject to change in line with our commitment to continuous improvement.

TTi’s ReelStrike™HandBook

13 Call 1800 816 277www.tti.com.au 13

Warranty Registration Card

To validate your warranty, please complete registration on-line at:

www.tti.com.au/warranty-registration

Alternatively if you are unable to register on-line fill in all the details below, copy

I have read and understood the instructions in this booklet.

[located on side of tank]

Model:

Serial Number:

Date Purchased:

Purchaser’s Name:

Post code:

Purchaser’s Address:

Phone #: Mobile #:

Email Address:

Purchaser’s Signature:

/.

/.

/.

/.

www.tti.com.au

1800 816 277

sales@tti.com.au

PO Box 137, Nathalia, VIC, 3638

Murray Valley Hwy, Nathalia, VIC 3638

Table of contents

Other TransTank Paint Sprayer manuals

Popular Paint Sprayer manuals by other brands

Croplands

Croplands CROPPAK US200F Operator's manual

Campbell Hausfeld

Campbell Hausfeld IN425101AV Operating and assembly instructions

Gardena

Gardena 884 operating instructions

WAGNER

WAGNER WallPerfect Flexio 687 E manual

HammerSmith

HammerSmith Paint Blast Instructions for use

Gloria

Gloria PRO 8 operating instructions