TransTank WeedMasta 55 Service manual

www.tti.com.au

Call 1800 816 277

Call our friendly team today to discuss our product range and complete sales catalogue.

www.tti.com.au

Call 1800 816 277

Call our friendly team today to discuss our product range and complete sales catalogue.

www.tti.com.au

Call 1800 816 277

55

WeedMasta

Operational Efficient Effective

www.tti.com.au

Call 1800 816 277

Call our friendly team today to discuss our product range and complete sales catalogue.

www.tti.com.au

Call 1800 816 277

Call our friendly team today to discuss our product range and complete sales catalogue.

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK

CONTENT OPERATORS HANDBOOK 2

Introduction

Safety

Mounting your WeedMasta

Mixing and Filling

Spraying

Maintenance

Calibration

Diagram

Parts List

Optional Accessories

Warranty

Warranty Registration Card

.....................

.....................

.....................

.....................

.....................

.....................

.....................

.....................

.....................

.....................

.....................

.....................

3

4

5

6

7

8

9

10

11

12

13

14

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 3

INTRODUCTION

Thank you for your purchase of a TTi WeedMasta 55.

Please read all instructions and precautions in this handbook carefully.

Congratulations on purchasing a high quality WeedMasta 55. The spray tank has been designed

to suit a wide range of ATV models, and incorporates numerous features with the main focus on

operator safety.

The spray tank allows use with the smaller ATV, or enables the inclusion of spray booms and

mounting brackets without exceeding loading limits of the ATV.

The spray tank is bafed to reduce product surge, thus increasing stability. A 4 litre clean water

bottle incorporated into the spray tank adds a further safety feature.

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 4

YOUR SAFETY

1. Read your ATV Owner’s Manual before mounting or using any equipment on your ATV. Comply

with all weight restrictions as specied by your ATV manufacturer, as overloading can cause injury

or death.

2. To ensure your own safety, comply with all relevant legislation and Codes of Practice

- Pesticides Act 1978

- Occupational Health and Safety Act 1983 (OHS Act)

- Code of Practice for the safe use of chemicals (including pesticides and herbicides) in

agriculture – Workcover Authority

3. Select and wear appropriate Personal Protection Equipment in accordance with the product

labelled you intend using.

4. Care should be taken when spraying in windy conditions as spray drift may contaminate the

operator or damage adjacent non- target vegetation.

5. Once the spraying operation has been completed, decontaminate spray tank and spray

accessories.. Dispose of tank rinsing in compliance with current regulations. See Point 1 in the

MAINTENANCE section for decontamination guidelines.

6. Personal Protection Equipment must be worn while decontaminating your sprayer

7. It is recommended that a speed of 10 km/h is not exceeded while spraying

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 5

MOUNTING YOUR WEEDMASTA

1. Your WeedMasta ATV Sprayer comes completely assembled

2. Mount the tank by strapping it to the cargo rack of your ATV, using the ratchet tie-down strap.

Follow the strap route as shown in Figure 1

3. Attach the hand lance rigid pipe to the hand lance trigger taking care not to overtighten or cross

thread the cap nut

4. Add approximately 5 litres of clean water to the spray tank

5. Connect the electrical lead to the battery ( red to the positive terminal - black to the negative

terminal ) Usually this involves removing the ATV seat.

6. The pump will commence pumping upon electrical connection. Depress the hand lance

trigger to exhaust entrapped air from the system. Release the hand trigger and the pump will

automatically shut off.

7. Your sprayer is now ready to commence callibration procedures, see calibration section or

spraying preparation

Additional Notes

1. Calibrate your sprayer using water only before adding chemical to the spray tank. See page

(9) for calibration procedures.

2. Ensure that the nozzles selected match the pump delivery. Insufcient nozzle or boom delivery

will cause the pump to cycle. This continual switching on and off will reduce battery and motor life.

pump cycling may also occur when using the hand lance and adjustable nozzle if the nozzle has

been set too ne. Should this occur, alter the setting of the nozzle tip until the cycling stops.

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 6

MIXING AND FILLING

The following steps are given as a guide for mixing and lling the sprayer:

1. Read the product label and follow the instructions carefully, taking special note with regard

to the order in which the products are added to the tank.

2. Measure out the correct quantity of pesticides, using clean measuring jugs used only for

this purpose.

3. Half ll the sprayer with clean water then add the measured pesticide.

4. Rinse out the measuring vessel and empty containers. Pour all rinsings into the sprayer

tank and top up the tank with water to the required level. Ensure thorough mixing by stirring

with a suitable round edged paddle.

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 7

SPRAYING

1. Before commencing spraying, plan the work effectively to reduced potential contamination to a

minimum.

2. Wind speed and direction must be taken into account. Avoid spraying on still, hot and sunny

days or when wind speeds exceed 6.5km/h.

3. Do not spray if spray drift appears to contaminate the operator, bystanders, watercourses or

any non-target vegetation.

4. Drift can be reduced by lower nozzle height, lower pressures or by tting larger nozzles.

5. To commence spraying, depress the hand lance trigger to activate the pump. Release the

trigger to stop the spray – the pump will automatically close off.

6. Spray at a constant speed (as used during calibration) and shut off the hand lance trigger at

the end of each swath or before changing direction.

7. Work in parallel lines at the correct spacing when spraying large areas – this is better than

moving the hand lance from side to side in a swinging movement which causes damage by

overdosing.

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 8

MAINTENANCE

After use the sprayer must be thoroughly decontaminated, inside and outside – including pump,

hoses, boom and hand lance to avoid damage to crops from harmful spray residues and to the

sprayer from corrosion or abrasion. As a guide following the decontamination procedures below:

1. After spraying, the tank, pump, hand lance and spray hose should be ushed by running it with

clean water, plus a recommended cleaning uid. It is best to clean sprayers in the eld or area just

treated. This avoids the difcult problem of disposing of the dilute washings.

2. The ller basket strainer must be removed from the tank and soaked in clean water and brushed

with a soft nozzle brush to remove trapped particles.

3. The suction strainer or foot strainer at the end of the suction line can be simply removed and

cleaned in the same way as the ller basket strainer – replace by inserting the hose tail back into

the suction line.

4. Nozzle lters (if tted), nozzle tips, nozzle caps and gaskets should be cleaned by soaking in

water, brushing with a nozzle brush and allowed to dry. Never blow through nozzles with your

mouth, nor use wire or pins to clear any blockages.

5. When re-assembling ensure that the quick t nozzle cap gasket is correctly positioned.

Unscrew the hand lance grip and remove the lter screen and clean the same way as described

for the suction lter. Ensure that the o-rings do not become displaced during cleaning.

Re-assemble the hand lance ensuring that the lter screen is correctly aligned in the handle body

before the hand lance grip is screwed back.

6. When storing the unit ensure that it is clean and dry and kept in a well ventilated place.

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 9

CALIBRATION

For effective spraying, ensure you have taken the following factors into account:

1. Work Rates

• Speed of operation

• Water points or nurse tanks

• Rate of travel

• Swath width

• Spray volume applied

2. Wind Direction and drift

• Wind Speed

• Wind Direction

• Airspeed at boom height

Avoid spraying on still warm days as convection currents may cause drift in

unpredictable directions.

Optimum wind speeds are between 3km/h to 7 km/h

• Wind drift is controlled by;

• Reducing nozzle height

• Reducing pressure and using larger nozzles

• Fit low-drift nozzles producing larger droplets

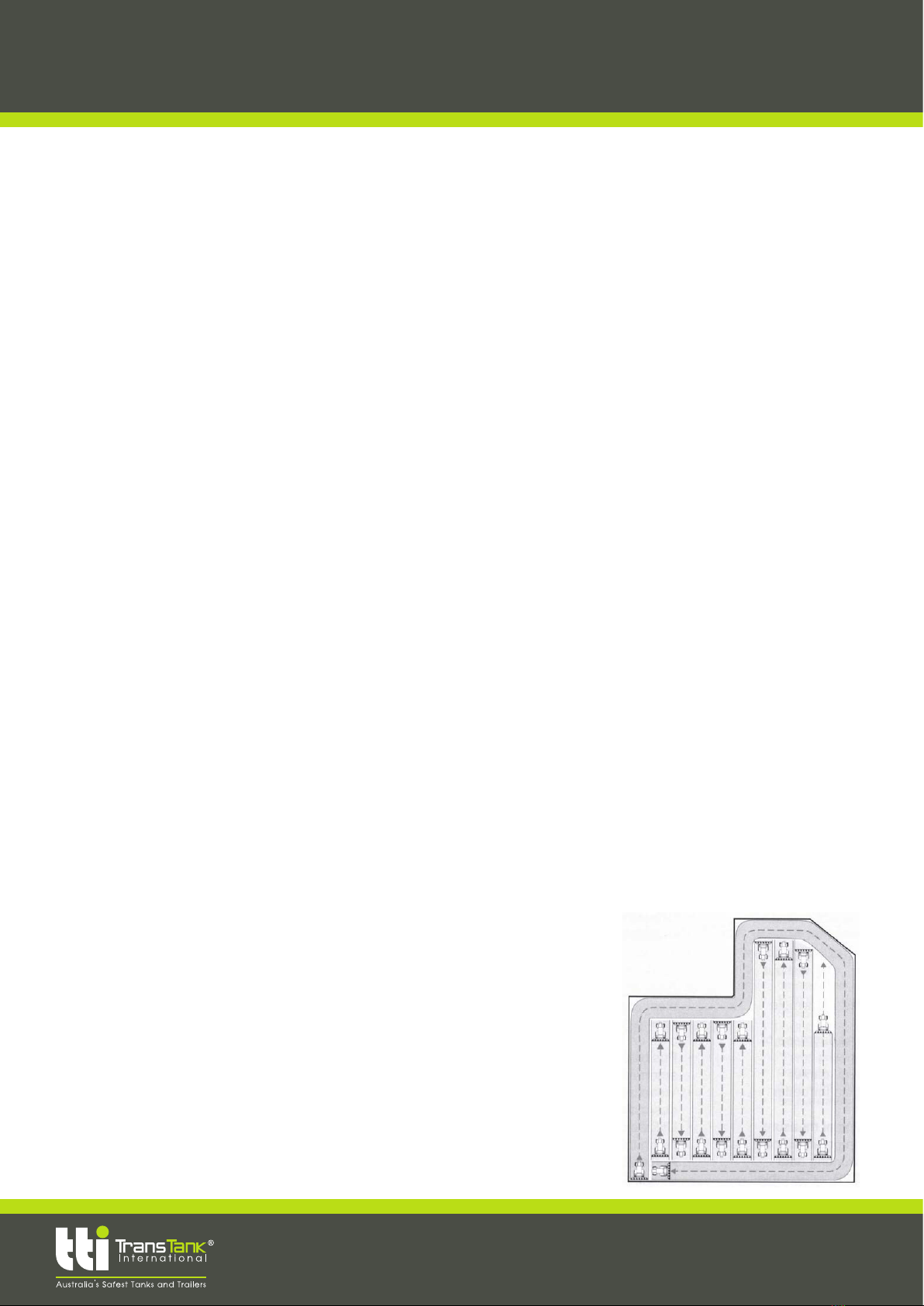

3. Field Work (See diagram below)

Swath marking and spraying

• Mark out to ensure proper pass matching – use ags foam markers or tramlines

• Where large obstructions exist in the middle of an area to be sprayed, mark out and

spray the area like a separate headland.

• The perimeter of the eld should be sprayed rst. The width of two swaths will give

adequate turning space at the ends of spray runs.

• Never spray while turning.

4. Speed

Maintain a constant speed when spraying. Should you need to

increase your spraying speed,

larger delivery nozzles must be tted. Re-calibrate as required

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 10

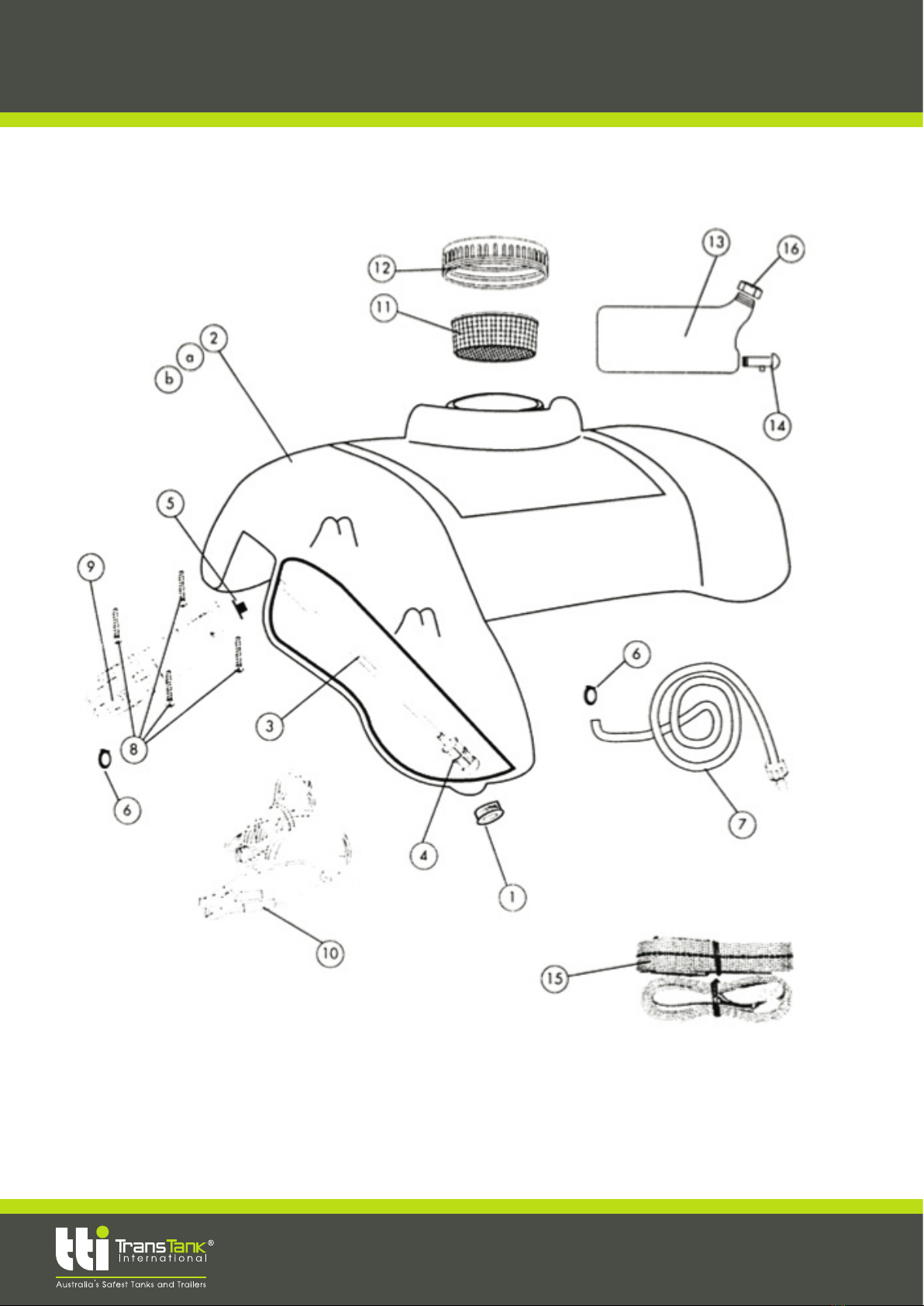

DIAGRAM

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 11

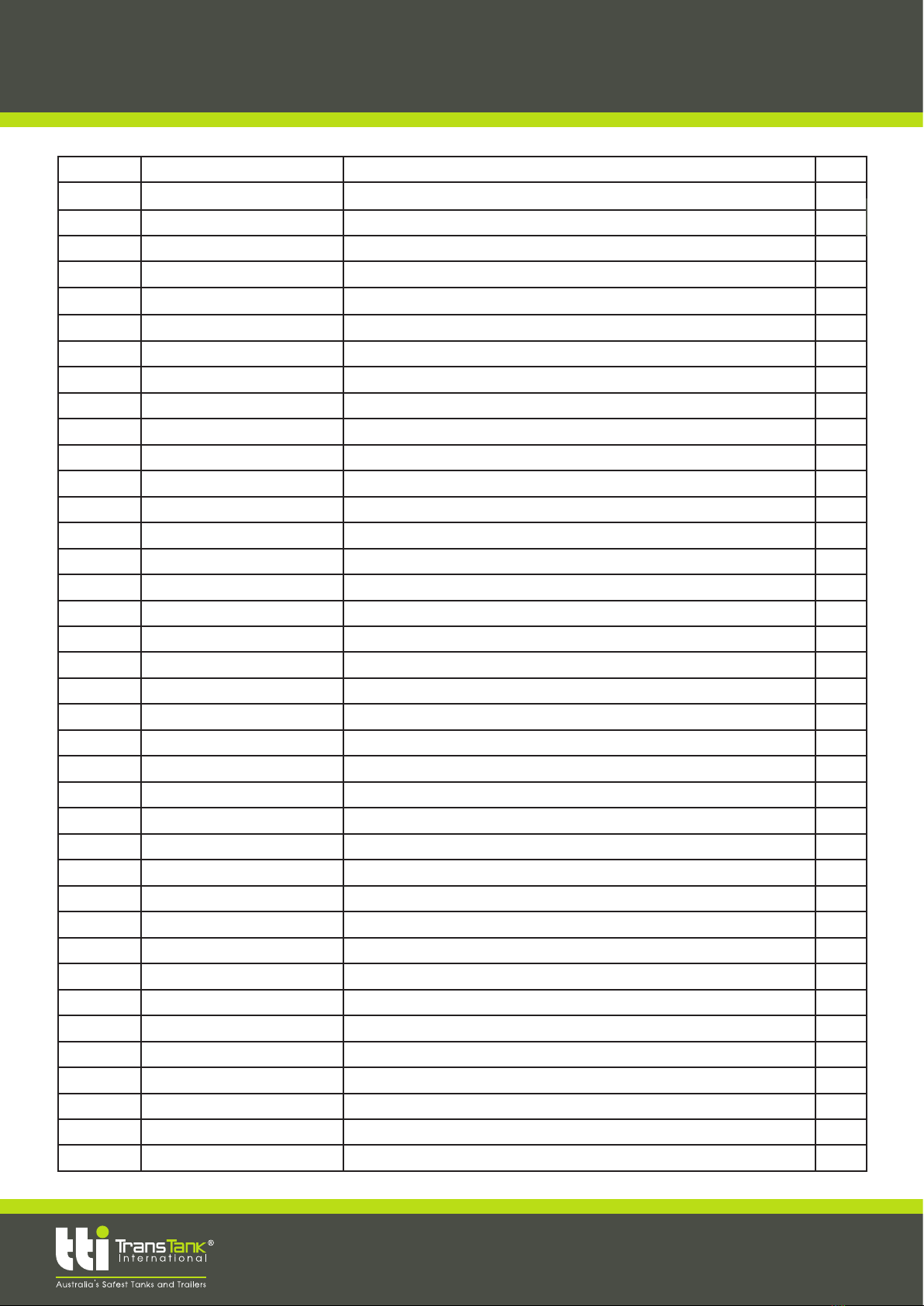

PARTS LIST

No. Code Description QTY

1 STA66 Drain Plug 1

2A ANEV35T 35 litre tank 1

2B ANEV35T 55 litre tank 1

3 STAHO8-S 8 mm suction hose

4 STA60 Filter 1

5 STA68 Through tank grommet 1

6 C13 Hose Clamps 1

7 STAHO8 4m - 8mm hose complete 1

8 //12SS23 Screws pump mounting 8

9 STAP023 SLV10 Shuro Pump 1

10 STA70 Electrical leads 1

11 YP287 Basket strainer 1

12 YP286K Tank lid and valve 1

13 STOO4WT 4 Litre water tank 1

14 TAPO3 Water tank tap 1

15 STA90 Tie Down Straps Pair 1

16 PTWK19 Cap for water bottle 1

17 135YP135 Nozzle 2 mm 1

18 136YP136 O-ring AN-5 1

19 137YP137 Front Elbow 1

20 726YP 726 Front elbow and nozzle 1

21 101YP101 O-ring AN-8 2

22 127YP127 Cone nut 2

23 138YP138 Cone nut 2

24 140YP140 Tube 1

25 727YP727 Pipe with nuts 1

26 167YP 167 O-ring AN-14 1

27 349YP349 O-ring AN-3 1

28 356YP356 Handle body 1

29 357YP357 Grip 1

30 358YP358 Trigger 1

31 359YP359 Trigger lock 1

32 363YP363 Spring 1

33 608YP608 O-ring AN-6 1

34 883YP883 Complete handle 1

35 885YP885 Complete lance 1

36 904YP904 Filter with O-rings 1

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 12

OPTIONAL ACCESSORIES

A wide range of accessories are available for use with your spot sprayer. Each accessory can be

tted and removed very simply without the use of any tool.

SKU Description

YA00B Rectangular spraying shield with fan nozzle

YA00C Conical spraying shield with fan nozzle

YAOOD 0.5 lance extension

YA00E 4 cone nozzle spray boom (spray width up to 2m)

YAOOF Wide angle herbicide nozzle and elbow – very useful for spraying weeds in lawns

YA00H Flexible double cone nozzle spray head

YAOO1 0.25 m exible lance extension

YAOOK 1 m aluminium lance extension

YAOOL 1.5 m aluminium lance extension

YA00R Telescopic 2 nozzle boom (spray width up to 1.2m )

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 13

WARRANTY

1. WARRANTY POLICY:

TTI will, at its option, repair or replace, without charge, any part covered by this warranty which is

found to be defective in material and/or workmanship within one (1) year* after date of sale to the

original retail purchaser unless the product is used for rental purposes, in which case this warranty

is limited to ninety (90) days. Upon request, the customer will make the defective part available

for inspection and/or return the defective part to TTI, transportation charges prepaid. All parts and

components are covered by this warranty except the following, which are warranted separately by

their respective manufacturers: - engines, gearboxes, pumps & regulators. TTi does not assume

any warranty obligation, liability or modication for these items, which are covered exclusively by

the stated warranty of the respective manufacturers.

2. WHAT THIS WARRANTY DOES NOT COVER:

A. This warranty does not cover defects caused by depreciation or damage caused by incorrect

mounting, normal wear, accidents, improper maintenance, improper use or abuse of the product,

alterations or failure to follow the instructions and warnings provided.

B. The customer shall pay any charges for making service calls, clean up time and transport

charges.

C. The use of non-genuine parts on equipment supplied by TTi will automatically negate any war-

ranty.

3. HOW TO OBTAIN SERVICE UNDER THIS WARRANTY:

Warranty service can be arranged by contacting your dealer or by contacting Trans Tank Interna-

tional, Call 03 5866 3266 or P O Box 137, Nathalia VIC, 3638. Proof of warranty registration and

date of purchase may be required to verify warranty coverage. Any defective parts returned to us

must be accompanied by a Return Goods Note. This form can be obtained by contacting Product

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 14

WARRANTY

Whilst every care has been taken in the preparation of these instructions, no liabilities can be ac-

cepted with regard to errors or omissions. Product specications are subject to change in line with

our commitment to continuous improvement.

Manufactured by: Trans Tank International

Murray Valley Highway

Nathalia 3638

Australia

FREECALL 1800 816 277

4. WARRANTY LIMITATION:

A. There is no other express warranty. Any warranty that may be implied from this purchase

including merchantibility and ness for a particular purpose is hereby limited to the duration of this

warranty and to the extent permitted by law. Any and all implied warranties are excluded.

B. TTI will not be liable for any incidental, consequential or special damages and/or expenses in

connection with the purchase or use of this equipment, to the extent permitted by law.

C. Only the warranty expressed in this limited warranty shall apply and no dealer, distributor, or

individual is authorized to amend, modify, or extend this warranty in any way. Accordingly, addition-

al statements, whether oral or written, do not constitute warranties by TTi, and should not be relied

upon.

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 15

WARRANTY REGISTRATION CARD

To validate your warranty, please complete registration on-line at

http://www.tti.com.au/index.php/warranty

Alternatively if you are unable to register on-line ll in all the details below, copy and email

to [email protected] or post to the address on the back cover.

I have read and understood the instructions in this booklet.

Model ________________________ Date purchased ____/ _____/_______

Serial Number__________________________ [located on side of tank]

Purchased from ________________________________________________________________

(Dealer Name and Town)

Purchaser’s Name ______________________________________________________________

Purchaser’s Address _____________________________________________________________

____________________________________________________

Post Code ___________________________________________

Phone # _____________________ Mobile # _____________________

Purchaser’s Signature ________________________

www.tti.com.au

Call 1800 816 277

OPERATORS HANDBOOK 16

www.tti.com.au

Call 1800 816 277

Trans Tank International

Murray Valley Hwy, Nathalia VIC 3638

PO Box 137, Nathalia VIC 3638

FREECALL: 1800 816 277

FAX: 03 5866 3019

www.tti.com.au

Table of contents

Other TransTank Paint Sprayer manuals