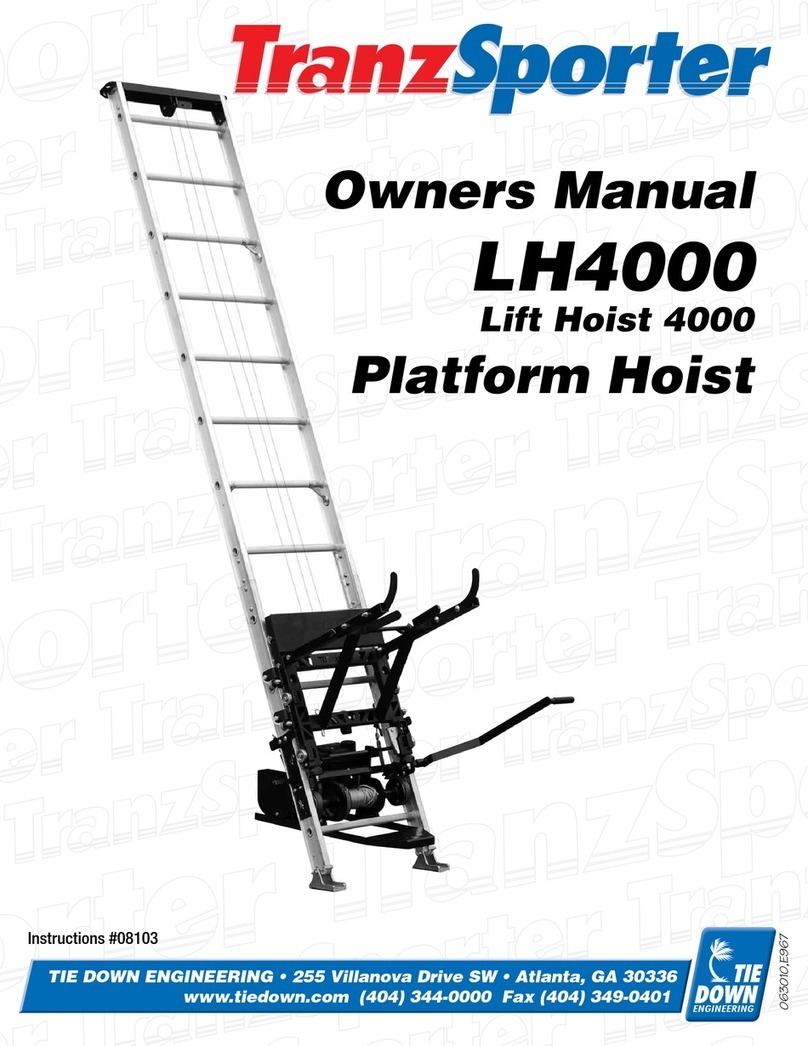

TIE DOWN ENGINEERING • Atlanta, GA 30336

www.tiedown.com (404) 344-0000

Page 3 of 4

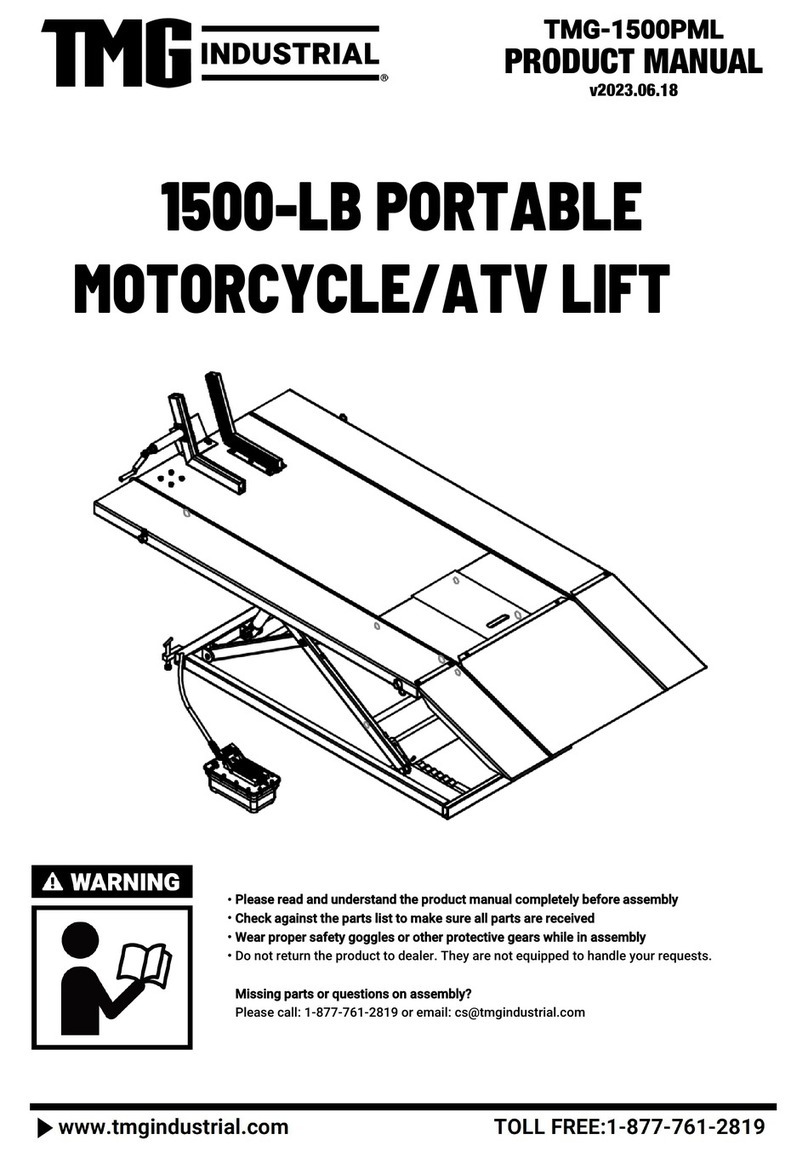

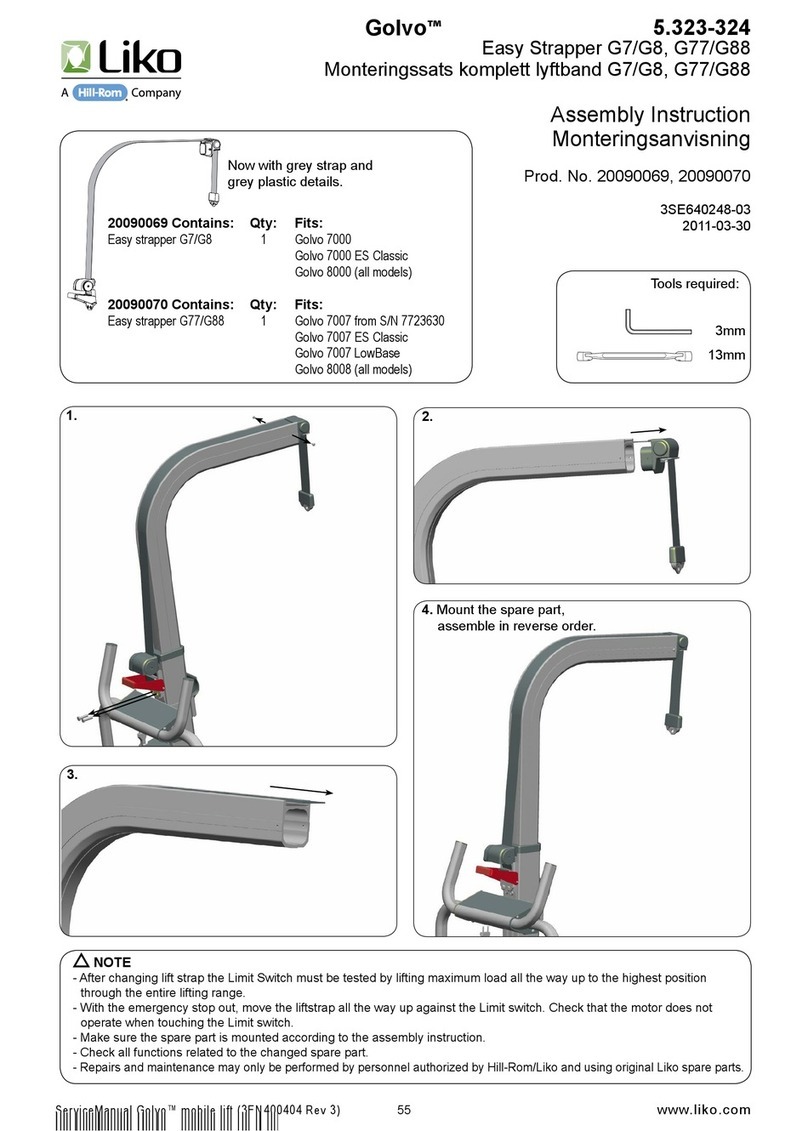

Carriage Base

Insert Safety Pins

from the inside

of the carriage

Support Strut

Beveled End

Beveled End

Support Slots

Round End

Platform

Base

Platform Back/Flap

Platform

Back/Flap

Step #3

Lift up one side of the carriage 90˚

and let it rest on its side.

Place the round end of the

support strut in the platform

(underside) base, align with

mounting holes.

The support strut must be

positioned with the beveled

end as shown right.

Insert 5/16”x 2” Bolt through

base and strut. Tighten nylock

nut with the bolt.

Important: Do not over-tighten

nylock nut so tight as to

prevent free movement.

Flip the carriage assembly 180˚.

Repeat for second support strut.

Step #4

Flip the carriage on its side with the

carriage base - wheels down and the

back/flap on flat ground.

With both hands, hold the beveled end

each of the support struts. Slide the

struts upward while holding the strut

and the carriage base with your

hands. Insert the beveled end strut

into the slots on the carriage base.

Step #5

From the inside of the carriage base

insert safety pins for both support

struts (labels indicate pin location).