TRANZSPORTER TP250 User manual

Red: 0-100-100-0 Blue: PMS 293

100-56-0-0

Color Logo use on white background only

Black Logo use on white background only

White Logo use on black background only

TP250

250 lb. Capacity

TP400

400 lb. Capacity

E1399: 022117

4 color

TIE DOWN ENGINEERING • Atlanta, GA 30336

www.tiedown.com (404) 344-0000

TIE DOWN ENGINEERING • Atlanta, GA 30336

www.tiedown.com (404) 344-0000

Instructions #08238

Updated: 2-21-17

For the Most Up to Date

Information and Instructions,

Visit the TranzSporter Web Site at

www.tranzsporter.com.

Platform Hoist

Owners Manual

Page 1 of 16

Congratulations on your Purchase of the TranzSporter Lift Hoist.

The TranzSporter Lift Hoist was designed to provide safe and continuous operation.

Features Include...

• Collapsible carriage comes with track cam followers for better tracking and handling.

• Aluminum deck and flap for lighter weight and longer life.

• Rolled goods/plywood bracket comes with unit and pins into carriage.

• Motor base is manufactured using laser cut steel tubing for extra strength and durability.

• Belt guard and foot pedal are detailed with aluminum diamond plate.

• Dual versatile brake may be operated from either side of platform hoist.

• An additional handle may be used to engage the carriage instead of using the foot pedal (#48468 handle kit sold separately).

• A 4 ft. heavy duty aluminum base track utilizes laser cut steel tube support plates for job site toughness.

• Base track features large cast aluminum feet for added stability.

• Dual band brake system for smoother stops.

• Amber colored carriage bumpers to protect against damage and wear from repeated lowering (can be rotated).

• Oversized clip pins for fast and simple removal of quick change cable drum and belt replacement.

User Responsibilities

PERFORM THE FOLLOWING AT THE START AND END OF THE WORK DAY AND AFTER

4 HOURS OF OPERATION DURING THE DAY:

• Check oil level in engine and fill according to manufacturer’s specifications.

• Check cable for smooth operation and for signs of wear.

• Check for loose bolts and tighten according to specifications.

• Check track sections and all other moving parts for excessive wear or fatigue.

• Check general condition of equipment.

• Check and confirm operator’s understanding of the proper operation for this equipment.

• When using the electric motor; check extension cords and connections for wear or damage.

• Check brake parts regularly for wear or damage.

• Check cable drum bearings, they should run smoothly when the brake is released. If there is any noise or if the cable drum does

not spin freely, replace drum bearings immediately.

• Check for minimal clearance between outer track cam followers.

WARNING:

• DO NOT OPERATE THIS EQUIPMENT IF ANY UNSAFE CONDITIONS EXIST OR OCCUR DURING OPERATION.

• KEEP TRACK SECTION CLEAR OF ALL ELECTRICAL WIRES AND EQUIPMENT. ALWAYS LOOK UP FOR ELECTRICAL WIRE PRIOR

TO MOVING TRACK SECTIONS.

• BE AWARE OF OVERHEAD OBJECTS.

• NEVER USE TRACK SECTIONS AS A LADDER.

• NEVER OPERATE HOIST WITH A HUMAN ON PLATFORM.

• NEVER STAND UNDER PLATFORM WHEN LOWERING.

• NEVER USE INDOORS OR IN AN AREA WITH POOR VENTILATION (ELECTRIC MODEL IS EXCLUDED).

• NEVER USE HOIST TO LOWER MATERIAL.

Atlanta, Georgia 30336

Page 2 of 16

(404) 344-0000 • www.tranzsporter.com

Safety Instructions

CAUTION: Please read the safety warnings and Instructions contained in this manual before operating the lift hoist. Failure

to obey the warnings contained herein could result in damage to the equipment, personal injury, or death, this information

should not be a substitute for routine accident prevention, but rather an addition to routine accident prevention.

GENERAL SAFETY INSTRUCTIONS:

1. Transport and handle your lift hoist with care.

2. Unpack the TranzSporter carefully and inspect for any damage that may occur during transportation. DO NOT USE THE HOIST IF ANY

PART IS DAMAGED.

3. Please observe all safety and warning labels attached to the hoist.

4. Use only replacement parts furnished by the manufacturer.

5. Always keep the area around the base section of the TranzSporter hoist clear to help prevent slipping, tripping or falling against the hoist.

6. DO NOT ALLOW ANYONE TO OPERATE THE TRANZSPORTER HOIST WHO HAS NOT BEEN THOROUGHLY AND PROPERLY

TRAINED IN THE CORRECT OPERATION AND USE OF THIS HOIST.

7. This hoist is manufactured to lift materials only. Do not use the lift hoist for the purpose of transporting personnel from one level to another.

8. Do not climb the TP-Series hoist or use as a personnel ladder.

9. Do not overload - maximum lifting capacity for the TP250 is 250 lbs. with a load capacity of 230 lbs. Maximum lifting capacity for the TP400

is 400 lbs. with a load capacity of 380 lbs.

10. Keep hands, feet and other body parts as well as clothing away from the track sections and moving or rotating parts of the TP-Series hoist

when starting the engine or when operating the hoist.

11. Do not allow any persons to walk or work under or near the TP-Series hoist while in operation.

12. Do not use this hoist to transport hot asphalt or any other hot molten substance from one elevation to another.

13. Store all parts of the TP-Series hoist in such a fashion as not to damage any of the components.

14. Do not operate indoors or in an area with poor ventilation. Electric motor model is excluded.

15. Never lift sheet or panel goods without the use of the plywood brackets and the tie down straps provided (See page 14).

Warning labels are attached to the TP250/400 and are weather resistant. If you notice any of these decal’s missing from your

hoist, please contact TIE DOWN ENGINEERING for a replacement label.

Remember: Safety First!!

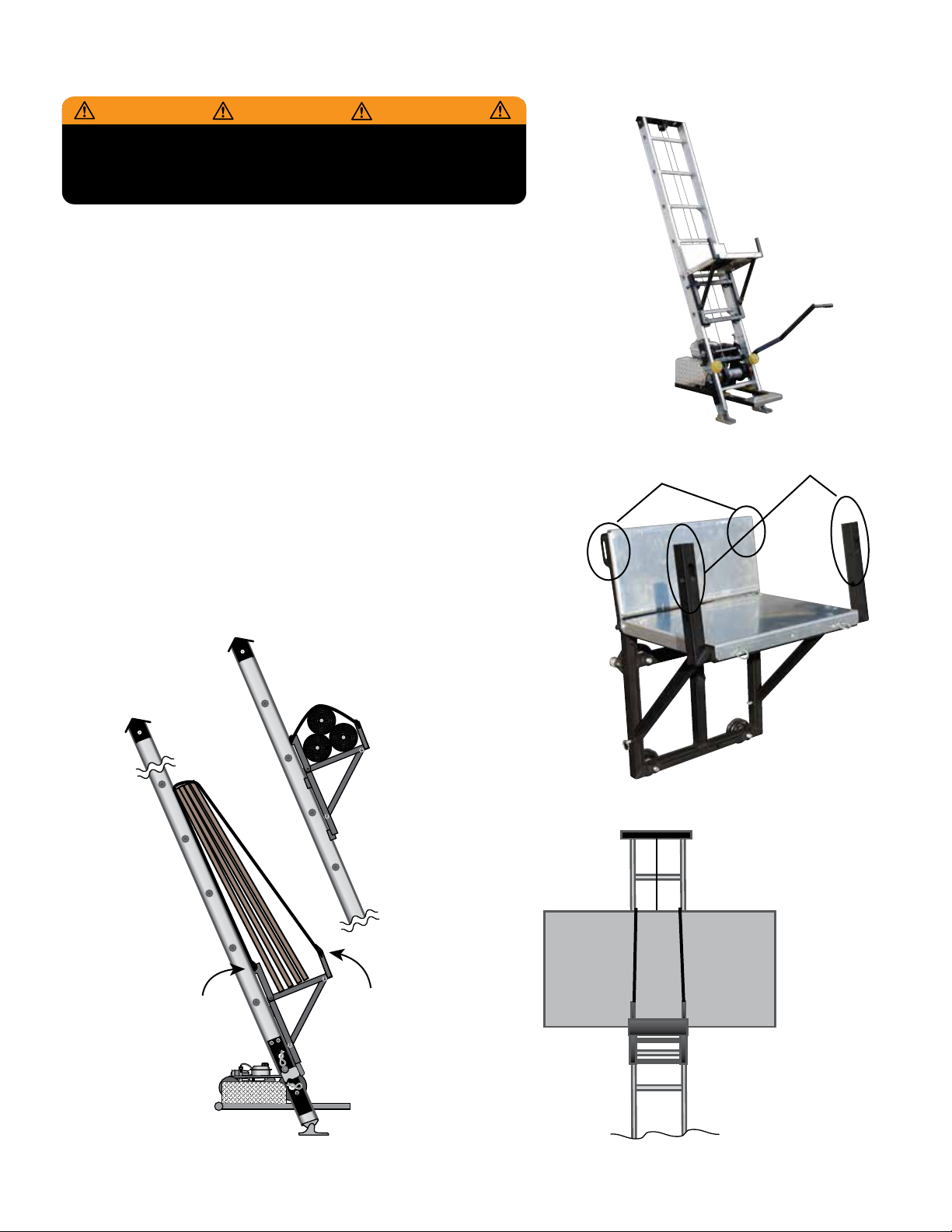

15640-2

WARNING

DO NOT REMOVE THIS TAG!

SHOCK HAZARD

KEEP ENTIRE LIFT HOIST

CLEAR OF ALL UTILITY

AND ELECTRICAL WIRING!

15641-2

DO NOT REMOVE THIS TAG!

IMPORTANT SAFETY INFORMATION

• TOP OF HOIST MUST BE SECURED TO ROOF USING “S” HOOKS (PROVIDED)

AND TWO LENGTHS OF ROPE (NOT PROVIDED)

• BRAKE TENSION SPRINGS MUST BE CHECKED FOR CORRECT TENSIONING DAILY

(BEFORE USE) IN ORDER TO PREVENT LOAD SLIPPAGE

• KEEP BRAKE DRUMS AND BRAKE SHOES FREE OF OIL, LUBRICANTS, AND

EXCESSIVE MOISTURE, CHECK FOR DAILY WEAR AND REPLACE WHEN NECESSARY

• DO NOT OPERATE THIS UNIT IF ANY COMPONENT PARTS EXHIBIT DAMAGE

OR WEAR. THIS INCLUDES ALL TRACK SECTIONS

WARNING

SAFETY LATCH MUST BE

ENGAGED WHEN LIFT

HOIST IS NOT IN USE

DO NOT REMOVE THIS TAG!

15642-2

Instructions Inside Tube

(Remove Red End Cap to Read)

WARNING WARNING WARNING

FAILURE TO READ AND UNDERSTAND THE OPERATING

INSTRUCTIONS CAN RESULT IN PROPERTY DAMAGE,

PERSONAL INJURY OR EVEN DEATH TO USER OR OTHERS

#15726

15640-2

WARNING

DO NOT REMOVE THIS TAG!

SHOCK HAZARD

KEEP ENTIRE LIFT HOIST

CLEAR OF ALL UTILITY

AND ELECTRICAL WIRING!

15641-2

DO NOT REMOVE THIS TAG!

IMPORTANT SAFETY INFORMATION

• TOP OF HOIST MUST BE SECURED TO ROOF USING “S” HOOKS (PROVIDED)

AND TWO LENGTHS OF ROPE (NOT PROVIDED)

• BRAKE TENSION SPRINGS MUST BE CHECKED FOR CORRECT TENSIONING DAILY

(BEFORE USE) IN ORDER TO PREVENT LOAD SLIPPAGE

• KEEP BRAKE DRUMS AND BRAKE SHOES FREE OF OIL, LUBRICANTS, AND

EXCESSIVE MOISTURE, CHECK FOR DAILY WEAR AND REPLACE WHEN NECESSARY

• DO NOT OPERATE THIS UNIT IF ANY COMPONENT PARTS EXHIBIT DAMAGE

OR WEAR. THIS INCLUDES ALL TRACK SECTIONS

WARNING

SAFETY LATCH MUST BE

ENGAGED WHEN LIFT

HOIST IS NOT IN USE

DO NOT REMOVE THIS TAG!

15642-2

Page 3 of 16

Congratulations on purchasing the TranzSporter TP250 Hoist. Please read the following instructions completely before

starting assembly.

The TP250 Hoist ships in 4 units:

1) Box - Base Section, Top Cap & Brake Handle 2) Box - Collapsible Carriage & Plywood Attachments

3) Box - Motor Weldment & Manuals 4) Bundle of Tracks (3 -8 ft. Sections)

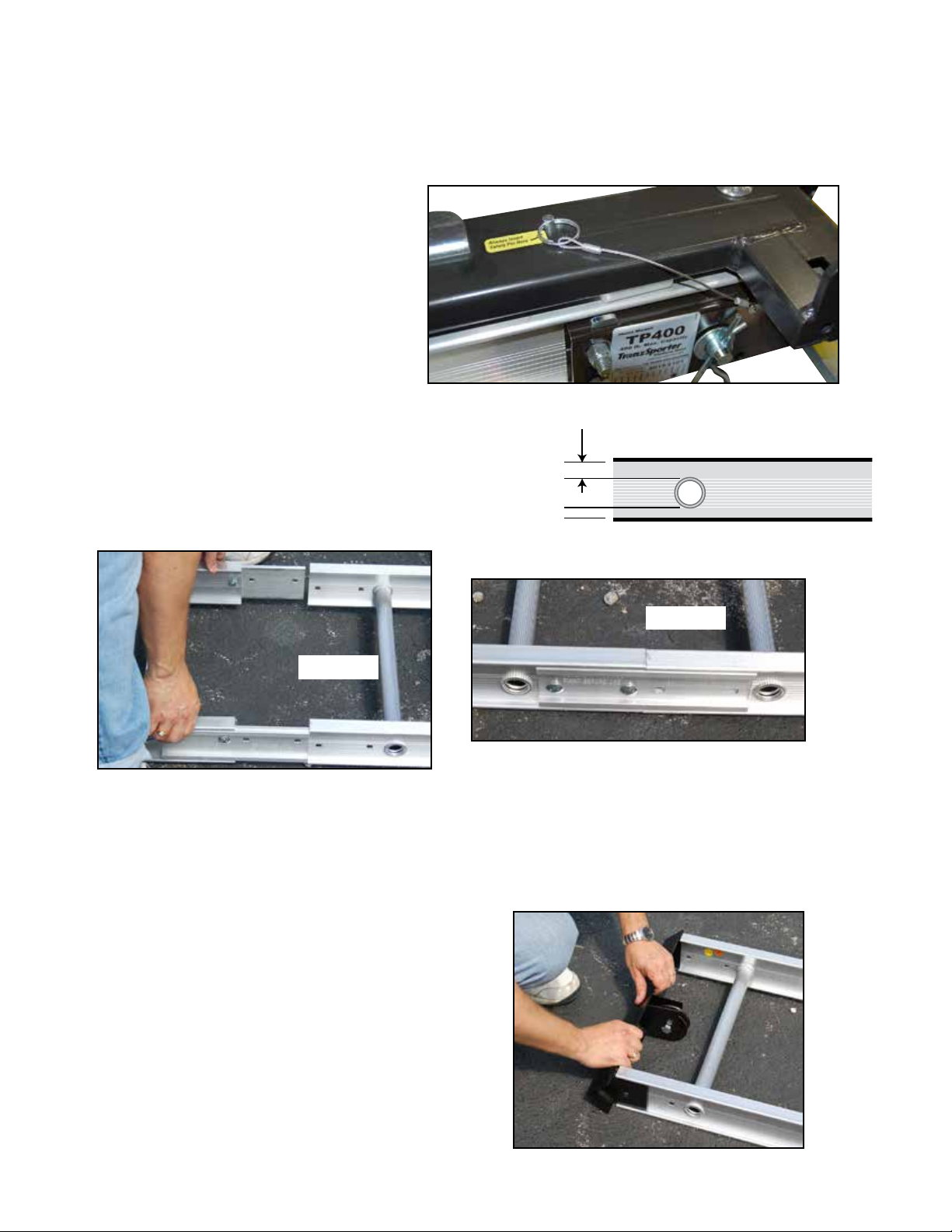

Step 4

“Roll”carriage assembly onto the base. At this time lock the base in

place using the Safety Pin as shown. Be sure to loop the lanyard over the

carriage base as shown.

Important: Always check for wear or damage to

the safety pin cable/pull ring assembly. Failure

to replace damaged safety pin cable assembly

may cause damage or personal injury.

Step 2

Remove base section from its box and place on a clean floor or assembly area. Remove the top cap with a 7/16” wrench

(one bolt/nut on each side).

Step 3

Starting at the top of the track section slide carriage

assembly onto track section so that the four rollers

connect to the top rail of the track section.

Step 1

If you have not already assembled the carriage assembly: Stop Now.

You must first assemble the carriage, follow the assembly instructions included in the #2 Box - “Collapsible Carriage & Plywood Attachments”.

Top Cap

Assembly Instructions for the TP250 Hoist

Instructions for the TP400 Hoist skip to page 7

Atlanta, Georgia 30336

Page 4 of 16

Step 5

Lay one track section on a flat floor with the “front” side up. This is

determined by the space between the track cross bar and the track

section edge as shown above.

Step 6

Attach splice plates to the bottom section of the track. Splice plates are mounted on the outside track section. Slide the top section track

into the groves on the inside track section, attach with 2 nuts and bolts per side (Pictures 4 & 5).

NOTE: DO NOT SUBSTITUTE NUTS AND BOLTS

Use 3/8”x 3/4” bolts and 3/8” nut keeps (lockwasher and nut combined).

Front

Back

Picture 5

Picture 4

Step 7

Reattach the top cap to the end of the last section of track section you intend to use. Assemble with two 3/8”x 3/4” hex head bolts with lock nuts

provided. Make sure that the top cap end slides into the outside of the track section (picture 6).

Picture 6

Assembly Instructions for the TP250 Hoist

Instructions for the TP400 Hoist skip to page 7

(404) 344-0000 • www.tranzsporter.com Page 5 of 16

Feed end cable

through pully

Unwind cable

from the back

Attach cable to

the back of the

carriage (cross bar

)

Step 10

Attach cable to the carriage assembly, pass bolt through

lock washer, washer and cable end/eye. Tighten bolt as

shown right. Bolt

Cable Eye/End

Lock Washer Washer

Carriage Cross Bar

Assembly Instructions for the TP250 Hoist

Instructions for the TP400 Hoist skip to page 7

You have completed the assembly of the TP250 Hoist

Skip to page 10 for Operation and Placement Instructions.

Step 8

From the back side of the hoist, remove the end of the cable from

the drum (shown right). It helps to attach the brake handle, use

the brake handle back releases the brake drum. The cable will

then easily un-spool. Staying on the outside (back) of the base

section and track section, take the cable to the top of the last track

section where the top cap pulley is attached.

Step 9

Feed the cable end through the pulley as shown above , and

down the front side of the track section to the back of

the carriage assembly.

Atlanta, Georgia 30336

Page 6 of 16

Assembly Instructions for the TP400 Hoist

Congratulations on purchasing the TranzSporter TP400 Hoist. Please read the following instructions completely before

starting assembly.

The TP400 Hoist ships in 4 units:

1) Box - Base Section, Top Cap & Brake Handle 2) Box - Collapsible Carriage & Plywood Attachments

3) Box - Motor Weldment & Manuals 4) Bundle of Tracks (3 -8 ft. Sections)

Step 2

Remove base section from its box and place on a clean floor or assembly area. Remove the top cap with a 7/16” wrench

(one bolt/nut on each side).

Step 3a

Starting at the top of the track section slide carriage assembly onto

track section so that the four rollers connect to the top rail of the

track section.

Step 3b

Adjust Tension Bracket - Make sure the TP400 carriage rollers are

on track, and the carriage rolls easily. There are two adjustable

track roller guides on the inside carriage assembly (see right).

Turn the nut clockwise/counter clockwise the adjust the tension (free

play) between the carriage and the tracks. If the carriage moves too

much in and out, tighten the adjustable tension bracket nut.

Correct adjustment should alow for minimal contact between the

carriage and the tracks

Step 1

If you have not already assembled the carriage assembly: Stop Now.

You must first assemble the carriage, follow the assembly instructions included in the #2 Box - “Collapsible Carriage & Plywood Attachments”.

Top Cap

Adjustable Inside Track Roller Guide

Tension Bracket

(404) 344-0000 • www.tranzsporter.com Page 7 of 16

Step 5

Lay one track section on a flat floor with the “front” side up. This is

determined by the space between the track cross bar and the track

section edge as shown above.

Step 6

Attach splice plates to the bottom section of the track. Splice plates are mounted on the outside track section. Slide the top

section track into the groves on the inside track section, attach with 2 nuts and bolts per side (Pictures 4 & 5).

NOTE: DO NOT SUBSTITUTE NUTS AND BOLTS

Use 3/8”x 3/4” bolts and 3/8” nut keeps (lockwasher and nut combined).

Front

Back

Picture 5

Picture 4

Step 7

Reattach the top cap to the end of the last section of track

section you intend to use. Assemble with two 3/8”x 3/4” hex

head bolts with lock nuts provided. Make sure that the top cap

end slides into the outside of the track section (shown right).

Assembly Instructions for the TP400 Hoist

Step 4

“Roll”carriage assembly onto the base. At this time lock

the base in place using the Safety Pin as shown.

Important: Always check for wear

or damage to the safety pin cable/

pull ring assembly. Failure to replace

damaged safety pin cable assembly

may cause damage or personal injury.

Atlanta, Georgia 30336

Page 8 of 16

Assembly Instructions for the TP400 Hoist

Double back/feed end

cable through pully on

the back of carriage

(cross bar)

Feed end cable

t

hrough pully

Unwind cable

from the back

Attach cable to

the back side of the

pully bracket

Step 8

From the back side of the hoist, remove the end of the cable from

the drum (shown right). It helps to attach the brake handle, use the

brake handle back releases the brake drum. The cable will then

easily un-spool. Staying on the outside (back) of the base section

and track section, take the cable to the top of the last track section

where the top cap pulley is attached.

Step 10

Remove the nyloc nut/washer/lock washer, from the

top cap assembly, place the eye end over the bolt,

replace the washer/lock washer and tighten the nyloc

nut as shown right.

Bolt

Cable Eye/End

Nyloc Nut

Cable is

looped around

carriage pully

Lock Washer

Washer

Top Cap

Step 9

Feed the cable end through the pulley as shown above,

and down the front side of the track section to the

back of the carriage assembly.

Feed the cable end through the pully on back of

TP400 carraiage. Return the cable end to the top cap.

(404) 344-0000 • www.tranzsporter.com Page 9 of 16

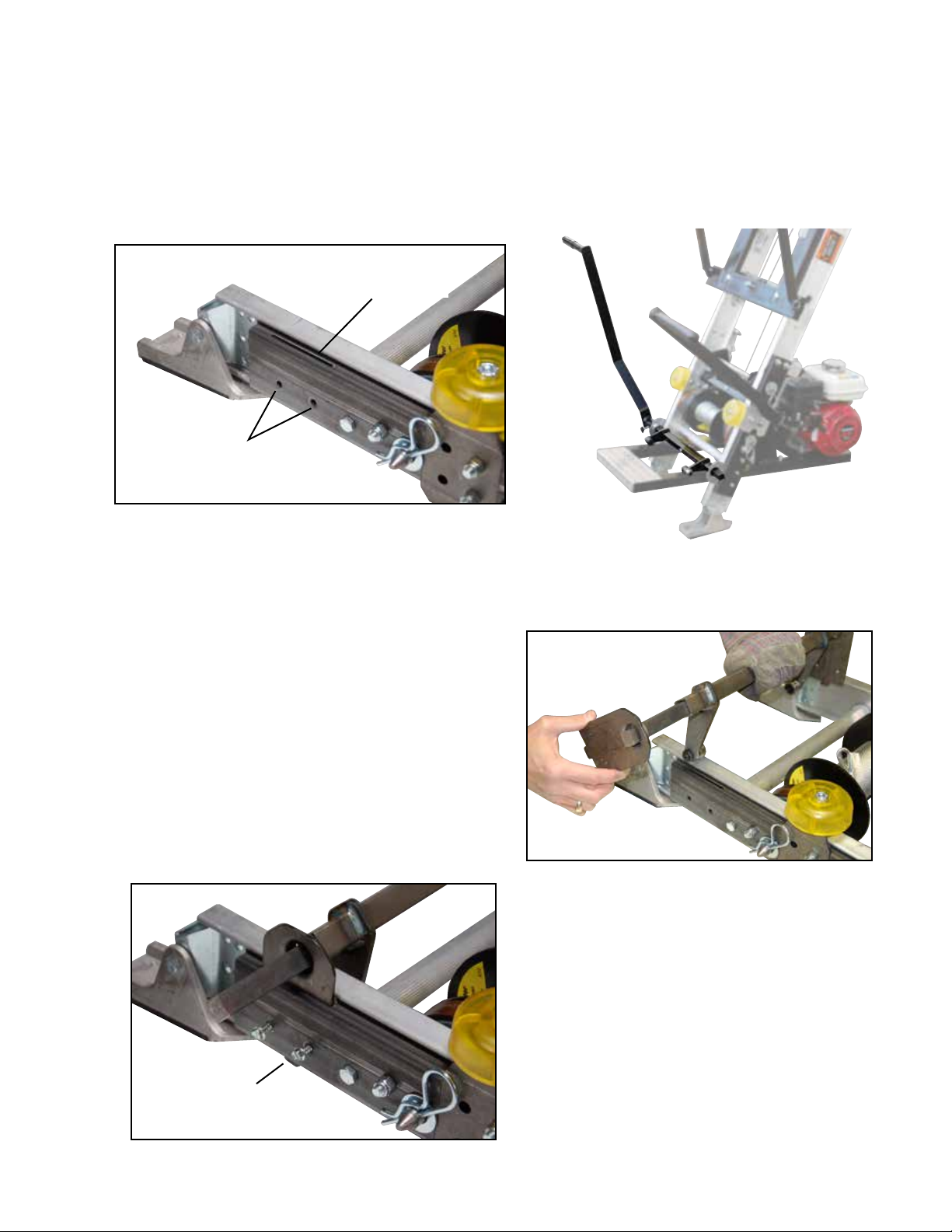

Engine Base

Assembly Arm

Engine Base

Assembly Arm Retaining

Rings

Step 12

Mount the motor assembly to the base unit; from behind the hoist; the foot pad of the motor base slides under the track base section,

while “hanging” the motor base. The motor assembly arms must fit outside the two retainer rings shown above.

Step 11

See “Raising Hoist” instructions (page 12 ) for proper positioning/placement of base at the set at job site.

Step 13

Before starting the engine...

Attach the “V” belt to the large pulley (next to cable drum assembly on

track base), then to the small pulley on the motor base (shown right).

Step 14

Slide the brake handle over the brake arm and tighten thumb screw provided.

Step 15

If needed, remove plywood brackets and rotate 90 degrees. Secure the

two plywood/rolled goods brackets with push pins provided (shown right).

IMPORTANT:

When lifting panel goods, panels must be secured with tie down straps.

Atlanta, Georgia 30336

Page 10 of 16

Assembly Instructions TP250/400 Secondary Handle Kit #48468 (Purchased Separately)

Allows use of a left side handle to engage the motor and carriage. It is highly recommended when using with the Solar/Plywood Saddle

Carriage. Can be used for both TP250 & TP400 models.

Parts included with the Secondary Handle Kit:

1) Handle. 2) Pivot/Brake Weldmont

3) 2 Mounting Plates 4) 4 Screws

Step 1

Lay the base section flat on a hard surface. Locate the mounting slot

and holes on the bottom portion of the base section.

Step 2

With one hand, hold the pivot/brake weldment just

above the lower base section. Slide the mounting

plates over the pivot/brake rod. Make sure the raised

hole side of the mounting plates goes on the inside.

Step 3

Holding the pivot/brake weldment/mounting plates with one

hand; slide the mounting plates into the slots on both sides

of the base section. The plates should slide into place with the

notch fitting thru the base section.

Using the two holes provided; insert two screws per side.

Tighten screws using a screw driver or wrench.

Attach secondary handle on either side of the hoist.

Mounting Holes

Mounting Plate

“Notch”

Mounting Slot

(404) 344-0000 • www.tranzsporter.com Page 11 of 16

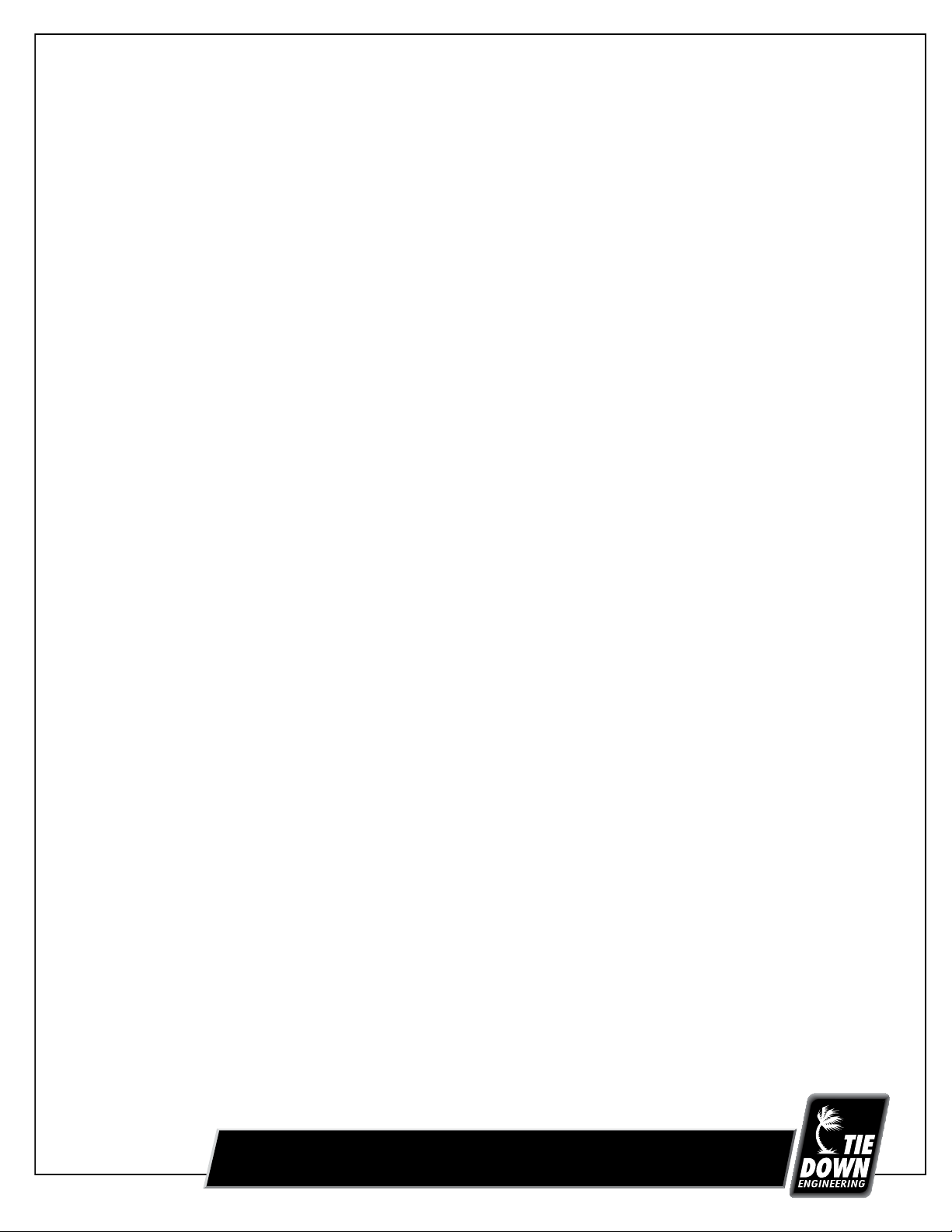

Raising the Track Section Assembly

WARNING: KEEP TRACK SECTIONS CLEAR OF ALL ELECTRICAL WIRES

AND EQUIPMENT. BE AWARE OF OVERHEAD WIRES BEFORE RAISING

TRACK SECTIONS. ELECTRICITY KILLS!

The hoist assembly is extremely top heavy and must be kept under control at all times. Two alternate

methods are suggested for raising the platform hoist to the operating position. See Track Section

Support Chart (page 13) for approximate distances of the base from the bottom track.

Procedure “A”

This procedure requires two or preferably three men.

1. Lay the assembled track sections with the platform attached parallel to the building wall that is to support the hoist.

2. Tie a rope to the head bracket and have the man on roof pull up the hoist while the other man on the ground braces the shoes on

the bottom base section to prevent slippage of the hoist shoes. The third man on the ground may aid in erecting by “walking”

the hoist up hand over hand by the rungs.

3. When the hoist reaches a vertical position, carefully turn the hoist 90 degrees with the platform pointing away from the building.

Move the bottom of the hoist away from the building 1/4 of the height of the building where the top of the hoist is to be supported.

Make allowances for overhang.

Procedure “B”

1. Place track section assembly perpendicular to the building with the bottom shoes of the steel bottom section resting against the

building to prevent slipping.

2. Tie a rope to the top bracket and have the man on the roof pull up the hoist while the other man on the ground braces the shoes

on the steel bottom base section to prevent slippage of the hoist shoes. The third man on the ground may aid in erecting by

“walking” the hoist up hand over hand by the rungs.

3. When the hoist reaches a vertical position, move the bottom of the hoist away from the building 1/4 of the height of the building

where the top of the hoist is to be supported. Angle of track sections from building should be between 18 and 20 degrees.

Make allowances for an overhang. See track section chart for approximate distances of the base from the building.

4. Tie the track section to the roof with a rope fastened to a cross tie on the top bracket to prevent slippage of the track section.

DO NOT TIE ROPE TO THE RAILS - THIS WILL PREVENT THE PLATFORM FROM OPERATING PROPERLY.

5. Mount the power unit to the top rung of the bottom base section. Attach the V-belt to the pulley on the power unit. Slide the

brake handle over the brake arm and install the locking pin provided.

6. Remove any ropes used to secure the platform during transportation.

7. Make certain the shoes on the steel bottom section are firmly resting on level ground. This will help to prevent track section

slippage or uneven loading of the track section which could cause damage or injury to personnel and/or to equipment.

Atlanta, Georgia 30336

Page 12 of 16

Gasoline Engine

1. Handle fuel with care. It is EXTREMELY flammable and explosive under certain conditions.

2. Do not smoke, allow open flames or sparks to be present during the refueling operation.

3. Use only an approved fuel container to transport fuel.

4. Do not fuel while engine is hot - allow to cool before attempting the refueling operation.

5. Replace all fuel tank caps securely and wipe the spilled fuel before restarting engine.

6. Do not operate the TP-Series gasoline engine in an enclosed area. The exhaust can be especially hazardous and cause death

in an enclosed area.

7. Stop the engine and lower the platform when leaving the vicinity of the hoist.

8. Always stop the engine, lower the platform, wait for all moving parts to stop, and allow the engine to cool before disassembling

or moving the hoist.

9. Disconnect the spark plug wire from the plug before disassembling or moving the hoist.

10. DO NOT store the engine in an enclosed area.

11. Allow engine to cool before storing.

12. DO NOT store engine where it might be subjected to flames, sparks, extreme heat or any other source of combustion.

15640-2

WARNING

DO NOT REMOVE THIS TAG!

SHOCK HAZARD

KEEP ENTIRE LIFT HOIST

CLEAR OF ALL UTILITY

AND ELECTRICAL WIRING!

15641-2

DO NOT REMOVE THIS TAG!

IMPORTANT SAFETY INFORMATION

• TOP OF HOIST MUST BE SECURED TO ROOF USING “S” HOOKS (PROVIDED)

AND TWO LENGTHS OF ROPE (NOT PROVIDED)

• BRAKE TENSION SPRINGS MUST BE CHECKED FOR CORRECT TENSIONING DAILY

(BEFORE USE) IN ORDER TO PREVENT LOAD SLIPPAGE

• KEEP BRAKE DRUMS AND BRAKE SHOES FREE OF OIL, LUBRICANTS, AND

EXCESSIVE MOISTURE, CHECK FOR DAILY WEAR AND REPLACE WHEN NECESSARY

• DO NOT OPERATE THIS UNIT IF ANY COMPONENT PARTS EXHIBIT DAMAGE

OR WEAR. THIS INCLUDES ALL TRACK SECTIONS

WARNING

SAFETY LATCH MUST BE

ENGAGED WHEN LIFT

HOIST IS NOT IN USE

DO NOT REMOVE THIS TAG!

15642-2

(404) 344-0000 • www.tranzsporter.com

WARNING: BEFORE LOWERING THE TRACK SECTIONS, CAREFULLY CHECK FOR OVERHEAD OBJECTS

AND POWER LINES. ELECTRICITY KILLS

Raising the platform with or without load

WARNING: THE OPERATOR OF THIS HOIST UNIT SHOULD WEAR APPROPRIATE SAFETY EQUIPMENT WHICH SHOULD

INCLUDE APPROVED HAND PROTECTION, HEAD PROTECTION AND EYE PROTECTION.

To raise the platform on the TP250, face the platform and stand as far as possible from the hoist to operate. Place your foot on the

foot control pad to engage the motor to the cable drums V belt, permitting the platform to roll up the track section. When the platform

reaches the top, release foot IMMEDIATELY. This will apply the self energizing brakes. Move away from the hoist while the load is

being removed from the platform.

Lowering the platform

To lower the carriage, stand to the right or left side of the hoist and grasp the brake handle. Lightly feather the platform down by

engaging and disengaging the brake to slow the carriage. Lower the carriage to the ground at a slow speed (not to exceed 50/feet per

minute). Continue to decelerate the platform as it nears the ground to prevent damage to the platform or bottom bumper stops.

DO NOT USE THE HOIST TO LOWER MATERIALS.

CAUTION: NEVER APPLY THE BRAKE ABRUPTLY - BROKEN HOIST CABLES AND/OR SEVERE INJURY TO PERSONNEL OR

EQUIPMENT MAY OCCUR. MAKE CERTAIN PLATFORM DOES NOT EXCESSIVELY STRIKE THE BOTTOM BRACE STOPS UPON

REACHING THE BOTTOM OF THE TRACK SECTION.

Lower and dismantle the platform hoist assembly in the reverse of the erection procedure, observing all safety procedures.

Track Section Chart - Brace Support and Proper Set Up Distance at Job Site

Track lengths in excess of 28 feet require the use of the telescoping brace (#60005). The table below provides the suggested

information for the distance of the bottom track from the building and the location of the track support for various conditions.

Building Length of Base To Track Brace Location

Height Track Building Cross Tie from Bottom

12’ 16’ 4’-6” Not Required

16’ 20’ 5’-0” Not Required

20’ 24’ 6’-6” Not Required

24’ 28’ 6’-6” Not Required

28’ 32’ 7’-6” 11th and 13th

32’ 36’ 8’-0” 14th and 16th

36’ 40’ 9’-0” 19th and 21st

40’ 44’ 10’-0” 26th and 25th

42’ 44’(max) 10’-6” 25th and 27th

REPAIR INFORMATION

Your lift hoist is designed to provide years of service, however, when your hoist requires parts, service or repairs, please contact

your nearest authorized dealer, or call 1-800-241-1806, Ext. 1525 for information on where to take your platform hoist.

Page 13 of 16

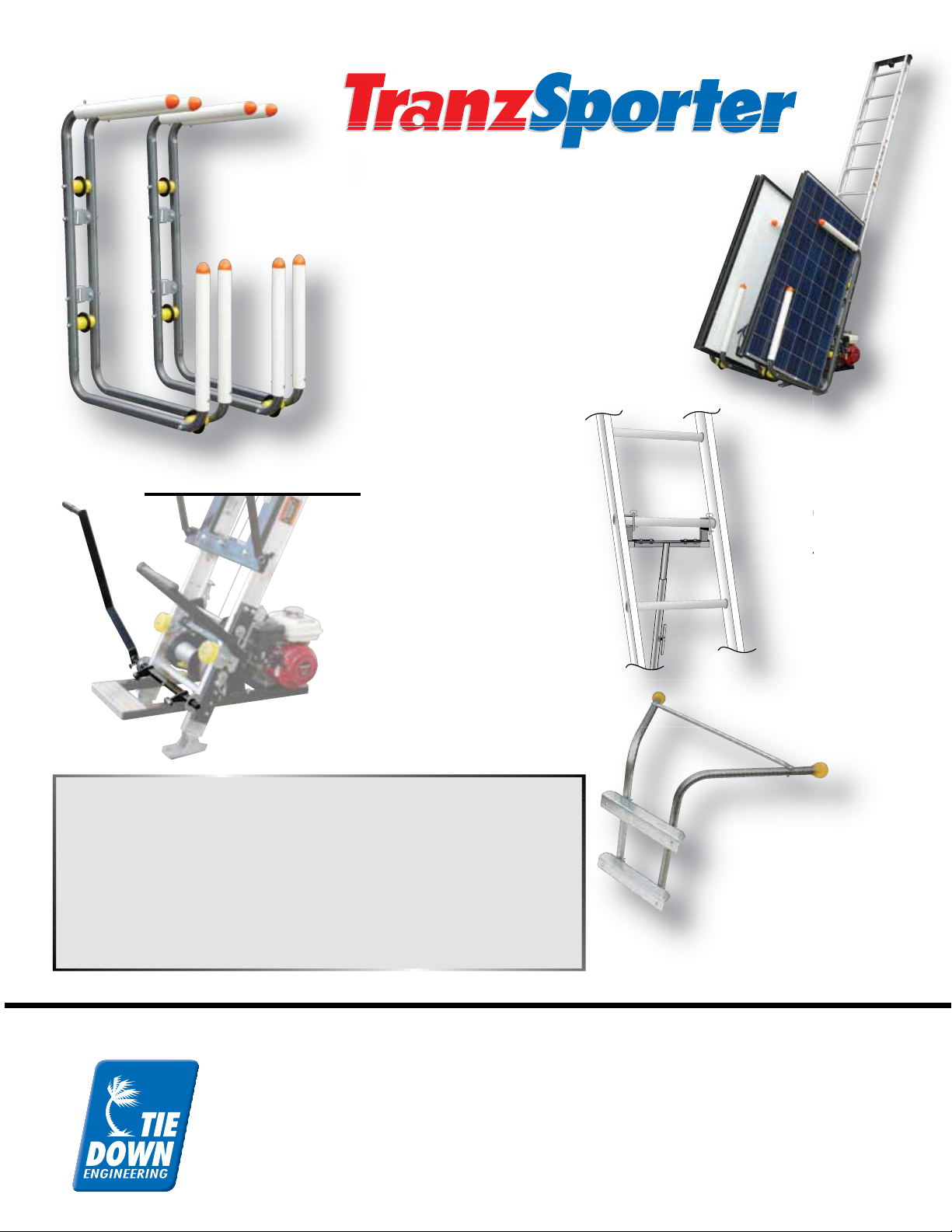

Plywood/Flat Panel Tie Down and Lifting Instructions

Plywood Bracket

Tie Downs -

Secure straps through

slotted holes provided.

Tie down strap

must loop over

all materials and

must attach at

tie down locations.

NOTE:

ALWAYS CENTER FLAT

PANEL LOADS

Platform Back

Flap Tie Down -

Secure straps through

flap slots provided

on back.

WARNING WARNING WARNING

FAILURE TO READ AND UNDERSTAND THE OPERATING

INSTRUCTIONS CAN RESULT IN PROPERTY DAMAGE,

PERSONAL INJURY OR EVEN DEATH TO USER OR OTHERS

• Use the proper tie down equipment - If you are not securing your cargo with the

proper safety straps, it could come loose during lifting, resulting in injury or death.

• Never hoist anything wider than the 8” - larger plywood sheets can make

controlling your hoist difficult and dangerous, especially when considering

windy conditions. Wide panels must be centered to prevent tipping.

• Attach your safety straps to slotted tie-down points - Do not hook your tie-down straps

to the plywood, straps must pass over the top. Secure your safety straps to the carriage

top flaps slotted holes (the metal frame) and to the plywood brackets only (Refer

to the drawings for tie down slot locations).

• Maintain a manageable speed - The wind’s effects on sheets of plywood or panel

goods, as well as the higher center of gravity, can make hoisting difficult

and dangerous.

• Check all tie-down connections. Safety straps may come loose during transport.

Always check strap for damage or wear. Replace when damaged or worn.

Tie Down Strap Slots Tie Down Strap Slots

Plywood Bracket

Tie Downs -

Secure straps through

slotted holes provided.

Tie down strap

must loop over

all materials and

must attach at

tie down locations.

NOTE:

ALWAYS CENTER FLAT

PANEL LOADS

Platform Back

Flap Tie Down -

Secure straps through

flap slots provided

on back.

WARNING WARNING WARNING

FAILURE TO READ AND UNDERSTAND THE OPERATING

INSTRUCTIONS CAN RESULT IN PROPERTY DAMAGE,

PERSONAL INJURY OR EVEN DEATH TO USER OR OTHERS

Atlanta, Georgia 30336

Page 14 of 16

TIE DOWN ENGINEERING • Atlanta, GA 30336

www.tiedown.com (404) 344-0000

TRANZSPORTER PRODUCT LINE LIMITED WARRANTY

Tie Down Engineering will repair or replace, free of charge, any part, or parts of the TranzSporter lift hoist that are defective

in material or workmanship or both. The limited warranty is in effect for 90 days from date of purchase. Return the defective

unit to the dealer or contact Tie Down direct at 800-241-1806, x1525.

This warranty does not apply to damage or loss caused by any or all of the following circumstances or conditions:

• Damage caused during assembly or installation.

• Parts, accessories, materials or components used with or replacing any TIE DOWN lift hoist part not obtained from or

approved in writing by TIE DOWN.

• Misapplication, misuse and failure to follow the directions or observe cautions and warnings on installation, operation,

application, inspection or maintenance specified in any TIE DOWN quotation, acknowledgment, sales literature,

specification sheet or installation instruction and service manual ("applicable literature").

• Use of product in any other application other than those described in TIE DOWN’s product information materials.

If any TIE DOWN products are found upon TIE DOWN's examination to have been defective when supplied, TIE DOWN will

either: credit the purchaser's account for the purchase price of the TIE DOWN product; replace the TIE DOWN product; or

repair the product. TIE DOWN has sole discretion in choosing which option to provide. For this LIMITED WARRANTY to

apply, TIE DOWN must receive notice of the alleged defect within 30 days of either the discovery of the alleged defect or

the expiration of the warranty period, whichever is earlier. Any claim not made within this period shall conclusively be

deemed waived.

If requested by TIE DOWN, purchaser shall return the alleged defective product to TIE DOWN for examination at purchasers

expense. TIE DOWN will not pay for expenses incurred in returning a product to TIE DOWN without TIE DOWN's prior written

authority. TIE DOWN shall not be liable for any other expenses purchaser incurs to remedy any defect. Purchasers waive

subrogation on all claims under any insurance.

Limitation of Liability: It is expressly agreed that the liability of TIE DOWN is limited and TIE DOWN does not function as

an insurer. THE REMEDIES SET FORTH IN THIS WARRANTY SHALL CONSTITUTE THE EXCLUSIVE REMEDIES AVAILABLE TO

THE PURCHASER OR USER AND ARE IN LIEU OF ALL OTHER REMEDIES, EXPRESS OR IMPLIED. THE LIABILITY OF TIE DOWN,

WHETHER IN CONTRACT, IN TORT, UNDER ANY WARRANTY OR OTHERWISE, SHALL NOT EXCEED THE PURCHASE PRICE OF

THE PARTICULAR PRODUCT MANUFACTURED, SOLD OR SUPPLIED BY TIE DOWN.

To Obtain Technical Assistance: To enable TIE DOWN to respond to a request for assistance or evaluation of customer or

user operating difficulty, please provide at a minimum the following information by calling 404-344-0000:

• Model number, serial number and all other data on the specific component which appears to be involved in the difficulty.

• The date and from whom you purchased your TIE DOWN product.

• State your difficulty, being sure to mention at least the following: application, nature of load involved, and

weight of the load.

THIS WARRANTY DOES NOT COVER NOR EXTEND TO INCIDENTAL OR CONSEQUENTIAL DAMAGE. Some states do not

allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply

to you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

No representative has authority to make any representation, promise or agreement except as stated in this Limited

Warranty. TIE DOWN reserves the right to make design and other changes upon its products without any obligation to

install the same on any previously sold or delivered products.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THOSE DESCRIBED ABOVE. EFFECTIVE JANUARY 2015 THIS

WARRANTY SUPERSEDES ALL PRIOR WARRANTIES, WRITTEN OR IMPLIED.

E1401/Rev. 030615

Page 15 of 16

Hoist Accessories

H

Solar/Plywood Panel Saddle Carriage

Allows lifting of four solar panels or plywood

sheets. Unique design allows panels to roll

off towards the contractor, preventing leaning

while on the roof top. Requires roof top

anchoring; straps included with carrier.

Solar/Plywood Panels attach to TP400

carriage frame. Solar/Plywood Panel Kit

#48469 is a complete carriage system for use

with the TP250.

Secondary Handle Kit

Allows use of a left side handle to

engage the motor and carriage. It

is highly recommended when

using with the Solar/Plywood

Saddle Carriage. Includes all

hardware brackets and handle.

Can be used for both TP250 &

TP400 models.

Part # Hoist Accessories

48467 TranzSporter Solar/Plywood panel accessory for TP400 Platform Hoist

48469 Complete Solar Carrier for TP250

48468 Secondary Handle Kit for TP250 & TP400

10092 4 ft. TranzSporter Track Section for TP250 and TP400

10091 8 ft. TranzSporter Track Section for TP250 and TP400

60005 Telescopic Support Brace for TP250 and TP400

48599 TranzSporter Stand-Off/Stabilizer

Telescopic

Support Brace

Used with TP250 &

TP400 models over

28 ft.

Telesco

p

Su

pp

ort

Used wi

t

TP400

m

28 ft.

Solar/Plywood Saddle

Stand-Off/Stabilizer

This unique stabilizer attaches

to the platform hoist track

section allowing proper

stand-off from roof and gutter.

Helps prevent costly gutter

damage when placed directly

on roof. Assembly required.

Roofing Products Division

TIE DOWN ENGINEERING

Atlanta, Georgia 30336

800-241-1806 • 404-344-0000

ISO 9001:2008 Certification

Trade, brand, names and drawings are the intellectual property of

TIE DOWN ENGINEERING. ©2014 TIE DOWN, Inc.

Manual #08238 (Rev. 3-23-2015) Page 16 of 16

Other manuals for TP250

3

This manual suits for next models

1

Table of contents

Other TRANZSPORTER Lifting System manuals

Popular Lifting System manuals by other brands

Auton

Auton 3000-INH installation manual

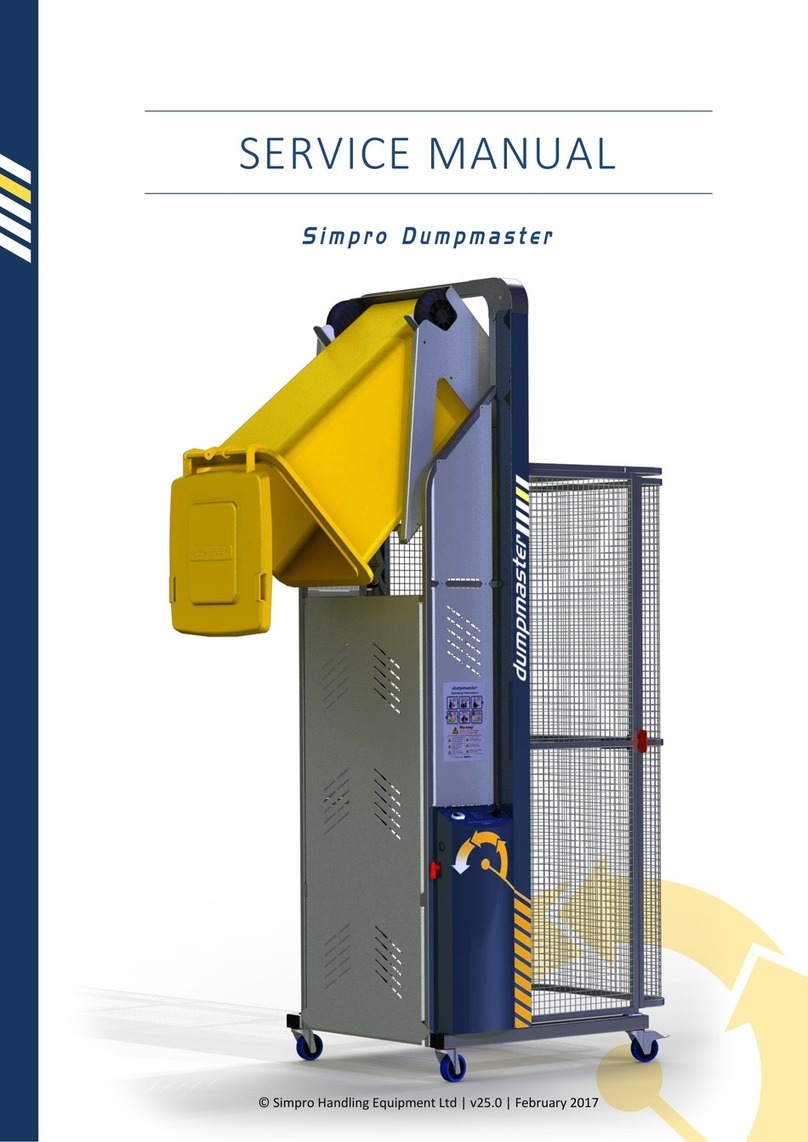

Simpro

Simpro Dumpmaster Service manual

Joerns Healthcare

Joerns Healthcare Hoyer HPL402 User instruction manual & warranty

Rotary

Rotary MCH14 Series Installation-safety-operation-maintenance

AMGO

AMGO A240 Installation and service manual

Handicare

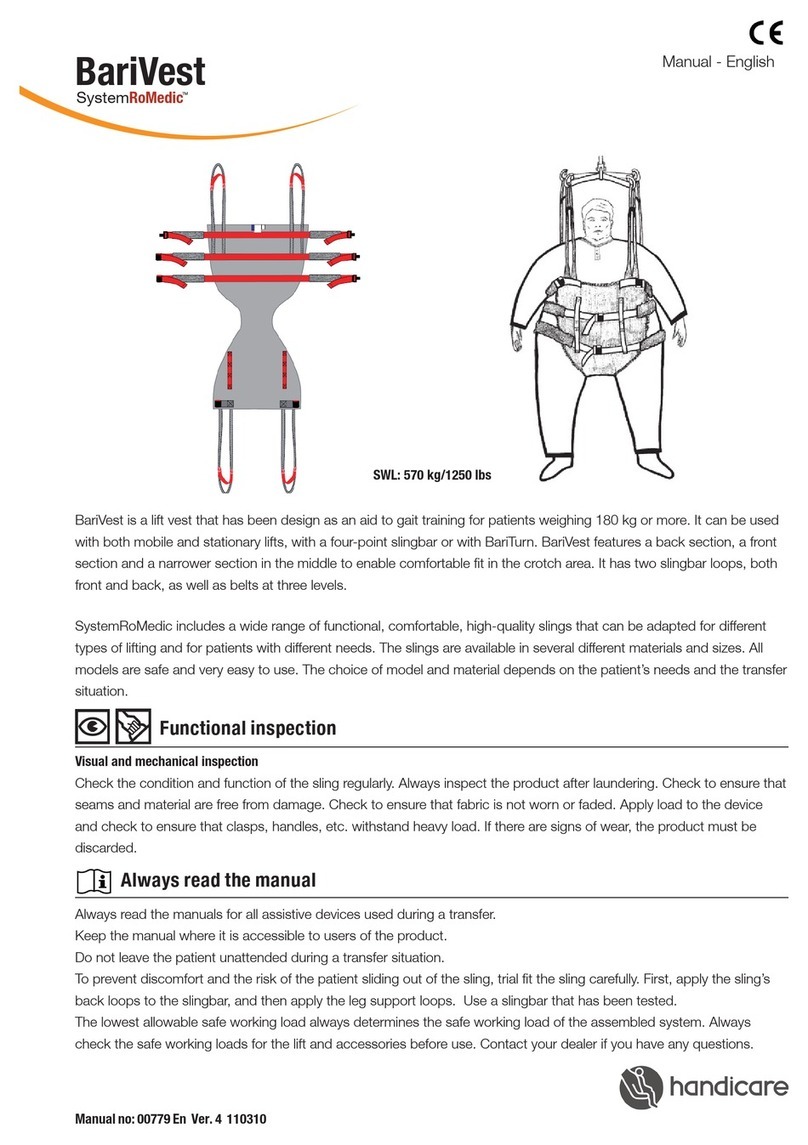

Handicare SystemRoMedic BariVest XXXL manual

The Handy

The Handy OX 1800 operating instructions

LGMG

LGMG A30JE Maintenance manual

Custom Elevator

Custom Elevator HYD-7.540 owner's manual

Liko

Liko UltraTwin FreeSpan Instruction guide

American Access

American Access Entrada Series installation manual

Strong Racks

Strong Racks PowerRax Double Bike Lift manual