Clarke CAT152 Instructions for use

Other Clarke Water Filtration System manuals

Clarke

Clarke CAT183 Installation and operation manual

Clarke

Clarke FR1 User manual

Clarke

Clarke CAT186 Installation and operation manual

Clarke

Clarke Air CAT159 Installation and operating instructions

Clarke

Clarke CAT180 Installation and operation manual

Clarke

Clarke CAT184 Installation and operation manual

Clarke

Clarke CAT192 Installation and operation manual

Clarke

Clarke CAT191 Installation and operation manual

Clarke

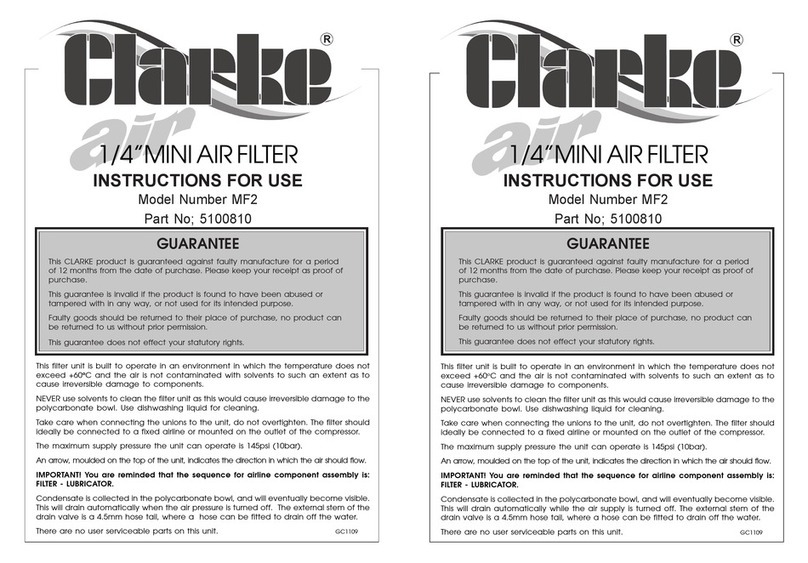

Clarke MF2 User manual

Clarke

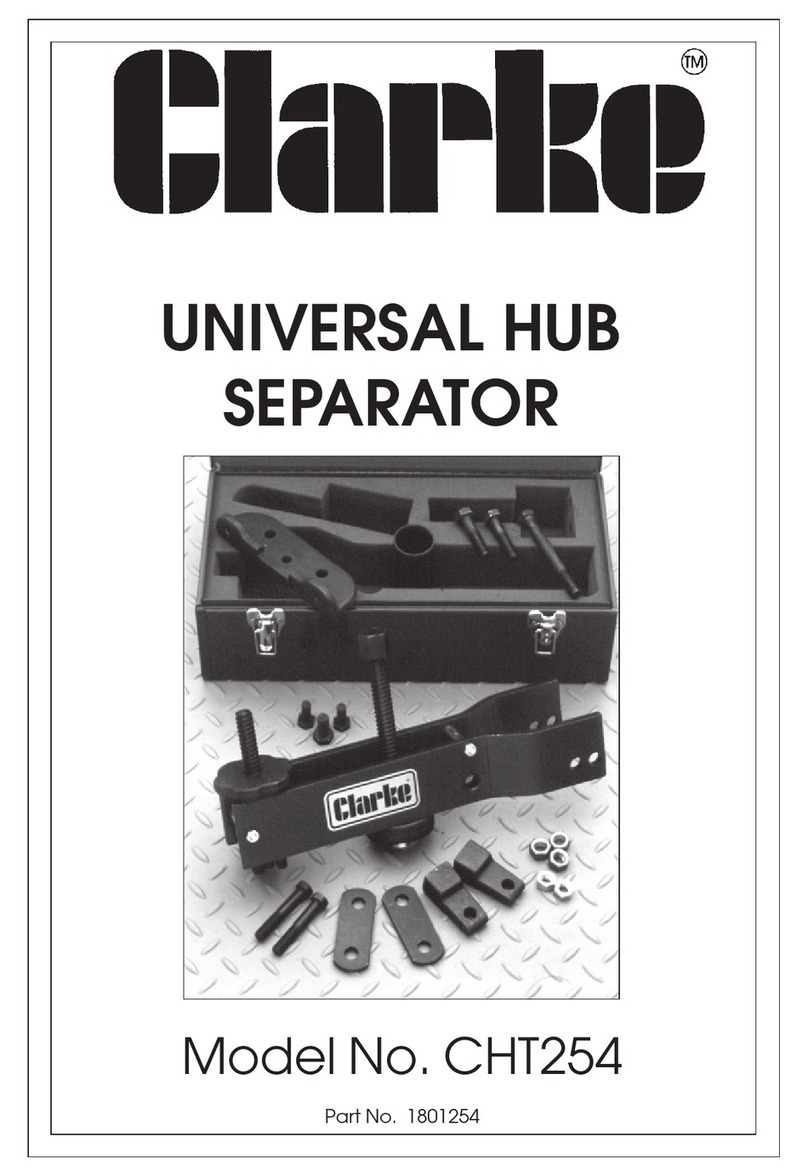

Clarke CHT254 User manual

Clarke

Clarke CMF2 Installation and operation manual

Clarke

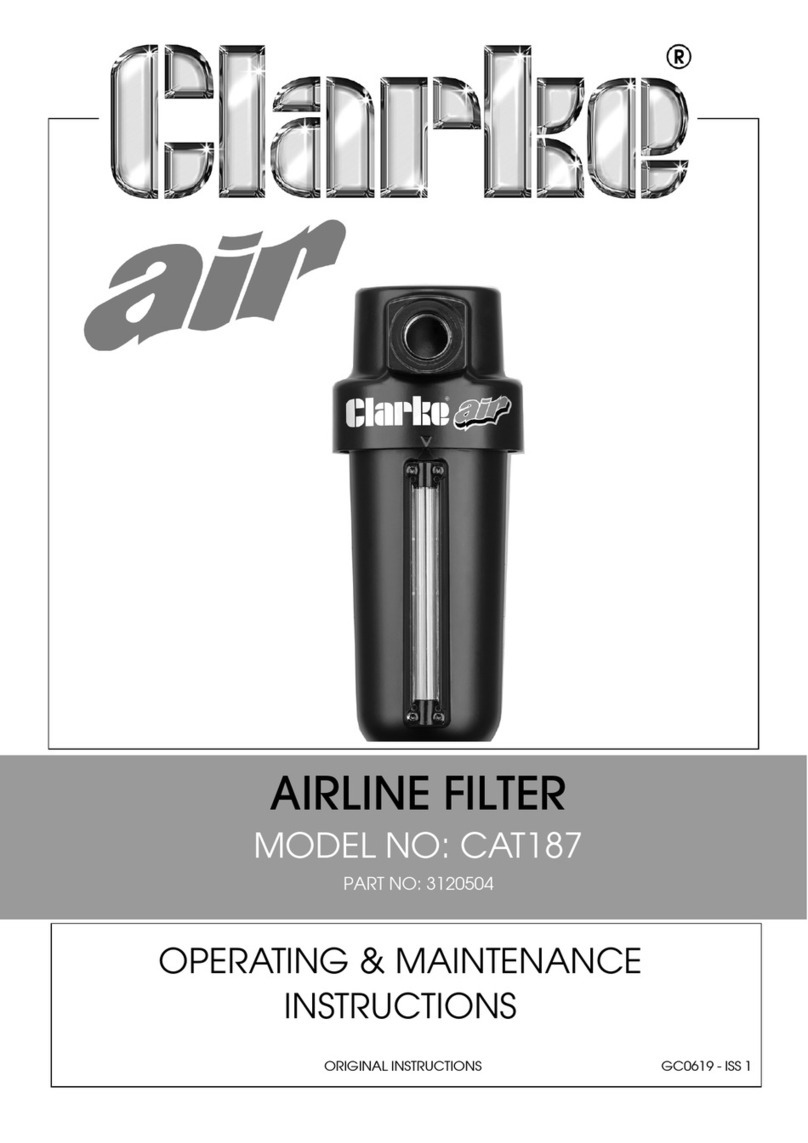

Clarke CAT187 Installation and operation manual

Clarke

Clarke CAT197 Installation and operation manual

Clarke

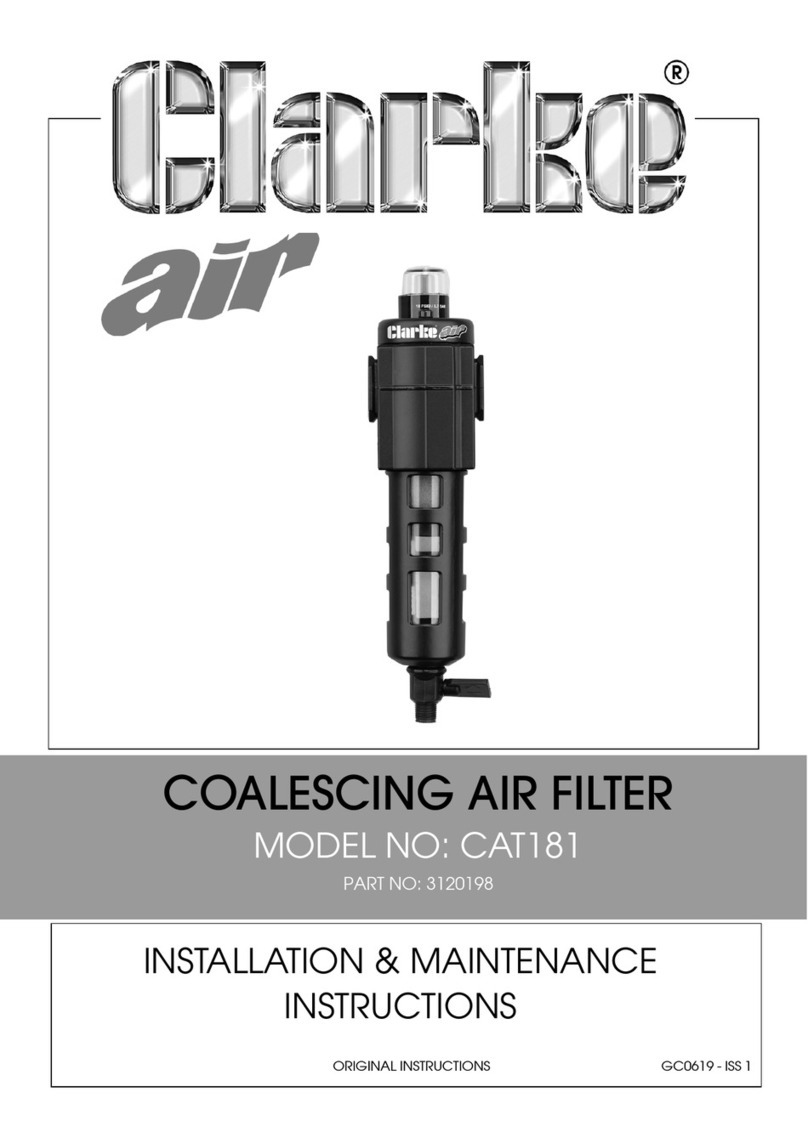

Clarke CAT181 Installation and operating instructions

Clarke

Clarke CAT193 Installation and operation manual

Clarke

Clarke CAT185 Installation and operation manual

Clarke

Clarke CAT182 Installation and operating instructions

Clarke

Clarke CAT161 Manual

Popular Water Filtration System manuals by other brands

Wisy

Wisy LineAir 100 Installation and operating instructions

Schaffner

Schaffner Ecosine FN3446 Series User and installation manual

Pentair

Pentair FLECK 4600 SXT Installer manual

H2O International

H2O International H20-500 product manual

Renkforce

Renkforce 2306241 operating instructions

Neo-Pure

Neo-Pure TL3-A502 manual