Traulsen G-Series User manual

MASTER SERVICE MANUAL

For All Full Size Undercounter, G-Series and R&A

Refrigerator, Freezer, Dual-Temp and Hot Food

Units

Traulsen

4401 Blue Mound Road Fort Worth, Texas

76106 Phone: (800) - 825 - 8220

Part Number 375-60351-00 Form Number TR36015 revised 3/17

1

Introduction

Traulsen provides this manual as an aid to the service technician in installation, operation and

maintenance of Traulsen units from year 2010 to present. When used properly. This service manual can

help the service technician maintain, troubleshoot and diagnose most of the problems and malfunctions

that may occur with the controllers. While we believe that most aspects of the controllers are covered in

this manual should you encounter a condition not addressed, or require a wiring diagram please

contact.

ITW Refrigeration

Traulsen

4401 Blue Mound Road Fort Worth, TX 76106

Attn: Service Department

Phone: (800) 825-8220

Fax: (817) 740-6757

To improve your service communication experience be sure to have the following available when

contacting technical support:

✓Serial number

✓Model number

✓A detailed explanation of the problem.

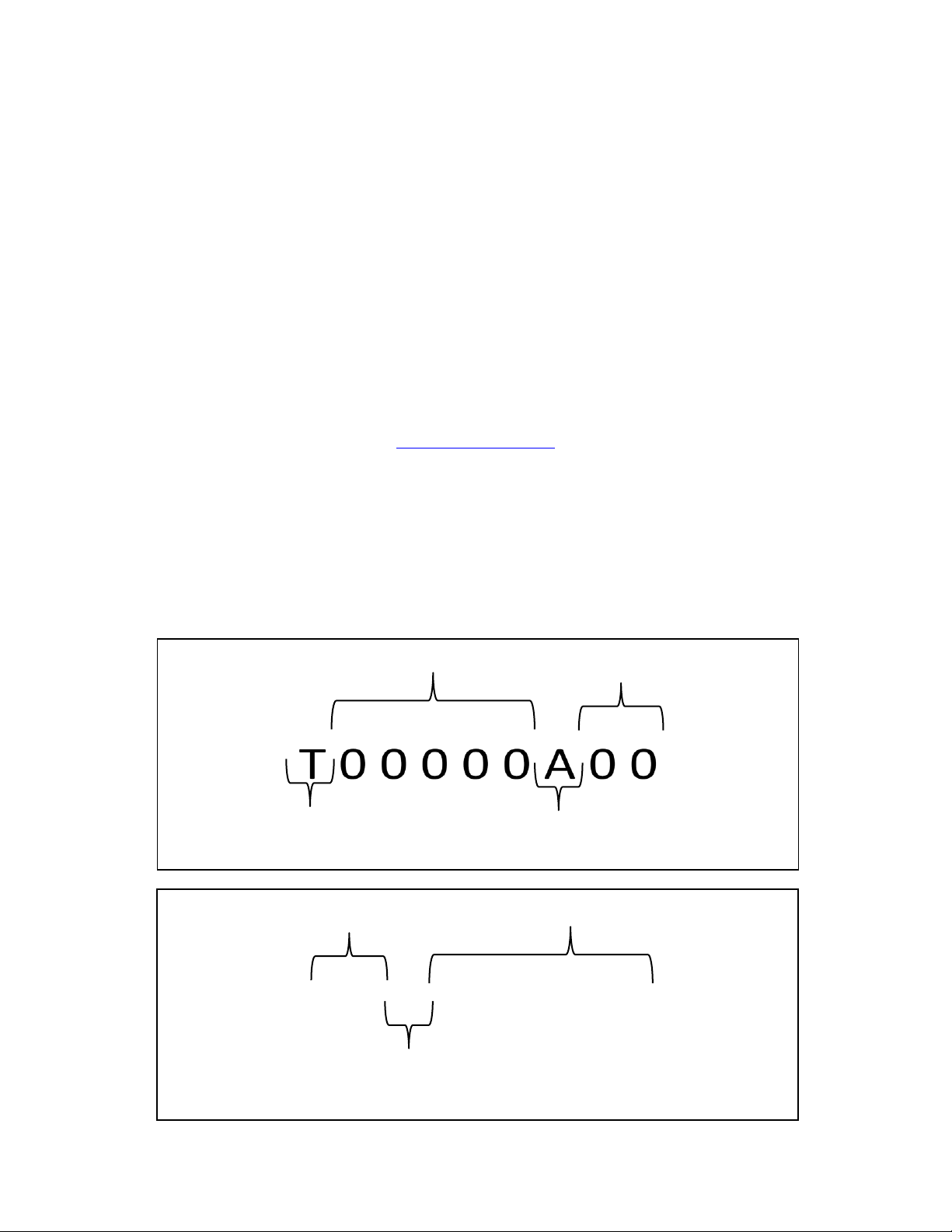

How to Read a Traulsen Serial Number

T FOR TRAULSEN

INDICATES WHERE BUILT

ALL SERIALS START WITH T OR V

MANUFACTURE MONTH CODE

A=JANUARY; B=FEBUARY; C=MARCH……..

LAST 2 DIGITS OF MANUFACTURE YEAR

UNIQUE SERIAL CODE

MANUFACTURE MONTH CODE

A=JANUARY; B=FEBUARY; C=MARCH……..

FIRST 2 DIGITS OF MANUFACTURE YEAR

UNIQUE SERIAL CODE

1 7 A 0 0 0 0 0 0

2

TABLE OF CONTENTS

Section I

Intela-Traul Control System

Page

a.

Intela-Traul Control System Overview

4

b.

Intela-Traul Alarm Codes from 2010 to present

5

c.

Control Access & Programming

6

d.

Troubleshooting Traulsen Intela-Traul Sensors

7

e.

Troubleshooting Traulsen Intela-Traul MIT II relay module

10

f.

RH Sensor Module

12

Section II

Refrigeration System

a.

Troubleshooting Traulsen Refrigeration System

14

b.

TXV Troubleshooting

15

c.

Troubleshooting a Frozen Evaporator Coil

16

d.

Compressor Troubleshooting

17

Section III

Compact & Milk Cooler Controls

a.

Danfoss Control Electronic Controller

20

b.

Danfoss Control Sensors

21

c.

Milk Cooler Temperature Checklist

22

Section IV

Preventive Maintenance

a.

Preventive Maintenance

24

Section V

Door Frame Heaters

a.

Door Frame Heater installation

27

b.

Door Frame Heaters in Roll-In units

30

c.

Door Frame Heaters in Half Height units

31

Section VI

Wiring Diagrams

a.

G & R/A Series

33

b.

UHT Danfoss Series

34

c.

ULT Danfoss Series

35

d.

Milk Cooler Danfoss Series

36

Section VII

G-Series Control (Blue Display)

a.

Control Overview

38

b.

Control Programing

39

c.

Display Errors

44

d.

Control Board Detail

45

Section VII

R/A-Series Control (Green Display)

a.

Control Overview

48

b.

Control Programing

49

c.

Control Board Detail

54

3

Section I

Intela-Traul Control System

4

I. a –Intela-Traul Control System Overview

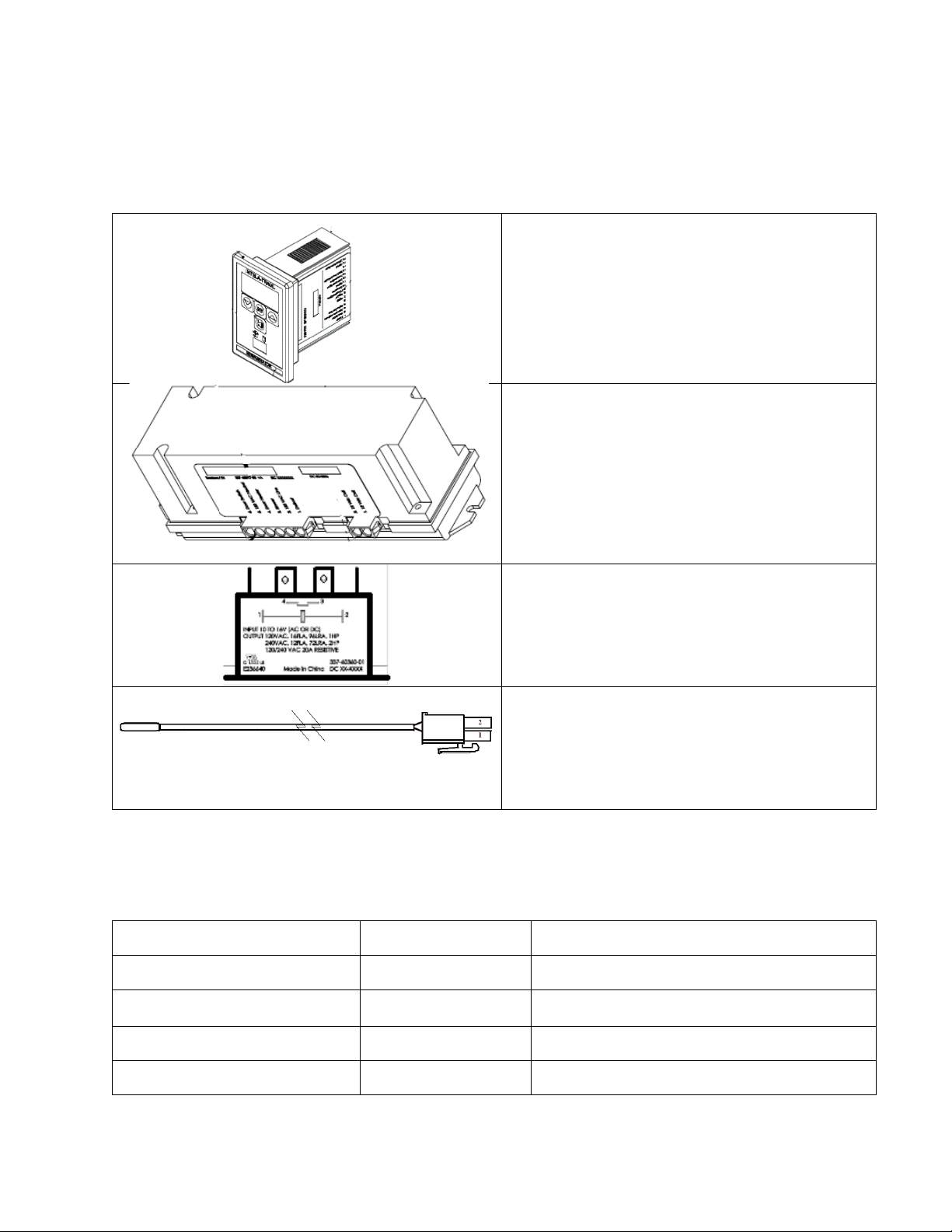

Intela-Traul Components:

Component

Description

Control Head

•Microprocessor Control

•User Interface

Relay Module

•DC Power Supply

•Blower Relay

•Defrost Heater Relay

•Door Frame Heater Relay

•Supplies 12VDC to Compressor Relay

Hybrid Relay

•Hybrid Solid State Relay

•Compressor/Condenser Relay

•12VDC Coil Voltage

Sensors

•Green –Cabinet Air

•Blue –Evaporator Coil

•Yellow –Liquid Line

Table 1

Basic Control Function:

Function

Component

Trigger

Cycles Door Frame Heaters

Door Frame Heaters

Based on Control Settings (will vary)

Cycles Evaporator Blower Motor

Evaporator Blower

Based on Control Settings (will vary)

Controls Defrost Cycle

Defrost Heater

Time Initiated, Terminated by Blue Evap Coil

Sensor Temp

Cycles Refrigeration System

Refrigeration System

Green Cabinet Air Sensor Temp

Triggers Alarm/Trouble Code

Alarms

Based on Control Settings

Table 2

5

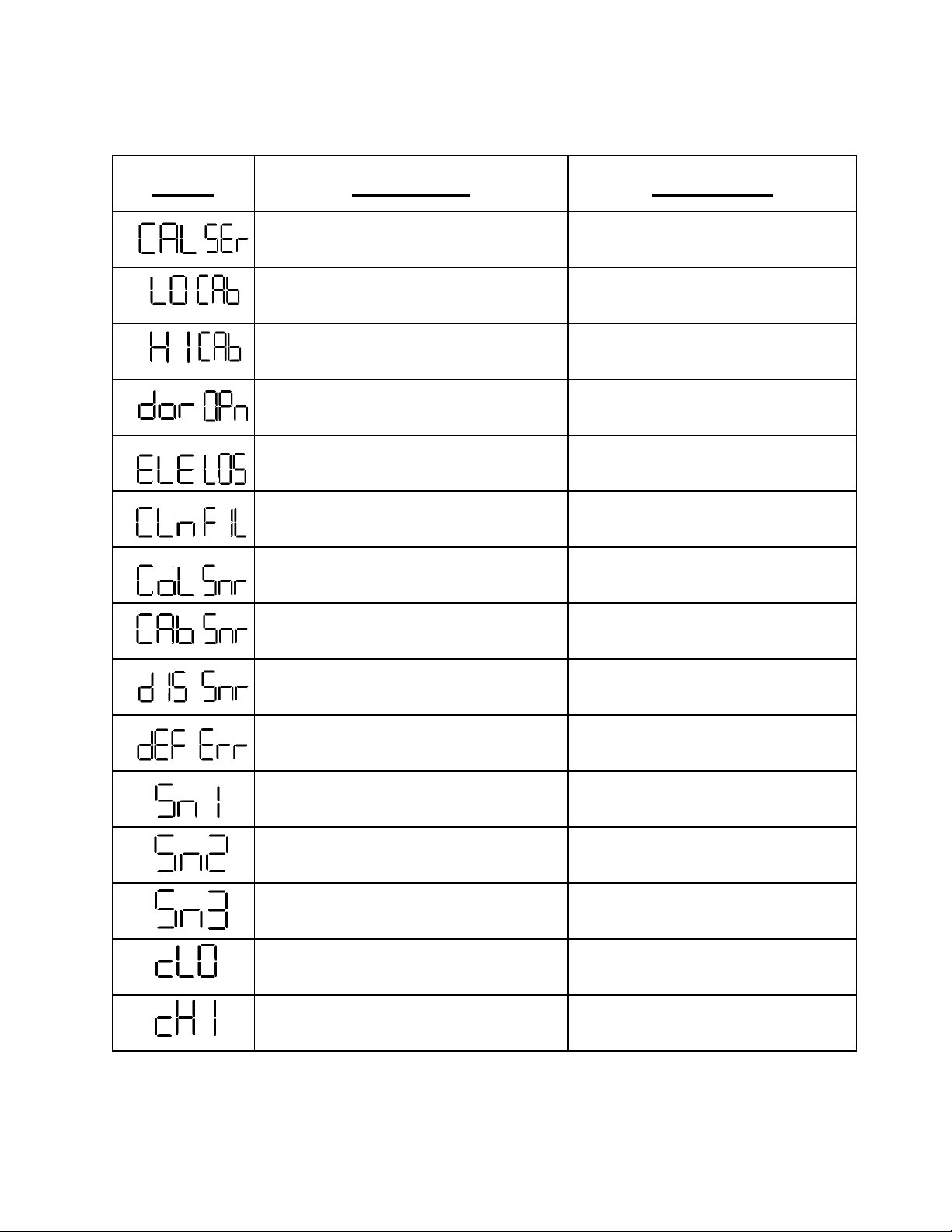

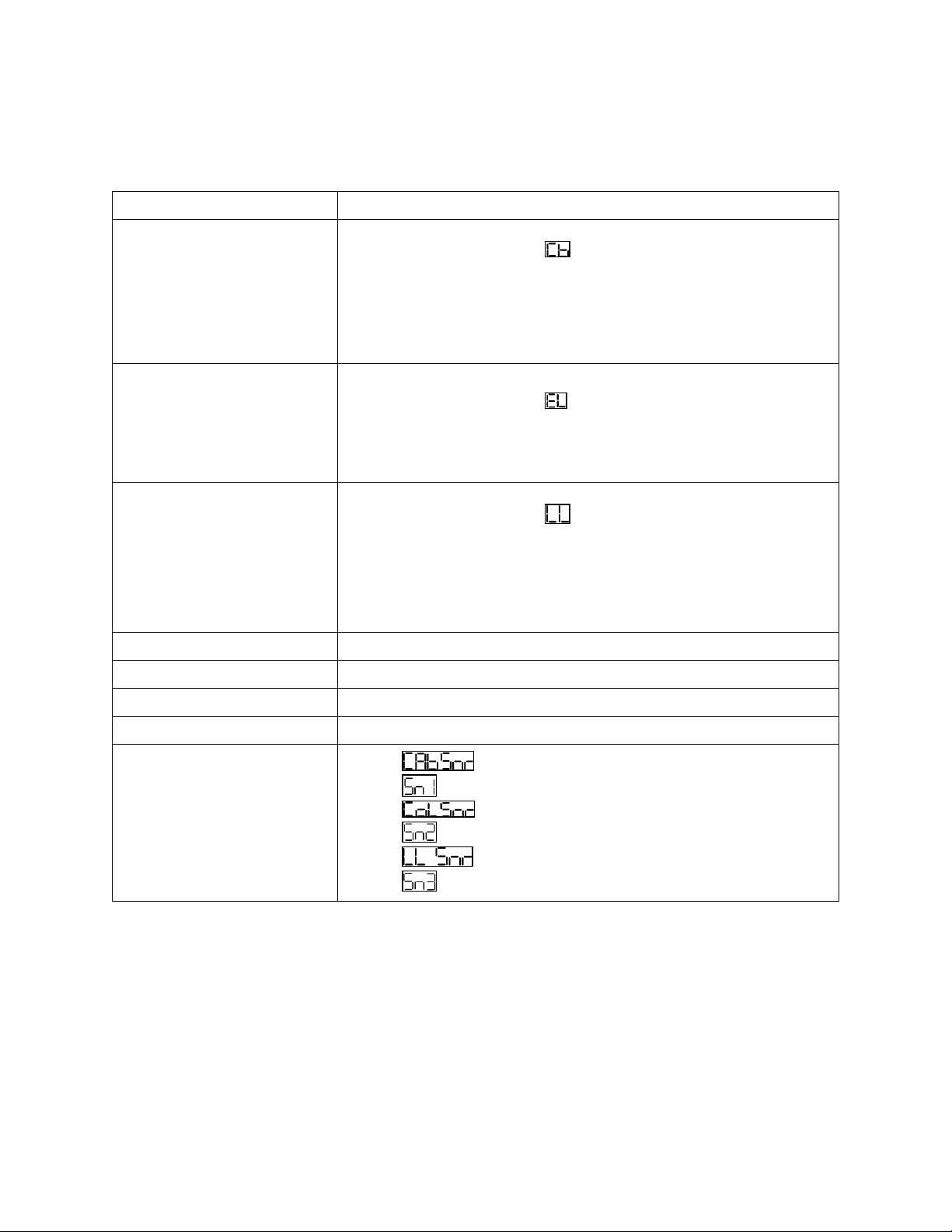

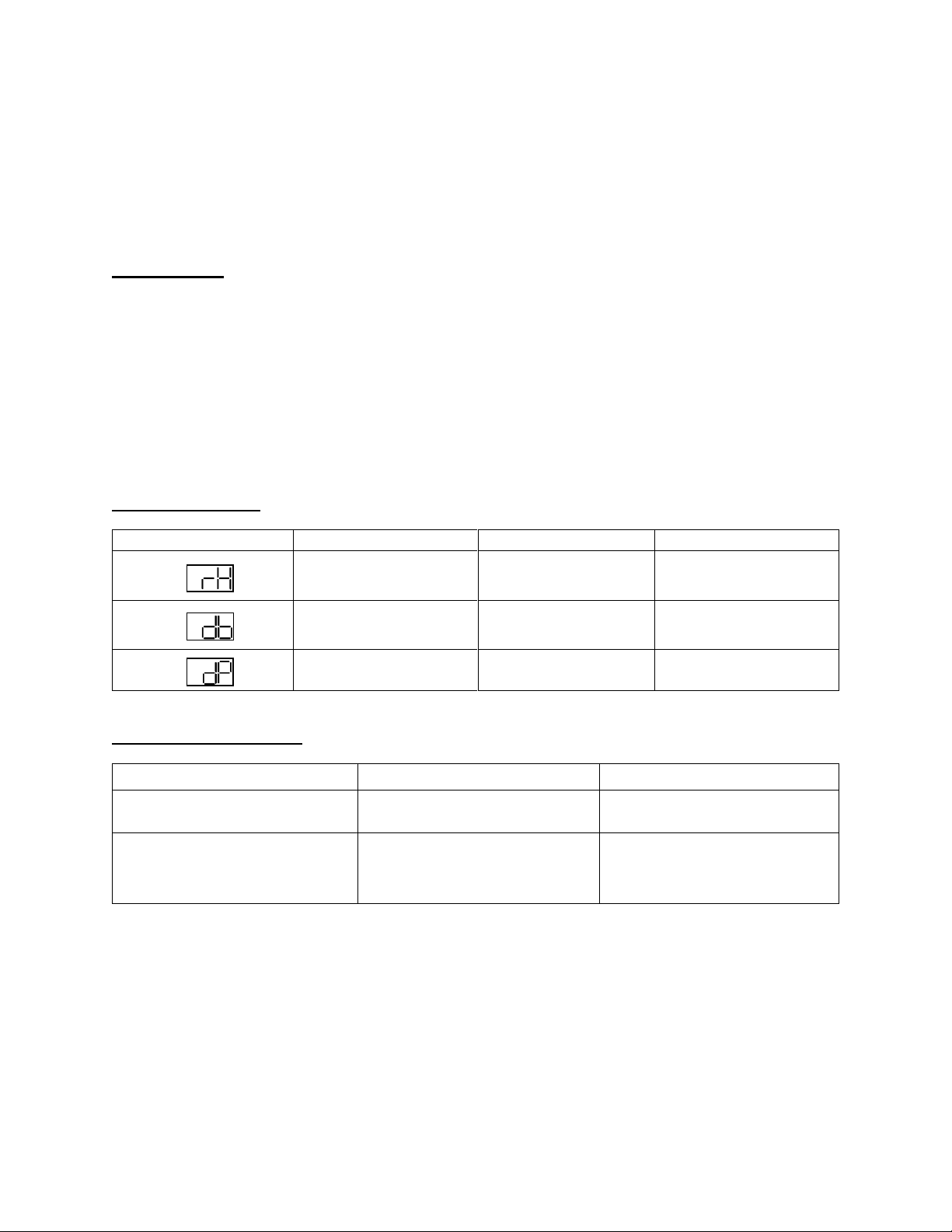

I. b - Intela-Traul Alarm Codes from 2010 to present

Alarm

Description

Clear Alarm

Refrigeration System Low Charge

Repair Refrigeration System

Low Cabinet Temperature Alarm

Return Cabinet Temperature to

Normal Range

High Cabinet Temperature Alarm

Return Cabinet Temperature to

Normal Range

Door Open Alarm

Close Door

Power Loss Alarm

Press Alarm Cancel

Clean Condenser Alarm

Clear/Clean Condenser Coil

Coil Sensor Open or Shorted

Replace Coil Sensor

Cab Sensor Open or Shorted

Replace Cabinet Sensor

Discharge Line Sensor

open or shorted

Replace Discharge Line Sensor

Defrost Terminates by Time, Not

Temperature, for 72 hours.

Troubleshoot Defrost Cycle

Cab Sensor Open or Shorted

Replace Cabinet Sensor

Coil Sensor Open or Shorted

Replace Coil Sensor

Liquid Line Sensor Open or Shorted

Replace Liquid Line Sensor

Low Cabinet Temperature Alarm

Return Cabinet Temperature to

Normal Range

High Cabinet Temperature Alarm

Return Cabinet Temperature to

Normal Range

Table 3

6

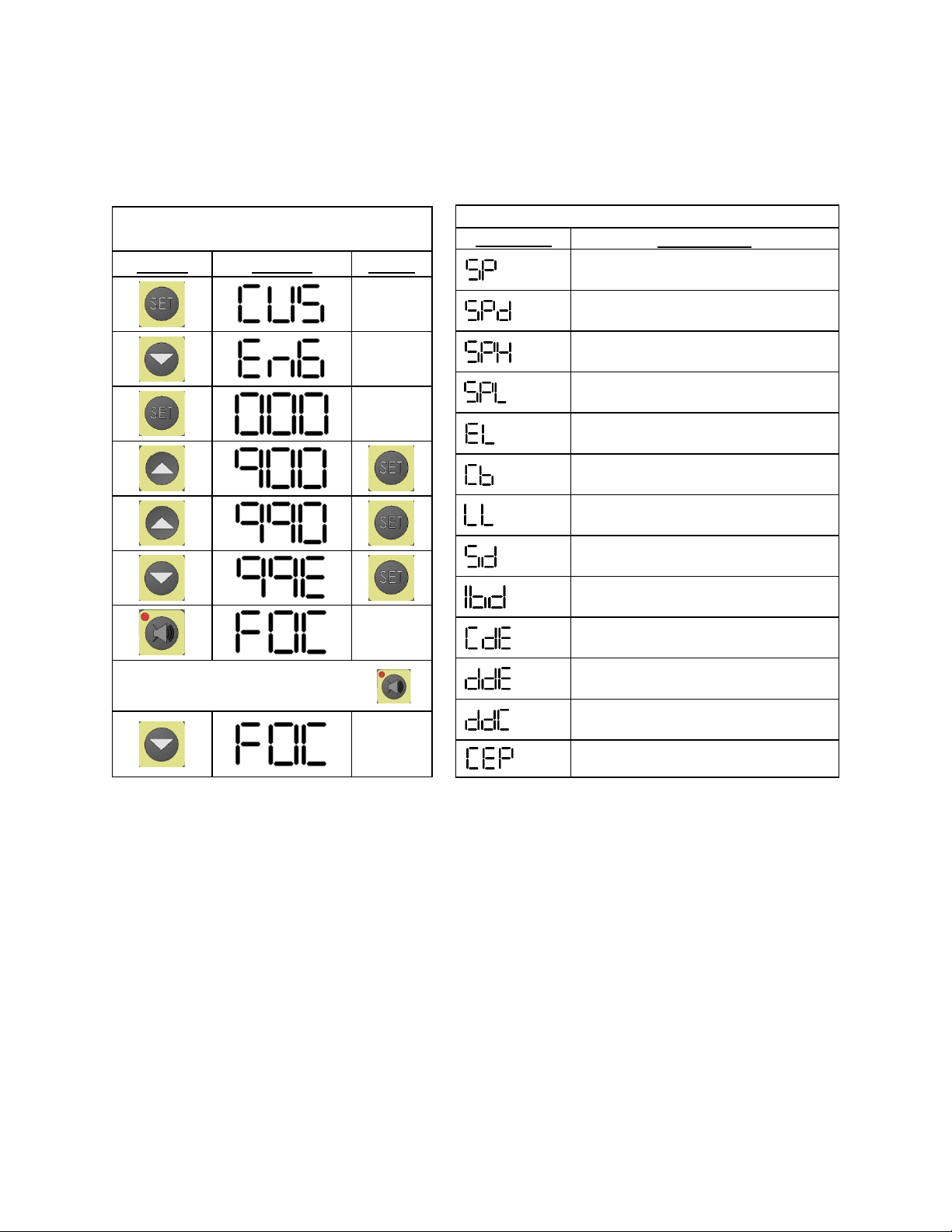

I. c –Intela-Traul Control Access & Parameters

To access the engineering/service menu follow the instruction below. As seen in Figures 1 & 2.

Figure 1

INTELA-TRAUL Access

Press

Display

Press

If control does not have

INTELA-TRAUL Key Parameters

Parameter

Description

Set Point

Set Point Differential

Set Point High

(Equip Prior to 2010 only)

Set Point Low

(Equip Prior to 2010 only)

Evaporator Coil Sensor Temp

Cabinet Air Sensor Temp

Liquid Line Sensor Temp

Start Manual Defrost

Intervals Between Defrost

(In hours)

Defrost Termination

Temperature

Drip Time After Defrost

Length of Defrost (In Minutes)

Reset to Factory Defaults

SET

SET

SET

SET

SET

Figure 2

7

I. d - Troubleshooting Traulsen Intela-Traul Sensors

Sensor Function:

•Cabinet Sensor (Green): The Cabinet sensor reads the temperature of the return air

and relays that value back to the control head. The control head either cycles the

compressor on or off depending on the temperature set points. If cabinet sensor reads

60⁰F (15 ⁰C) or higher the unit will not go into defrost and you can’t put into manual

defrost.

•Coil Sensor (Blue): The Coil sensor reads the evaporator coil core temperature and

returns that value back to the control head. The control head uses this input to terminate

the defrost cycle at 45⁰F (7.2⁰C) evaporator core temperature. In addition the control head

uses the evaporator coil core temperature to control evaporator fan delay.

•Liquid Line Sensor (Yellow): The Liquid Line sensor reads the temperature of the liquid

line and returns that value back to the control head. The control head uses the liquid line

temperature to trigger a clean coil alarm at 140⁰F (60⁰C) (R&A series only) & cycles the

compressor off on high temp limit at 160⁰F (71.1⁰C) liquid line temperature.

Basic Troubleshooting:

All sensors (cabinet, coil, liquid line) can be tested for accuracy using a Volt Ohm Meter.

•When checking a sensor value through the control a reading of -40⁰F(-40⁰C) indicates an

open in the sensor or sensor circuit and a reading of 266⁰F (130⁰C) indicates a short in

the sensor or sensor circuit. See Table 4 for control head sensor parameters.

•An ice & water solution consisting of mostly ice with just enough water to submerse the

sensor should be used to create a controlled environment of approximately 32⁰F (0⁰C).

This solution likely needs to be agitated or stirred to maintain a consistent temperature

throughout. At 32⁰F(0⁰C) all sensors should return an Ohm reading of 32,000 Ohms +/-

10%. See Table 5 below for temperature & Ohms relationship of all Intela-Traul

sensors.

TEMP (OF)

R (OHMS)

TEMP (OC)

20

46.2K

-6.7

25

39.9K

-3.9

30

34.6K

-1.1

32

32.7K

0.0

35

30.1K

1.7

40

26.1K

4.4

Table 5

Sensor

Parameter

Cabinet Air

Evaporator Coil

Liquid Line

Table 4

8

I. d - Troubleshooting Traulsen Intela-Traul Sensors

Quick Reference Table 6

Item

Details

Cabinet Sensor

•Green

•Control parameter

•Reads return air

•Compressor cycles off of cabinet sensor value

•If cabinet sensor reads 60⁰F (15 ⁰C) or higher the unit

will not go into defrost and you can’t put into manual

defrost.

Coil Sensor

•Blue

•Control parameter

•Reads evaporator coil temperature

•Terminates defrost

•Temperature fan delay after defrost & start up

Liquid Line Sensor

•Yellow

•Control parameter

•Reads liquid line temperature

•Triggers clean filter alarm @ 140⁰F (60⁰C) (R&A Series

Only)

•Compressor safety; Cycles compressor off @ 160⁰F

(7.1⁰C)

Sensor Open

•-40⁰F (-40⁰C)

Sensor Short

•266⁰F (130⁰C)

Sensor can fail anywhere

•Between -40 & + 266 (-40⁰F & (130⁰C)

Sensor Test

•32K Ω @ 32⁰F (0⁰C)

Alarm Codes (R&A Series

Only)

•Open or shorted cabinet sensor

•Open or shorted cabinet sensor

•Open or shorted evaporator coil sensor

•Open or shorted evaporator coil sensor

•Open or shorted liquid line sensor

•Open or shorted liquid line sensor

Table 6

9

I. d - Troubleshooting Traulsen Intela-Traul Sensors

Advanced Trouble Shooting Tips

There are a variety of reasons for the symptoms listed in Table 7. This troubleshooting table is

intended to address the most common reasons associated with the Intela-Traul sensors only.

Further troubleshooting outside the scope of this document may be required.

Symptom

Possible Causes

Cabinet temperature display reads

lower temperature than actual cabinet

temperature

•Evaporator coil is frozen up

•Defective cabinet sensor

•Cabinet sensor not in proper location

Cabinet temperature display reads

higher temperature than actual

cabinet temperature

•Defective cabinet sensor

•Air flow obstruction

•Cabinet sensor not in proper location

Evaporator coil is frozen up

•Evaporator coil sensor is out of tolerance and

terminating defrost to soon

•Cabinet air sensor is out of tolerance causing

cabinet air temp to run too low

Display temperature reads -40⁰F

(-40⁰C)

•Cabinet sensor is open

•Cabinet sensor is disconnected

•Cabinet sensor wire harness is open

•Cabinet sensor pin connector is loose or has a

weak connection

Compressor cycles off before cabinet

temperature is satisfied

•Liquid line sensor is out of tolerance and

return to high of a temperature causing the

compressor to cycle off

•Liquid line is reaching 160⁰F (71.1⁰C) and

cycling the compressor off on high temp limit

Table 7

10

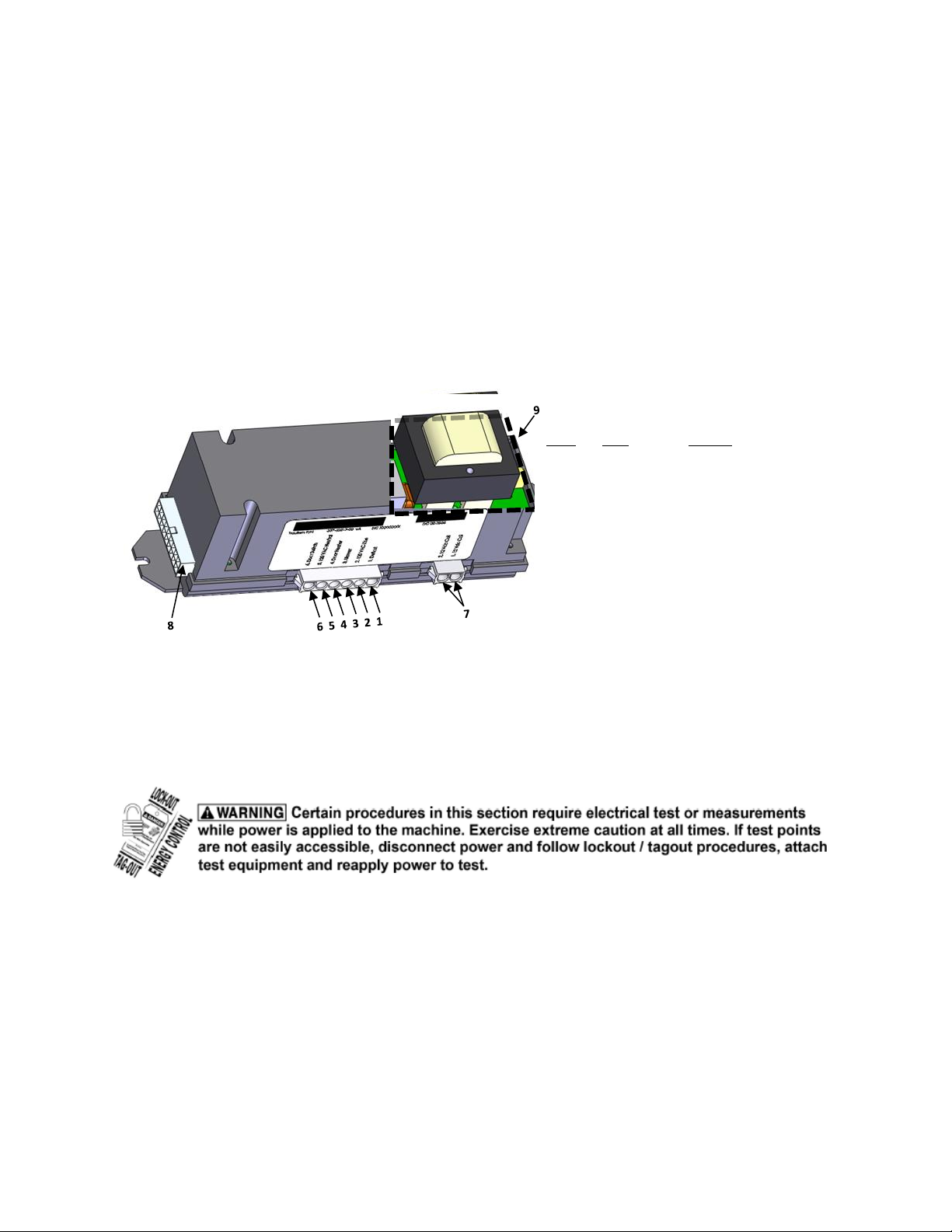

I. e - Troubleshooting Traulsen Intela-Traul MIT II Relay Module

Relay Module Function:

The Traulsen Relay Module is a long black rectangular box approximately 2 x 2 x 7 inches (5.08

X 5.08 X 17.08 centimeters) located behind the controller (front panel display) that contains

several switching relays. The relays inside the module are used to send line voltage to the

compressor (or heaters if a Hot Food box) fan motor(s), or defrost heaters or defrost solenoids,

as needed. The actuation of these relays is controlled by low voltage DC signals sent from the

Intela-Traul™ Control.

Relay Module Architecture:

Relay Module Control Voltage:

Relay control voltage is checked at the 18pin connector which delivers a range of 1-5VDC to the

relay module when the control is calling for a relay to be energized. When checking for relay

control voltage the 18pin connector MUST remain connected.

Note: Items 1, 3, & 4 are equipped with snubber circuits to reduce arcing and increase relay life. As

result Line Voltage will always be measured at the relay output regardless of relay state, open/closed.

Item # Color Function

1 Purple 115vac Output to Defrost Heater

2 Black 115vac Input Line Voltage Power

3 Gray 115vac Output to Evaporator Fan/Blower(s)

4 Orange 115vac Output to Door Frame Heater(s)

5 White 115vac Line Voltage Neutral

6 Yellow 115vac Input from Door Switch(s)

7 Pink 12VDC Output Compressor Relay Control Voltage

8 18pin connector 1-5VDC Control Voltage from Intela-Traul™ Controller

9 Transformer Line Voltage to 12V Transformer

Figure 3

11

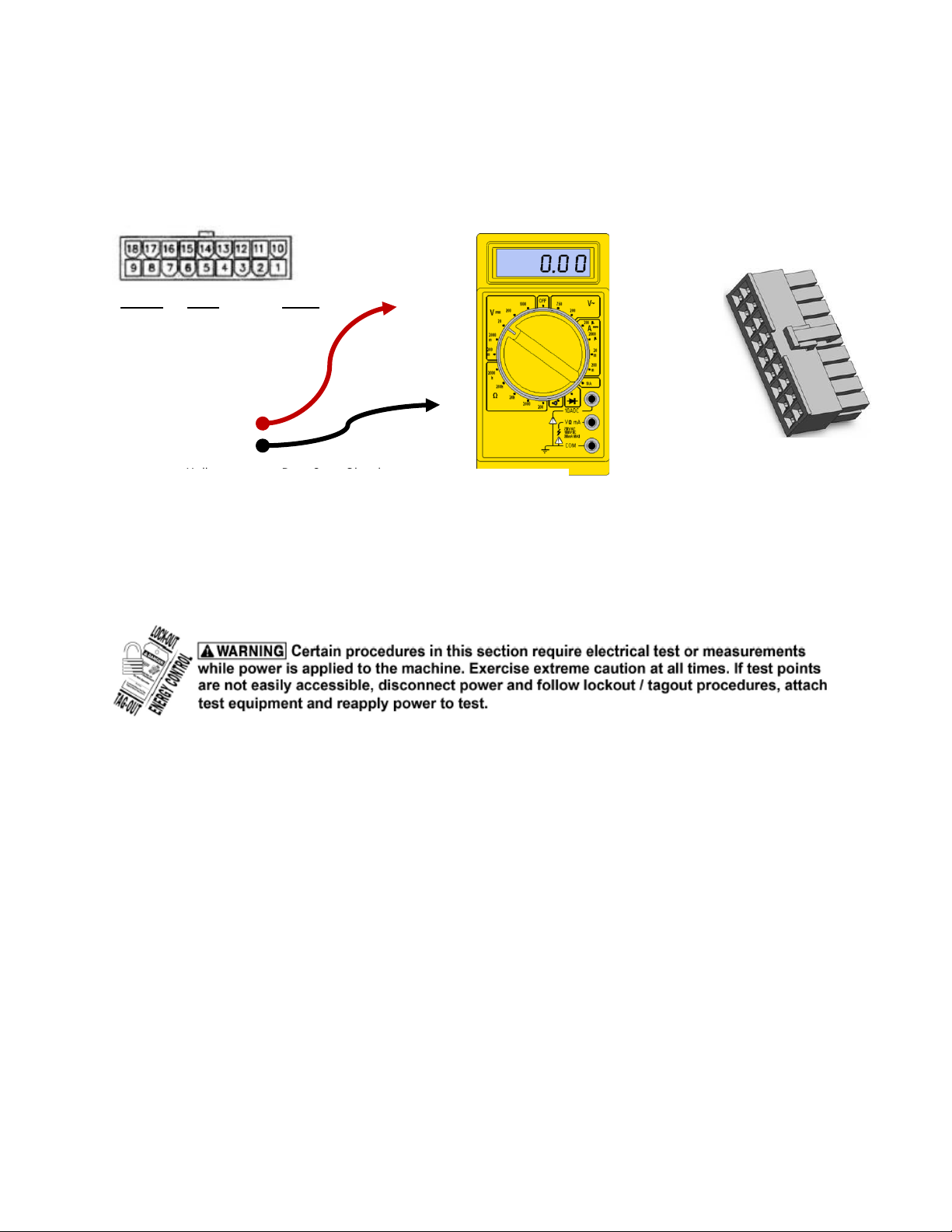

I. e - Troubleshooting Traulsen Intela-Traul MIT II Relay Module

Relay Module Control Voltage (Cont):

Relay Module Output Voltage:

If the 1-5VDC control voltage from the Intela-Traul™ has been confirmed but the corresponding

component is not energized output voltage from the relay module needs to be confirmed. The

simplest way to confirm whether or not the relay inside the relay module has failed is to jump out

the relay contacts. You can do this by unplugging the six pin connector and jump pin 2 (Black,

115vac input) to the corresponding output pin. If the component energizes then the relay

module likely needs to be replaced. If the component still does not energize then further

troubleshooting of the component is needed.

Pin No.

Color

Signal

1

Gray

Blower

2

Orange

Door Heater

3

Green

Alarm From Controller

4

Black

Return to Horn

5

Unused

6

Unused

7

White/Purple

-RS485

8

Black

Ground

9

White

12vac

10

Blue

Compressor

11

Purple

Defrost

12

Yellow

Door Open Signal

13

Red

Power to Horn

14

Unused

15

Unused

16

Pink

+RS485

17

Red

12 VDC Controller Power

18

Black

12vac

Check control voltage by inserting meter leads into the

back of the 18pin connector at the appropriate points.

18pin connector must be connected to the relay

module.

Figure 4

12

I. f - RH Sensor Module

The Intela-Traul RH module (Relative Humidity Sensor) is found on the Traulsen Energy Star

rated units, from October 2014 to the present. This technical bulletin may not cover all the

situations that may arise in the field and final diagnosis of field based equipment is the sole

responsibility of the technician contracted to perform any work required.

Functionality:

The RH module senses the ambient temperature and relative humidity and communicates the

information to the MIT II control. The MIT II control uses this data to perform the following tasks.

As seen in Table 8.

•Cycle the door heater based on ambient temperature and humidity conditions.

•Increase/decrease the intervals between defrosts based on the number of door

open/close events and the ambient temperature conditions. + or -75%.

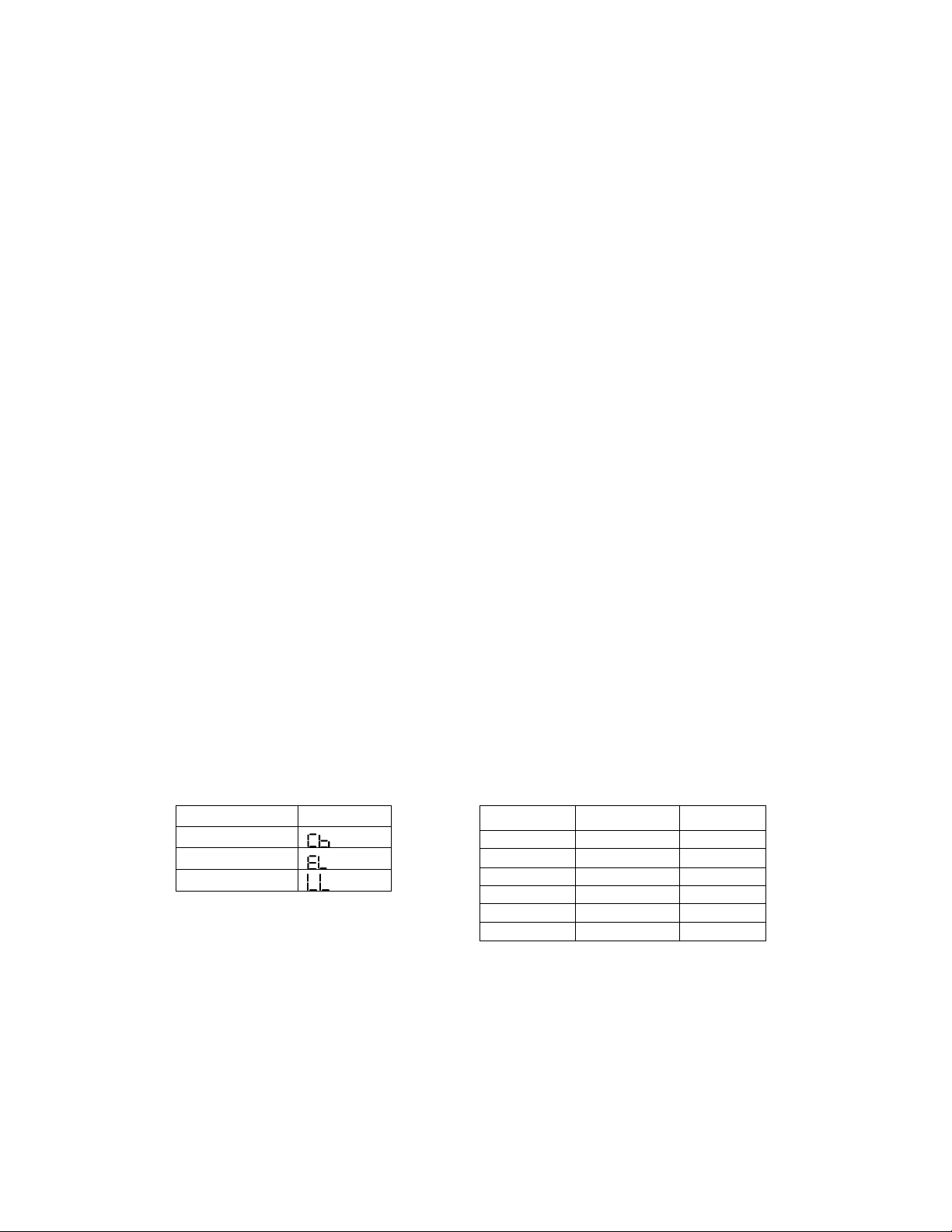

Parameters Table:

Displayed

Parameter Name

Sample Value

Description

Relative Humidity

(Ambient)

55.0

Relative humidity of

the room.

Dry Bulb

Temperature

75.0

Ambient temperature

of the room.

Dew Point

Temperature

65.0

Calculated dew point

temperature.

Table 8

Troubleshooting Table:

Symptom

Possible cause

Solution

Excessive condensation on

the door.

Inaccurate reading from the

RH module.

Unplug RH sensor. Replace

the RH sensor module.

Coil freezes up.

The RH module extends the

interval between defrost

based on ambient conditions.

Unplug RH sensor. Put unit

into manual defrost. Replace

RH sensor.

Table 9

Note: You can disconnect the RH Sensor and the unit will run with its default settings.

13

Section II

Refrigeration System

14

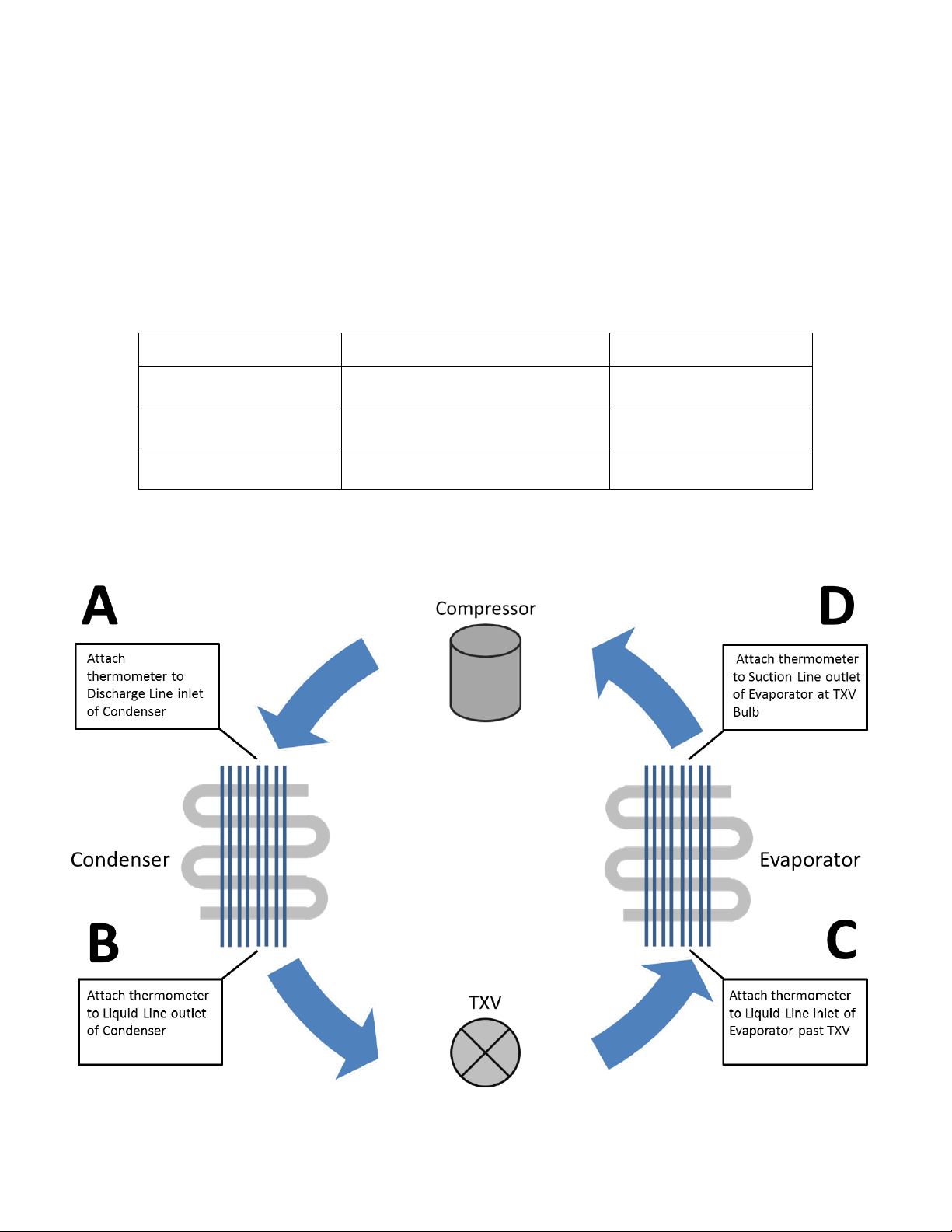

II. a - Troubleshooting Traulsen Refrigeration System

Introduction:

This is to inform the field how to trouble shoots the refrigeration system with the use of a

thermometer. As seen in Figure 5.

Trouble Shooting Refrigeration System by Temperature:

Use Table 10 and corresponding chart (Figure 5) to aid in troubleshooting a Traulsen

refrigeration system with the use of thermometers.

ITEM

FORMULA

TRAULSEN SPEC

Condenser Split

(A + B)/2-Ambient Temperature

30OF (-1.1OC)

Sub-cooling

(A + B)/2-B

4OF to12OF

(-15.5⁰C -11.1⁰C)

Evaporator Superheat

D-C

5OF to 7OF

(-15⁰C to 13.9⁰C)

Table 10

Note: Unit must be running for at least 5-10 minutes before checking temperatures and insulate sensing bulb

of thermometer for most accurate readings.

Figure 5

15

II. b - TXV Troubleshooting

Standard Operating Parameters:

•Superheat –7⁰F(-13.9⁰C)

•Subcooling –4OF-12OF (-15.5⁰C TO -11.1⁰C)

Troubleshooting:

Table 11

Moisture Contamination:

A restriction caused by moisture will thaw when the TXV is warmed and the system will begin to

function properly until the moisture finds its way back to the TXV and freezes at the orifice

again. See Table 11.

Superheat

Subcooling

Diagnosis

Above 7F

Below 4F

Refrigerant Charge is Low

Below 5F

Above 12F

System Overcharged

Above 7F

Above 12F

Restriction in High Side or Metering Device

(As measured in Figure 5, Page 14)

16

II. c - Troubleshooting a Frozen Evaporator Coil

Table 12 is intended to aid in diagnosing the root cause of a frozen evaporator coil on a

Traulsen upright reach-in refrigerator or freezer. This may not cover all situations that may arise

in the field and final diagnosis of field based equipment is the sole responsibility of the

technician contracted to perform any work required.

Frozen Evaporator Troubleshooting Table

Potential Causes

Details

Cabinet Sensor out of tolerance

(See TTB006 Sensors for sensor

troubleshooting)

•Color: Green

•Control parameter

•Reads return air

•Compressor cycles off of cabinet sensor value

Coil Sensor out of tolerance

(See TTB006 Sensors for sensor

troubleshooting)

•Color: Blue

•Control parameter

•Reads evaporator coil temperature

•Terminates defrost @ 45⁰F (7.2⁰C)

•Fan delay

Ambient Air Infiltration

•Door(s) not closing properly

•Gasket(s) not sealing properly

•Door(s) left open for extended periods of time

•Evaporator hump cover not sealed properly

Compressor relay stuck closed

•Coil voltage 12VDC

•Coil wires: Pink

•Contacts

oCommon: Black wire

oN/O: Blue wire

Lack of Air Flow

•Evaporator fan motor not functioning

•Obstruction in air duct or at evaporator coil

Refrigeration System (Traulsen

recommends the refrigeration system be

tested using the methods outlined in

TTB009)

•Low charge

•Restricted metering device

•Moisture/contaminates in the system

Defrost Heater

•Defrost heater open

•Defrost heater circuit or relay open

Control Settings

•Set point to low (refrigerator only)

oControl parameters: or &

(depending on the age of control system)

•Defrost lockouts set to frequently

oControl parameters: , , ,

Table 12

17

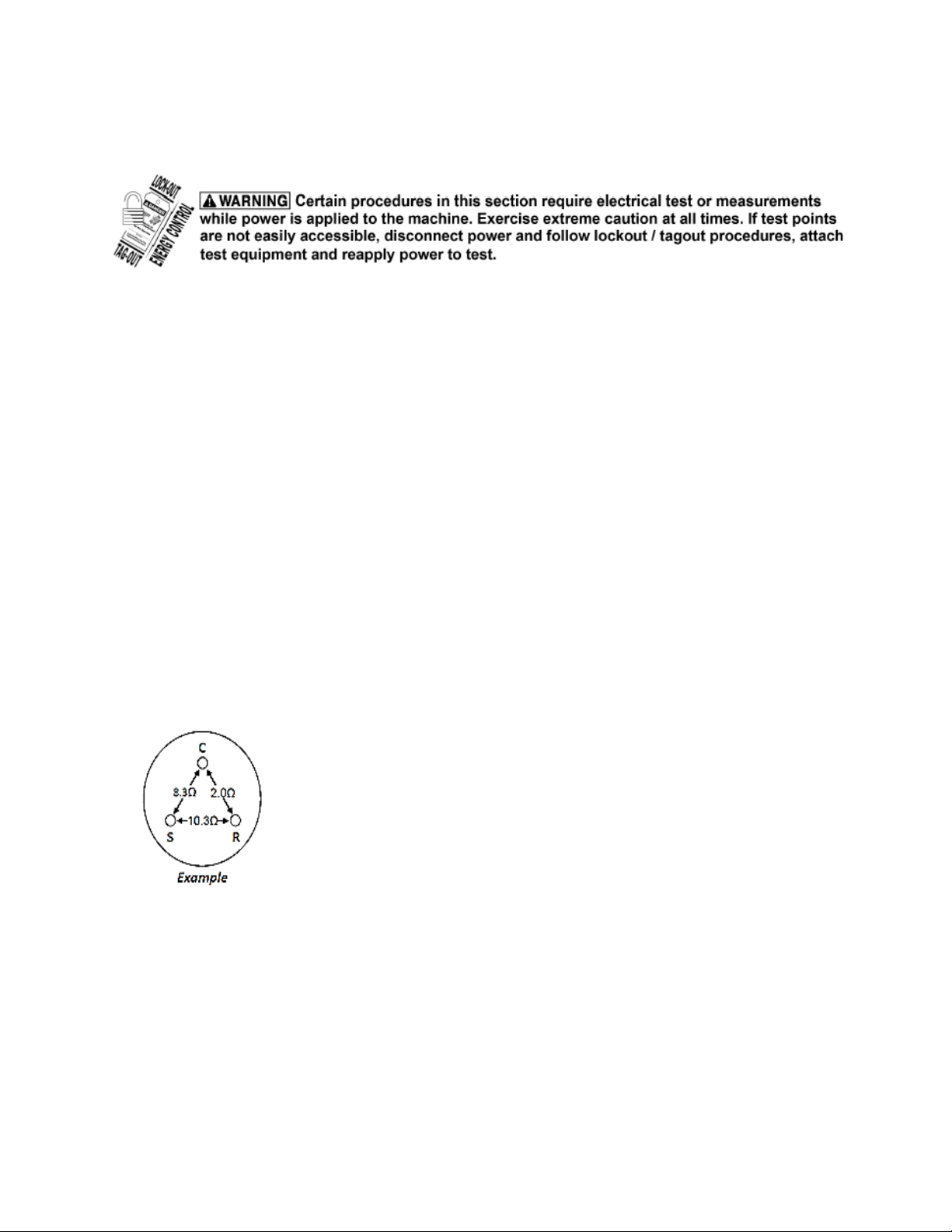

II. d - Compressor Troubleshooting

Tools Required:

•Basic hand tools

•Clamp around amp meter

•Volt Ohm meter

•Basic 3 in 1(1/2 HP)

Terminology:

•OEM –Original Equipment Manufacturer –Refers to the manufacturer of a piece of

equipment or component.

•RLA –Rated Load Amps –The OEM test conditions amperage rating (does not

necessarily indicate the normal running amperageas conditions and applications can vary

from OEM test conditions)

•LRA –Locked Rotor Amps –The OEM test condition lock rotor amperagerating indicating

the expected amperage at which a motor does not turn when power is applied.

•Start Components –The capacitor and relay combinations used to start and/or run a

compressor motor consist of a start capacitor and start relay if IAA is shown on the serial

number of the compressor. If CAA is listed then there will be a potential relay along with a

start capacitor and a run capacitor.

Ω= OHM= Unit Resistance

R= Run

S= Start

C= Common

Figure 6 shows the readings of the resistance through the compressor

motor windings. (C-S C-R). If the windings are good the start winding

resistance (C-S) will always be higher than the run winding resistance

(C-R).

Note: This example shows one set of possible combinations that can be seen in the field. Resistance values

will vary between different compressors.

Figure 6

18

II. d - Compressor Troubleshooting

Basic Troubleshooting:

•What is my amp draw and voltage when the compressor is starting?

•What is the resistance of the windings?

•What is the RLA (Rated Load Amps) of the compressor?

•What is the LRA (Locked Rotor Amps) of the compressor?

•Check the start components?

Symptom Reason Possible Resolution

0 amps

Check for voltage between C &

R terminals.

No: Check external overload & find

where power loss is.

Yes: open winding or the internal

overload is open

Amps lower then

RLA

Lower head & high suction.

Weak valves, busted crankshaft or

connecting rod.

Slightly higher

amps then RLA

Overload opens after

compressor runs for a time.

Bad run capacitor, tight bearings, or

winding issues.

Very high amps

but not LRA

Issue with compressor

windings.

Ohm windings and compare with

manufacturer’s resistances.

Reading LRA

Compressor not starting,

reading 5 to 6 times RLA.

Check start capacitor, start relay

&wires for burning, try 3 in 1.

Check voltage drop (+/-10%) and for

resistance.

Table 13

19

Section III

Compact & Milk Cooler Controls

Other manuals for G-Series

3

Table of contents

Other Traulsen Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use