Traulsen TB Series User manual

TB SERIES GLYCOL PIZZA/SALAD/SANDWICH PREP TABLES

Hours of Operation: Monday - Friday 7:30 a.m. - 4:30 p.m.

(CST)

4401 Blue Mound Road Fort Worth, Texas 76106 (USA)

OWNER’S MANUAL

*Please Note: This manual is intended for use with the above referenced equipment manufactured after April 01, 2019. To obtain a copy of the correct Owner’s Manual to support

the same products manufactured prior to this date, please contact Traulsen Service at (800) 825-8220.

-1-

I. THE SERIAL TAG Page 1

a) Serial Tag & Location Page 1

b) Reading The Serial Tag Page 1

II. RECEIPT INSPECTION Page 2

III. INSTALLATION Page 2

IV. PRESTART CHECKS Page 3

V. OPERATION Page 3

a) Operation Page 3

b) Pan Chiller Page 3

c) Lower Storage Cabinet Page 4

d) Shutdown For Extended Period Page 4

e) Removing Food Product At Night Page 4

f) Leaving Food Product In The Unit

Throughout The Night Page 4

VI. CONTROL BASICS Page 4

a) Control Display Page 4

VI. CONTROL BASICS (continued)

b) Unlocking the Keypad Page 5

c) Adjusting The Cabinet Temperature

Setpoint Page 5

d) Adjusting The Rail Temperature

Setpoint Page 5

e) Initiating A Defrost

VII. General Care Page 5

a) General Care Page 5

b) Adjusting The Shelves Page 5

c) Cleaning The Condenser Page 6

d) Cleaning The Lower Storage Cabinet Page 6

VIII. TROUBLE SHOOTING Page 6

IX. SERVICE/WARRANTY INFORMATION Page 7

a) Service Information

b) Service Support Information

c) Warranty Registration

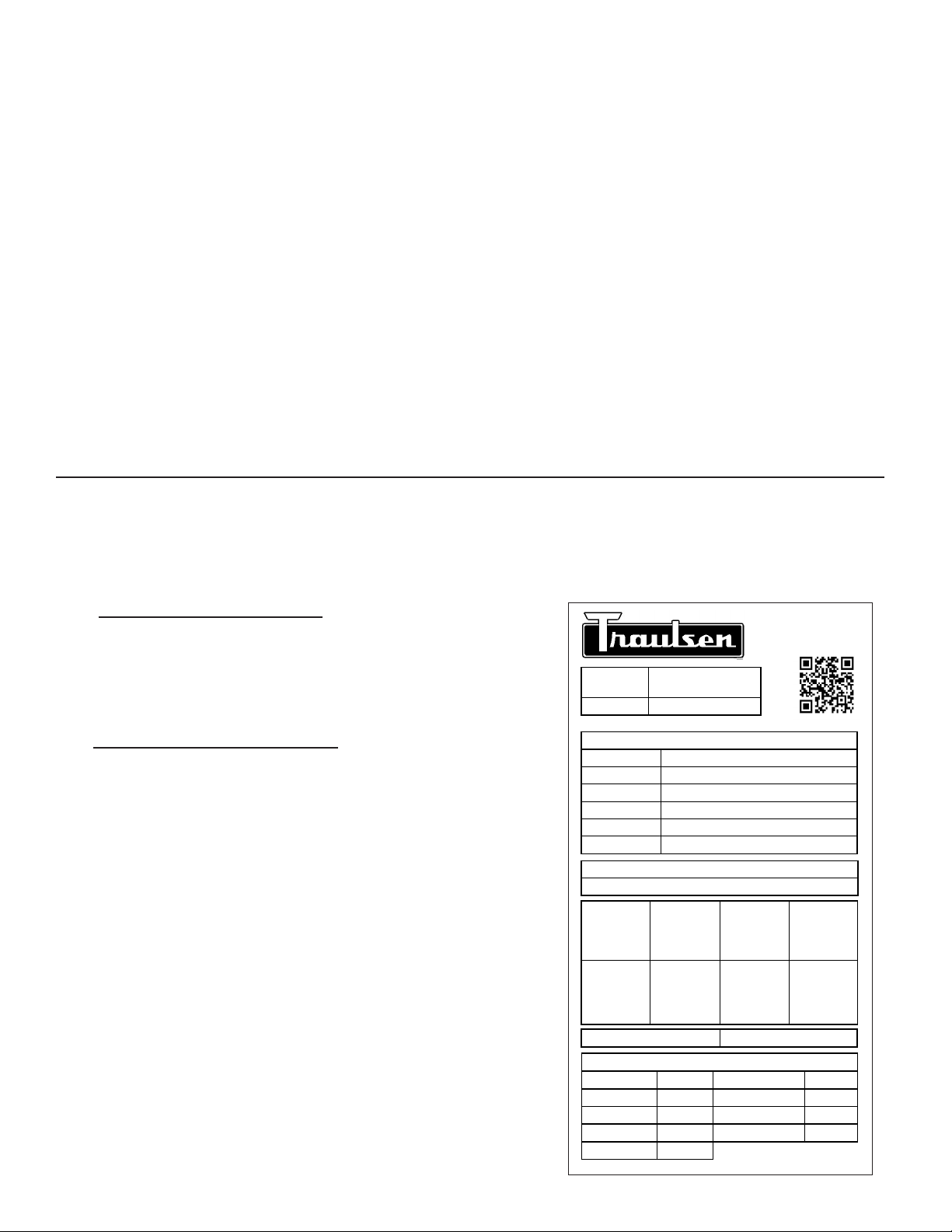

I. THE SERIAL TAG

I. a - SERIAL TAG & LOCATION

The serial tag is a permanently afxed label on which is recorded

vital electrical and refrigeration data about your Traulsen product,

as well as the model and serial number. This tag is located in the

right interior compartment on all standard KBP Series models.

I. b - READING THE SERIAL TAG

• Model = The model # of your Traulsen unit

• (S/N) Serial Number = The permanent ID# of your Traulsen

unit

• Refrigerant SYS1= System 1 Refrigerant type used and refrigerant

charge

• Design Pressure= System 1 High and Low Pressure

• Refrigerant SYS2= System 2 Refrigerant type used and refrigerant

charge

• Design Pressure= System 2 High and Low Pressure

• Volts = Voltage

• Hz = Cycle

• Total Current = Maximum amp draw

• Min Circuit Amps = Minimum circuit ampacity

• Agency Labels = Designates agency listings

This unit is listed to UL 471, CSA 120 and NSF 7 by an approved NRTL.

Consult the factory or unit data plate for approval information.

• Components = Component Ratings

4401 Blue Mound Rd.

Ft. Worth, TX 76106

800-825-8220

Input Power (ELIN) -FOR INDOOR USE ONLY

115-208/230V ~ 60Hz 8.0A (8,0A)

MODEL:

MODELO:

MODELE: RDT232WUT-FHS

S/N: T25364A14

REFRIGERANT / REFRIGERANTE / RÉFRIGÉRANT

SYS1 (REFM): R-134a 8.4oz 238.1 g (238,1 g)

Hi Press. (PRESH): 500psi 3.45 MPa (3,45 Mpa)

Lo Press. (PRESL): 250 psi 1.72 Mpa (1,72 Mpa)

SYS2 (REFA): R-404a 12.5oz 354.4g (354,4g)

Hi Press. (PRESH): 500psi 3.45MPa (3,45MPa)

Lo Press. (PRESL): 250psi 1.72Mpa (1,72Mpa)

(Symbol 1)

(Alt Safety / Other

1)

(Symbol 2)

(Alt. San / Other 2)

(Symbol 3)

(Alt. En. / Other 3)

(Symbol 4)

(WEEE)

(Symbol 5)

(Safety)

(Symbol 6)

(Sanitaon)

(Symbol 7)

(Energy)

(Symbol 8)

(Customer QR

Code / Other 4)

Device/Part Number: PartNum (UL/NSF Notes)

SCAN FOR SERVICE INFO

COMPONENTS / COMPOSANTS / COMPONENTES

COMP AMPS: EVAP FAN AMPS:

COND FAN AMPS: LIGHT WATTS:

DEF HTR AMPS: CTRL AMPS:

DOOR HTR AMPS: MIN AMPS:

MAX AMPS:

370-60297-00 REV.A 11/20/14

4401 Blue Mound Rd.

Ft. Worth, TX 76106

800-825-8220

Input Power (ELIN) -FOR INDOOR USE ONLY

115-208/230V ~ 60Hz 8.0A (8,0A)

MODEL:

MODELO:

MODELE: RDT232WUT-FHS

S/N: T25364A14

REFRIGERANT / REFRIGERANTE / RÉFRIGÉRANT

SYS1 (REFM): R-134a 8.4oz 238.1 g (238,1 g)

Hi Press. (PRESH): 500psi 3.45 MPa (3,45 Mpa)

Lo Press. (PRESL): 250 psi 1.72 Mpa (1,72 Mpa)

SYS2 (REFA): R-404a 12.5oz 354.4g (354,4g)

Hi Press. (PRESH): 500psi 3.45MPa (3,45MPa)

Lo Press. (PRESL): 250psi 1.72Mpa (1,72Mpa)

(Symbol 1)

(Alt Safety / Other

1)

(Symbol 2)

(Alt. San / Other 2)

(Symbol 3)

(Alt. En. / Other 3)

(Symbol 4)

(WEEE)

(Symbol 5)

(Safety)

(Symbol 6)

(Sanitaon)

(Symbol 7)

(Energy)

(Symbol 8)

(Customer QR

Code / Other 4)

Device/Part Number: PartNum (UL/NSF Notes)

SCAN FOR SERVICE INFO

COMPONENTS / COMPOSANTS / COMPONENTES

COMP AMPS: EVAP FAN AMPS:

COND FAN AMPS: LIGHT WATTS:

DEF HTR AMPS: CTRL AMPS:

DOOR HTR AMPS: MIN AMPS:

MAX AMPS:

370-60297-00 REV.A 11/20/14

-2-

II. RECEIPT INSPECTION III. INSTALLATION

II. a - RECEIPT INSPECTION

Carefully inspect your Traulsen unit for damage during

delivery. If damage is detected, you should save all crating

materials and make note on the carrier’s Bill of Lading

describing the damage. A freight claim should be led

immediately. If damage is subsequently noted during or

immediately after installation, contact the respective carrier

and le a freight claim. There is a ve (5) day limit to le

freight damage with the carrier. Under no condition may a

damaged unit be returned to Traulsen without rst obtaining

written permission (return authorization). You may contact

Traulsen customer care at 800-825-8220.

Some models may use R-290 (Propane)

as a refrigerant. If ammable refrigerant is present, follow

instructions as labeled on the unit. Proper care must be taken

to avoid any damage to the refrigeration system including

refrigerant tubing, condenser, evaporator coils during

handling, moving, installation and cleaning as it may cause

risk of re or explosion. If damaged, unit must be moved to

well ventilated area away from any sources of ignition.

Further service and repair must be performed by qualied

refrigeration technicians familiar with applicable safety

standards for ammable refrigerants. Technicians must

use appropriate personal protective equipment and follow

applicable safety precautions to avoid risk of re or explosion.

Do not damage evaporating catch pan support

brackets on the bottom of the unit when lifting the prep table

from the shipping pallet (see photo below)!

III. a - INSTALLATION

Prep table models can be installed with no clearance at the

back and sides of the units.

All units are supplied with a cord and plug, which can simply

be plugged into a dedicated appropriately sized outlet.

Some components are packed and shipped inside the lower

storage cabinet to avoid damage during shipment. Remove

these items from the cabinet and remove packing materials.

If unit is equipped with shelves, cut and remove the plastic

ties holding the shelves in place.

Place cutting board on rail so that holes in cutting board line

up with pins on the counter top.

Slide evaporating catch pan over support brackets all the

way to the back of the prep table positioning it below the

prep table drain outlets.

-3-

III. a - INSTALLATION (continued)

Open the condensing compartment hinged louver door and

check the glycol level in plastic expansion tank.

A non-toxic food grade 35% Propylene Glycol level in the

overow tank may be above the “Maximum Fill Line” or not

visible in the bottle when the unit arrives. Propylene Glycol

level in the overow tank varies and may or may not be

visible in the bottle based on the following conditions:

• Variations in the environment temperature;

• Variation in unit temperature.

If the unit is powered down after normal working hours, the

Propylene Glycol level may rise above the “Maximum Fill

Line”. This is normal operation and is inuenced by the above

conditions.

Close louver door remove rear condensing unit cover and

check if glycol ball valve is in the open position. Re-attach

rear louver.

Cut zip-tie securing electrical cord and plug cord into wall

socket.

GAS REFRIGERATION LINES IN CONDENSING

UNIT AREA ARE SHIPPED UNDER PRESSURE!

IV. PRESTART CHECKS

IV. a - PRESTART CHECKS

Glycol Prep Tables are shipped with factory pre-set

temperature settings. Although Traulsen Glycol Prep Tables

are tested at factory before shipment, there are variables

that can affect cooling performance of the unit:

• Ambient Temperature

IV. a - PRESTART CHECKS (continued)

• Humidity Level

• Air stream patterns

• Over-shelves/Heat lamps

• Product temp prior to loading into refrigerated pan

chiller well.

• Surrounding equipment.

All temperature settings can be adjusted by the Customer

or Authorized Traulsen Service Agent within +/- 3 °F.

V. OPERATION

V. a - OPERATION

Some models may use R-290 (Propane)

as a refrigerant. Consult detailed owner’s manual available

at www.traulsen.com before attempting to install or service

units with R-290 or other ammable refrigerants. All safety

precautions must be followed to avoid risk of re or explosion.

Contact Traulsen for additional information at 800-825-8220.

Plug cordset into wall outlet (self contained models). Open

the louver door, ip the main power switch ON and close the

door. Observe the Temperature Display through the opening

in the louver door.

When the Glycol Temperature cools to 30°F (-1°C), the unit

is ready to go!

V. b - PAN CHILLER

To ensure proper food temperatures are maintained

in exposed insert pans, the following conditions are

recommended.

1. All food brought to line must be at 41°F (5°C) or below.

2. No direct air blowing on food product from other

equipment in the kitchen (max air velocity 50 FPM/0.234

Meter/second).

3. Room ambient temperatures of 86°F (30°C) or less

around working area of Pan Chiller.

4. All shelving mounted over insert pans (with heated

equipment above it) must be insulated. No line of sight

from radiant heat sources to insert pans.

5. Occasional stirring of certain foods may be required in

order to maintain consistent temperatures.

III. INSTALLATION (continued) IV. PRESTART CHECKS (continued)

-4-

V. b - PAN CHILLER (continued)

6. Some food products chill faster than others i.e., lettuce,

dried tomatoes, etc.

7. For remote refrigerators with pan chiller systems, it is

imperative that the existing refrigeration equipment be

sized properly and in good working condition.

8. Traulsen recommends specified pans for optimum

performance (see spec sheet for recommended

suppliers).

V. c - LOWER STORAGE CABINET

The lower storage cabinet is designed to maintain

temperature between 33°F (0.55°C) and 40°F (4°C). If

the base is overloaded with warm food products, a certain

amount of time is required to remove heat from items before

operating temperatures can be maintained. The system is

only designed for storage of refrigerated product. Frequently

opening the doors or drawers will increase the temperature

in the cabinet and will require a certain amount of time to

recover.

V. d - SHUTDOWN FOR EXTENDED PERIOD

If the prep table and lower storage cabinet are not to be

used for an extended period of time, disconnect the electrical

power supply and open the doors (or drawers) to the lower

storage cabinet. As soon as the divided bars and the cabinet

have warmed to room temperature, wipe out the pan chiller

cavity and base interior.

V. e - REMOVING FOOD PRODUCT AT NIGHT

If you are storing product in the refrigerated storage base

and food needs to be removed from Pan Chiller at night,

simply close the night cover after removing food pans. This

will improve energy efciency during overnight hours. If ALL

food is removed from unit (pan chiller and refrigerated base

both empty), ip the ON/OFF switch to shut down entire unit.

To turn unit back on, ip switch ON.

V. f - LEAVING FOOD PRODUCT IN THE UNIT

THROUGHOUT THE NIGHT: (Recommended)

This unit is preset at factory and does not require periodic

shutdowns for the defrost cycle. This upgraded glycol

refrigeration system eliminates the operational burden

of removing food pans prior to the defrost period or for

overnight storage. No defrost cycle means that food can be

consistently cooled 100% of the time, day or night.

V. f - LEAVING FOOD PRODUCT IN THE UNIT

THROUGHOUT THE NIGHT (continued)

Plastic wrap should be placed over exposed food prior to

closing the night cover to help prevent condensation from

getting into the food.

The night cover must be closed if food is being left in the

pan chillers overnight.

VI.CONTROL BASICS

VI. a -CONTROL DISPLAY

Your equipment has been configured for optimum

performance. This document will serve as guide, if there is a

need to adjust the controller settings via the simple display.

On the left side is a unlock symbol and a three digit LED

display. This typically displays the cabinet temperature and

the rail temperature, prexed with ‘C’ and ‘r’ respectively.

The cabinet and rail temperature are displayed alternately.

At the center of the display there are four icons that reect

the status of the compressor, fans, defrost and alarms. On

the right are ve capacitive touch buttons. They will be used

to access the controller settings.

Status and Button Symbols:

Compressor Status

Fan Status

Defrost Status

Alarm / Door Open

Unlock Symbol

+ or Next Key

- or Previous Key

Unlock or Modify Key

Esc or Back Key

Display or Enter Key

V. OPERATION (continued) V. OPERATION (continued)

Table of contents

Other Traulsen Commercial Food Equipment manuals

Popular Commercial Food Equipment manuals by other brands

Diamond

Diamond AL1TB/H2-R2 Installation, Operating and Maintenance Instruction

Salva

Salva IVERPAN FC-18 User instructions

Allure

Allure Melanger JR6t Operator's manual

saro

saro FKT 935 operating instructions

Hussmann

Hussmann Rear Roll-in Dairy Installation & operation manual

Cornelius

Cornelius IDC PRO 255 Service manual

Moduline

Moduline HSH E Series Service manual

MINERVA OMEGA

MINERVA OMEGA DERBY 270 operating instructions

Diamond

Diamond OPTIMA 700 Installation, use and maintenance instructions

Diamond

Diamond G9/PLCA4 operating instructions

Cuppone

Cuppone BERNINI BRN 280 Installation

Arneg

Arneg Atlanta Direction for Installation and Use