RAC SERIES

Page 10

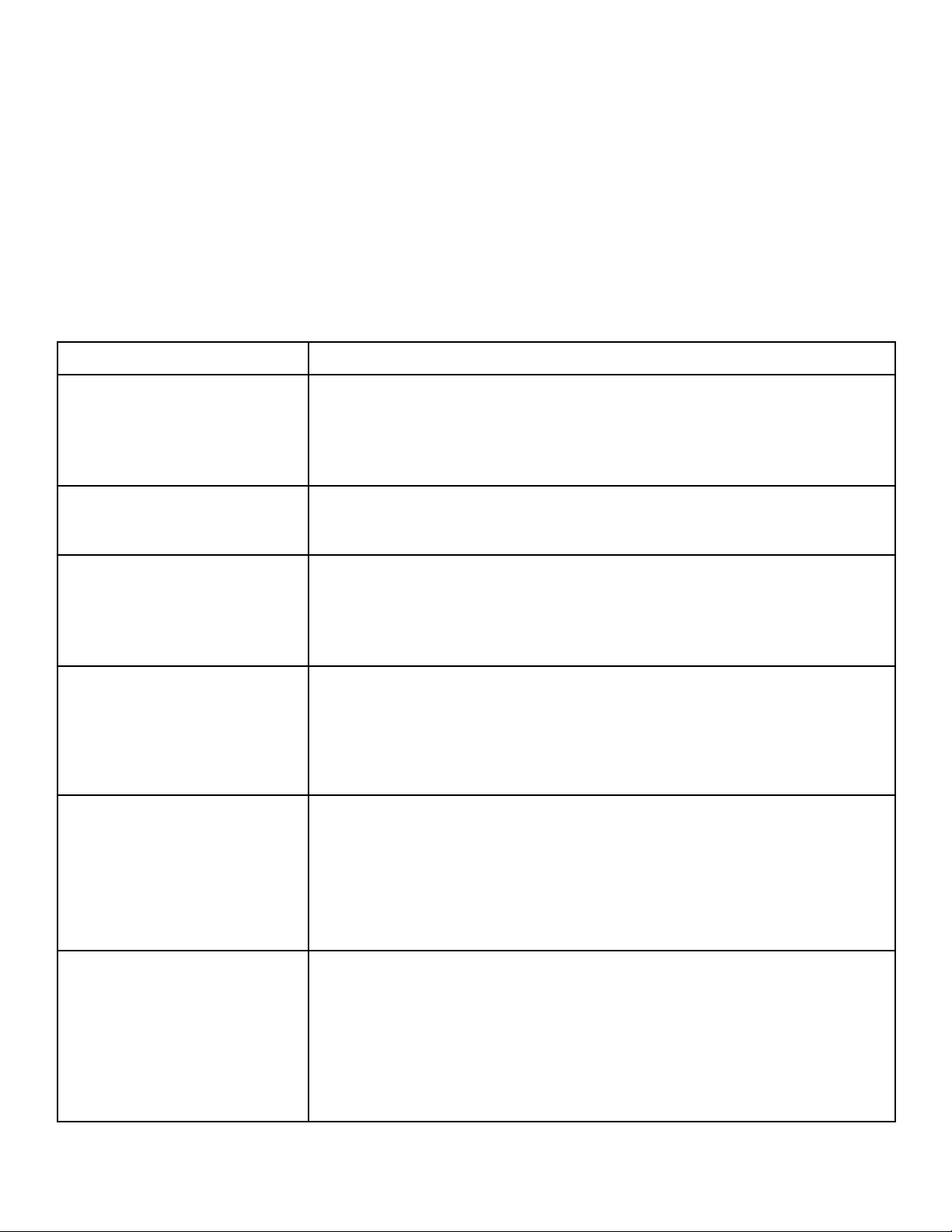

PROBLEM POSSIBLE CAUSE

1. Product zone temperature too high. • Control Setting Too High - Reset Control.

• Inadequate Air Circulation - Rearrange Product Load To Improve Air Circulation And Flow. Keep Empty

Trays in Position.

• Unit May Need To Be Manually Defrosted.

• Unit May Be In Defrost Cycle. See Indicator Light. Close Door And Wait 20 Minutes for Defrost Cycle

To Finish.

• Clean the Condenser.

2. Condensing unit fails to start - no hum. • Line Disconnected - Reconnect.

• Fuse - Replace Fuse.

• Overload Protection - Determine Reason & Correct, Replace If Necessary.

• Unit may need to be defrosted or has tripped off due to overload. Wait 30 minutes: Unit will self-reset.

3. Condensing unit fails to start - hums but

trips on overload protector.

• Improperly Wired - Check Wiring Against Diagram trips on overload protector.

• Low Voltage - Determine Reason & Correct.

• Starting Capacitor Defective - Determine Reason & Replace

• Relay Not Closing - Determine Reason & Correct, Replace If Necessary

• Compressor Motor Has Winding Open Or Shorted - Replace Compressor

• Internal Mechanical Trouble In Compressor - Replace Compressor

• Unit may need to be defrosted or has tripped off due to overload. Wait 30 minutes: Unit will self-reset.

4. Condensing unit starts, but fails to

switch.

• Improperly Wired - Check Wiring Against Diagram off of “start” winding.

• Low Voltage - Determine Reason & Correct.

• Relay Failing To Open - Determine Reason & Correct, Replace If Necessary.

• Run Capacitor Defective - Determine Reason & Replace.

• Excessively High Discharge Pressure - Check Discharge Shut-Off Valve, Or Insufcient Cooling On

Condenser.

• Compressor Motor Has Winding Open Or Shorted - Replace Compressor.

• Internal Mechanical Trouble In Compressor - Replace Compressor.

5. Condensing unit starts and runs, but

short cycles on overload protector.

•Additional Current Passing Through Overload Protector - cycles on overload protector. Check Wiring

Diagram. Check For Added Fan Motors, Pumps, etc., Connected To Wrong Side Of Protector.

• Low Voltage To Unit (or unbalanced if three phase) - Determine Reason & Correct.

• Overload Protector Defective - Check Current - Replace Protector.

• Run Capacitor Defective - Determine Reason & Replace.

• Excessive Discharge Pressure - Check Ventilation, Restrictions In Cooling Medium, Restrictions in

Refrigeration System.

• Suction Pressure Too High - Check For Possibility Of Misapplication. Use Stronger Unit.

• Compressor Too Hot (return gas) - Check Refrigerant Charge (x leak) Add If Necessary.

• Compressor Motor Has Winding Shorted - Replace Compressor.

6. Condensing unit runs but short cycles

on.

• Overload Protector - See #4 Above.

• Thermostat - Differential Set Too Close.

• High Pressure “Cut-Out” Due To:

a) Insufcient Air or Water Supply - Check Air or Water Supply To Condenser, Correct

b) Overcharge - Reduce Refrigerant Charge

c) Air In System - Purge

• Low Pressure “Cut-Out” Due To:

a) Liquid Line Solenoid Leaking - Replace

b) Compressor Valve Leak - Replace

c) Undercharge - Fix Leak, Add Refrigerant

d) Restriction In Expansion Device - Replace Device

10. SERVICE (continued)

10B - SPARE PARTS:

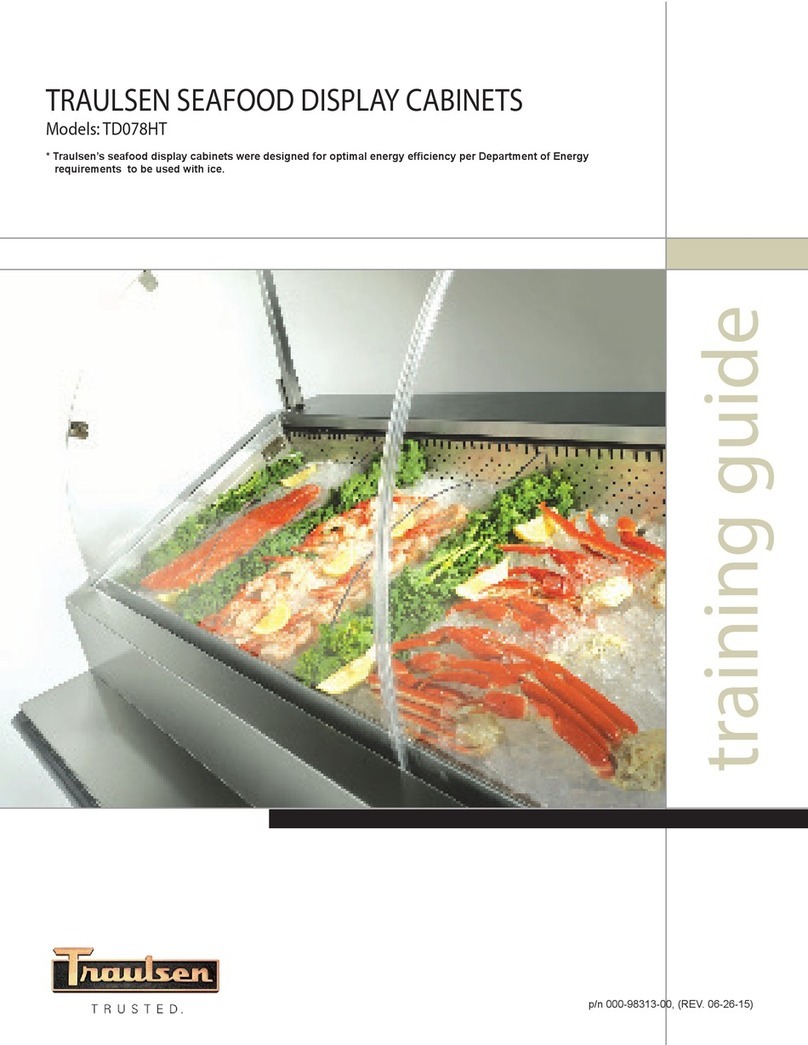

Spare or replacement parts may be obtained through a parts supplier or one of our authorized service agents. You may

obtain the name of a service agent from the MENU/SERVICE TAB on our website: www.traulsen.com

10C - WARRANTY REGISTRATION:

For your convenience, the warranties on your new Traulsen unit may be registered with us by one of two methods. Com-

pleting the enclosed warranty card (shipped with the unit), or by lling out the on-line warranty registration form located on

the MENU/SERVICE TAB on our website: www.traulsen.com

11. TROUBLESHOOTING GUIDE

11A. TROUBLESHOOTING GUIDE CHART: