Page.7

17602099‐12/9/2019

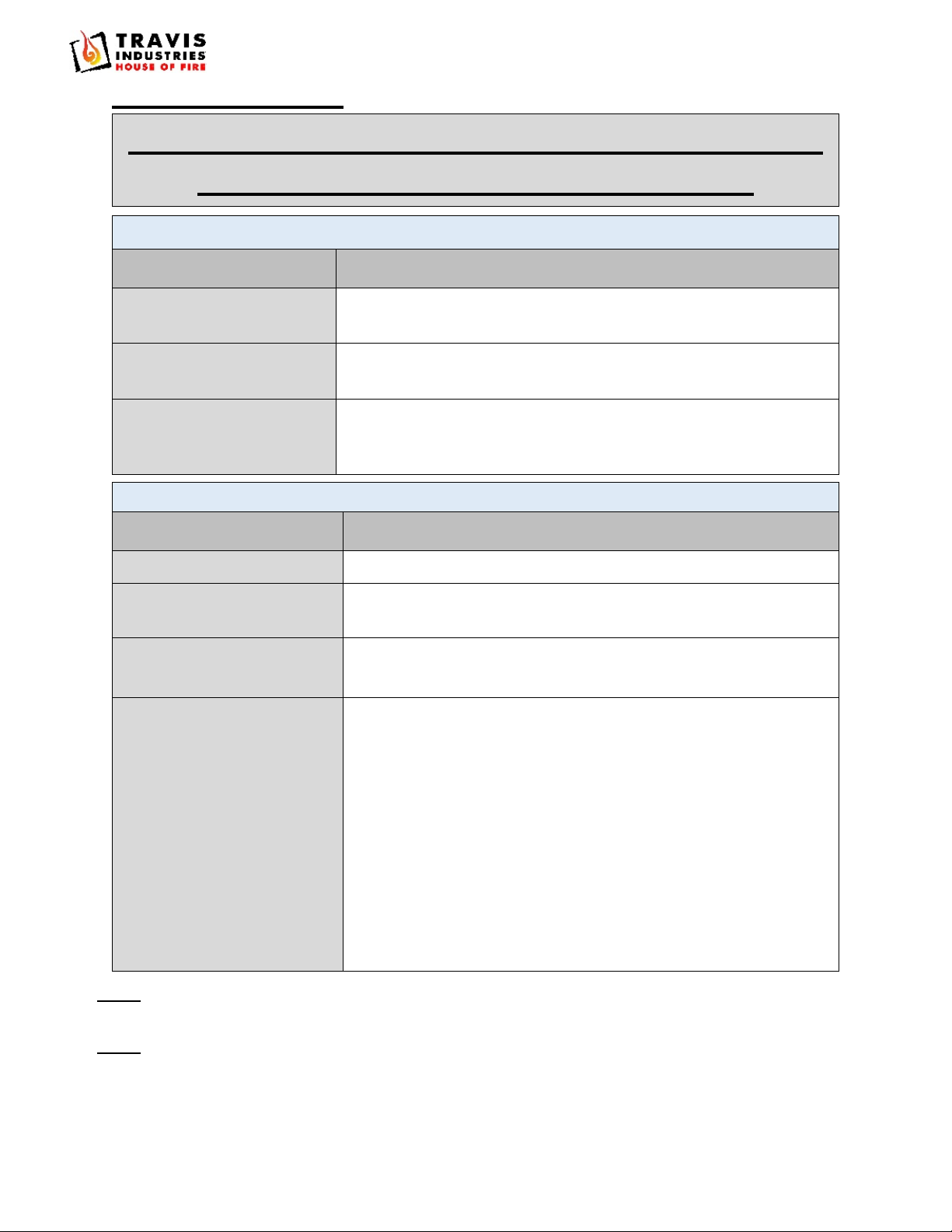

Torch Wiring Diagram

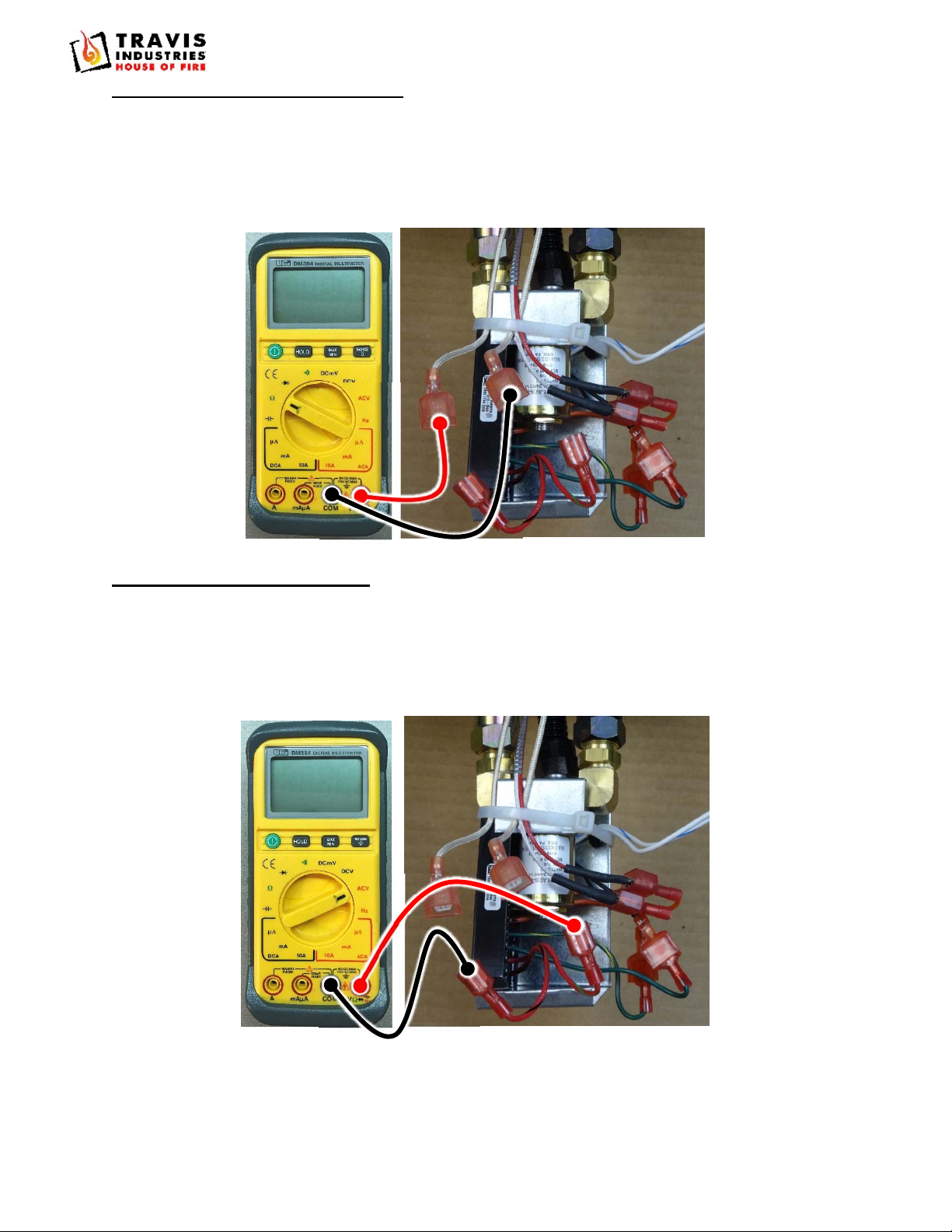

All wiring inside the torch leads to the control module. The module has remained the same, but

the color of the wires from the module has changed. See the two diagrams below.

Control Module Wiring Diagram – July 2019 or Later

* NOTE: The thermopile must connect to the control module as shown above (white/orange wire connects

to the white thermopile wire and orange wire connects to red thermopile wire). Do not reverse

the wires. If the wires are reversed, the torch will not work correctly.

Control Module Wiring Diagram – July 2019 or Earlier

* NOTE: The thermopile must connect to the control module as shown above (orange/white wire connects

to the white thermopile wire and orange wire connects to red thermopile wire). Do not reverse

the wires. If the wires are reversed, the torch will not work correctly.

WARNING ATTENTI ON

Here is another sticker with

im por t ant i n f or m at i on t hat you

should also read

UL

GHJH

TravisInd.

Makes nice

Fireplaces

Bl ah bl ah bl ah bl ah

yadda yad da bl ah

blah y adda y adda

How m uch w ood could a woodchuc k

chuck if a w oodchuck could chuck

wood?

He’d chuck as m uch w ood as a

woodchuc k co uld c huck if a

woodchuc k co uld c huck wood.

I have no idea what this sticker says but I will put in this text to

make i t l ook m or e real i sti c. Pl ease m ake su r e you read t he

actual l abe l so you don 't hur t yoursel f.

Thank you f or y our at t e nt i on t o t his i mport ant m at ter .

I have no idea what this sticker says but I will put in this text to

make i t l ook m or e real i sti c. Pl ease m ake su r e you read t he

actual l abe l so you don 't hur t yoursel f.

Thank you f or y our at t e nt i on t o t his i mport ant m at ter .

Why do you never see a

hippopotamu s hiding in a

tree?

Because they are good at it!

What do you do when y ou

see a s pace man?

You park m an!

Red*

White*

White/Orange*

Orange* White/Gree

Green

White

Red

White/Red

Black

White/Yellow

Yellow

24VAC Control

Module

1

+

WARNING ATT ENT I O N

Here is anot her s t icker with

import ant inform ation t hat y ou

should also r ead

U

L

GHJH

Travis Ind.

Makesnice

Fireplaces

Blah blah blah blah

yadda yadda blah

blah yadda yadda

How much wood could a woodchuck

chuck if a woodchuck c ould c huc k

wood?

He’d chuck as m uc h wood as a

woodchuck could chuck if a

woodchuck cou ld c huck wood.

I ha v e no idea wha t t his st ick er sa ys but I will put in t his t ext t o

make it look mor e realistic. Please m ak e s ur e y ou r ead t he

actua l label so you d on't hurt your self .

Thank y ou for y our att ention t o this im por t ant m att er .

I ha v e no idea wha t t his st ick er sa ys but I will put in t his t ext t o

make it look mor e realistic. Please m ak e s ur e y ou r ead t he

actua l label so you d on't hurt your self .

Thank y ou for y our att ention t o this im por t ant m att er .

Why do you n ever see a

hippopotam us hiding in a

tree?

Because t hey ar e good at it!

What do you do when you

see a sp ace man?

You par k m a n!

Red*

White*

Orange

Orange/White* Green/Yellow

Green

White

Red/Black

Red/Green

Black

White/Blue

White

24VAC Control

Module

1

+