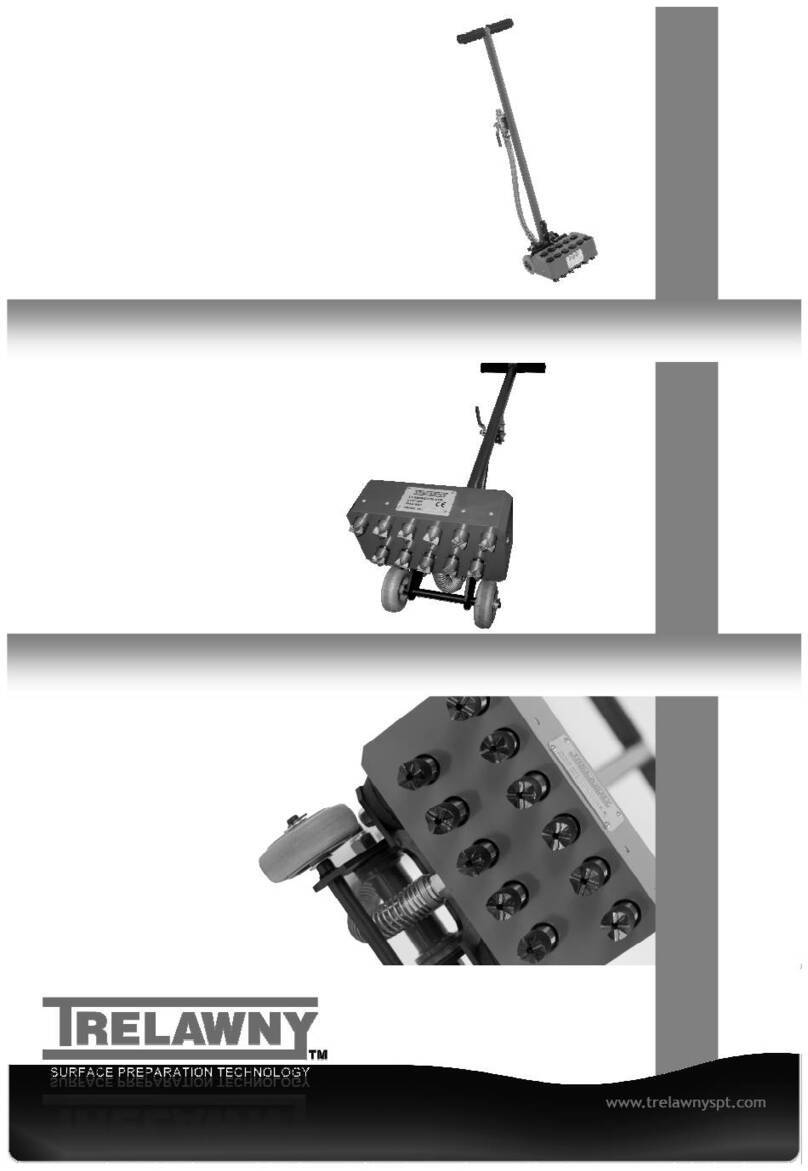

Trelawny LR2 User manual

Long Reach Scalers

Operation and Maintenance Manual

www.trelawnyspt.co.uk

OPERATION

General Information

Before operating, performing maintenance or

repairing the Long Reach Scaler this manual

must be read and understood by the operator,

if in any doubt, ask your supervisor before

using this equipment.

Local safety regulations must be followed at

all times. Failure to follow these instructions

could result in damage to the Scaler and/or

personal injury.

Trelawny SPT Limited disclaims all

responsibility for damage to persons or

objects arising as a consequence of incorrect

handling of the tool, failure to inspect the tool

for damage or other faults that may influence

the operation prior to starting work, or failure

to follow the safety regulations listed or

applicable to the job site.

The tool is primarily designed for the removal

of workshop soiling, solidified paint spills,

carpet and ceramic tile removal, heavy rust,

and scale, concrete splashes and ; it can also

be used for the removal of laitance from

concrete.

This tool must not be used in a fixture.

This tool can be purchased in either Needle

Scaler or Chisel Scaler versions, with an

adaptor available for converting from one

version to another. It can be used both

indoors and out.

Air Supply

The compressed air must be free from water

and dirt. The installation of a filter/regulator/

lubricator air preparation set (with moisture

trap) adjacent to the tool is strongly

recommended.

Always clear the air hose before connecting to

the tool. Ensure that no moisture

(condensation) is present in the air hose.

Ensure that a minimum 10mm (3/8”) bore air

hose is used and that all couplings are

secure, leak free and in good condition.

Limit the length of air hose to 10M (33ft).

Where extra length is necessary, for each

additional 15M (50ft) of air hose used, the

pressure drop is approximately 0.21bar

(3psi).

For safe and efficient operation the correct

operating pressure is 6.2bar (90 psi).

Do not let the operating pressure fall below

5.5bar (80p.s.i.) or rise above 6.9bar (100 psi)

absolute maximum.

Preferably, the compressor should be able to

supply a minimum of 2.8 L/s (6 cfm).

In particularly cold temperatures it is

recommended that a proprietary anti-freeze

lubricating oil is used.

Lubrication

Oil the tool daily before use. Put a few drops

of one of the following zinc free air tool

lubricants through the air inlet.

SHELL S22 or R10

CASTROL Hyspin ZZ32

See also the section on AIR SUPPLY for

further information and recommendations.

Safety

Always, read through these instructions first

before use.

Do-

Be aware that this tool is not electrically

insulated.

Wear Personal Protective Equipment

including safety goggles, footwear, ear

defenders and gloves. In some environments

it will be necessary to wear

facemasks or breathing apparatus.

Be aware that this tool can create dust and

flying debris.

Keep hands and clothing away from moving

parts.

Store this tool in a secure and dry

environment.

Be aware of others working around you.

Ensure that this tool is lubricated daily.

Always observe safe-working practices at

all times.

Do not-

Allow the tool to run unattended.

Modify this tool in any way, as this will

invalidate the warranty and could lead to

serious injury.

Allow the tool to run continuously whilst not in

contact with the surface being prepared.

Use the tool if you become tired, this can lead

to physical strain or injuries.

Hold the exposed chisel or needles whilst the

tool is in use, this could cause vibration

damage to the hands.

Use this tool in potentially explosive

environments.

Drag this tool by the air hose.

Use petrol (gasoline), thinners or any other

high flash point solvent to clean the tool.

Care must be taken to avoid damaging or

tripping over the trailing air hose.

Please note: Unrestrained hoses can whip

dangerously if they become detached.

Risk of Hand-arm

Vibration injury

These tools may cause Hand-arm Vibration

Syndrome injury if their use is not adequately

managed.

We advise you to carry out a risk assessment

and to implement measures such as:

Limiting exposure time [i.e. actual trigger time,

not total time at work], job rotation, ensuring

the tools are used correctly, ensuring the tools

are m aintained according to our

recommendations, and ensuring that the

operators wear personal protective equipment

[PPE] particularly gloves and clothing to keep

them warm and dry.

Employers should consider setting up a

programme of health surveillance to establish

a benchmark for each operator and to detect

early symptoms of vibration injury.

We are not aware of any PPE that provides

protection against vibration injury by

attenuating vibration emissions.

See ‘Specifications’ section for vibration

emission data.

Further advice is available from our Technical

Department.

We strongly advise you to visit the Health &

S a fe t y E x ec u ti v e w e b si t e h t t p: / /

www.hse.gov.uk/vibration This site provides

excellent advice and information on HAV and

it includes a Hand-arm Vibration Exposure

Calculator that is easy to use to work out the

daily vibration exposure for each of your

operators.

Starting work

Please note:

The carbon steel chisels or needles provided

with these tools are not intended for use in a

potentially explosive atmosphere.

Prior to operating the tool check: -

That all fittings are secure, free from leaks

and air hoses are in good condition.

That the air pressure is correct for this tool

6.2 bar (90 p.s.i.).

Put a few drops of a recommended lubricant

into the air inlet of the tool.

To operate the tool, which is dependant on

the type of lever fitted, for those fitted with a

safety lever, first push thumb button forwards

and then for both styles of lever, pull the lever

towards the hand grip to start the tool, then

apply the Chisel or Needles to the surface

being prepared.

Note: Several types of Chisel are available for

the Long Reach Chisel Scaler to suit the job in

hand, including Aluminium Bronze spark

resistant Chisels; a Needle Scaler Attachment

is also available.

See parts list for details.

Warning! This tool will continue to run for a

few seconds after releasing the throttle lever;

it is recommended that the tool remains in

contact with the work surface until the air is

exhausted. Gloves and personal protective

equipment must be worn when using this tool.

(See previous section on Risk of Vibration

Injury). Care must be taken to avoid damaging

or tripping over the air hose. Maintain contact

with the work surface with sufficient pressure

to keep the tool from bouncing off the surface.

Handled correctly the Long Reach Scaler will

work quickly and efficiently.

To switch off, simply release the throttle

lever.

Safe use of this tool requires a solid stance

and secure foothold, the tool may be used in

other postures but care must be taken to

ensure the operator adopts a firm and stable

position. Excessive operator pressure will not

improve the tools efficiency but could cause

premature tool failure and increase operator

fatigue. It could also increase the vibration

emission level.

Never allow the tool to run continuously

whilst not in contact with the surface being

prepared.

Do not use the Scaler as a lever, if the Chisel

becomes embedded in the material, withdraw

and try again. Never allow the tool to run

continuously whilst not in contact with the

surface being prepared.

MAINTENANCE

Chisels

Various sizes and types of Chisel are

available.

See parts list for details.

Fitting of Chisel Holder

Before fitting the Chisel Holder (31),

disconnect the tool from the air supply.

To fit the Chisel Holder (31) ensure that the

pinch bolt (30) on the Chisel Holder is loose,

screw the Chisel Holder fully on to the

Cylinder (10).

Turn the knurled collar on the Chisel Holder

(31) until the retaining ball is fully visible.

Insert the Chisel (32) into the Chisel Holder

(31) and select the nearest position to align

the blade with the Throttle Lever (7).

Turn the collar half a turn to lock the Chisel

(32) in place.

If the Chisel (32) does not line up, it may

require the Chisel Holder (31) to be

unscrewed slightly.

Tighten the pinch bolt (30) using a 6mm AF

Allen key. To release the Chisel (32), rotate

the knurled collar until the retaining ball is fully

visible and remove the Chisel (32).

Needle Holder Attachment

Before fitting the Needle Scaler Attachment,

disconnect the air supply to the tool.

Assemble the component parts of the Needle

Scaler attachment in the following order;

insert the Needles (26) into the Needle Holder

(25), place the Spring (27) over the Needles,

Pointed tip needles

Sharpened to a nail point, these are most

effective in breaking through very hard scale

on surfaces where some surface indentation

is permissible - or where keying (i.e. profile) of

the surface is desirable.

Pointed tip needles are available in 3mm and

4mm only.

Chisel tip needles

These are general purpose needles, flattened

to a chisel like blade and are most effective in

the removal of thicker material, while leaving a

less pitted surface than the Pointed tip

needles but still giving some surface

indentation (i.e. profile).

Chisel tip needles are available in 3mm only.

Flat tip needles

Machined to a flat tip, these needles will leave

slight marking (i.e. profile) on the surface; the

2mm needles can have a burnishing effect.

2mm Needles are recommended for use on

thin gauge metals and any surface where light

treatment is desired.

Flat tip needles are available in three sizes -

2mm, 3mm and 4mm.

Maintenance

Only a competent person, in a suitably

equipped workshop, must carry out

maintenance.

Disconnect the tool from the air supply

before carrying out any maintenance or

any of the operations in the next sections.

Clean all debris from the exterior of the tool.

Cleaning

At intervals of no more than 40 hours or if

operation becomes unproductive and the

Piston shows signs of sticking, dismantle and

clean with a highly refined paraffin.

Replace worn components as necessary.

Immediately after cleaning, thoroughly oil the

tool with one of the recommended lubricants.

Piston and Cylinder Removal

Remove the Chisel Holder (31) or Needle

Attachment as previously described. Clamp

the Cylinder (10) firmly in a vice using the flats

provided. Using a suitable wrench and the

spanner flats provided, unscrew the Cover

(14) from the Cylinder (10). This may initially

need some extra effort to break the bond.

With the Cylinder (10) free of the Cover, push

the Piston (9) out of the Cylinder (10).

Remove the Cylinder (10) from the vice and

inspect all parts for wear, particularly the

Piston (9) and the Cylinder’s bores. Remove

the two O’ Rings (11)(12) from the Cylinder

(10).

Valve Body Servicing

Clamp the Valve Body Assembly firmly in a

vice at the Valve Body (6) using the flats

provided, with the Throttle Lever (7)

uppermost. Using a 3mm diameter pin punch

and small hammer, remove the Throttle Lever

Roll Pin (8), and remove the Throttle Lever

(7). Rotate the Valve Body (6) 180 degrees in

the vice to gain access the Valve Cap (1).

Unscrew the Valve Cap (1) using a

screwdriver, check the Valve Cap 'O' Ring (2)

for signs of deterioration, remove the Spring

(3), push out the Valve Stem (4) and remove

the valve seat 'O' Ring (5). Check the Valve

Stem (4) and 'O' Ring (5) for wear.

Assembly

Before any assembly takes place, ensure all

parts are clean and are coated in a thin film of

recommended air tool lubricant.

It is strongly recommended that all the

O’Rings and any other worn parts be replaced

using only genuine Trelawny spares.

Valve Body Assembly

Clamp the Valve Body firmly in a vice, using

the flats provided, and with the threaded hole

uppermost.

Insert the valve seat 'O' Ring (5) into Valve

Body (6), followed by the Valve Stem (4),

Spring (3), then the Valve Cap (1) complete

with its 'O' Ring (2), tighten the Valve Cap (1)

with a screwdriver.

Rotate assembly 180 degrees in the vice.

Using a 3mm diameter pin punch locate and

align the Throttle Lever (7) in position, then

drive in the Throttle Lever Roll Pin (8) into the

pin location.

Piston and Cylinder Assembly

Fit new O’Rings (11)(12) to the Cylinder (10),

Lubricate the Piston (9) and Cylinder bore,

insert the Piston (9) into the Cylinder bore.

Ensure that the threads on the Cylinder (10)

and in the Cover are clean and dry.

Clamp the Cylinder (10) in a vice using the

flats provided.

Then using a suitable wrench on the spanner

flats provided, tighten the Cover onto the

Cylinder (10) and torque to 135Nm (100lbs/ft).

Refit the Chisel Holder/Needle Scaling

Attachment as described previously.

Recommended

Lubricants

Oil the tool daily before use. Put a few drops

of one of the following zinc free air tool

lubricants through the air inlet.

SHELL S22 or R10

CASTROL Hyspin ZZ32

Disposal

When the tool and its accessories are taken

out of service for disposal, it is recommended

that: -

They are rendered unusable to prevent

improper re-use.

They are dismantled into component form,

segregated according to material composition

and disposed of using waste recycling

processes specified by local regulations.

Machinery Directive

Information

This tool has been designed and produced in

accordance with the following directive:

2006/42/EC Machinery Directive

and applicable harmonised standard:

EN ISO 1 1148-4:2010

insert the Anvil (24) into the Needle Holder

(25), then place the assembly into the

Intermediate Tube (28). Check the service

layout for clarification. Screw the assembly

fully onto the Cylinder (10) and tighten the

pinch bolt (30) using a 6mm AF Allen key.

Slide the Front Tube (29) on to the

Intermediate Tube (28) until approximately

25mm (1”) of Needle protrudes from the Front

Tube (29). Tighten the pinch bolt (30) using a

6mm AF Allen key.

As the Needles wear, adjust the Front Tube

by loosening the Allen Screw and adjusting

the Front Tube so that approximately

1” (25mm) of Needle protrudes from the Front

Tube (29) and then retighten the Allen Screw.

The correct

position of parts

when changing

needles

Hold the needles loosely

and shake the holder,

needles will fall into location

holes

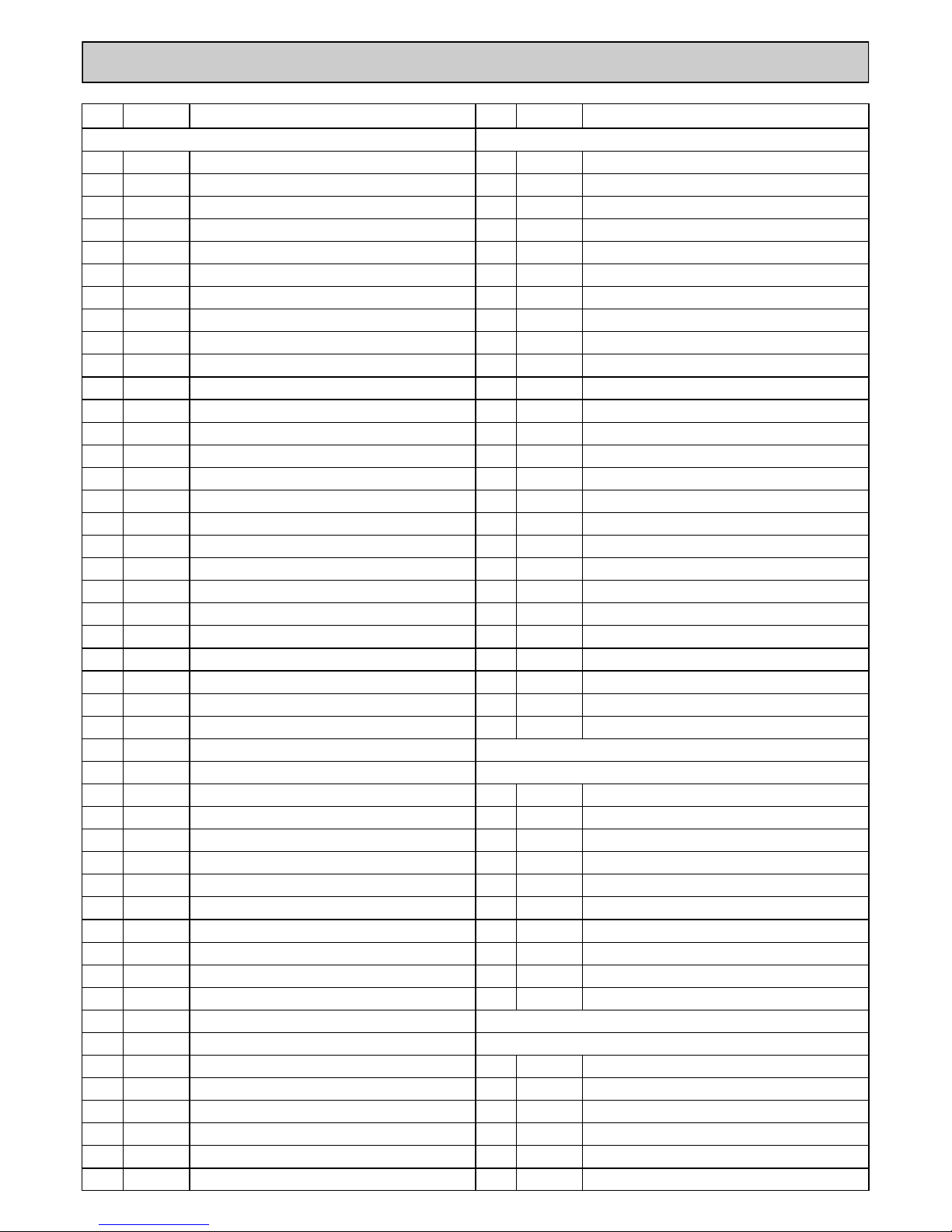

SERVICE LAYOUT - Standard Scaler

SERVICE LAYOUT - Lite Scaler

PARTS LIST

ITEM PART No DESCRIPTION ITEM PART No DESCRIPTION

Common components Common components

1 615.3021 Valve Cap 29 417.3032 Front Tube (Straight)

2 809.0139 O’Ring (Valve Cap) 418.3032 Front tube (Round)

3 712.3022 Valve Spring 415.3532 Needle Scaler Assembly (Items 24 to 28)

4 618.3022 Valve Stem 30 806.0830 Cap Head Screw

5 809.0089 O’Ring - (Valve Seat) 31 419.3541 Chisel Holder Assembly 5/8” Hex

6 616.3021 Valve Body 32 705.1102 Chisel 5/8” Hex 8” Long x 4” Blade

423.3021 Valve Body Assembly BSP Thread (inc items 1-8) 431.3504 Scraper Holder - includes 4” Replaceable Blade

423.3521 Valve Body Assembly NPT Thread (Inc items 1-8) 431.3508 Scraper Holder - inc 8” Replaceable Blade

431.3512 Scraper Holder - inc 12” Replaceable Blade

7 716.3000 Throttle Lever 431.3904 Scraper Holder - inc Bevelled 4” Replaceable Blade

8 813.0108 Roll Pin 431.3908 Scraper Holder - inc Bevelled 8” Replaceable Blade

9 612.3001 Piston 431.3912 Scraper Holder - inc Bevelled 12” Replaceable Blade

10 613.3101 Cylinder 439.3504 Pack of 5 Scraper blades 4”

11 809.0289 O’Ring (Cylinder -small diameter) 439.3508 Pack of 5 Scraper blades 8”

12 809.0299 O’Ring (Cylinder -large diameter) 439.3512 Pack of 4 Scraper blades 12”

24 610.3001 Anvil 439.3524 Pack of 5 Bevelled Scraper blades 4”

25 601.3003 3mm Needle Holder 439.3528 Pack of 5 Bevelled Scraper blades 8”

601.3002 2mm Needle Holder 439.3522 Pack of 5 Bevelled Scraper blades 12”

601.3004 4mm Needle Holder 705.1100 Chisel 5/8” Hex 9” Long x 2” Blade

26 412.1165 6 x 2mm Needle Sets (Flat Tip) 705.1106 Chisel 5/8” Hex 9” Long x 2” Blade

413.2128 6 x 3mm Needle Sets (Chisel Tip - standard fitment) 705.1112 Chisel 5/8” Hex 8” Long Spark Resistant 4” Blade

413.1128 6 x 3mm Needle Sets (Flat Tip) 708.1100 Comb Holder 5/8” Hex for 1 1/2” Steel Comb

413.3128 6 x 3mm Needle Sets (Pointed Tip) 708.1101 Comb 1 1/2” Wide

403.1328 1 x 3mm Needle Sets (Beryllium Copper) 641.3512 Yoke for Scraper Blades (no blade)

414.2119 6 x 4mm Needle Sets (Chisel Tip) 806.0816 Button Head Screw for Yoke/Scraper Blade

414.1119 6 x 4mm Needle Sets (Flat Tip) 824.0800 Nyloc Nut for Yoke/Scraper Blade

414.3119 6 x 4mm Needle Sets (Pointed Tip)

442.1107 Pack of 2000 2mm Needles (Flat Tip) Long Reach components (Standard tool)

452.1110 Pack of 100 2mm Needles (Flat Tip) 14 425.3225 2’ Cover std

443.2107 Pack of 1000 3mm Needles (Chisel Tip) 425.3425 4’ Cover std

443.1107 Pack of 1000 3mm Needles (Flat Tip) 425.3525 5’ Cover std

443.3107 Pack of 1000 3mm Needles (Pointed Tip) 425.3625 6’ Cover std

443.1307 Pack of 500 3mm Needles (Beryllium Copper) 18 717.3055 Rubber Handle Grip

453.2110 Pack of 100 3mm Needles (Chisel Tip) 19 717.3501 Cover Grip

453.1110 Pack of 100 3mm Needles (Flat Tip) 20 624.3001 Handle Tube

453.3110 Pack of 100 3mm Needles (Pointed Tip) 21 623.3001 Centre Tube

453.1310 Pack of 100 3mm Needles (Beryllium Copper) 22 625.3001 Locknut

444.2107 Pack of 500 4mm Needles (Chisel Tip) 23 810.9000 Sealing Washer

444.1107 Pack of 500 4mm Needles (Flat Tip)

444.3107 Pack of 500 4mm Needles (Pointed Tip) Long Reach components (Lite tool)

454.2105 Pack of 50 4mm Needles (Chisel Tip) 14 425.3498 4’ Lite Cover

454.1105 Pack of 50 4mm Needles (Flat Tip) 425.3598 5’ Lite Cover

454.3105 Pack of 50 4mm Needles (Pointed Tip) 425.3698 6’ Lite Cover

27 712.3001 Compression Spring 19 717.3501 Cover Grip

28 416.3132 Intermediate Tube 21 627.3598 Threaded Adapter

SPECIFICATION

H1* Indicates that the test was taken at the primary handgrip location, next to the throttle lever.

H2* Indicates that the test was taken at the secondary handgrip position.

Noise level measured in accordance with: EN ISO 15744: 2008

Risk of Hand Arm Injury

(k) ** Equals the factor of uncertainty, which allows for variations in measurement and production. Vibration Data figures are tri-axial, which gives the total vibration

emission.

Because of various factors, the range of vibration emission during intended use can vary. The vibration is dependent on the task, the operators grip, and feed force

employed etc.

NOTE: The above vibration levels were obtained from tri-axial measurements to comply with the requirements of “The Control of Vibration at Work Regulations 2005*” and

the revisions to the (8662) now EN ISO 28927:2012 and EN ISO 20643:2005 series of standards. These values are at least 1.4 times larger than the values obtained from

single axis measurements.

*Based on European Union Council Directive 2002/44/EC (Physical Agents (Vibration) Directive)

If your company has any problem with our products or would like to discuss the possibility of an improvement being made to them, then please do not hesitate to contact us.

Your comments are both important and appreciated.

All rights reserved. Any unauthorised use or copying of the contents or part thereof is prohibited.

This applies to trademarks, model denominations, part numbers and drawings.

Use only genuine Trelawny spares.

The use of non-Trelawny spare parts invalidates the warranty.

Model Type LR2 LR4 LR4 Lite LR5 LR5 Lite LR6 LR6 Lite

Piston Diameter 28.6mm 28.6mm 28.6mm 28.6mm 28.6mm 28.6mm 28.6mm

Piston Stroke 39mm 39mm 39mm 39mm 39mm 39mm 39mm

Blows per Minute 2200 2200 2200 2200 2200 2200 2200

Air Consumption 2.1lps

(4.5cfm) 2.1lps (4.5cfm) 2.1lps (4.5cfm) 2.1lps (4.5cfm) 2.1lps (4.5cfm) 2.1lps (4.5cfm) 2.1lps (4.5cfm)

Air Inlet 1/4” BSP (c/w 1/4”BSP to 3/8” hose tail)

Overall Length 740mm (29”) 1100 (43”) 1100 (43”) 1400mm (55”) 1400mm (55”) 1710mm (67”) 1710mm (67”)

Nett Weight 4.8kg (10.6bs) 5.7kg (12.6lbs) 3.7kg (8.2lbs) 6.25kg (13.8lbs) 4.05kg (8.9lbs) 6.9kg (15.2lbs) 4.55kg (10lbs)

Noise Level Lpa db(A) - Chisel Scaler 81.3 80.5 85.8 82.4 81.2 84.3 84.2

Noise Level Lpa db(A) - Needle Scaler 103.1 103.5 104.7 103 104.5 103.5 104.5

Noise Level Lwa db(A) - Chisel Scaler 94.3 93.5 98.8 95.9 - - -

Noise Level Lwa db(A) - Needle Scaler 116.1 117.7 116.5 116 117.5 116.5 117.5

Vibration Level AEQ - Needle Scaler H1* (k)

** 5.55 0.81 7.7 0.73 1.24 0.77 1.58

Vibration Level AEQ - Needle Scaler H2* (k)

** 1.09 1.02 1.12 1.03 0.64 1.08 0.88

Vibration Level AEQ - Chisel Scaler H1* (k)** 0.82 2.49 2.81 3.08 1.4 5.13 0.78

Vibration Level AEQ - Chisel Scaler H2* (k)** 1.22 1.6 1.64 1.6 1.93 1.28 1

NOTES

NOTES

Trelawny SPT Ltd

13 Highdown Road, Sydenham Industrial Estate, Leamington Spa,

Warwickshire, CV31 1XT, United Kingdom

Telephone: +44 (0)1926 883781 - Fax: +44 (0)1926 450352

Email: sales@trelawny.co.uk

© TSPT UK 2009 Part No: 735.3500 issue 13.2.17 www.trelawnyspt.co.uk

This manual suits for next models

6

Table of contents

Other Trelawny Media Converter manuals