TRI-TECH MEDICAL MCP100A Manual

- 1 -

Tri-Tech

Medical Inc.

Manufacturer of

Medical Gas Pipeline Equipment

Installation & Operating Instructions for

Area,

Master &

Combination

Alarm Systems

- 3 -

Tri-Tech

Medical Inc. Table of Contents

Contents

Introduction---------------------------- 5

Features & Benefits --------------------- 5

Major components ------------------------ 7

Alarm Panel Installation ------------ 15

Rough-In Box Installation ------------- 15

Mounting----------------------------------- 15

Wiring -------------------------------------- 16

Plumbing ----------------------------------- 17

Front Panel Installation ---------------- 18

Wiring alarm front to power supply---- 19

Installing the Transducers------------- 19

Wiring the transducers ------------------- 20

Wiring the Remote Devices ---------- 21

Labeling the Alarm Front ------------- 22

Alarm Displays & Functions ------- 9

Component identification---------------- 8

CPU module displays & functions --- 9

Power on indicator------------------------ 9

Silence button ----------------------------- 9

Test button --------------------------------- 9

Program mode indicator ----------------- 9

Program button ---------------------------- 9

Module button----------------------------- 9

Units button-------------------------------- 9

Alarm button------------------------------- 9

History button ----------------------------- 9

View Alarm History ------------------- 9

Clear Alarm History ------------------- 9

Identification (ID) button ---------------- 9

Status LED--------------------------------- 9

CPU reset ---------------------------------- 9

Gas (Area) module displays &

functions ----------------------------------- 10

Gas service--------------------------------- 10

Pressure LED Digital Display----------- 10

Pressure LED Hi/Normal/Low Display- 10

Units of measure LED display ---------- 10

Remote Signal (Master) module displays

& functions-------------------------------- 10

Normal status LED ----------------------- 10

Abnormal status LED -------------------- 10

Remote signal description label--------- 10

Alarm Operation ---------------------- 13

Component identification ---------------- 12

Remote signal (master) module --------- 13

Gas (area) module------------------------- 13

Silencing the alarm ----------------------- 13

Testing the alarm-------------------------- 14

Programming the Alarm ------------ 25

Keypad identification--------------------- 24

Accessing the Program Mode ----------- 25

Hi/Low pressure limits ------------------- 25

Remote Signal Alarm Points ------------ 26

Alarm Repeater Delay-------------------- 26

Units of Measure Display---------------- 27

Zone Identification # --------------------- 27

Adding/Removing Modules --------- 28

System Alert Codes ------------------- 34

Appendix A

Glossary of Terms -------------------- 35

Appendix B

Alarm Specifications ----------------- 36

Appendix C

Signal Wire Color Code Log-------- 37

Technical Assistance---- 800-253-8692

or 440-937-6244

- 4 -

Tri-Tech

Medical Inc. Introduction

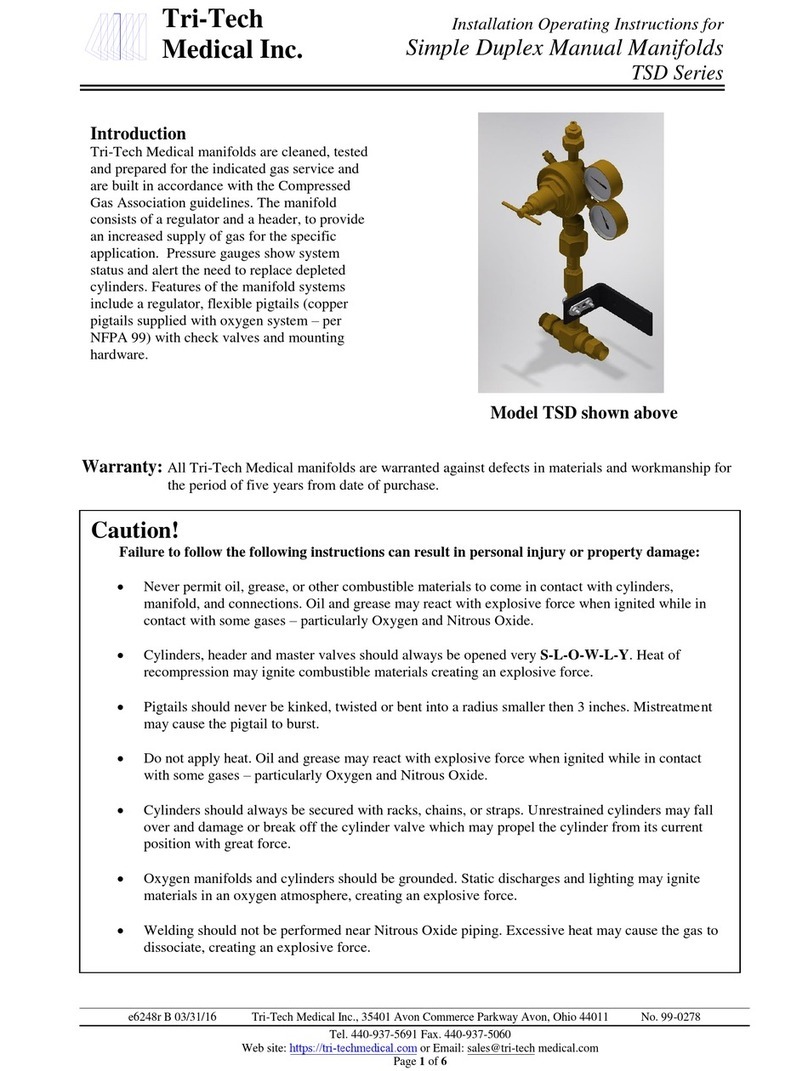

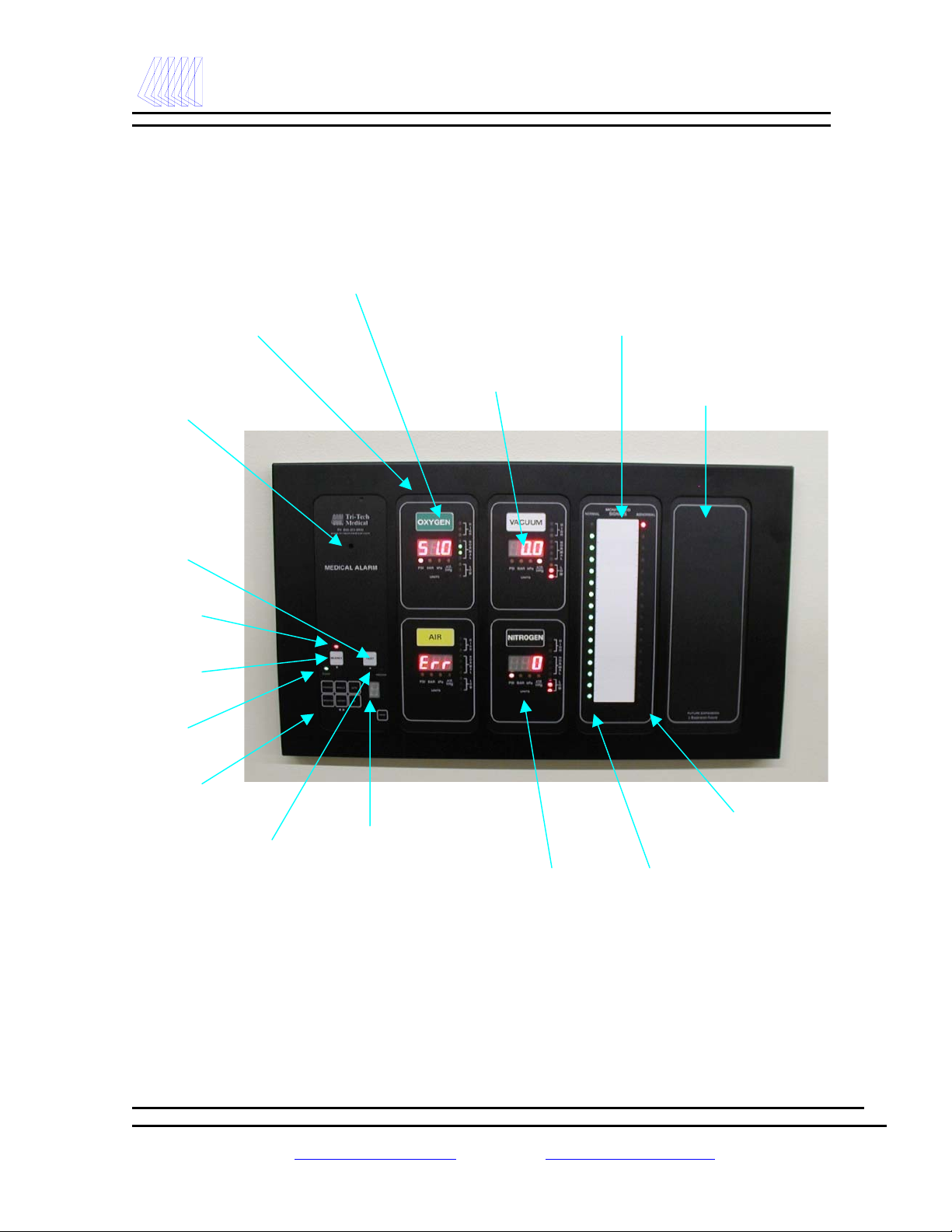

Gas (Area)Module

Audible alarm location

Color coded gas

identification label

Digital pressure

display

Units of measure indicator

PSI and Hg or Bar or kPa

Remote signal (master) description label

Power on indicator

Alarm silence indicator

Alarm silence button

Program mode indicator

Alarm test button

Status code display

Programming keypad

Remote signals normal

status LEDs - Green

Slot for future expansion with label

Remote signals abnormal

status LEDs - Red

- 5 -

Tri-Tech

Medical Inc. Introduction

Introduction

The Tri-Tech Medical gas alarm system monitors the status of the medical gas distribution system and

provides audible and visual indicators. The alarm can be used in conjunction with the Tri-Tech Medical

MCP100A or ACP-100-A Interface Panel to communicate all alarm/status information to the building

management system. The Tri-Tech alarm system monitors the status of the medical gas sources in accordance

with NFPA 99 and CSA Z305.1, and are C.U.L. listed.

Features & Benefits

Microprocessor controlled

State of the art maintenance free electronics

provide excellent reliability.

Remote signal modules

Provides monitoring of 16 separate remote

devices.

Self test program – alarm code display

LED display reveals the nature of the malfunction

and reduces maintenance time.

Three year PC board guarantee

A quality product you can buy with confidence.

Independent multiple master alarms

When service is interrupted to one alarm the

other(s) continue to operate independently.

Transient signal filter

Prevents or reduces nuisance (false) alarms

signals created by RFI interference.

Transient alarm notification

Indicates which parameter experienced a transient

(brief intermittent) signal.

Audio & visual signal indicators

Audible alarm and visual display of both normal

and abnormal status of each signal monitored

assures prompt and informative indication of a

problem.

Programmable remote signals

Configure each remote signal independently

(either normally closed, normally open or turn

unused signals off).

Programmable gas module high and low set

points – (Programmed from factory at 60/40 psig

and 12 in Hg).

Compact unit

Requires minimal wall space.

Optional building management interface panel

Allows communication with building

management system.

Alarm history recall

Can recall previous alarm signals even after the

alarm condition has been corrected and the alarm

panel has been cleared.

CUL Listed

Alarm repeat feature

Adjustable from 5 minutes to 4 hours (factory

programmed for 10 minutes).

Easy to install and service

Hinged frame with lanyards for easy

accessibility.

.

- 6 -

Tri-Tech

Medical Inc. Introduction / Components

Rough-in box or back box

Transducer AssembliesFront panel or front

- 7 -

Tri-Tech

Medical Inc. Introduction / Components

Introduction

The Tri-Tech Medical gas alarm system monitors the status of the medical gas distribution system and

provides audible and visual indicators. The alarm panel can be interfaced with a Tri-Tech Medical MCP100-A

or ACP-100-A Building Management interface panel for remote monitoring of the entire facility.

The Tri-Tech Medical gas alarm system is a two or three section assembly comprised of a rough-in box, a front

panel and transducers (only if it is an area alarm or combination alarm).

Rough-in box

The rough-in box houses the power supply, fuse, on/off switch, and a terminal strip for electrical wiring. An

isolated transformer reduces the 110V or 220V AC input to low voltage DC.

Front panel

The front panel includes enclosed printed circuit boards with programming circuitry.

The CPU module includes a power on indicator, programming buttons, an audible alarm, and an LED

status display.

The Remote Signal module(s) can monitor up to 16 signals per circuit board. Multiple remote signal

modules can be ordered in a single alarm. The signals can be configured to display an abnormal

condition on either a normally closed (NC) or a normally open (NO) circuit. Each signal may also be

turned off if it is not being utilized.

The Gas (Area) module(s) on the front panel are identified with gas specific, color coded labels (per

NFPA 99 or CSA Z305.1). The gas displays include LED’s which indicate high/normal/low pipeline

pressure. A digital LED display shows the actual gas pressure. The gas pressure may be displayed in

PSI and Hg, or BAR or kPa. The unit is pre-programmed to display PSI / Hg from the factory, but

may be re-programmed in the field to display BAR or kPa.

Transducers

The transducer converts pressure to an electrical signal and supplies the electrical signal to the front panel.

After the initial 24 hour 150 psi standing pressure test (required per NFPA 99) has been completed the

pressure/vacuum transducers are mounted in the rough-in box. The transducers may be remotely attached to

the piping system at distances no further than 100 feet using Beldon 8777 shielded cable. Tri-Tech Medical

recommends mounting the transducers in the alarm back box – not remotely. Should a transducer require

service or replacement is considerably more time consuming to locate and replace or service remotely located

transducers

- 8 -

Tri-Tech

Medical Inc. Alarm Displays & Functions

Gas (Area)Module

Audible alarm location

Color coded gas

identification label

Digital pressure

display

Units of measure indicator

PSI and Hg or Bar or kPa

Remote signal (master) description label

Power on indicator

Alarm silence indicator

Alarm silence button

Program mode indicator

Alarm test button

Status code display

Programming keypad

Remote signals normal

status LEDs - Green

Slot for future expansion with label

Remote signals abnormal

status LEDs - Red

- 9 -

Tri-Tech

Medical Inc. Alarm Displays & Functions

Alarm Displays & Functions

CPU Module

Power on Indicator

The power on indicator (green LED) is illuminated

whenever electrical power (120 or 240 VAC) is

connected to the alarm.

Test Button

When the Test button on the front panel is pressed, the

alarm undergoes a self-test checking the lights and

displaying the gas settings. If errors are detected, they

are displayed on the status LED and/or on the area

module gas LED displays.

Status Display

The status LED displays system alert codes when a

problem occurs (these are numeric). See System Alert

Codes on page 34 for details.

The status LED also displays a “P” whenever the

alarm is in the program mode.

Alarm Silence

In the event of an alarm condition an audible alarm

sounds. The audible alarm can be silenced by pressing

the alarm silence button. Whenever there is an alarm

condition and the alarm has been silenced, the Alarm

Silence Indicator LED will be illuminated. The high

or low pressure LED or the remote signal LED will

remain illuminated until the alarm condition is

rectified.

Program Mode Indicator

The Program Mode Indicator LED is only illuminated

when the alarm has been placed in the program mode

(see Programming the Alarm page 25). It should be

noted that when this LED is illuminated and the alarm

is in the program mode, it is not monitoring or

reporting alarm conditions for the medical gas

systems.

History Button

The History button may be pressed and held at any

time to view alarm history. Viewing alarm history is

only active when the History button is depressed,

releasing the button returns the alarm to normal

operation. When depressed “H” will be displayed in

the Status Display LED.

Gas(Area) Module - If there was an alarm condition

for any gas (area) module, the High and/or Low

Pressure LEDs will be illuminated. If both the High

and Low Pressure LEDs are illuminated, the gas has

had both a High and Low alarm.

Remote Signal (Master) Module – If there was an

alarm condition for any Remote Signal the Red LED

will be illuminated. All other LED’s will be off.

Clear Alarm History – To clear alarm History you

simply press the History button, hold it down and

press Silence button (while the history button is still

depressed.

Program Button

See Programming the Alarm pages 25 – 27

Module Button

See Programming the Alarm pages 25 - 27

Units Button

See Programming the Alarm pages 25 - 27

Repeater Button

See Programming the Alarm pages 25 - 27

ID (Identification) Button

See Programming the Alarm pages 25 - 27

CPU Reset Button

See Programming the Alarm pages 25 - 27

- 10 -

Tri-Tech

Medical Inc. Alarm Displays & Functions

Gas Displays (Area Module)

Pressure Reading Display

The LED pressure reading displays the pressure as

indicated by the transducer. Whichever of the PSI or

BAR or kPa lights is illuminated reveals the unit of

measure displayed on the LED pressure reading. The

Nitrogen gas display indicates one tenth of the actual

pressure when displayed using kPa units (i.e. 1100 kPa

is displayed as 110 and the kPa x 10 LED is

illuminated).

High / Normal / Low Status Lights

In addition to digitally displaying the pressure of a

gas, the pressure is displayed by a series of green,

yellow & red LEDs reflecting the pressure as either

normal, high or low. These indications are relative to

the high and low pressure set points which have been

programmed into the alarm. These high and low set

points should be set in accordance with NFPA 99 and

CSA Z305.1 at ±20% of the normal operating

pressure.

As the pressure climbs above normal line pressure to

20% above normal line pressure, the LED’s on the

upper side of normal will illuminate, then the

uppermost normal & yellow High LED’s will

illuminate, finally the two red High LED’s will

illuminate. Simultaneously with the Red LED’s

illuminating, the audible alarm will sound.

As the pressure falls to below normal line pressure to

20% below normal line pressure, the LED’s on the

lower side of normal will illuminate, then the

lowermost normal & yellow low LED’s will

illuminate, finally the two red Low LED’s will

illuminate. Simultaneously with the Red LED’s

illuminating, the audible alarm will sound.

Units Button & PSI / BAR / Kpa LED’s

By placing the alarm in the program mode (see

Programming the Alarm page 25 ) the units button

toggles the LED pressure readings on the gas displays

between PSI (inches Hg for vacuum & evacuation

BAR / kPa LEDs. The corresponding PSI, BAR or

kPa LED is illuminate indicating which units are being

displayed on the gas display.

Note: Vacuum & evacuation are actually displayed as

inches Hg in the PSI mode. The Nitrogen gas display

indicates one tenth of the actual pressure when

displayed using kPa units (i.e. 1100 kPa is displayed

as 110 and the kPa x 10 LED is lit. The power on

LED is illuminated whenever electrical power is

connected to the alarm.

Note Alarm settings are maintained even if power is

interrupted.

Remote Signal Status LED’s

(Master Module)

Normal Status Light (Green)

The normal green status light when illuminated

signifies that the equipment being monitored is not in

an alarm condition. A flashing green light indicates a

normal condition, but a transient (see glossary of

terms for definition) signal from source equipment has

been detected.

Abnormal Status Light (Red)

The abnormal status light when illuminated signifies

that the equipment being monitored is in an alarm

condition.

Note: If no LED is illuminated the remote signal

status LEDs have probably been set in the unused or

off position. This can be verified by having the alarm

run a self-diagnostic check. Simply press the Test

button. As the alarm runs thru the test cycle, observe

the Status Display LED when the Remote Signal in

question is blinking. A “d” displayed on the Status

Display LED indicates that the Remote Signal has

been disabled.

Remote Signal Description Label

The remote signal description label identifies the

equipment that is being monitored on the normal and

abnormal LED’s to the left and right of the label.

- 12 -

Tri-Tech

Medical Inc. Operation

Gas (Area)Module

Audible alarm location

Color coded gas

identification label

Digital pressure

display

Units of measure indicator

PSI and Hg or Bar or kPa

Remote signal (master) description label

Power on indicator

Alarm silence indicator

Alarm silence button

Program mode indicator

Alarm test button

Status code display

Programming keypad

Remote signals normal

status LEDs - Green

Slot for future expansion with label

Remote signals abnormal

status LEDs - Red

- 13 -

Tri-Tech

Medical Inc. Alarm Operation

Alarm Operation

Refer to the Alarm Installation section for the procedure necessary to install the alarm. The Programming The

Alarm section covers the procedures to follow in order to configure the alarm if the preprogrammed settings

are not appropriate. After installation has been completed and the alarm has been properly configured, it is

ready for operation.

Remote Signal (Master) Module

With electrical power applied to the alarm, the

system will monitor the status of the medical gas

distribution system.

The remote signals (master) module displays (via

LED indicators) the normal/abnormal status of the

remote equipment connected to the alarm. In

normal operation all active signals will be green.

Whenever an abnormal status signal is detected the

corresponding green LED will be extinguished and

the red LED will light. Simultaneously an audible

alarm will sound. Pressing the Silence button

silences the audible alarm (the Red LED continues

to be lit). The appropriate personnel should be

notified immediately of the alarm condition.

When the alarm condition has been rectified the

Red LED is automatically extinguished and the

Green LED illuminates.

Whenever an intermittent Transient (see Glossary

of Terms for definition) abnormal status signal is

detected from remote equipment by the alarm, the

Green or Red LED will start to flash. Transient

alarms indicate a potential problem. The

appropriate personnel should be notified of the

alarm condition. Pressing the Test or Repeater

button returns the flashing LED to normal

operation.

Note The Remote Signal (Master) alarm is set to

Ignore transient signals that are less than 0.6

seconds in duration.

Pressing the Test button initiates a self-test of the

alarm. Each LED will illuminate in succession for

2.5 seconds. The displays are then cleared and the

system circuitry is checked for proper voltages. If

no errors are found, the alarm returns to normal

operation. If an error is found, the error is

indicated on the Status Code Display.

Gas Modules

With the electrical power applied to the alarm and

the gas systems adequately pressurized, the

following indicators are illuminated: 1) the Power

On LED, 2) the pressure readings of the gas on

each gas display, 3) the Normal LED (green) on

each gas display.

If the pressure of one of the gases drops below the

low limit setting, the following events take place

simultaneously: 1) the Normal LED will be

extinguished, 2) the Pressure Low LED (red) will

light up, 3) an audible alarm will sound.

If the pressure of one of the gases rises above the

high limit setting, the following events take place

simultaneously: 1) the Normal LED will be

extinguished, 2) the Pressure High LED (red) will

light up, 3) an audible alarm will sound.

Silencing the Alarm

Press the Silence button when the alarm is

sounding and the alarm will be silenced.

This alarm is equipped with a Repeater Delay

feature which monitors only the Gas Module

(Area) alarms. The Repeater Delay has been

factory programmed to make the alarm re-sound

every 11 (eleven) minutes as long as the alarm

condition exists. (Note: Remote Signal (Master)

alarms are not monitored by the Repeater Delay).

- 14 -

Tri-Tech

Medical Inc. Alarm Operation

Testing the Alarm

Pressing the Test button initiates a self-test of the

alarm, resets any system status alerts that may be

active and re-initiates the alarm-repeat function.

Pressing any key will abort the test displays but

not the internal tests.

The test commences in the following order:

1. The alarm will sound, the status display

will display “8” and the 1st active module

will be displayed with all lights

illuminated for 2.5 seconds. This is the

only time the alarm will sound and the

Program & Silence LED indicators will

illuminate during the test.

2. Each remaining active module will be

displayed with all lights illuminated for

2.5 seconds, in sequence. The Gas (Area)

Modules will be displayed first (if gas

modules exist). The Remote Signal

(Master) Modules will be displayed

second (if Remote Signal modules exist).

Each existing active module will be

displayed for 2.5 seconds.

3. After all existing modules have

completed the lamp verify test above, any

existing Gas (Area) Module set points

will be displayed for 2.5 seconds. If no

Gas Modules exist, these displays will be

bypassed. All the high set points will be

displayed for 2.5 seconds first with the

high alarm LEDs indicating which set

point you are observing. Any Master

modules that exist will not be illuminated

during this time. If a gas is not active, i.e.

the module exists but an “inactive shunt”

instead of a transducer is connected to the

gas, the gas display will be blanked.

4. Next the active Master modules will be

displayed, one at a time, displaying the

current alarm programming and the

contact state of each alarm point. Each of

the Master module displays will consist

of the following: The module will be

illuminated. The top parameter will be

flashing indicating it is the first alarm

point under test (the active alarm point).

The status display will display the current

contact state of the active alarm point.

This display will consist of: “C” =

closed, “O” = open, “d” = disabled. If

the active alarm point is disabled, both

alarm point LED’s (both the green & the

red) will be illuminated. This is only for

the test display. In normal operation,

both of the LED’s will be turned off.

After 2.5 seconds, the next lower alarm

point will flash and the status display will

show it’s contact state for 2.5 seconds.

This sequence will continue until the last

(bottom) alarm point has been displayed.

This action will continue until all active

Master module alarm points have been

displayed.

5. When all active modules have been

displayed (Gas and/or Master), the test

will be complete and the system will

return to normal operation. Remember,

you can exit the test at any time by

pressing any key.

- 15 -

Tri-Tech

Medical Inc. Alarm Installation

Alarm Installation

Installation of the Tri-Tech Medical alarm involves installing the rough-in box, the transducers (if it is an area

alarm or combination alarm) and front panel and making the necessary conduit, plumbing and electrical

connections. All installation and testing should be done in accordance with NFPA 99 or CSA Z305.1.

WARNING: All electrical power should be disconnected prior to installation.

WARNING: This device should only be installed by qualified personnel. Installation should not be attempted

by anyone not having general experience with the installation of devices of this nature.

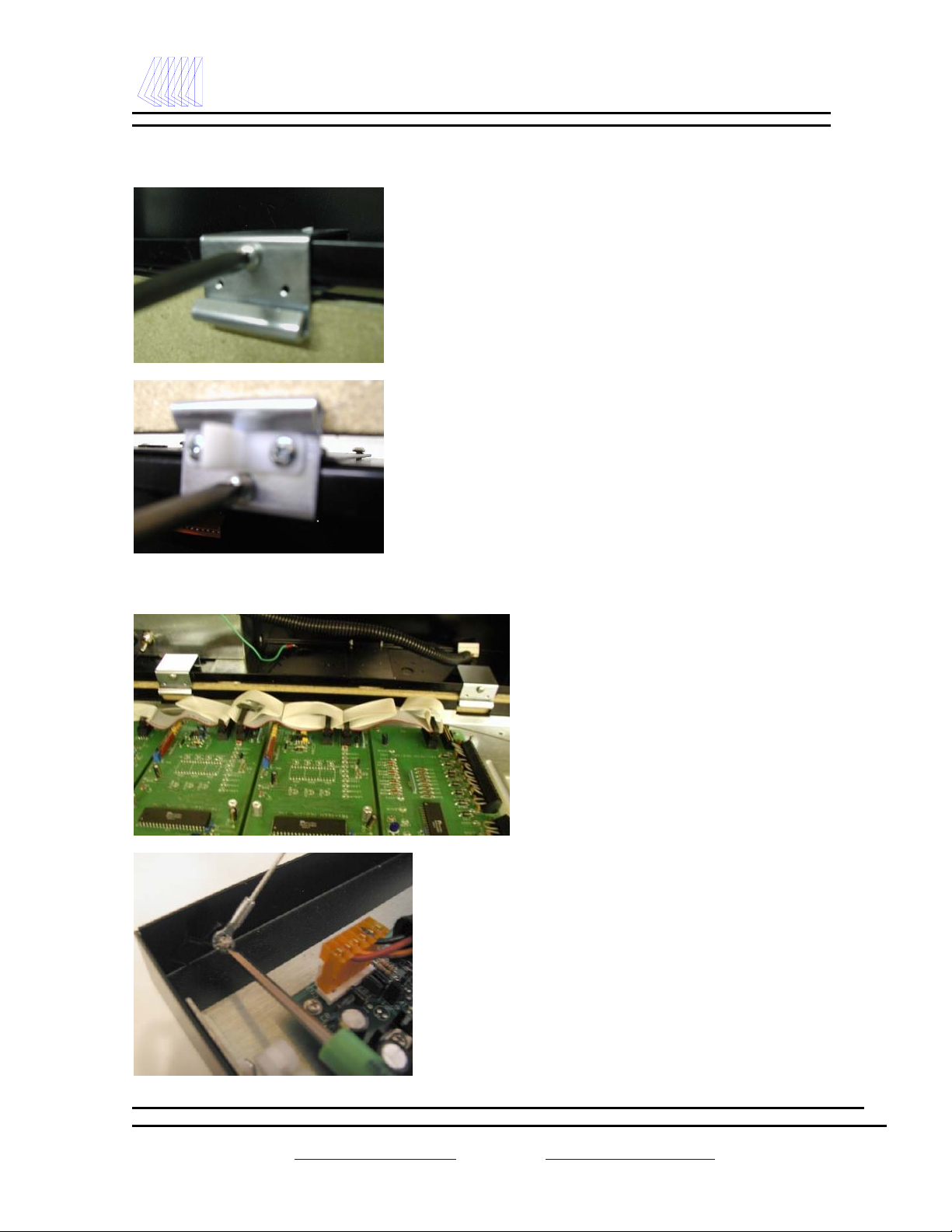

Rough-In Box Installation

(Side/end view of rough-in back box)

This is a rough-in box for a combination

alarm. Your rough-in box should look the

same or similar to this unit.

Refer to the building plans to determine the

location of the alarm.

The contractor is to provide rigid mounting

that will support the alarm box on both sides.

The metal flanges provided on both sides of

the rough-in box are to rest against the rigid

mounting brackets. Screws (contractor

provided) are to be driven thru the holes in

the metal flanges into the mounting brackets.

Mount alarm rough-in box so it will be flush

or just below the finished wall surface using

the adjustment feature on the flanges.

- 16 -

Tri-Tech

Medical Inc. Alarm Installation

Wiring

Route wires through the power supply conduit

installed in the bottom and left side of the rough-

in box. Connect the 110 or 220V AC facility

emergency power source electrical wiring to the

terminal strip provided on the lower left side of

the box. (N = neutral, H = hot, FG = field

ground)

The power supply hole is located in the bottom

(left side) of the rough-in box. Remove the

plaster cover and panel covering the power

supply. Remove the plug from the hole. Make

conduit connections for wiring from the facility

emergency power source.

To remove the power supply cover, loosen the

two screws at the top of the cover and slide the

cover to the right, then lift the cover over the

screw heads. Slide the wiring harness strain relief

to the left until it is free from the cover.

Use the ½” conduit knock-out provided on the

bottom left side of the rough-in box to route

conduit to supply either 110 or 220 V AC to the

power supply. Note: Separate conduit should

be used for low voltage wires (use knock outs

provided on the top of the box).

Neutral

Hot

Field

Ground

- 17 -

Tri-Tech

Medical Inc. Alarm Installation

Plumbing the Riser Extension Tubes

The wiring harness will be provided pre-wired to

the power supply. If by chance it is not pre-

wired, the single green ground wire should be

fastened to the screw on the top left corner of the

power supply board. The wiring plug in

connector (which should contain the rest of the

wires), plugs into the connector terminal on the

upper left corner of the power supply board. The

black wire will be on the top.

This is how the power supply should look when

the wiring is completed.

Replace the power supply cover and plaster

cover (to protect the unit while the drywall and

wall covering work are being done) after wiring

is complete

Riser extension tubes

After removing the protective plastic caps, connect the

riser extension tubes (only included if this is an area or

combination alarm) to the gas piping system. Make sure

drop is for the proper gas service. Using a purge gas to

insure cleanliness in the tubes, silver braze the joints.

Do not use soft solder. Conduct heat away from the

check valves. (A purge kit is required for purge

equipment connection to the system). The 150 psi

standing pressure test of the piping system must be

successfully completed and all pressure removed from

the system before connecting the transducers to the

system. Attaching transducers without depleting the

150 psi standing pressure first will result in damage

to the transducers!

Note: It is recommended that gas piping system tubing be connected from the extension tube to the ceiling for

a future or blank gas display even though a transducer is not being installed. Cap the unused tube at the

ceiling. This will simplify future expansion.

Note: It is also possible to install the transducers remotely (not in the alarm box). In this type of installation

the riser extension tubes should be removed from the alarm back box and connected to gas piping system at a

distance not to exceed 100 feet (wiring harness length) from the alarm back box. Belden 8777shielded cable is

required.

Note: Tri-Tech Medical recommends mounting the transducers in the alarm back box – not remotely. Should

a transducer require service or replacement is considerably more time consuming to locate and replace or

service remotely located transducers.

- 18 -

Tri-Tech

Medical Inc. Alarm Installation

Installing the Hinges & Clips

Installing the Alarm Front Panel

After the walls are finished, the hinges and

clips may be installed onto the rough-in box.

The two hinges should be fastened to the lower

front edge of the rough-in box using the screws

provided. The hinge should rest flat against the

surface of the drywall.

The clips should be fastened to the upper front

edge of the rough-in box opposite the hinges

using the screws provided. The clip should rest

flat against the surface of the drywall.

Slide the holes cut into the bottom edge of the

front panel over the front catch of the hinges.

Support the front panel in the open position to

attach the lanyards.

Attach the two (left & right side) lanyard

cables to the alarm front panel using the

screws provided.

- 19 -

Tri-Tech

Medical Inc. Alarm Installation

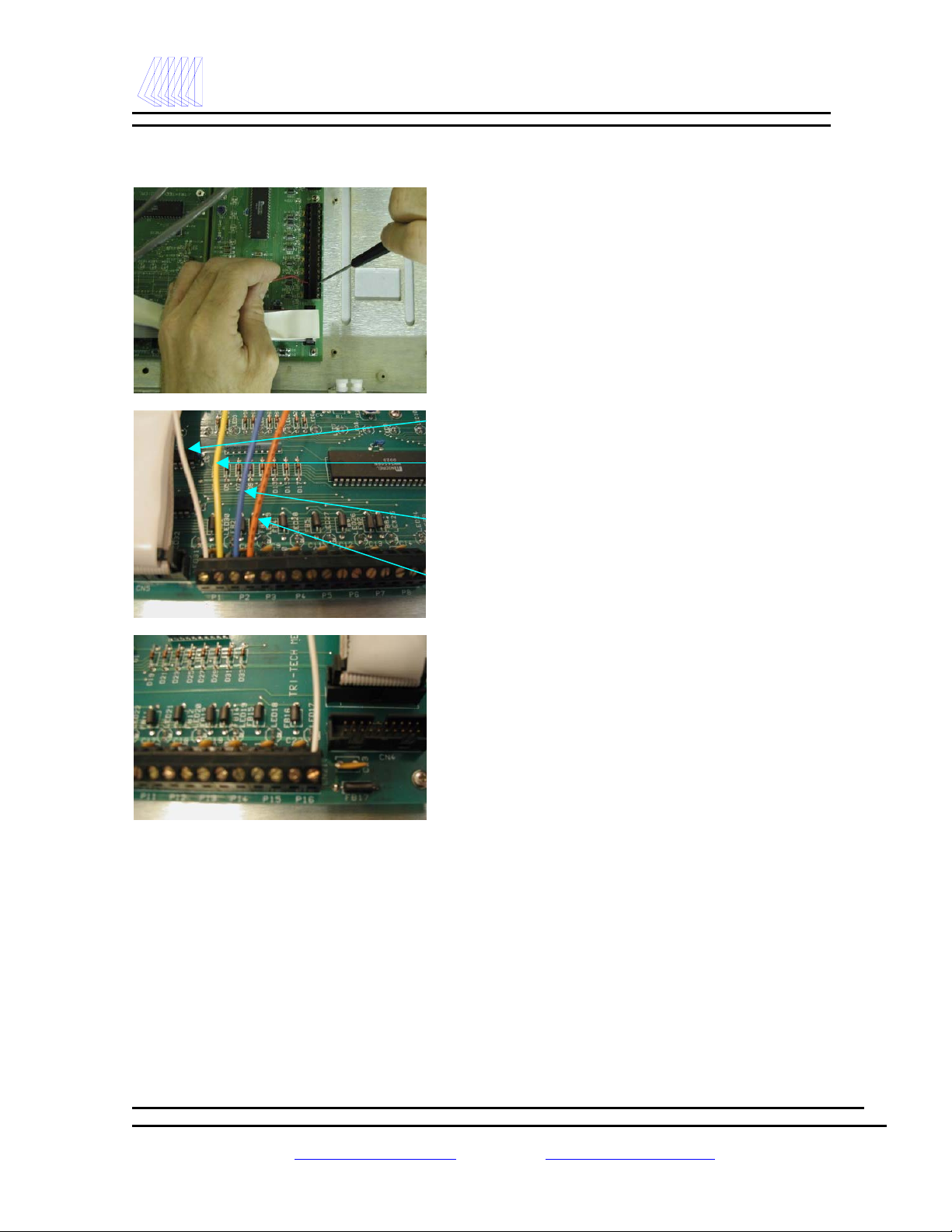

Wiring the Alarm Front Panel to the Power Supply

Installing the Transducers

Attach the green ground wire, which

is in the wiring harness, to the

ground screw on the left corner of

the front panel – just in front of the

power supply.

Attach the plug connector at the end of

the wiring harness to the appropriate

connector located at the top left corner of

the CPU circuit board. The plug should

lock into place. The plug can only be

inserted one way.

This is how the wiring harness plug

connector should look when properly

installed on the back of the CPU board.

After depressurizing the 150 psi

standing pressure from the piping

system, install the appropriate

transducers to the appropriate riser

extension tube connectors inside the

rough-in box. Hand tighten then

torque lightly with a wrench.

- 20 -

Tri-Tech

Medical Inc. Alarm Installation

Connecting the Transducer Wiring to the Alarm Front Circuit Board

Insert the transducer cable underneath the cable clip

as shown using the clips provided.

Insert the plug(s) from the transducer(s) to

the appropriate connector(s) on the back of

the gas module circuit board(s). The plug on

the transducer and the panel connector are

both labeled by gas symbol at the factory for

proper installation. The plug can only be

inserted one way.

Visually verify that the appropriate

transducer plug is being attached to the

appropriate gas module by looking at the

front of the alarm panel.

The transducer plug will look like this when

it is connected properly to the gas module.

- 21 -

Tri-Tech

Medical Inc. Alarm Installation

Wiring the Remote Devices to the Remote Signal (Master) Board

Locate the two banks of 16 terminal

connectors on the back of the

remote signal (master) board. There

are a total of 32 connection points –

two connection points for each

remote signal. The pairs are labeled

P1 thru P16 on the circuit board.

The top terminal of each pair is

where the signal wire should be

landed.

There are two options for landing the

common wire(s).

Option #1 – you can land the

corresponding common wire on the

bottom terminal of each pair of

terminal connectors.

This option is recommended for

maximum interference suppression.

Option #2 – you can connect all of

the common wires together and

land just one common wire on the

bottom terminal of P16.

Remote signal #1 –

signal wire

Remote signal #1 –

common wire

Remote signal #2 –

signal wire

Remote signal #2 –

common wire

- 22 -

Tri-Tech

Medical Inc. Alarm Installation

Labeling the Alarm Front

After all remote signal (master) wires have

been landed, identified & cataloged (using

appendix C in this manual), you are ready to

apply the remote signal labels. Remove by

unthreading the two nylon nuts shown here

from the back of the alarm front panel.

The panel will now lift out of the black frame.

Provided in the packaging with the alarm front

panel is a long white card and a pre-printed

sheet of labels for the remote alarm signals.

Wash your hands before handling these

labels and cards! Apply the labels to the

appropriate position on the card using the guide

lines on the card. When complete, insert the

card into the “Monitored Signals” label pocket -

between the stainless steel plate and the front of

the “Monitored Signals” label.

The gas modules are shipped pre-labeled from the

factory. If a gas service is changed to a different

gas or added to the alarm, it will be necessary to

insert the appropriate label in the pocket of the

gas module. The new gas label supplied by Tri-

Tech Medical will slide into the gas module label

pocket between the stainless steel plate and the

front of the gas module label.

When the labeling is completed, install the

stainless plate into the black frame and re-attach

with the two nylon nuts.

This manual suits for next models

1

Table of contents

Other TRI-TECH MEDICAL Medical Equipment manuals

Popular Medical Equipment manuals by other brands

AKW MediCare

AKW MediCare 3000 Series Installation and user care instructions

Super Star

Super Star S1100 Operation manual

Handicare

Handicare SystemRoMedic AmpSling Series manual

Ferno

Ferno Kwik Klip 031-4002 quick start guide

EDAN INSTRUMENTS

EDAN INSTRUMENTS SE-3 user manual

Current Solutions

Current Solutions ems 7500 instruction manual