TRI-TECH MEDICAL TSD Series Manual

e6248r B 03/31/16 Tri-Tech Medical Inc., 35401 Avon Commerce Parkway Avon, Ohio 44011 No. 99-0278

Tel. 440-937-5691 Fax. 440-937-5060

Web site: https://tri-techmedical.com or Email: sales@tri-tech medical.com

Page 1of 6

Tri-Tech

Medical Inc.

Installation Operating Instructions for

Simple Duplex Manual Manifolds

TSD Series

s

Model TSD shown above

Warranty: All Tri-Tech Medical manifolds are warranted against defects in materials and workmanship for

the period of five years from date of purchase.

Introduction

Tri-Tech Medical manifolds are cleaned, tested

and prepared for the indicated gas service and

are built in accordance with the Compressed

Gas Association guidelines. The manifold

consists of a regulator and a header, to provide

an increased supply of gas for the specific

application. Pressure gauges show system

status and alert the need to replace depleted

cylinders. Features of the manifold systems

include a regulator, flexible pigtails (copper

pigtails supplied with oxygen system –per

NFPA 99) with check valves and mounting

hardware.

Caution!

Failure to follow the following instructions can result in personal injury or property damage:

Never permit oil, grease, or other combustible materials to come in contact with cylinders,

manifold, and connections. Oil and grease may react with explosive force when ignited while in

contact with some gases –particularly Oxygen and Nitrous Oxide.

Cylinders, header and master valves should always be opened very S-L-O-W-L-Y. Heat of

recompression may ignite combustible materials creating an explosive force.

Pigtails should never be kinked, twisted or bent into a radius smaller then 3 inches. Mistreatment

may cause the pigtail to burst.

Do not apply heat. Oil and grease may react with explosive force when ignited while in contact

with some gases –particularly Oxygen and Nitrous Oxide.

Cylinders should always be secured with racks, chains, or straps. Unrestrained cylinders may fall

over and damage or break off the cylinder valve which may propel the cylinder from its current

position with great force.

Oxygen manifolds and cylinders should be grounded. Static discharges and lighting may ignite

materials in an oxygen atmosphere, creating an explosive force.

Welding should not be performed near Nitrous Oxide piping. Excessive heat may cause the gas to

dissociate, creating an explosive force.

e6248r B 03/31/16 Tri-Tech Medical Inc., 35401 Avon Commerce Parkway Avon, Ohio 44011 No. 99-0278

Tel. 440-937-5691 Fax. 440-937-5060

Web site: https://tri-techmedical.com or Email: sales@tri-tech medical.com

Page 2of 6

Tri-Tech

Medical Inc.

Installation Operating Instructions for

Simple Duplex Manual Manifolds

TSD Series

s

General Instructions

Manifolds should be installed in accordance with guidelines stated by the National Fire Protection Association,

the Compressed Gas Association, OSHA, Canadian Standards Association, and all applicable local codes. The

Carbon Dioxide and Nitrous Oxide manifolds should not be placed in a location where the temperature will

exceed 120°F (49°C) or fall below 20° F (-7°C). The manifolds for all other gases should not be placed in a

location where the temperature will exceed 120°F (49°C) or fall below -20°F (-29°C). A manifold placed in an

open location should be protected against weather conditions. During winter, protect the manifold from ice and

snow. In summer, shade the manifold and cylinders from continuous exposure to direct rays of the sun.

Leave all protective covers in place until their removal is required for installation. This precaution will keep

moisture and debris from the piping interior, avoiding operational problems.

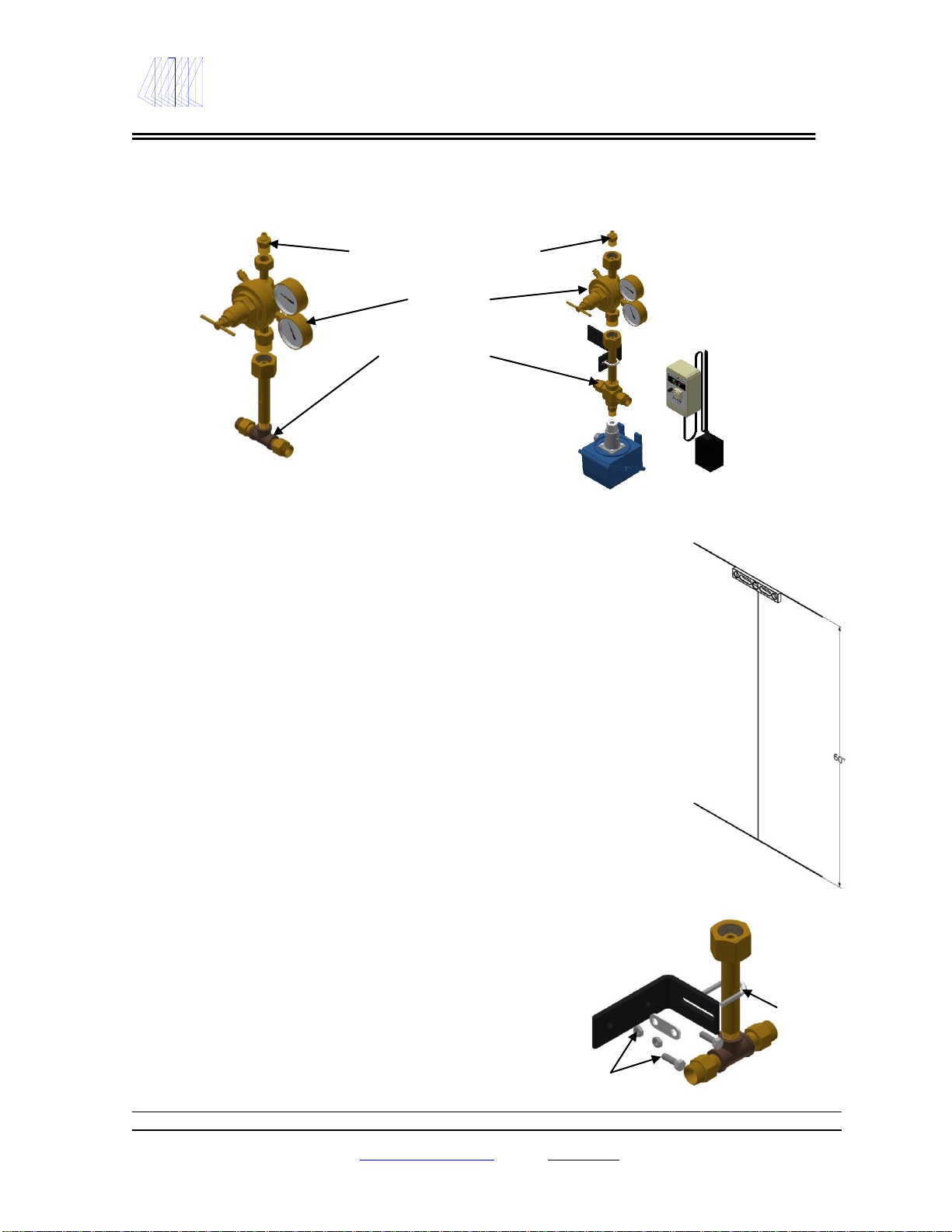

Wall Mount Floor Mount

FIGURE 1

Note: Mark the manifold on the wall from the center of the header bar to the floor is 60”

CAUTION:

Remove all protective caps prior to assembly. The protective cap may ignite due to heat of

recompression in an oxygen system.

e6248r B 03/31/16 Tri-Tech Medical Inc., 35401 Avon Commerce Parkway Avon, Ohio 44011 No. 99-0278

Tel. 440-937-5691 Fax. 440-937-5060

Web site: https://tri-techmedical.com or Email: sales@tri-tech medical.com

Page 3of 6

Tri-Tech

Medical Inc.

Installation Operating Instructions for

Simple Duplex Manual Manifolds

TSD Series

s

MANIFOLD ASSEMBLY

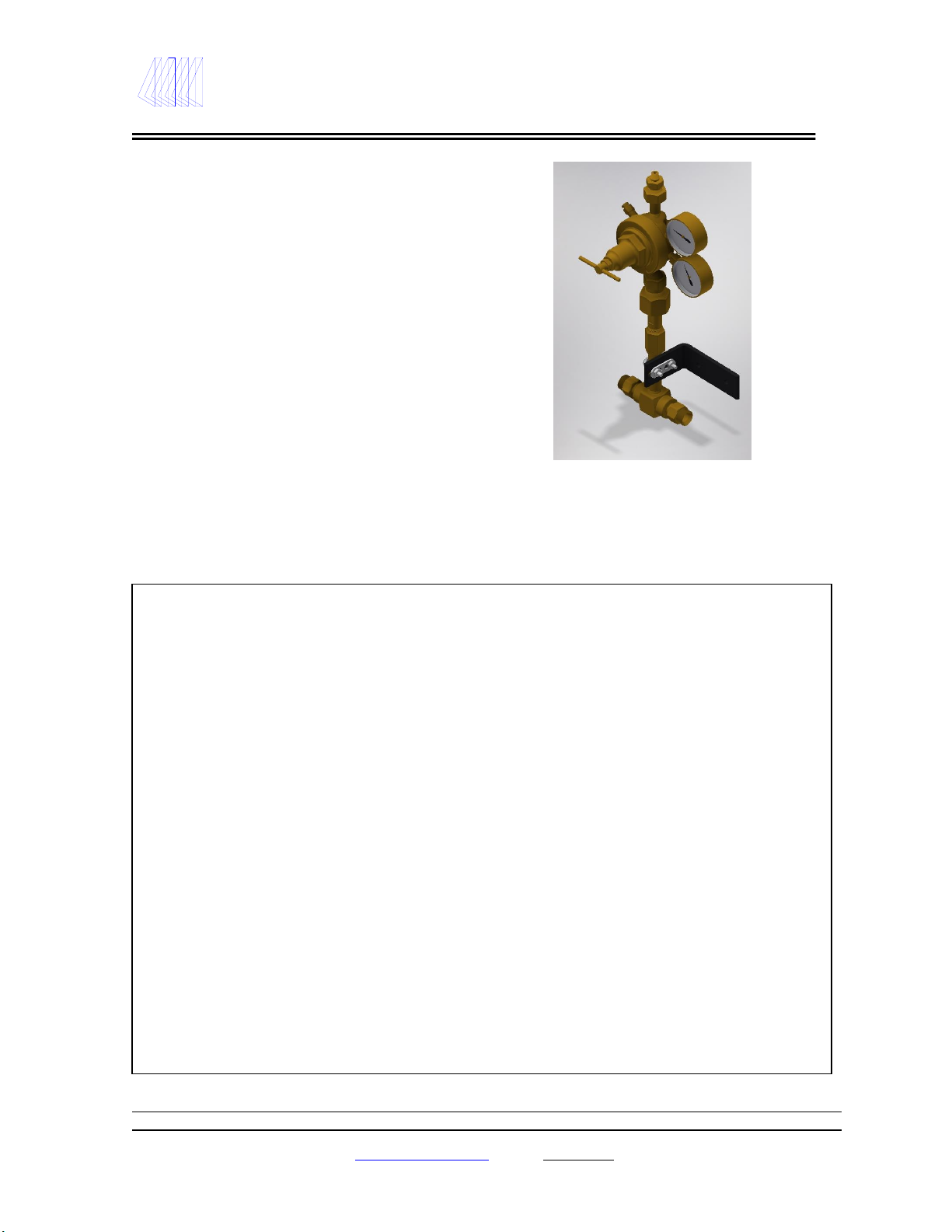

1. Assemble the manifold outlet fitting to the regulator outlet (Figure 2).

2. Assemble the headers assembly to the regulator inlet oriented as shown in Figure 2.

Manifold Outlet Connection

1/2" MNPT

Regulator

Header Section

Pressure Switch

FIGURE 2

Note: In some applications a relief valve may be required downstream of the manifold.

The relief valve is not included, it would be sold separately i.e. part no. RV-22-075 75 PSI,

RV-22-150 150PSI or RV-22-250 250PSI.

MANIFOLD INSTALLATION –Wall Mount Applications

1. Determine and mark the vertical center line for Spirit Level

installation of the manifold. (Figure 3).

2. Measure from the floor to a point 60” in height* of this vertical

line. Using a level, mark a horizontal line at this point extending

approximately 3” to the left and 3” to the right of center.

(*---Suggested manifold height. Wall mounting heights may Center

vary from one installation to another depending on available Line

space, cylinder height, etc.)

3. Remove the U-bolt assemblies from the mounting brackets.

Position the bracket so that the top of the bracket is aligned with

the horizontal line. Floor

Line

4. Mark the mounting holes and install fasteners suitable for the type

of wall construction. FIGURE 3

5. Mount the manifold by placing the header on the bracket. Fit the U-Bolt

over the header pipe and tighten the mounting nuts.

Header Assembly U-Bolt

Fasteners

Shown Right with:

optional cross, remote

alarm part # TAV-1 and

pressure switch part # PS-

160-3200.

Remote audio/visual

alarm –part # TAV-1

e6248r B 03/31/16 Tri-Tech Medical Inc., 35401 Avon Commerce Parkway Avon, Ohio 44011 No. 99-0278

Tel. 440-937-5691 Fax. 440-937-5060

Web site: https://tri-techmedical.com or Email: sales@tri-tech medical.com

Page 4of 6

Tri-Tech

Medical Inc.

Installation Operating Instructions for

Simple Duplex Manual Manifolds

TSD Series

s

MANIFOLD OPERATION

The TSD series manifolds are designed to operate in two ways; to provide an increased supply of gas as well as higher flow

rates than can be achieved using a single cylinder, or to provide a manual changeover to a reserve cylinder.

1. Install the two pigtails provided to the TSD manifold. Connect the two cylinders intended to be used.

Following the cylinder replacement guidelines on page 5.

2. S-L-O-W-L-Y open both cylinder valves (turn counter-clockwise to open). The high pressure gauge will show the

pressure of the cylinder having the highest pressure. (Figure 5)

3. Check the system connections for leaks using an oxygen compatible leak test solution. Correct any leaks

immediately.

4. Adjust the delivery pressure of the regulator to the desired pressure. The selection of the regulator set pressure may

vary due to application requirements. If a pressure setting less than 20 psig is required then a line regulator must

be installed at the manifold outlet.

5. Simulate a depleted bank by closing the cylinder valves and creating a flow of gas through the manifold. The

pressure reading on the gauges will drop.

6. S-L-O-W-L-Y open one of the cylinder valves (turn counter-clockwise to open). Note: this manifold is designed

so that one side is in service (cylinder valve open) while the second side is held in reserve (cylinder valve closed).

7. The manifold is now ready to supply your system.

Pressure Gauge

Regulator High Pressure Gauge

FIGURE 5

The manifold control includes the following components and features; regulator, flexible stainless steel braided pigtails

(or copper pigtails with oxygen systems) with check valve outlets. The manifold is designed to use a line regulator

(optional item) which can be mounted on the manifold outlet for delivery pressure less than 20 psig.

Gas flows through the manifold to the primary regulator and then through the line regulator (if installed). Final delivery

pressure is controlled by the either the line regulator or by the primary regulator should the application not require a line

regulator. (A line regulator is not provided with the manifold.)

As cylinders deplete the high pressure gauge on the regulator along with any alarm systems installed will indicate that the

bank of cylinders should be changed.

After replacing empty cylinder, the manifold is immediately ready for service.

Check Valve Outlets

oOuOutlets

e6248r B 03/31/16 Tri-Tech Medical Inc., 35401 Avon Commerce Parkway Avon, Ohio 44011 No. 99-0278

Tel. 440-937-5691 Fax. 440-937-5060

Web site: https://tri-techmedical.com or Email: sales@tri-tech medical.com

Page 5of 6

Tri-Tech

Medical Inc.

Installation Operating Instructions for

Simple Duplex Manual Manifolds

TSD Series

s

To insure proper operation, observe the following guidelines:

1. Carefully follow all instructions.

2. Be sure cylinder valve is fully opened.

3. Replace empty cylinder as soon as practical after the manifold has depleted, and the full reserve cylinder valve

has been opened, placing it in service.

CYLINDER REPLACEMENT AND HANDLING

1. Shut off cylinder valve on depleted cylinder.

2. S-L-O-W-L-Y loosen and remove the pigtail connection from the depleted cylinder.

3. Remove the depleted cylinder and replace the protective caps.

4. Remove the protective cylinder cap from the full replacement cylinder. With the valve outlet pointed away from

you or anyone else, slowly open each cylinder valve slightly, blow out any dirt or contaminants which may have

became lodged into the cylinder valve.

5. Place and secure full cylinders into position using chains, belts, or cylinder stands.

6. Connect pigtails to cylinder valves and tighten with wrench.

7. Open the header valve. S-L-O-W-L-Y turn the cylinder valve until each cylinder is fully on.

8. The manifold supply bank is now replenished and may be put in service by following the instructions on page 4.

(MANIFOLD OPERATION).

GENERAL MAINTENANCE

1. Main Section

a) Daily –record line pressure.

b) Monthly

1a. Check regulators and valves for external leakage.

1b. Check valves for closure ability.

c) Annually

1a. Check relief valve pressures.

1b. Check regulator seats.

2. Manifold Header

a) Daily –observe nitrous oxide and carbon dioxide systems for cylinder frosting or surface

condensation.

Should excessive condensation or frosting occur it may be necessary to increase manifold capacity.

b) Monthly

1a.Check cylinder pigtails for cleanliness, flexibility, wear, leakage, and thread damage. Replace

damage pigtails immediately.

3. Every 4 years

a) Replace all pigtails.

Table of contents

Other TRI-TECH MEDICAL Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual