TRI-TECH MEDICAL Genesys Series Manual

- 1 -

Tri-Tech

Medical Inc. Manufacturer of

Medical Gas Pipeline Equipment

Installation & Operating Instructions for

Genesys ®

Series Manifolds

Model LLU

Model CCU

2

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Features & Benefits

Features & Benefits

•Fully automatic changeover – no valves or levers to reset after each changeover

•Compatible with Tri-Tech Medical T-Net medical gas monitoring system saving you time and

improving safety

•Economizer software – ensures empty portable bulk vessels will not be put back into reserve

•Economizer hardware – allows head pressure from secondary portable bulk vessels to be used –

instead of vented

•Field upgradeable design – kits allow unit to be changed from - i.e. cylinders to portable bulk or

from standard flow to high flow or from lower delivery pressure to higher delivery pressure

•Circuit board triggers all required NFPA 99 alarms – simplifying wiring and reducing cost

•Unit includes hi/low line pressure transducer – eliminating need to purchase hi/low pressure switch

•Easy to service layout/design

•Microprocessor based control panel incorporates LED’s and illuminated text display readable even

in poor lighting conditions

•Electronic monitoring of circuits with 20 error, alarm or information messages displayed for ease of

maintenance

•Accurate, long life pressure transducers for monitoring of line pressure and bank pressures

•Analog gauges also provided for use in event of power failure

•Pressures may be displayed in PSIG / kPa / BAR

•Built in DISS gas specific emergency feed ports

•Built in emergency reserve bank ports

•Input power 120 VAC, 50 to 60 Hz

•Dual line pressure regulators on NFPA 99 models

•Gas specific header bar with integral check valves and cylinder pigtail assemblies

•Variety of header configurations available to meet the available space requirements of your

installation

•Available in weatherproof cabinet for outdoor installation

3

Tri-Tech

Medical Inc. Table of Contents

Contents

Features & Benefits ---------------------- 2

General Instructions --------------------- 4

Introduction-------------------------------- 4

Installation --------------------------------- 5

Mounting----------------------------------- 5

Plumbing ----------------------------------- 6

Electrical ----------------------------------- 8

Remote Alarm Wiring ------------------- 9

Installation – Pigtails & Cylinders ---- 10

Start Up and Checking Procedures --- 12

Model LLU Emergency Reserve

Plumbing & Wiring ---------------------- 14

Cylinder Replacement & Handling --- 15

Line Delivery Pressure Adjustment--- 15

Programming Adjustments------------- 16

General Maintenance -------------------- 17

Table of Error Codes -------------------- 17

Table of Alarm Codes-------------------- 18

Table of Information Codes ------------ 18

Replacement Parts------------------------ 19

Trouble Shooting Guide----------------- 21

Appendix A

Glossary of Terms ------------------------ 23

Appendix B

Technical Specifications ----------------- 24

Appendix C

Model CC Piping Schematic------------ 25

Appendix D

Model LL Piping Schematic ------------ 26

Appendix E

Operational Pressure Specifications -- 27

Appendix F

Relief Vent Plumbing -------------------- 28

Appendix G

T-Net Installation ------------------------- 29

Wiring Diagram – model CCU--------- 30

Wiring Diagram – model LLU --------- 31

Wiring Diagram – model CCU with heaters

------------------------------------------------ 32

Wiring Diagram – remote buzzer ----- 33

4

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Introduction & General Instructions

Introduction

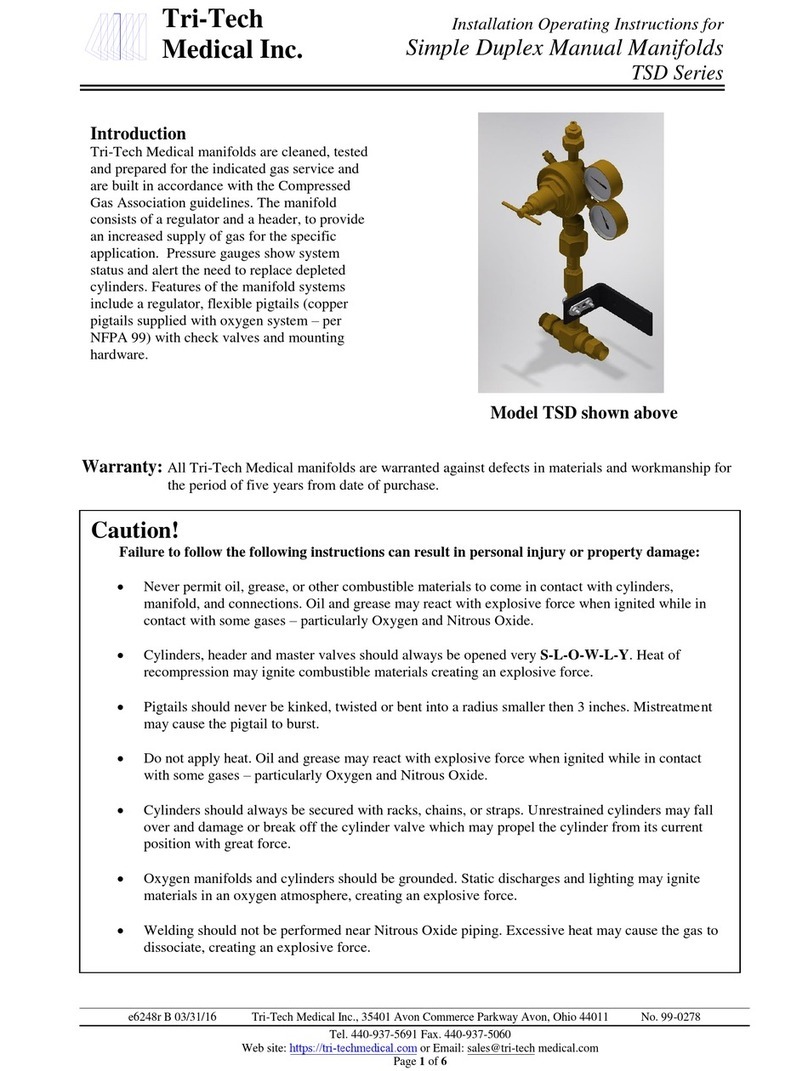

Tri-Tech Medical manifolds are cleaned for use with oxygen. Each system is tested for changeover, triggering of

alarms and leakage. Each unit is designed and prepared for the indicated gas service. Tri-Tech Medical manifolds are

built in accordance with the National Fire Protection Association and Compressed Gas Association guidelines.

Warranty

All Tri-Tech Medical manifolds are warranted against defects in material and workmanship for the period of one year

from date of purchase. All circuit boards are warranted against defects in material and workmanship for the period of

three years from date of purchase.

General Instructions/Location & Shelter

Manifolds should be installed in accordance with guidelines stated by the National Fire Protection Association, the

Compressed Gas Association, OSHA, and all applicable local codes. Carbon Dioxide and Nitrous Oxide manifolds

and cylinders should not be placed in a location where the temperature will exceed 120°F (49°C) or fall below 20°F

(-7°C). The manifolds for all other gas services should not be placed in a location where the temperature will exceed

120°F (49°C) or fall below 0°F (-18°C). A manifold placed in an open location should be protected against weather

conditions. During winter, protect the manifold from ice and snow. In summer, shade the manifold and cylinders

from continuous exposure to direct sunlight.

Leave all protective covers in place until their removal is required for installation. This precaution will keep moisture

and debris from the piping interior.

Caution

Failure to follow the following instructions can result in personal injury or property damage:

•Never permit oil, grease, or other combustible materials to come in contact with cylinders, manifold, and

connections. Oil and grease may react with explosive force when ignited while in contact with some gases

– particularly oxygen and nitrous oxide.

•Cylinder and master valves should always be opened very slowly. Heat of recompression may ignite

combustible materials creating an explosive force.

•Pigtails should never be kinked, twisted, or bent into a radius smaller than 3 inches. Mistreatment may

cause the pigtail to burst.

•Do not apply heat. Oil and grease may react with explosive force when ignited while in contact with some

gases – particularly oxygen and nitrous oxide.

•Cylinders should always be secured with racks, chains, or straps. Unrestrained cylinders may fall over and

damage or break off the cylinder valve which may propel the cylinder from its current position.

•Oxygen manifolds and cylinders should be grounded. Static discharges and lightning may ignite materials

in an oxygen atmosphere, creating a fire or explosive force.

•Welding should not be performed near nitrous oxide piping. Excessive heat may cause the gas to dissociate,

creating an explosive force.

•Remove all protective caps prior to assembly. The protective cap may ignite due to heat of recompression

in an oxygen system.

5

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Installation Instructions

Control Cabinet Installation

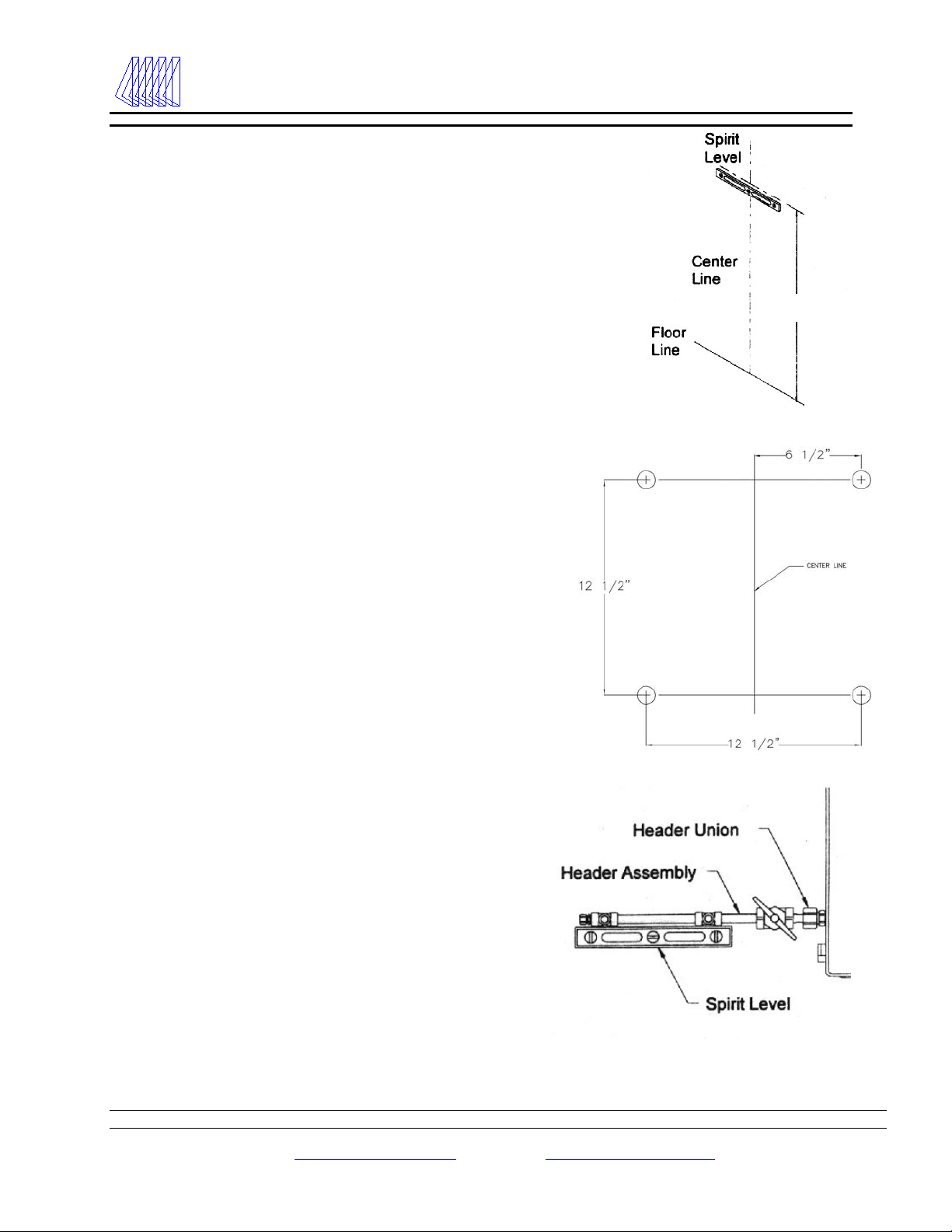

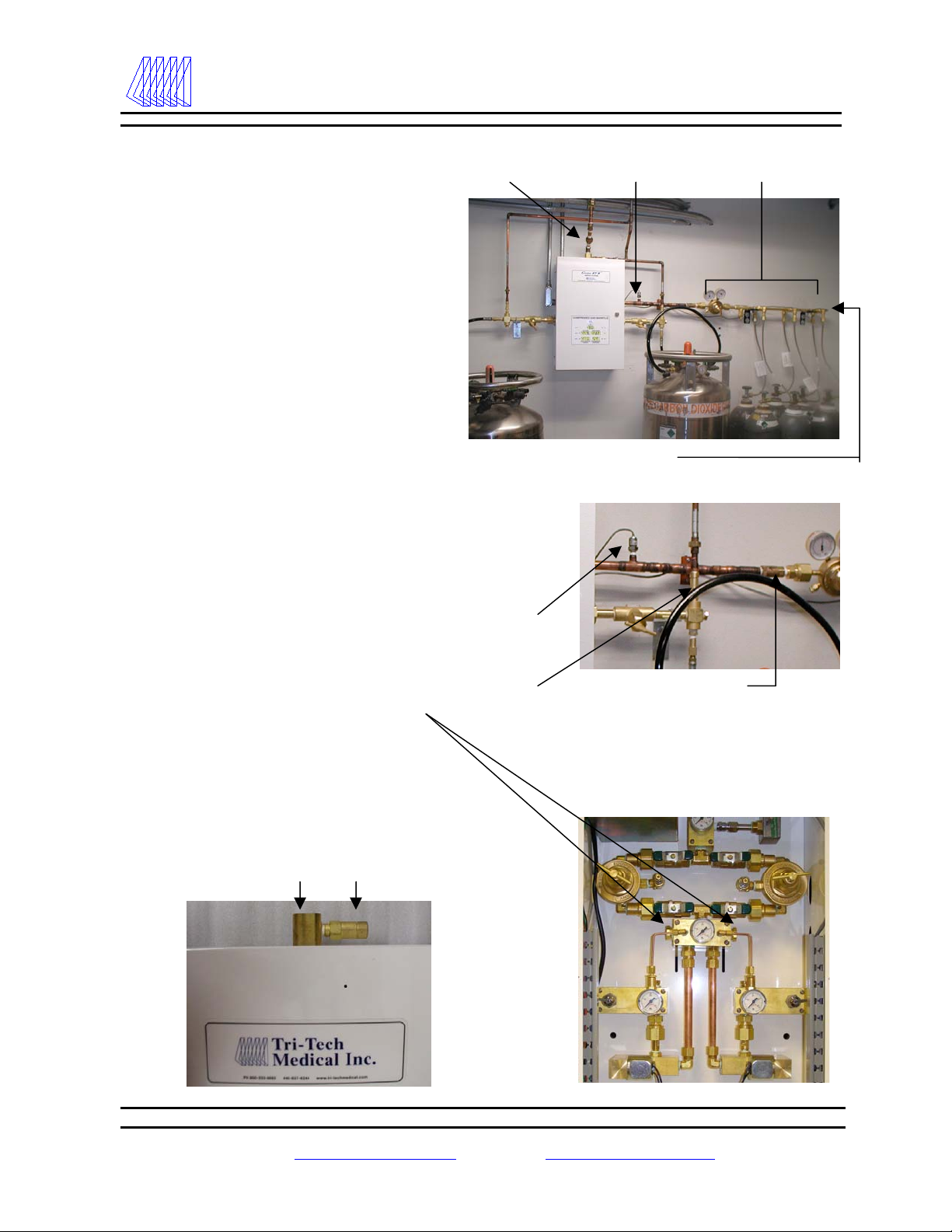

1. Determine and mark the vertical center line for

installation of the manifold control cabinet.

2. Measure from the floor to a point 60” in height*

above the finished floor of this vertical line. Using a

level, mark a horizontal line at this point extending

approximately 7” to the left and 7” to the right of

center. This line indicates the location for the bottom

two mounting bolts of the manifold control cabinet.

(* - suggested manifold height. Wall mounting

heights may vary depending on available space,

cylinder height, etc.)

3. Draw another horizontal line 12 ½” above and

parallel to the lower horizontal line. This line should

also extend 7” to the left and 7” to the right of center.

This line indicates the location for the upper two

mounting bolts of the manifold control cabinet.

4. Measuring from the vertical center line, along the two

horizontal lines, make a mark at 6 ¼” to the left and

another at 6 ¼” to the right of the vertical center line.

These four locations are the mounting hole locations

for the manifold control cabinet. Install the manifold

control cabinet using fasteners suitable for the type of

wall construction.

Header Installation

1. Attach the headers to the union on each side of the

manifold control cabinet. Using a level, mark the

placement of mounting brackets while keeping the

header on a horizontal plane.

2. Remove the U – bolt assemblies from the header

mounting brackets. Position the brackets so that the top

of the bracket is aligned with the bottom of the headers

and is centered between the cylinder connections. The

end bracket should be placed as close to the last cylinder

as possible to provide the most support and stability.

60”

6

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Installation Instructions

1. Mark the mounting hole and install fasteners

suitable for type of wall construction.

2. Fit the U – bolt over the header piping and tighten

the two mounting nuts.

Plumbing – Model CCU

1. The outlet of the manifold is located at the top center

of the unit as shown here. The outlet connection is ½

NPT female. It is recommended that a ½ NPT male

union should be installed between the outlet of the

manifold cabinet and the pipeline system. This union

is available as an accessory from Tri-Tech Medical

(part # 17-0169).

2. A 6” x ½ npt brass pipe nipple has been provided (on

CC models) to extend the intermediate relief piping

outside the cabinet wall.

3. It is also recommended that unions (part # 17-0169)

be installed between all relief valves and the relief

(vent) pipeline system(s). There are two ½ NPT relief

valve connections on the model CCU manifold. See

Appendix F page 28.

4. The intermediate relief valve extension pipe nipple

must be installed. It is bagged and shipped inside of

the cabinet for protection during shipment.

Outlet ½ F npt Line relief valve ½ F npt

Intermediate relief connection

(6” x ½ npt brass nipple

shown)

17-0169 Union shown here

7

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Installation Instructions

Plumbing – Model LLU

1. In addition to connecting the left & right

primary and secondary portable bulk

vessel supply banks, the LL models must

also have a high pressure reserve bank of

cylinders connected to the cabinet to be

in compliance with NFPA 99 guidelines.

2. The model LLU has one ½ NPT female

line pressure relief valve connection and

two 3/8 NPT female intermediate

pressure relief valve connections. (This

installation is typical – with the two

intermediate relief vent lines and the line

pressure relief vent line brought together

as a common vent line that exits the

facility either thru an exterior wall or the

roof). See Appendix F page 28.

3. A check valve (part number CV-050F)

must be installed between the emergency

reserve in use pressure transducer and

the high pressure reserve regulator.

4. The intermediate block has two ½ npt

plugs which may be removed to allow

the emergency reserve to be piped in

thru either the left or the right side of the

cabinet. Slots have been provided on

both the left and right sides of the control

cabinet to allow for the high pressure

reserve piping.

Emergency reserve low

pressure transducer (14-3001)

High pressure

reserve manifold

Emergency reserve in

use pressure transducer

Check valve (CV-050F)

Emergency reserve

in use pressure

transducer

(14-3002)

Intermediate

relief valve

Main line connection. Line pressure relief valve

(½ F npt outlet connection) (½ F npt outlet connection)

Main line outlet

connection

8

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Installation Instructions

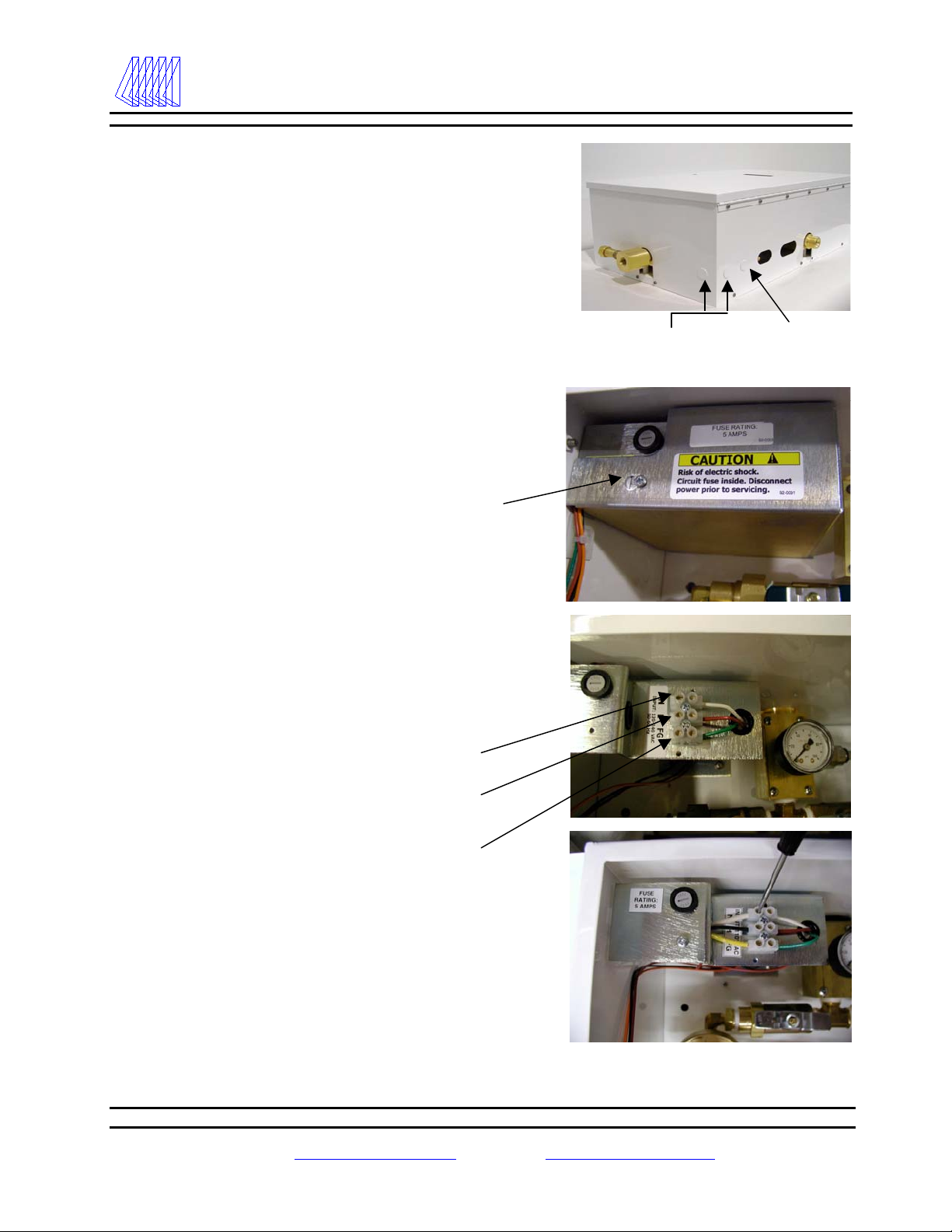

Electrical

1. Use one of the two ½” conduit knock-outs provided

located nearest to the top left corner of the cabinet

to route conduit to supply 120 VAC to the power

supply. Note: Separate conduit should be used

for low voltage wires (use knock outs provided

on the left side of the box).

2. Remove the power supply cover by loosening the

screw located at the top of the cover and then

sliding the power supply cover to the right until the

screw is in the center of the tear-drop shaped cut

out. Next, pull the cover forward until it clears the

screw head and the fuse. Note: the bottom of the

cover inserts into a slot in the back plate. Allow the

cover to rest on the dual line regulator assembly

plumbing just below the power supply.

3. Route wires of proper gauge (per local building

code requirement) through the power supply

conduit, thru the grommet on the power supply

bracket and into the terminal strip.

Neutral

Load

Field Ground

4. Connect the 120 VAC facility emergency power

source electrical wiring to the terminal strip

provided on the front of the power supply mounting

bracket (per photos right). (N = neutral, L = load,

FG = field ground)

Note: The ground must be a solid earth ground with

little or no resistance. A “noisy” earth ground may

affect the digital display of the manifold.

Conduit knockouts for

120 VAC

Conduit knockout for

low voltage alarm signals

9

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Installation Instructions

Wiring – remote alarms

1. Wires for remote alarms should be brought into the

cabinet thru conduit or shielded cables (check local code

requirements) thru the knockouts on the left side of the

cabinet shown here. . Note: Separate conduit should

be used for high voltage wires – never run low

voltage wires in the same conduit as high voltage

wires.

2. If you are installing a model CCU (cylinder x cylinder)

cabinet there are three alarm signals recommended per

NFPA 99, High Line Pressure, Low Line Pressure and

Reserve in Use. The CCU circuit board will trigger all

three of these alarms (no hi/low pressure switch is

required). The line pressure transducer must be installed

outside of the cabinet – downstream of the source or

main line valve with the cable being wired to the

manifold circuit board to comply with NFPA 99. In this

photo the line pressure transducer has been assembled

into our PSM-XX assembly and connected to the gauge

port on the downstream (patient side) of the source valve

and wired to the manifold circuit board.

3. The line pressure transducer may also be mounted inside

the cabinet (as shown here). In this arrangement, a

hi/low pressure switch (sold separately) will be required

to meet the NFPA 99 recommendations. Note: the

hi/low pressure switch would be wired directly to the

master alarm panels – not to the manifold circuit board.

4. Remote alarm wires are connected to the circuit board at

the terminal gate labeled X6. Signal wires and Common

wires for Low Line Pressure, High Line Pressure and

Secondary in Use should be connected to the terminals

as indicated.

5. Note: all remote alarm terminals are normally closed

when the gas pressure is in the normal range. The

hi/low set points pre-programmed into the manifold

circuit board logic chip are as per the charts on page 27.

6. Note: an additional set of dry contacts labeled

“Secondary Alarm Signal Output” has been provided on

the X5 terminal to provide an alarm condition should the

120 VAC become disconnected.

Knock out for low voltage

remote alarm wiring

Line pressure transducer

10

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Installation Instructions

Installing pigtails & attaching

cylinders – CCU models

1. The check valve outlet fittings on

the manifold header bars are CGA

(Compressed Gas Association) gas

specific threads. Each of these

fittings has an integral check valve.

Make sure the 3 digit CGA number

stamped on the outer perimeter of

these fittings matches the CGA

number stamped on the mating

CGA fittings on the pigtails.

2. Connect the pigtails to the check

valve outlets on the manifold

headers.

3. Check the master valves to be

certain they are open (turn counter-

clockwise to open). (Note: the

master valve should always be left

open. It is to be used only in the

event of an emergency).

4. SLOWLY open all cylinder valves

(turn counter-clockwise to open).

Check all cylinder and pigtail

connections for leaks using an

oxygen safe leak test solution (any

bubbles forming around

connections indicate leakage).

Check valve

outlet fittings

Line transducer

mounted on patient

side of source valve

using PSM-04 N2O

assembly.

Master valves

Attach pigtails to

header check valve

outlets using 1-1 /8”

open end wrench

11

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Installation Instructions

Installing pigtails & attaching

cylinders – LLU models

1. This photo shows a completed

installation. Note the copper tubing

and unions are installed and

furnished by the installer.

2. The check valve outlet fittings on

the manifold header bars are CGA

(Compressed Gas Association) gas

specific threads. Each of these

fittings has an integral check valve.

Make sure the 3 digit CGA number

stamped on the outer perimeter of

these fittings matches the CGA

number stamped on the mating

CGA fittings on the pigtails. Attach

the pigtails to the check valve outlet

fittings on the manifold header bars.

3. Connect the other end of the pigtail

to the “Use” valve mating fitting on

the portable bulk vessel. Open the

use valve (turn counter-clockwise to

open). The pressure building valve

or regulator should be turned on or

opened for all vessels connected to

the manifold (both service and

reserve banks). Allow

approximately 1 hour for the

portable bulk vessel(s) to build

pressure.

4. Check all cylinder and pigtail

connections for leaks using an

oxygen safe leak test solution (any

bubbles forming around

connections indicate leakage).

5. Verify that the pressure being

supplied to the manifold cabinet

exceeds the minimum inlet pressure

requirements per the table on page

27.

Intermediate relief

lines with unions for

left bank, right bank.

Final line vent line

with union. Line

relief is ½ F npt,

intermediate reliefs

are 3/8 F npt. See

page 28 vent

plumbing diagram.

Ports for 2 pigtails

Intermediate

pressure relief valve

x 3/8 F npt

Common vent line thru

roof or outside wall. (3/4

recommended)

Final line vent line with

union.

Emergency reserve inlet.

12

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Start Up & Checking Procedures

Start up & checking procedures

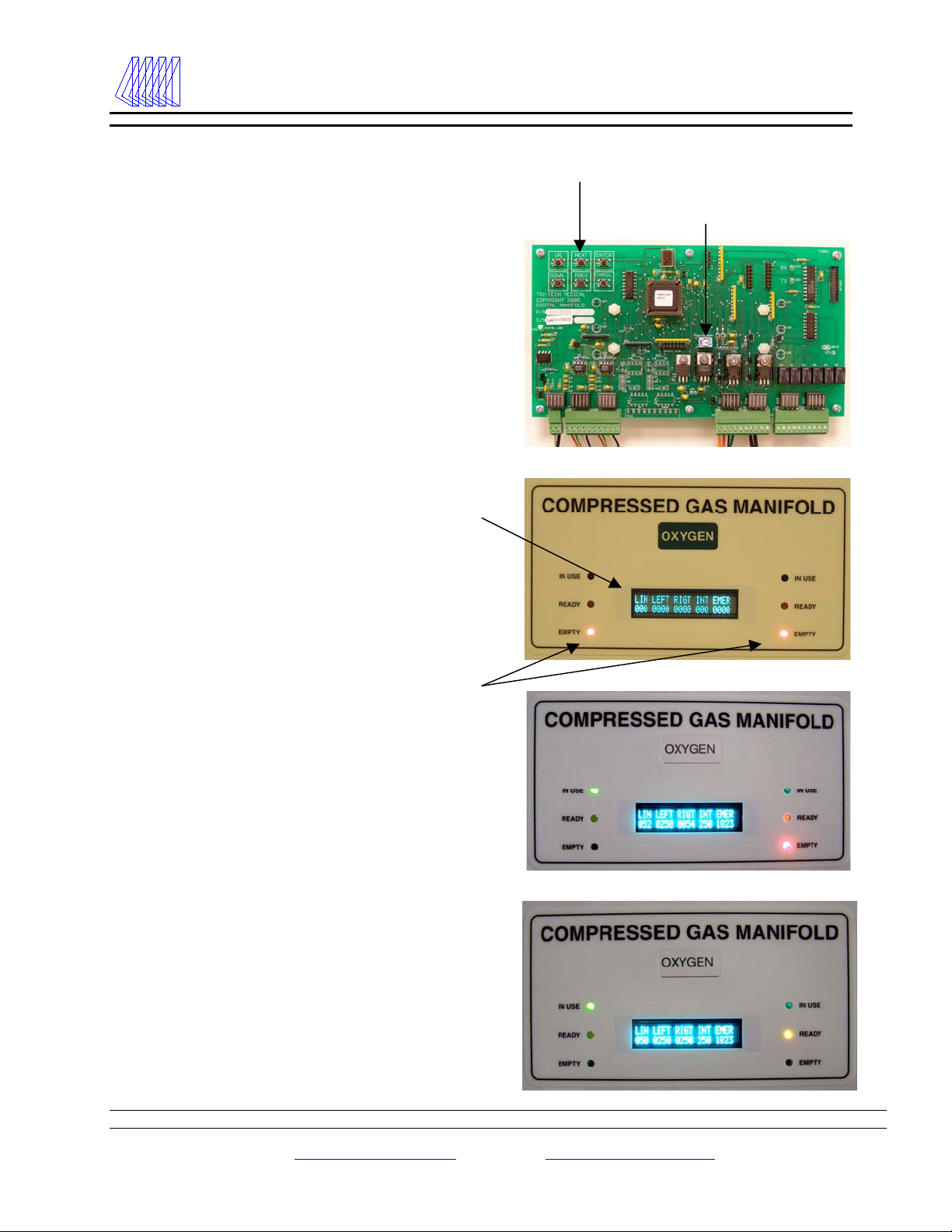

The manifold is pre-programmed (per page 27) and tested

before it is shipped. You may, however, wish to modify

some of the programming (see page 16). The unit has

been designed to allow some programming to be simply

and safely altered in the field.

1. Start with all portable bulk vessels and cylinders

turned off and with zero pressure supplied to the

manifold cabinet. To conduct the initial start-up

testing of the manifold, it is simpler and faster if

the circuit board is switched from the standard

‘cycling view’ (this is the mode in which it is

shipped) to the ‘global view’. To do this, the

cover must be removed from the circuit board and

the top #1 dip switch must be switched from the

RUN mode to the PROGRAM mode.

2. Turn on the 120 VAC to the unit. For model

CCU the display should illuminate showing all

zeros for the Line Pressure (LIN), Left Bank

Pressure (LEFT) and Right Bank Pressure

(RIGHT). The intermediate (INT) and

emergency reserve (EMER) displays should also

display zeros. The INT and EMER displays will

always display zeros on the global view screen of

CC models and will not display when the mode is

switched to the cycling view. (CC models). The

INT and EMER displays are only activated on LL

models. Both the left & right bank Red

(Depleted) LED’s should be illuminated. Both

the left and right bank Green (In Use) and Yellow

LED’s (Ready) should be extinguished.

3. SLOWLY open one cylinder valve on the left

bank. The left bank pressure gauge (inside the

cabinet) and the text display (on the outside of the

cabinet) should show the full pressure of the

cylinder. The Red (Depleted) LED for the left

bank should have extinguished leaving only the

Green (In Use) LED illuminated.

4. SLOWLY open one cylinder valve on the right

bank. The right bank pressure gauge (inside the

cabinet) and the digital display (on the outside of

the cabinet) should show the full pressure of the

cylinder. The Red (Depleted) LED for the right

bank should have been extinguished and the

Yellow (Ready) LED should have illuminated.

Program control buttons

Dip switch #1 RUN/PROGRAM

13

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Start Up & Checking Procedures

Start up & checking procedures (cont’d)

5. Turn off all open left bank cylinder valves. Create a slight flow

of gas in the delivery pipeline system. DISS demand valves

have been provided on the line regulators. Mating DISS

fittings may be used to create a flow of gas within the manifold

cabinet. The left bank pressure text display and pressure gauge

should fall and the control automatically switches over to the

right bank. Delivery pressure remains constant. The left bank

Red (Empty) LED will illuminate. The secondary supply in

use alarm should activate on the master alarm(s).

6. SLOWLY reopen the cylinders on the left bank. The left bank

pressure gauge and digital display should return to full

pressure. The left bank yellow (Ready) LED will illuminate

simultaneously the left bank red (Empty) will extinguish. All

remote secondary supply in use alarms will be canceled.

7. Repeat steps 5 & 6 to simulate an empty right bank.

8. If the unit is a model LL, it will also display pressures for the

intermediate area (INT) and the emergency reserve (EMER)

and trigger the master alarm signal for “Emergency Reserve in

Use” and “Emergency Reserve Low”. To properly adjust the

emergency reserve regulator the primary and secondary banks

must both be shut off and the cabinet pressure drained.

SLOWLY open one cylinder on the emergency reserve bank

and observe the EMER pressure display and check to make

sure it agrees with the gauge on the emergency reserve

regulator. Adjust the delivery pressure from the emergency

reserve regulator following the table on page 27 (if this is a 50

psig line pressure application this regulator should be set to 65

psig). When testing the Emergency Reserve in Use and

Emergency Reserve Low master alarms please note – there is

a 10 second delay designed into the manifold logic. The

Emergency Reserve in Use alarm will be triggered when the

INT pressure falls below 70 psig (50 psig line pressure

application) for more than 10 seconds. The Emergency

Reserve Low alarm will be triggered when the EMER pressure

falls below 1200 psig for more than 10 seconds. Test the

Emergency Reserve in Use alarm by first pressurizing both the

primary & secondary and the emergency reserve banks, close

the valves on both the primary & secondary bank vessels,

establish a gas flow thru the manifold. Approximately 10

seconds after the primary then secondary banks deplete to

empty, the Emergency Reserve in Use alarm should be

triggered.

9. After you are satisfied that the manifold is functioning properly

and that all master alarm signals are being triggered properly.

The manifold circuit board should be returned to the ‘cycling

view’ mode. This is achieved by moving the dip switch from

the PROGRAM to the RUN position.

Dip switch #1 RUN/PROGRAM

14

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Emergency Reserve – Model LLU

Model LLU – Emergency Reserve

Plumbing & Wiring

1. The model LLU includes digital displays for the

emergency reserve bank pressure and the intermediate

area pressure. (Refer to appendix E – page 27)

Remote master alarms will be triggered by the model LLU

for the five required NFPA 99 alarms; high line pressure, low

line pressure, secondary in use, emergency reserve in use and

emergency reserve low.

Refer to the appendix D on page 26 for information on

setting the delivery (outlet) pressure of the emergency

reserve regulator and pre-programmed emergency reserve in

use and emergency reserve low alarm set points.

2. The emergency reserve low bank pressure transducer

(part # 14-3001) should be installed on the extra port on

the RWP series manifold. This port is located prior

(upstream) to the master valve and the regulator.

Note: if the 14-3001 and 14-3002 transducers are not

used (and pressure switches are used instead or not

used at all because a reserve manifold is not being

used) the “Reserve Alarms” programming option (see

page 16) must be disabled and the 35-3013 high

pressure reserve jumper kit must be installed or else

error codes will be displayed by the circuit board.

Emergency reserve low bank pressure transducer (14-3001)

Emergency reserve in use pressure transducer (14-3002)

3. The emergency reserve in use pressure transducer (part #

14-3002) should be installed on copper tubing (provided

by plumbing contractor) after (downstream) of the check

valve (part # CV-050F).

Check valve (part # CV-050F)

Master alarm signal wiring

(use X6 terminals on circuit board)

4. Both the emergency reserve bank pressure transducer

and the emergency reserve in use transducer must be

wired to the manifold circuit board as indicated by the

labeling instruction. Remote master alarm signal and

common wires must also be connected to the manifold

circuit board as indicated by the labeling instruction.

15

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Cylinder Replacement & Line Pressure Adjustment

Cylinder replacement & handling

1. Close all cylinder valves on the depleted bank.

2. SLOWLY loosen and remove the pigtail

connection from the depleted cylinders.

3. Remove depleted cylinders and replace protective

caps.

4. Place and secure full cylinders into position using

chains, belts or cylinder stands.

5. Remove protective cylinder caps from full

replacement cylinders. With the valve outlet

pointed away from all people in the area, slowly

open each cylinder valve slightly for a split

second to blow out any dirt or contaminants that

may have become lodged into the cylinder valve.

6. Connect pigtails to cylinder valves and tighten

with wrench.

7. SLOWLY turn each cylinder valve until each

cylinder is fully on.

8. Observe the following conditions: The red

(Empty) LED is extinguished and the yellow

(Ready) LED is illuminated and the secondary in

use alarm is cancelled.

9. The manifold supply bank is now replenished and

automatically placed in “reserve”.

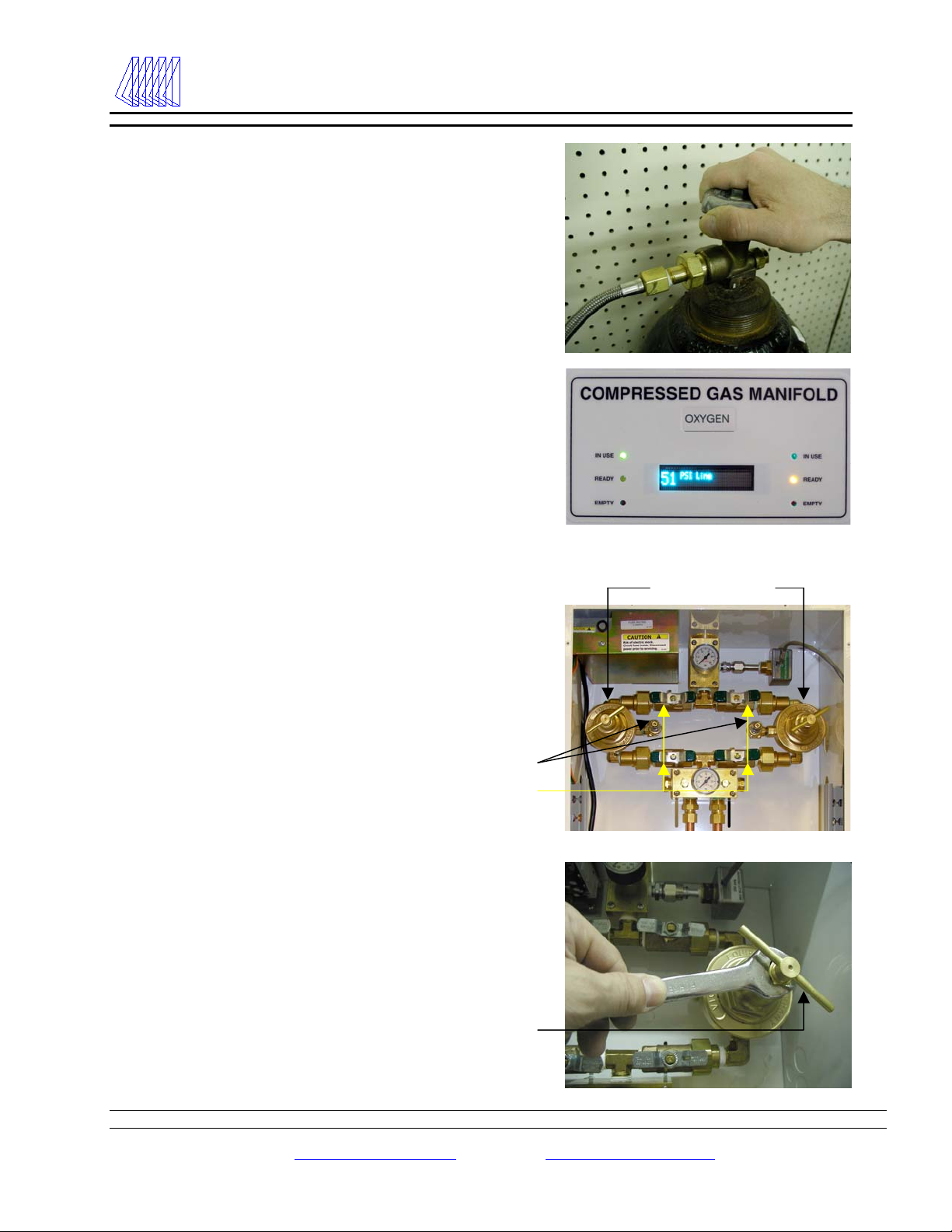

Line delivery pressure adjustment

1. Leave the manifold in full operational status.

2. Create a flow condition in the delivery piping

system. DISS demand valves have been provided

on the line regulators for this purpose. Mating

DISS fittings may be used to create a flow of gas

within the manifold cabinet.

3. Open the manifold cabinet door and locate the

line pressure regulators. Ball valves on the inlet

and outlet sides of each regulator determine

which regulator is “on line” and which is “off

line”. Note: when the ball valve handle is

perpendicular to the pipeline, the ball valve is

closed. Per NFPA 99, one line regulator should

be valved closed and the other valved open.

4. Turn the T – bar handle clockwise to increase

pressure or counter-clockwise to decrease

pressure. It may be necessary to use a 3/4” open-

end wrench, loosen the locknut on the adjusting

screw (on high flow models only).

5. After adjustment, retighten the locknut on the

adjusting screw and close the cabinet door.

DISS demand valves

Ball valves

T – Bar Handle

Line regulators

16

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Programming Adjustments

Programming Adjustments

The manifold is pre-programmed and tested before it is

shipped. You may, however, wish to modify some of the

programming. The unit has been designed to allow some

programming to be simply and safely altered in the field.

The aspects of the program which may be altered include:

the low line pressure alarm set point, the high line pressure

alarm set point, the emergency reserve low alarm set point

(LL models only), the reserve alarms (for both Emergency

Reserve in Use and Emergency Reserve Low) may be

disabled, the units of measure (psig, bar or kPa), the

calibration of the line pressure sensor, the display scroll

time (in seconds) and the logic software (this should only

be changed if the unit is being converted).

1. To make any programming change, the cover

must be removed from the circuit board and the

top #1 dip switch must be switched from the RUN

mode to the PROGRAM mode.

2. Once the #1 dip switch has been changed from

the RUN mode to the PROGRAM mode, the

display should look like this

3. Use the NEXT or PREVIOUS buttons to toggle

thru the menu choices. When you find the item

you wish to reprogram, use the UP or DOWN

buttons to display the new setting desired and

then use the ENTER button to save changes to the

programming. Note – if the ENTER button is

not pressed for each and every change, that

programming change will not be saved. The

display will display the word SAVED when you

have successfully saved a programming change.

4. Return the dip switch to the RUN position and

replace the circuit board cover when you are

finished making changes to the programming.

Displays showing common pre-programmed alarm set

points

Program control buttons

Dip switch #1 RUN/PROGRAM

17

Tri-Tech

Medical Inc. Genesys®Manifold Systems

General Maintenance & Error Codes

General Maintenance

Control Cabinet Headers & Pigtail

Daily Record line and bank pressures Observe nitrous oxide and carbon dioxide systems

for cylinder frosting or surface condensation. Should

excessive condensation or frosting occur it may be

necessary to increase manifold capacity.

Monthly Check regulators, compression fittings

and valves for external leakage.

Check valves for closure ability.

Alternate line regulator in use (if dual).

Inspect valves for proper closure.

Check pigtails for cleanliness, flexibility, wear,

leakage, kinked, pinched or twisted and thread

damage. Replace damaged pigtails immediately.

Inspect header check valve outlets for closure ability.

Annually Check relief valve pressures

Check regulator seats.

Every 4 years Replace all pigtails

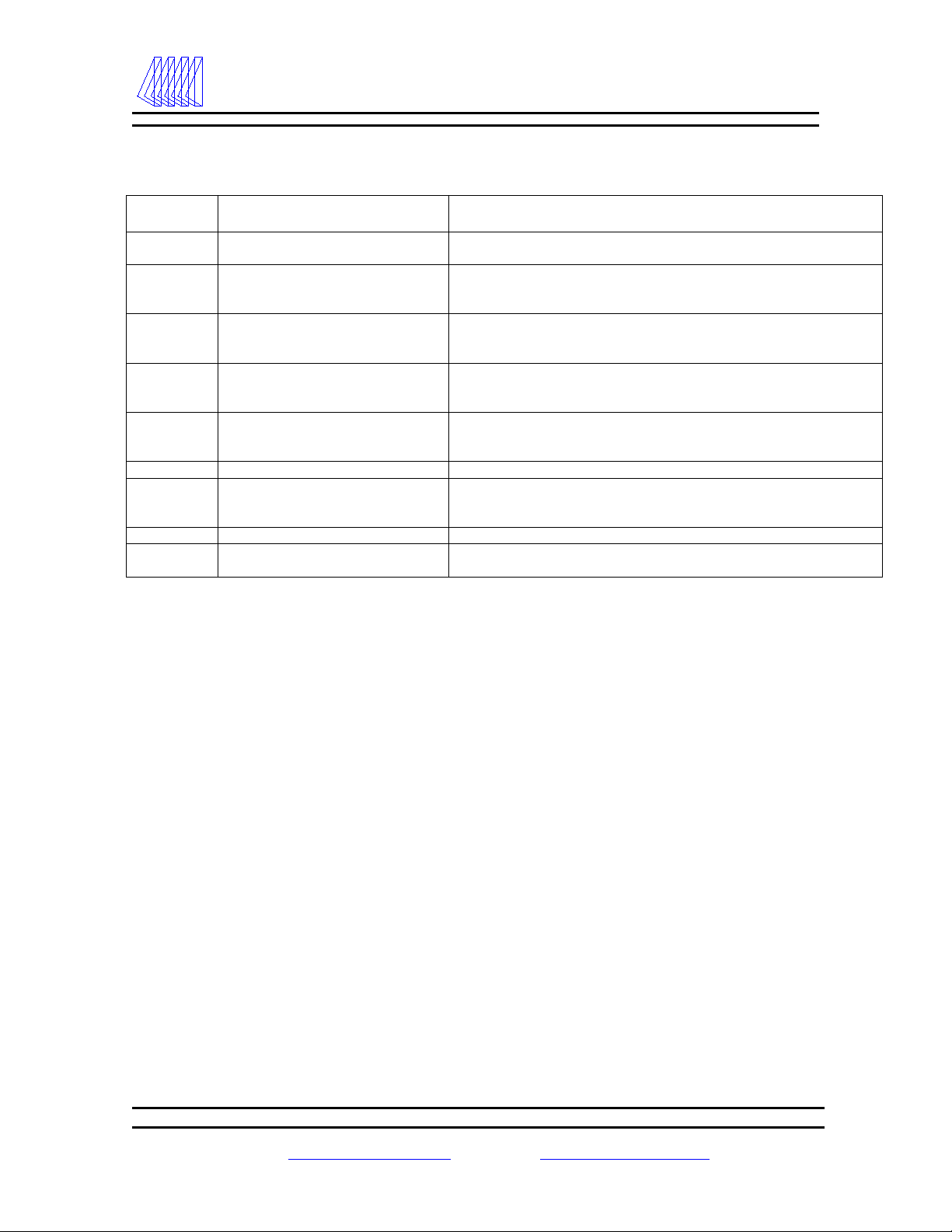

Error Codes, Alarm Codes & Information Codes

Code

Displayed

Message Displayed Explanation

Error 01 Left bank sensor out of range This condition is activated when the left sensor’s raw readings are at

either extreme. Can be caused by a disconnected, wired incorrectly, bad,

or over-pressurized sensor.

Error 02 Right bank sensor out of range This condition is activated when the right sensor’s raw readings are at

either extreme. Can be caused by a disconnected, wired incorrectly, bad,

or over-pressurized sensor.

Error 03 Intermediate pressure out of range This condition is activated when the intermediate sensor’s raw readings

are at either extreme. Can be caused by a disconnected, wired incorrectly,

bad, or over-pressurized sensor. (LL models only).

Error 04 Emergency reserve out of range This condition is activated when the emergency sensor’s raw readings are

at either extreme. Can be caused by a disconnected, wired incorrectly,

bad, or over-pressurized sensor. (LL models only)

Error 05 Left bank pressure high In CC models this message is displayed whenever the left inlet bank

pressure exceeds 3,000 psi. In LL models this message is displayed

whenever the left inlet bank pressure exceeds 500 psi.

Error 06 Right bank pressure high In CC models this message would be displayed if the right inlet bank

pressure exceeds 3,000 psi. In LL models this message would be

displayed if either inlet bank pressure exceeds 500 psi.

Error 07 Intermediate pressure high Message is displayed whenever the intermediate pressure exceeds 500 psi.

(LL models only).

Error 08 Emergency reserve pressure high Message is displayed whenever the high pressure emergency reserve bank

pressure exceeds 3,000 psi. (LL models only).

Error 09 Line sensor noise detected Message is displayed if a gas board detects noise in the signal from it’s

digital sensor. Noise is detected if the protocol checksums do not match.

Error 10 Line sensor failed to respond Message is displayed if a line sensor is not responding.

Error 11 Line sensor is disconnected Message is displayed whenever a line sensor is disconnected.

Error 12 Secondary supply leak detected Message is displayed when a leak is detected in the secondary bank. (CC

models only).

Error 13 Emergency reserve leak detected Message is displayed when a leak is detected in the emergency reserve

bank. (LL models only).

Error 14 Gas type mismatch This error code is triggered by a mismatch in gas type between the line

sensor and user selected gas type in setup of the manifold circuit board.

18

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Alarm & Information Codes

Error Codes, Alarm Codes & Information Codes (continued)

Code

Displayed

Message Displayed Explanation

Alarm 01 Line pressure low Message is displayed and low line pressure relay activated whenever the

line pressure is below the programmed low line pressure alarm set point.

Alarm 02 Line pressure high Message is displayed and high line relay activated whenever the line

pressure is above the programmed high line pressure alarm set point (high

line pressure alarm is triggered).

Alarm 03 Secondary supply in use Message is displayed and secondary in use relay activated when the

manifold has switched over to the secondary bank. Clears when tank is

replaced.

Alarm 04 Emergency reserve in use Message is displayed and emergency in use relay activated whenever the

intermediate pressure is below the programmed emergency in use

pressure alarm set point. (LL models only).

Alarm 05 Emergency reserve pressure low Message is displayed and emergency low relay activated whenever the

emergency pressure is below the programmed emergency reserve low

pressure alarm set point. (LL models only).

Info 01 Economizer in use – see manual Message is displayed whenever the ready bank pressure exceeds the

service bank pressure by 50 psig or more. The logic compares the service

and ready bank pressures once a second. (LL models only).

XX% Remains (CC models only - except for N2O & CO2 services). It calculates the

percent of gas remaining in the service bank.

Definitions and clarifications

Alarm Code – Alarm conditions per NFPA 99C and Z7396.1 guidelines.

Error Code – Messages that provide diagnostic information to assist in resolving system problems.

Information Codes – Messages that provide information regarding the operation of the system.

19

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Replacement Parts

Item Part Number Description

Primary Regulator &

Repair Kit 68-0003 Primary regulator

68-0003RK Primary regulator repair/rebuild kit

Line Regulators &

Repair Kits 68-0004 Line regulator standard flow 5 - 125 psig

68-0004RK Standard flow line regulator repair/rebuild kit

68-0002 Line regulator high flow 5 - 125 psig

68-0002RK High flow line regulator repair/rebuild kit 5 - 125 psig

68-0001 Line regulator high flow 10-200 psig

68-0001RK High flow line regulator repair/rebuild kit 10 - 250 psig

Circuit Board 35-1001 LL series PLC board with digital displays

35-1002 CC series PLC board with digital displays

35-1003 CC series PLC board with text display

35-1004 LL series PLC board with text display

Power Supply AA400-C Power supply

Transducers/Sensors 14-3001 0 - 2,500 psig transducer with 12' cable ER Reserve Low

14-3002 0 - 500 psig transducer with 8' cable ER Reserve in Use

14-3003 0 - 250 psig transducer with 10' cable N2 for old style units

14-3004 0 - 100 psig transducer with 10' cable Oxygen for old style units

14-3005 0 - 100 psig transducer with 10' cable Med Air for old style units

14-3006 0 - 100 psig transducer with 10' cable N2O for old style units

14-3007 0 - 100 psig transducer with 10' cable CO2 for old style units

14-3024 0 - 250 psig transducer with 1.5' cable N2 for new style units

14-3025 0 - 100 psig transducer with 1.5' cable Oxygen for new style units

14-3026 0 - 100 psig transducer with 1.5' cable Med Air for new style units

14-3027 0 - 100 psig transducer with 1.5' cable N2O for new style units

14-3028 0 - 100 psig transducer with 1.5' cable CO2 for new style units

Solenoid Valves 48-1007 Solenoid valve for CC series

48-1008 Left Solenoid valve for LL series

48-1009 Right Solenoid valve for LL series

Check Valve 17-4003 Intermediate check valve 1/2 npt male x 1/2 OD tube

Tubes & Compression

Fittings 17-4012 Compression Sleeve 1/2 OD tube - glass filled Teflon

17-4005 Compression Nut for 17-4012

Q1100-1 1/2 OD copper tube x 7"

17-4013 Compression Sleeve 3/8 OD tube - glass filled Teflon

17-4024 Compression Nut for 17-4013

Gauges 14-1018 0 - 4,000 psig 1 1/2" x 1/8 m npt center back gauge

14-1016 0 - 400 psig 2" x 1/4 m npt bottom port gauge

14-1017 0 - 400 psig 1 1/2" x 1/8 m npt center back gauge

14-1009 0 - 300 psig 1 1/2" x 1/8 m npt center back gauge

14-1008 0 - 100 psig 1 1/2" x 1/8 m npt center back gauge

Relief Valves RV-22-075 75 psig x ½ M npt inlet with pipe away adaptor

RV-22-150 150 psig x ½ M npt inlet with pipe away adaptor

RV-22-250 250 psig x ½ M npt inlet with pipe away adaptor

RV-11-400 400 psig x ¼ M npt inlet with pipe away adaptor

20

Tri-Tech

Medical Inc. Genesys®Manifold Systems

Replacement Parts

Item Part Number Description

Pigtails for CC, TMC,

RWP & RSP Models

20-1001 24” single loop rigid copper O2 – CGA 540

20-0001 24” Flexible stainless braided O2 - CGA 540

20-0001CV 24” Flexible stainless braided O2 - CGA 540 w/ Check valve

20-1002 24” single loop rigid copper N2O – CGA 326

20-0002 24” Flexible stainless braided N2O - CGA 326

20-0002CV 24” Flexible stainless braided N2O - CGA 326 w/ Check valve

20-0003 24” Flexible stainless braided CO2 – CGA 320

20-0003CV 24” Flexible stainless braided CO2 - CGA 320 w/ Check valve

20-0004 24” Flexible stainless braided AIR – CGA 346

20-0004CV 24” Flexible stainless braided Air - CGA 346 w/ Check valve

20-0005 24” Flexible stainless braided Inert – CGA 580

20-0005CV 24” Flexible stainless braided Inert - CGA 580 w/ Check valve

Pigtails for LL & TML

Models

20-2001 72” Flexible – O2 – CGA 540

20-2002 72” Flexible – N2, Ar, He– CGA 580

20-2003 72” Flexible – CO2 – CGA 320

20-2004 72” Flexible – N2O – CGA 326

Union for Vent Lines 17-0169 Union 3 piece ½” M npt x ½” M npt 1 ¼ - 14 UNS

Master Valve GMV-1001 Master Valve 1/2" F npt x 1/2 F npt

Master Valve Repair

Kit

GMV-1001RK Master valve rebuild kit

35-3013 High Pressure Reserve Jumper Kit

Heater element 35-2001 Ceramic Heater

Accessory 35-3012 Manifold buzzer kit

This manual suits for next models

2

Table of contents

Other TRI-TECH MEDICAL Medical Equipment manuals

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual