Triacta PowerHawk 6320 User manual

PowerHawk 6320

High Density Meter

Installation Guide

© 2013 Triacta Power Technologies All Rights Reserved

Triacta Power Technologies, and the Tricata logo are trademarks of Triacta

Power Technologies Inc.

All other trademarks that may be used in this document are the property of

their respective holders.

Copyright © Triacta Power Technologies Inc., 2004 to 2013

All rights reserved.

Triacta assumes no responsibility for the accuracy of the information

presented, which is subject to change without notice.

Disclaimers

This document contains confidential information which is proprietary to

Triacta Power Technologies Inc. Copying and/or distribution of this

material is prohibited without the prior approval of authorized Triacta

personnel.

Triacta products are intended for commercial uses. The customer hereby

agrees that the use, sale, licence or other distribution of the products for any

such application without the prior written consent of Triacta, shall be at the

customer's sole risk. The customer hereby agrees to defend and hold

Triacta harmless from any claims for loss, cost, damage, expense or

liability that may arise out of or in connection with the use, sale, licence or

other distribution of the products in such applications.

The warranties provided for Triacta products, if any, are set forth in

contractual documentation entered into by Triacta and its customers.

This document was originally written in English. If there is any conflict or

inconsistency between the English version and any other version of a

document, the English version shall prevail.

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

Table of Contents i

Table of Contents

PowerHawk 6320 Meter Installation Guide

System description.......................................................................... 1

PowerHawk 6320 system specifications .............................................................................. 1

Front panel display ......................................................................................................... 1

Installation

Pre-installation................................................................................. 4

Pre-installation check list ...................................................................................................... 4

Site planning ......................................................................................................................... 5

Access to power and lighting ......................................................................................... 5

Installation procedures ................................................................... 6

Mounting the PowerHawk .............................................................................................. 6

Installing voltage transformers for three-phase service greater than 120V ................... 6

Installing the reference voltage cable and power cable in a 120/240V application ........ 8

Using the auxiliary power input .................................................................................... 11

Installing the current transformers ............................................................................... 12

Using 5A CT converters with the PowerHawk 6320 meter .......................................... 15

Connecting the phone line ........................................................................................... 16

Connecting the Ethernet cable ..................................................................................... 16

Connecting pulse inputs ............................................................................................... 16

Start-up sequence for the PowerHawk 6320 meter ........................................................... 17

The initial report ........................................................................................................... 17

Display navigation .............................................................................................................. 18

Normal mode ............................................................................................................... 18

Diagnostics mode ........................................................................................................ 18

Recording the meter map ................................................................................................... 20

Regulatory Compliance

CSA .............................................................................................................................. 22

Federal Communications Commission (FCC) statement ............................................. 22

Industry Canada Class A emission compliance statement .......................................... 22

Avis de conformité aux normes d'Industrie Canada ..................................................... 23

Safety requirements and certification ................................................................................. 23

Access to equipment .................................................................................................... 23

Servicing the equipment .............................................................................................. 23

Equipment servicing ..................................................................................................... 23

Electrical safety compliance ............................................................................................... 23

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

ii Table of Contents

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

PowerHawk 6320 Meter Installation Guide 1

PowerHawk 6320 Meter Installation Guide

This document provides general information about the PowerHawk 6320 high-density meter,

and procedures to install and start up the unit, and complete the initial configuration.

• “System description” on page 1

• “Pre-installation” on page 4

• “Installation procedures” on page 6

• “Start-up sequence for the PowerHawk 6320 meter” on page 17

• “Regulatory Compliance” on page 22

Thisdocumentationisintendedfor thoseresponsible forinstallingandconfiguring PowerHawk

meters.

Installers must be licensed electricians with knowledge of local and national safety regulations.

System description

The PowerHawk 6320 high-density meter is single-phase, poly-phase, and three-phase devices

with 20 individual meters. All PowerHawk units are designed for residential, commercial and

industrial use with a wye service. They display the power and consumption readings for each

measurement point.

PowerHawk 6320 system specifications

The PowerHawk system architecture includes:

• single-phase, poly-phase (network) and three-phase compatiblity

• 120/240V and 120/208V configurations

• 20 individual meter points

• local Ethernet configuration interface via PC and web browser

• onboard modem and Ethernet ports for remote reporting

Front panel display

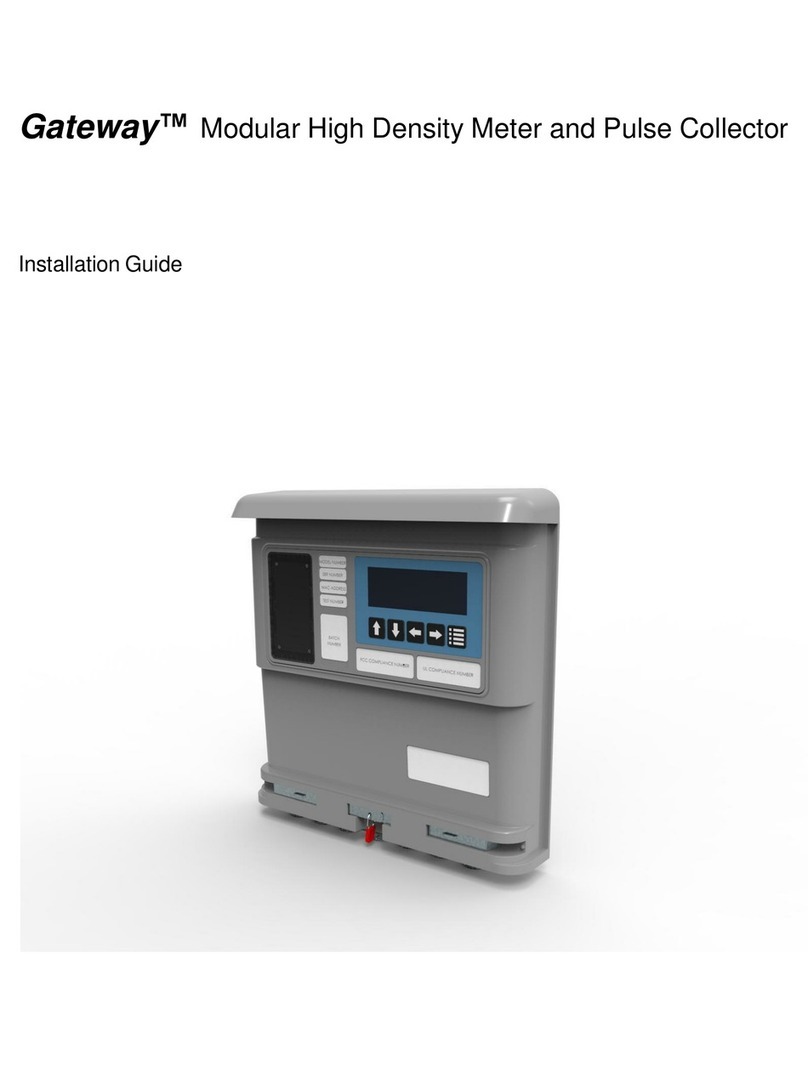

As shown in Figure 1, the PowerHawk 6320 has the following front panel features:

•LCD - displays 2 rows of 16 characters for each of the 20 meters

•Display button - cycles through the available information for each of the 20 meters

•Left and right arrow buttons - selects which of the 20 meters is on the display

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

2PowerHawk 6320 Meter Installation Guide

Figure 1: PowerHawk front panel

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

PowerHawk 6320 Meter Installation Guide 3

Table 1 lists the system specifications of the PowerHawk 6320 high-density meter.

Table 1: PowerHawk 6320 specifications

Specification Description

Dimensions Height: 16 in. (40.6 cm)

Width: 10 in. (20.3 cm)

Depth: 2 in. (5.1 cm)

Weight 5.5 lb (2.5 kg)

Reference input voltage 120/208V, 3W+N+PE

120/208V, 2W+N+PE

120/240V, 2W+N+PE

Voltage tolerance 108V to 127V

Maximum current 125 mA, 60 Hz

Current probes 200 A, 400 A, 800 A

Measurement accuracy Measurement Canada Approved

Pulse input Dry form A and solid-state form A compatible

Internal 3.3V pull-up

Maximum frequency 10 Hz

Minimum pulse width 20 ms

NVM storage 120 days in 15-minute intervals

Onboard modem V.90

Onboard Ethernet port 10 Mb/s

Fuse rating F1, F2, F3: T80 mA or T100 mA, 250V

F4: T80 mA or T125 mA, 250V

Operating temperature 32oF to 122oF (0 to 50oC)

Operating humidity 0 to 90% non-condensing

Usage environment For indoor use only

Maximum altitude 6562 ft. (2000 m)

Pollution degree 2

Installation Category II

Measurement Category III

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

4Installation

Installation

This section provides pre-installation, installation and system start-up procedures as follows:

• “Pre-installation” on page 4

• “Installation procedures” on page 6

• “Start-up sequence for the PowerHawk 6320 meter” on page 17

Pre-installation

This section provides information about activities that must be performed before installing the

equipment at the site. The following topics are covered:

• “Pre-installation check list” on page 4

• “Site planning” on page 5

Pre-installation check list

The following Triacta Power equipment is required for each installation:

• PowerHawk 6320 high-density meters

• two 25-pair CT cables per PowerHawk meter with amphenol connectors, available in

lengths of 13 ft. (4 m) or 26 ft. (8 m)

• serialized current transformers for metering

Note: The current transformers supplied by Triacta are certified, and comply with national

electrical codes.

When you receive your order, verify that the items listed above are included with the shipment,

and visually inspect them for damage. If any parts are missing or damaged, contact your Triacta

representative.

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

Installation 5

The installer must provide the following tools and equipment before proceeding with the

installation:

• an appropriate breaker for the type of panel: single-, poly-, or three-phase depending on

the installation, or a fused disconnect switch

• current/voltage meter to test the phasing of panels

• phone or butt set to test the phone line

• RJ11 junction box

• RJ11 splitter to tap into the existing junction box

• RJ11 patch cable

• xDSL filter if required (many businesses have their internet access on the same line as the

fax)

• RJ45 Ethernet patch cable

• 4-wire 14 AWG (1.63 mm2) cable for three-phase PowerHawk installation

• 3-wire 14 AWG (1.63 mm2) cable for single-phase or poly-phase PowerHawk installation

• small flat-head screwdriver

• crimping tool

• 22 AWG to 18 AWG crimps

• wire strippers

• four 1-inch (25-mm) #8 mounting screws suitable for the selected mounting surface

Site planning

1. Determine the number of PowerHawk units to be installed and ensure there is adequate

space.

2. Determine the number of analog phone lines or ethernet drops required, and ensure they

are installed before installing the PowerHawk unit.

3. Determine the number and types of meters or monitors required (single-phase, poly-phase,

or three-phase).

Access to power and lighting

The installation site must be supplied with access to the main electrical panel and any

sub-panels. Portable or permanent lighting must be available to provide the installers with a

clear view of the equipment and of the installation environment. Each installation may vary

depending on physical site restrictions.

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

6Installation

Installation procedures

This section provides information about activities that must be performed to install the

PowerHawk in a single-phase, poly-phase, or three-phase application (120/208V or 120/240V).

The installation procedures must be performed in the order listed in Table 2 to ensure safety and

proper functioning of the equipment.

WARNING: If the equipment is installed or used in a manner not specified in this

document, the protection of the equipment may be impaired.

Table 2: Installation procedures

Mounting the PowerHawk

The PowerHawk is mounted adjacent to the main breaker box. The unit can be mounted either

horizontally or vertically, depending on the preferred routing of the wiring. It should be securely

mounted with four 1-inch (25 mm) #8 mounting screws suitable for the selected mounting

surface. If mounting the unit on a gyprock surface, also use cylinder plugs.

1. Remove the front cover from the PowerHawk by removing the four screws with a Phillips

screwdriver. Keep the cover and screws in a safe place for re-installing.

2. Mount the PowerHawk on the wall and secure it by inserting a screw in each mounting

keyhole and tightening the screws.

Installing voltage transformers for three-phase service greater than 120V

Voltage transformers are required when monitoring services greater than 120V. Measurement

Canada approved VTs to reduce theline-to-neutral voltage of the serviceto120V. The accuracy

class should be 0.3% or better, with a burden rating of 150VA.

Installation type Installation procedure and page reference

208V/240V installation “Installing the reference voltage cable and power cable in a 120/240V

application” on page 8

“Using the auxiliary power input” on page 11

“Installing the current transformers” on page 12

“Using 5A CT converters with the PowerHawk 6320 meter” on page 15

“Connecting the phone line” on page 16

“Connecting pulse inputs” on page 16

“Connecting the Ethernet cable” on page 16

“Start-up sequence for the PowerHawk 6320 meter” on page 17

“The initial report” on page 17

“Recording the meter map” on page 20

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

Installation 7

Voltage transformers must be mounted in a listed electrical enclosure. Mount the voltage

transformer enclosure between the supply voltage and the PowerHawk. Transformer

configuration must be Y||Y. Figure 2 shows a block diagram of a complete three-phase 4-wire

installation.

Figure 2: Typical three-phase 4-wire installation

H1 X1

H2 X2

H1 X1

H2 X2

H1 X1

H2 X2

C

B

A

N

N

A

B

C

1

2

3

4

12

Z

5

6

7

8

13

11

12

Shorting block detail

10

9

Legend:

1 Shorting block enclosure

2 Shorting block

3 Breaker panel

4 Current transformer

5 Load breaker

6 Meter breaker

7 Transformer enclosure

8 PowerHawk meter

9 Load

10 Cable

11 Shorting jumper

12 Shorting block

13 DIN rail

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

8Installation

Installing the reference voltage cable and power cable in a 120/240V

application

The PowerHawk has two voltage inputs. Auxiliary voltage is phase-independent and only

provides power to the internal circuits. The reference voltage (A, B, C, N) provides phase

voltages for power calculations, and the configuration depends on the type of service being

metered (single-phase, poly-phase, or three-phase).

The PowerHawk 6320 is shipped from the factory with shorting wires in the auxiliary power

inputs that power the unit from the reference voltage inputs. The following procedures explain

how to connect the reference voltage inputs for each of the service types. For instructions on

how to use the auxiliary power inputs see “Using the auxiliary power input” on page 11.

For a single- or poly-phase panel, use a 3-wire (red, black, white) 14 AWG (1.63 mm2) cable.

For a three-phase panel, use a 4-wire (red, black, blue, white) 14 AWG (1.63 mm2) cable.

Metallic, flexible armored cable (BX cable) is recommended for commercial installations.

As a safety precaution, the PowerHawk must be connected to its own breaker or switched

disconnect so it can be powered down separately by tripping a single breaker. The disconnect

device must located within easy reach of the meter operator, and must be labeled. For multiple

PowerHawk installations, the same disconnect can be used to power all PowerHawk units.

To install the power cable in a 120/240V application

WARNING: Ensure that the breaker you use to provide power to the PowerHawk is off

before connecting the power cable.

CAUTION: When connecting the power, ensure that there is a 1-inch loop of wire on each

lead inside the unit.

Note: If the breaker panel does not designate phase A and phase B feeds, make your own

designation and use it for the rest of the installation.

1. Connect the PowerHawk A, B, and N leads to the breaker or fused disconnect as follows:

WARNING: The A, B, wiring sequence between the PowerHawk and the panel must

match, or the measurement readings will be wrong.

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

Installation 9

a. For a single-phase panel (see Figure 3), connect:

• PowerHawk A terminal to breaker phase A (red wire)

• PowerHawk B terminal to breaker phase B (black wire)

• PowerHawk neutral terminal to neutral bar in panel (white wire)

• Earth wire to earth post using lug provided

• Phase C is not connected

Figure 3: PowerHawk 120/240V single-phase connection

Earth

Phase A (red)

Phase B (black)

Phase C

Neutral (white)

AUXA to A

shorting wire

AUXN to N

shorting wire

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

10 Installation

b. For a three-phase wye panel (see Figure 4), connect:

• PowerHawk A terminal to breaker phase A (red wire)

• PowerHawk B terminal to breaker phase B (black wire)

• PowerHawk C terminal to breaker phase C (blue wire)

• PowerHawk neutral terminal to neutral bar in panel (white wire)

• Earth wire to earth post using lug provided

Figure 4: PowerHawk 120/208V three-phase wye service connection

2. Replace the front cover of the PowerHawk and secure it in place with the four screws.

3. If more than one meter is being installed, repeat this procedure for each additional meter.

Earth

Phase A (red)

Phase B (black)

Phase C (blue)

Neutral (white)

AUXA to A

shorting wire

AUXN to N

shorting wire

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

Installation 11

Using the auxiliary power input

The PowerHawk comes equipped with an auxiliary power input that can be used to power the

system independently from the reference voltage inputs described in the previous section.

Because the default configuration for powering the unit is through the reference voltage inputs,

the system is configured at the factory with shorting wires on the auxiliary power input. If you

choose to power the unit through the auxiliary power input, the shorting bars must be removed

from the auxiliary power connector before connecting the reference voltage inputs.

The auxiliary power inputs are 120V and require a separate breaker or fused disconnect switch.

Figure 5 shows the auxiliary power connections.

To connect the auxiliary power input

1. Remove the second punch-out at the top of the unit.

2. Remove the shorting wires connecting AUXA to A, and AUXN to N on the auxiliary

power input connector.

3. Connect PowerHawk AUXA and AUXN to a 120V source.

4. Connect the earth wire to the earth post using the lug provided.

Figure 5: Connecting auxiliary power input

Earth

Phase A (red)

Phase B (black)

Phase C (blue)

Neutral (white)

AUXA

AUXN Earth

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

12 Installation

Installing the current transformers

The mA solid-core current transformers (CTs) are connected directly to the CT cables. When

using a 5A CT adaptor, the adaptor is connected to the CT cable and the 5A CT is connected to

the adaptor.

All solid-core and CT adaptors are labeled for use with a specific meter, and must be used with

the correct meter port to ensure meter accuracy.

As shown in Figure 6, CTs are N Amp solid-core CTs that are installed on existing connections.

Current transformers connect to the PowerHawk through the two 25-pair CT cables labeled

Cable 1 and Cable 2. See Table 3 for the definition of the CT probe pairs within the cable colour

scheme.

Note: All CTs should have external shorting blocks to limit open circuit voltages to safe

levels.

Installation of mA CTs

Each CT has a black and white wire pair and uses butt connectors to attach the CT to a specific

PowerHawk probe pair. The direction of the energy flow is indicated on the CT, as shown in

Figure 6.

Figure 6: 200A: 80mA current transformer

Energy

Flow

Load

Source

Energy

Flow

Load

Source

X1

X1

X2 X2

Standard CT

part 908-314-01

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

Installation 13

Note: The standard 200A:80mA current transformer shipped with the PowerHawk 6320 is

part number 908-314-01 (shown on the right in Figure 6). When retrofitting an installation

or redeploying previously shipped current transformers, verify the part numbers and

connect the correct X1 and X2 leads to the CT cable as instructed in “To install the current

transformers” on page 13.

To install the current transformers

WARNING: Power must not be applied until all CTs are connected to the appropriate

circuits, the CTs have been connected to the cables, and both cables have been connected to

the PowerHawk. Failure to do so may result in dangerous voltages on the CT lead that may

cause severe injury and equipment damage.

1. Connect the 25-pin amphenol connector of cable 2 to the PowerHawk connector located at

the bottom of the unit, and secure it in place with the retaining clips. Repeat for cable 1.

2. Feed the free end of Cable 1 and Cable 2 through a 3/4-inch punch-out on the hydro panel

with strain relief.

3. Strip the plastic sheaths back to an appropriate length to expose the wire pairs. Cut and

strip the CT leads and wire pair leads to an appropriate length.

4. Crimp the CT probe leads to the CTs for each PowerHawk as follows: black CT wire to

first half of the CT probe pair, white CT wire to the second half of the CT probe pair. See

Table 3 for the list of probe colour pairs for the PowerHawk 6320 high-density meters.

5. Switch the breaker off for the circuit being installed and remove the feed wire. Place the

CT over the wire and reconnect to the breaker.

6. Repeat steps 3 to 5 for the remaining CTs.

Note: The direction of the energy flow is indicated on the CT.

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

14 Installation

Table 3: Colour pair identification for PowerHawk 6320 high-density meters

Cable 1

Pairs Connect Black

CT lead to: Connect White

CT lead to: Cable 2

Pairs Connect Black

CT lead to: Connect White

CT lead to:

P1-1 Black Green P11-1 Black Green

P1-2 Black White P11-2 Black White

P1-3 Black Red P11-3 Black Red

P2-1 Red Green P12-1 Black Brown

P2-2 Red White P12-2 Black Yellow

P2-3 Black Orange P12-3 Black Blue

P3-1 Black Brown P13-1 Green White

P3-2 Black Yellow P13-2 Red Orange

P3-3 Black Blue P13-3 Red Brown

P4-1 Green Yellow P14-1 Red Yellow

P4-2 Green Blue P14-2 Red Blue

P4-3 Green White P14-3 Red Green

P5-1 White Blue P15-1 White Brown

P5-2 Green Orange P15-2 White Yellow

P5-3 Green Brown P15-3 White Blue

P6-1 Blue Yellow P16-1 Red White

P6-3 White Orange P16-3 Black Orange

P7-1 Red Orange P17-1 Green Yellow

P7-3 Red Brown P17-3 Green Blue

P8-1 Blue Orange P18-1 Blue Yellow

P8-3 Blue Brown P18-3 White Orange

P9-1 White Brown P19-1 Blue Orange

P9-3 White Yellow P19-3 Blue Brown

P10-1 Red Yellow P20-1 Green Orange

P10-3 Red Blue P20-3 Green Brown

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

Installation 15

Using 5A CT converters with the PowerHawk 6320 meter

When both low-current (200A and 400A) and high-current (600A or higher) circuits need to be

measured with the same PowerHawk meter, converters are available to allow the use of

Measurement Canada approved 5A CTs with the appropriate current rating. 5A CT converters

transform the 5A maximum output from a standard CT to the 80mA maximum of the

PowerHawk meter.

The 5A side of the converter is the black and red wire pair, and the 80mA side of the converter

is the black and white wire pair.

It is recommended that 5A converters and shorting devices be installed in a sealable metal

enclosure.

To connect the 5A CT to the converter on the PowerHawk 6320, follow these steps:

1. Connect the X1 lead of the 5A CT to the shorting device.

2. Connect the X2 lead of the 5A CT to the shorting device.

3. Connect the X1 lead (red) from the 5A side of the converter to the CT X1 lead on the

shorting device.

4. Connect the X2 lead (black) from the 5A side of the converter to the CT X2 lead on the

shorting device.

5. Connect the X1 lead (white) from the 80mA side of the converter to the X1 lead within the

25 pair cable for the selected meter point listed in Table 3.

6. Connect the X2 lead (black) from the 80mA side of the converter to the X2 lead within the

25 pair cable for the selected meter point listed in Table 3.

Figure 7 shows a 5A CT connected to the converter.

Figure 7: PowerHawk 6320 meter 5A CT connection to converter

5A Converter

Red (X1)

X1 to 25-pair Cable

Black (X2)

Energy

Flow

5A CT

Shorting

Block

X2

X1

Enclosure

Shorting

Bar

X2 to 25-pair Cable

NOT FOR DISTRIBUTION WITHOUT THE CONSENT OF TRIACTA POWER

Triacta Power Technologies PowerHawk 6320

16 Installation

Connecting the phone line

If the modem reporting option is being used, an analogue telephone patch cable is required to

connect the customer phone line to the PowerHawk.

1. Connect the patch cable between the termination block of the phone line and the

PowerHawk.

2. Disconnect the Ethernet cable (if an Ethernet cable is connected, reporting defaults to the

Ethernet port).

A single phone line can be daisy-chained to several PowerHawk meters.

Connecting the Ethernet cable

If the IP reporting option is being used, a separate RJ45 patch cable is required to connect the

Ethernet port for each PowerHawk meter to the local Ethernet network.

If the local network automatically assigns IP addresses through a DHCP server, the PowerHawk

meter will be able to report using its factory default IP settings. If there is no DHCP server, refer

to the PowerHawk meter Configuration Guide for instructions to configure default static IP

addresses.

Connecting pulse inputs

The pulse input on the PowerHawk 6320 can be used to count and report pulses generated by

another meter (pulsing device).

Connect the output of the pulsing device to PIN 2 and PIN 3 of the “pulse in” terminal blocks

in the PowerHawk 6320 meter, as shown in Figure 8. The pulse inputs are compatible with both

dry and solid-state form A contacts, 10 Hz maximum frequency, 20 ms minimum pulse width.

When the pulsing device provides dry relay contacts the pulse input is not polarity-sensitive.

Whenthepulsing device provides solid-state form A outputs, the GND (negative) terminal from

the source device must be connected to PIN 3 of the pulse in terminal block.

The pulsing device can be located up to 1,000 feet away from the PowerHawk meter with

22 AWG twisted pair wire.

Table of contents

Other Triacta Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

AEMC

AEMC MN306 user manual

Baumer

Baumer Hubner HENQ 1100 operating instructions

HELWIG CARBON

HELWIG CARBON BPK-Probe operating guide

Siemens

Siemens ARCADIS Avantic Installation and start-up manual

Seca

Seca mVSA 535 quick start

WATERS CORPORATION

WATERS CORPORATION TA Instruments DSC 2010 Operator's manual