TRIATEK FMS-1650L User manual

FMS-1650L

Installation Manual

Version: 04.02.17

TRIATEK FMS-1650L

The Next Generation in Critical Airow Controls

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

FMS-1650L

TRIATEK reserves the right to change product specifications without notice. TRIATEK reserves the right to change product specifications without notice.

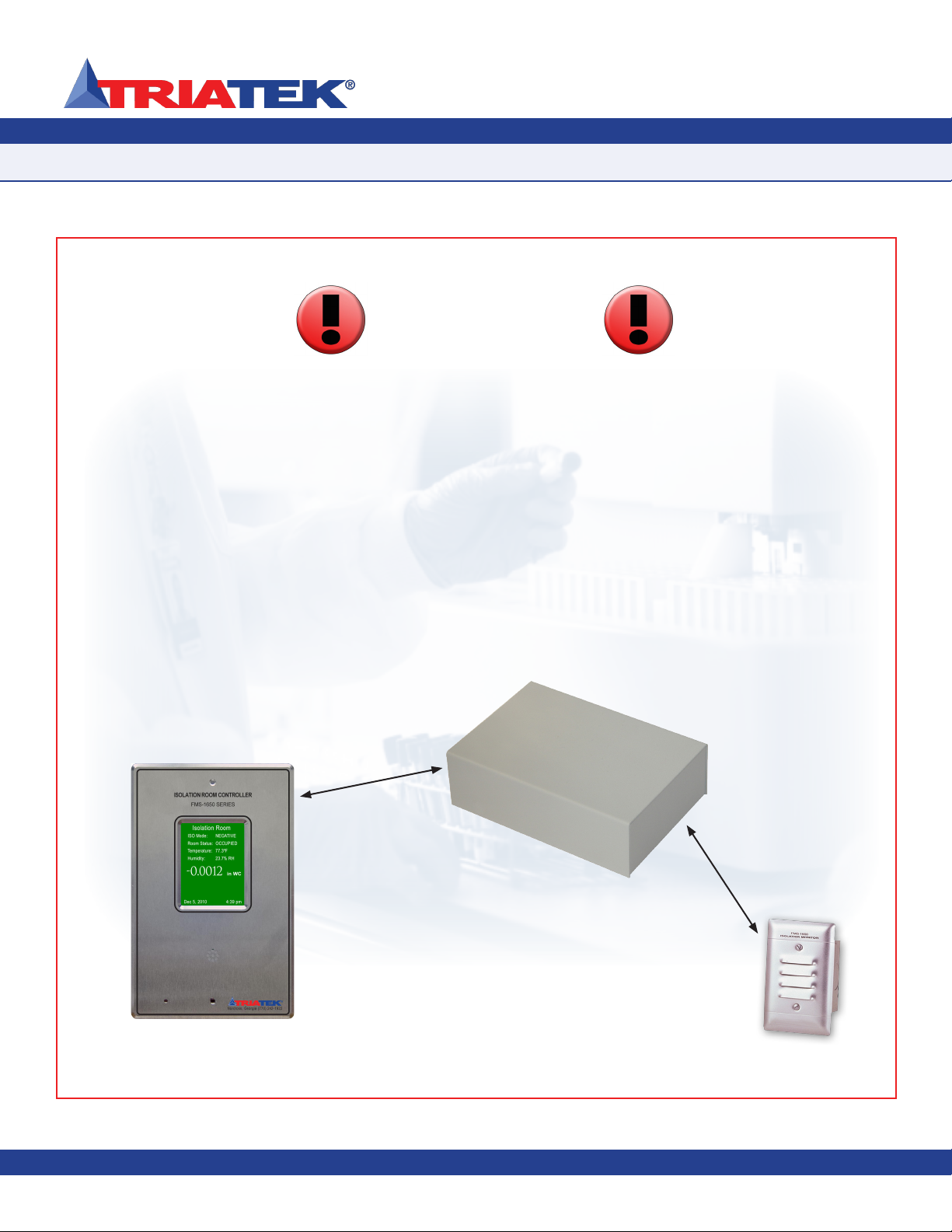

CAUTION

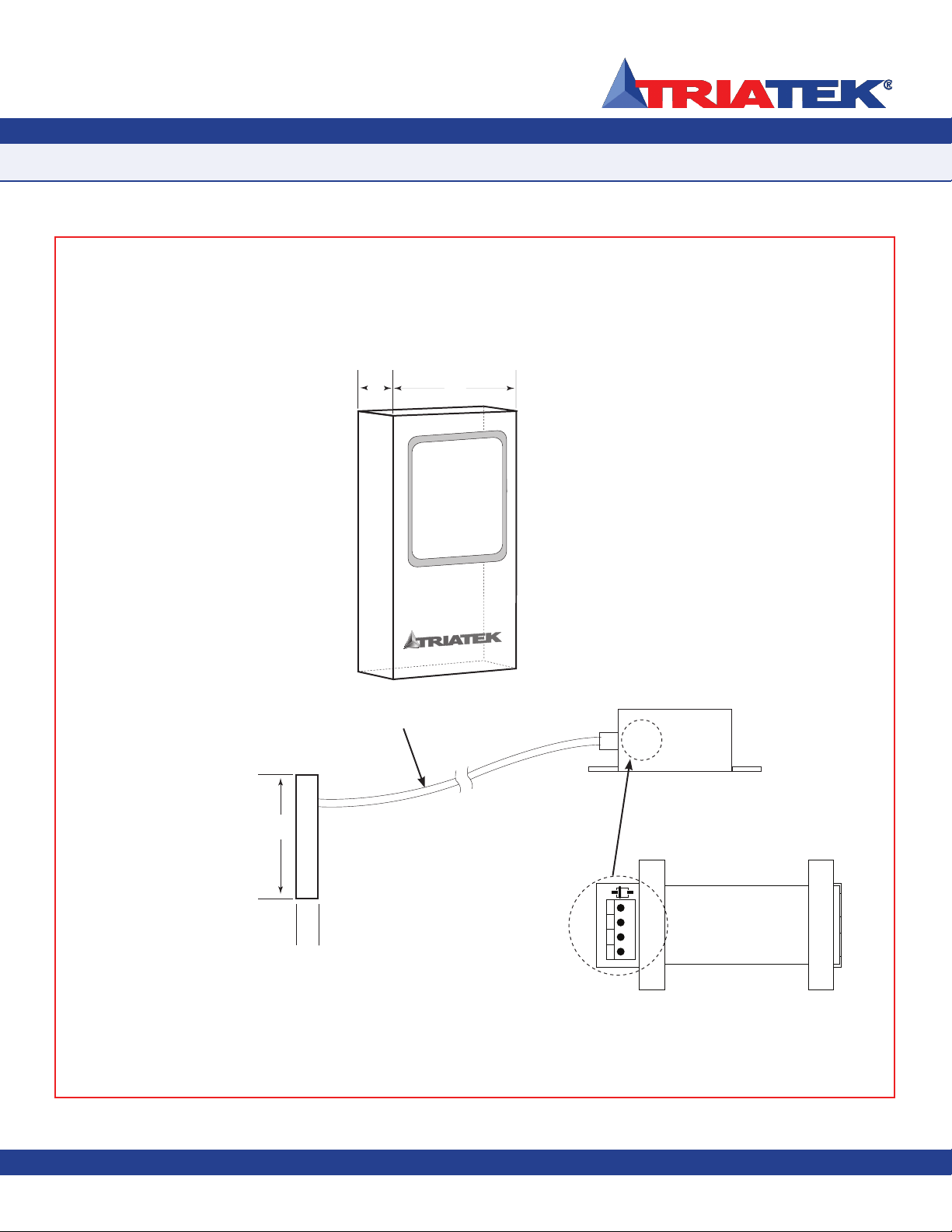

To preserve the accuracy of the calibration, the remote sensor

module MUST be installed no more than 10 feet from the

FMS-1650L controller module using the supplied interface cable.

Failure to do so could result in inaccurate differential pressure

readings.

The display module may be located up to 4000 feet from the

FMS-1650L controller module.

Distance not to exceed

4000 feet

Distance not

to exceed

10 feet

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

FMS-1650L

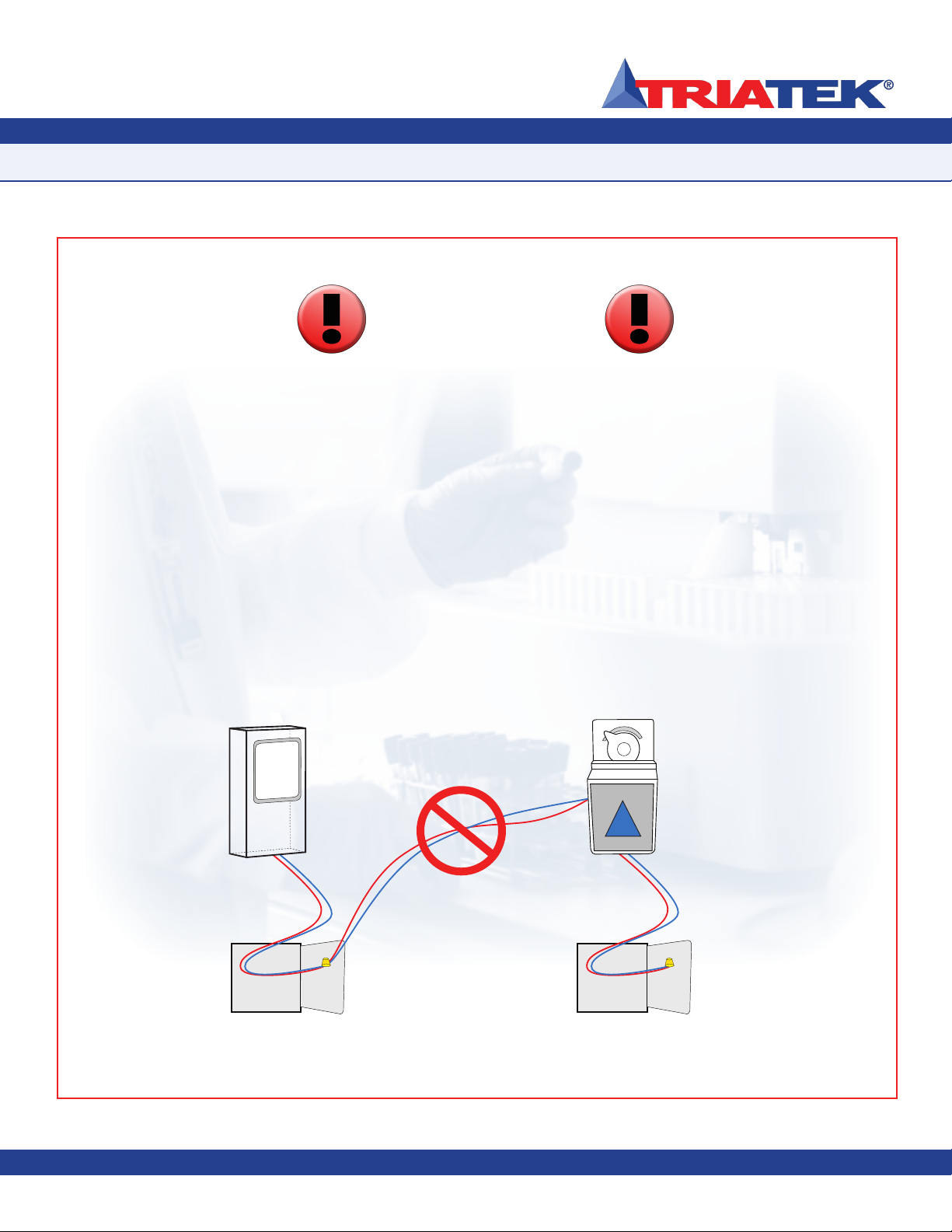

CAUTION

FAST ACTING

ELECTRONIC ACTUATOR

Controller Actuator

120/24VAC, 30Va Transformer

Supplied by Triatek

120/24VAC, 20Va Third Party

Transformer

CORRECT

Failure to follow the enclosed wiring diagrams could result in

damage to your equipment and could void your warranty. Wiring

diagrams can also be found at www.triatek.com.

Under no circumstances should a single transformer be split

between actuator and controller. Doing so will damage the

actuator, the transformer, the controller or all units. A single

120/24V 30Va transformer is required for the controller and a

separate 120/24V 20Va transformer is required for the actuator.

CORRECT

TRIATEK reserves the right to change product specifications without notice.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

FMS-1650L

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice. Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

GENERAL

Specifications

…………………………………………………………………………………………………………………………… 1 - 2

Part Number Guide ………………………………………………………………………………………………………………………… 2

Overview …………………………………………………………………………………………………………………………………… 3

MOUNTING/WIRING

FMS Case Dimensions …………………………………………………………………………………………………………………… 4

FMS Display Mounting Hole Pattern ……………………………………………………………………………………………………… 5

Controller Mounting Hole Pattern ………………………………………………………………………………………………………… 6

Remote Sensor Option ………………………………………………………………………………………………………………… 7 - 9

Remote Sensor Connector Strip ………………………………………………………………………………………………………… 10

Function Descripations …………………………………………………………………………………………………………………… 11

Analog Output to Modulated Air Controller …………………………………………………………………………………………… 12

Analog Input to Remote Pressure Sensor - 0 - 10V …………………………………………………………………………………… 13

Analog Input to Remote Pressure Sensor - 4-20mA Out …………………………………………………………………………… 14

Analog Input to 2 Remote Pressure Sensors - 0 - 10V Out ………………………………………………………………………… 15

Analog Input to 2 Remote Pressure Sensors - 4-20mA Out ………………………………………………………………………… 16

Adding Input to Temperature Sensor …………………………………………………………………………………………………… 17

Digital Input to Door Switch ……………………………………………………………………………………………………………… 18

Digital Input to Flow Switch ……………………………………………………………………………………………………………… 19

Digital Input to Occupancy Sensor ……………………………………………………………………………………………………… 20

Relay Output to Alarm …………………………………………………………………………………………………………………… 21

Relay Output to Warning ………………………………………………………………………………………………………………… 22

Relay Output 1 …………………………………………………………………………………………………………………………… 23

Relay Output 2 …………………………………………………………………………………………………………………………… 24

Power ……………………………………………………………………………………………………………………………………… 25

Isolated Power Supply …………………………………………………………………………………………………………………… 26

COMMUNICATIONS

Wiring ……………………………………………………………………………………………………………………………………… 27

General Wiring …………………………………………………………………………………………………………………………… 28

FMS-1650L PROGRAMMING

Basic Programming

………………………………………………………………………………………………………………… 30 - 33

Main Display Screen ……………………………………………………………………………………………………………………… 33

Main Display Screen …………………………………………………………………………………………………… 30 - 31

Configuring Isolation Room Controller ……………………………………………………………………………………… 31

Set Target Setpoints ………………………………………………………………………………………………………… 31

Setting Up the Analog Output ………………………………………………………………………………………… 31 - 32

Setting the Isolation Mode …………………………………………………………………………………………………… 32

Changing Display Settings ……………………………………………………………………………………………… 32 - 33

Built-In Diagnostics …………………………………………………………………………………………………………… 33

INSTALLATION MANUAL

Table of Contents

TRIATEK reserves the right to change product specifications without notice. TRIATEK reserves the right to change product specifications without notice.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

FMS-1650L

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

INSTALLATION MANUAL

Table of Contents

MODULE SETTINGS

Configuring Display Module Settings …………………………………………………………………………………………… 34 - 35

CLEANING THE DISPLAY

Cleaning the FMS-1650L ……………………………………………………………………………………………………………… 36

TRIATEK reserves the right to change product specifications without notice.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 1 -

FMS-1650L

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice. Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Electrical

4 Analog Inputs …………………………………………………………………………………………………………………4-20mAdc, 0-5Vdc or 0-10Vdc

4 Analog Outputs ………………………………………………………………………………………………………………………… 0-5Vdc or 0-10Vdc

4 Digital Inputs ………………………………………………………………………………………………0-5Vdc or 0-24Vdc, Active-High or Active-Low

4 Relay Outputs ………………………………………………………………………………………………………………………………………1A@24Vdc

Input Impedance ……………………………………………………………………………………………………………………………………… 10k - 0 Ω

Output Impedance ……………………………………………………………………………………………………………………………………… Ω 0 -10k

Power Supply …………………… Class 2, 24Vac ±10%, 30VA universal 120/240 to 24 Vac, 60/50 Hz, step-down isolation transformer provided

Communications

LonWorks® FTT-10A peer-to-peer network ………………………………………………………………………Two-Wire Twisted Pair, FTT-10A signaling

Recommended Cable Type ………………………………………………………………………………………………………………………………………

• Level IV, 22AWG Unshielded Plenum UL Type CMP (Windy City 105540; Connet Air W22IP-2001; Metro Wire MWC-1000)

• Level IV, 22AWG Shielded Plenum UL Type CMP (Windy City 106500; Connet Air W22IP-2002; Metro Wire MWC-1002)

Touch Screen User Interface

LCD Size ……………………………………………………………………………………………………………………………………………3.2” diagonal

LCD Type ……………………………………………………………………………………………………………………………………………Transmissive

Resolution ………………………………………………………………………………………………………………………………………240 x 320 portrait

Viewing Area ……………………………………………………………………………………………………………………………50.60 mm x 66.80 mm

Color Depth …………………………………………………………………………………………………………………………………18-bit or 262K colors

Backlight Color ………………………………………………………………………………………………………………………………………………White

Luminous Intensity ………………………………………………………………………………………………………………………………min 2500 cd/m2

GENERAL

Specications

TRIATEK reserves the right to change product specifications without notice.

FMS-1650L -1-0-1

Case Style # of Remote Sensors

T = thin (flush) 1 = single sensor

S = surface 2 = dual sensor

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 2-

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

FMS-1650L

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

SUBHEAD

Specications

Mechanical

FMS-1650L Display Module Housing (Surface Mount) ……………………………………………………………………………………3”W x 5”H x 0.75”D

FMS-1650L Display Module Housing (Flush Mount) …………………………………………………………………………………5.6”W x 8.5”H x 0.75”D

FMS-1650L Controller Housing ………………………………………………………………………………………………………… 4.1”W x 6”H x 1.85”D

Environmental

Operating Temperature ……………………………………………………………………………………………………………… 32° to 125° F Operating

Operating Humidity ………………………………………………………………………………………………………… 10% - 95% RH, Non-condensing

Venturi Valve (Order Separately)

Diameter …………………………………………………………………………………………………………………………… 6”, 8”, 10”, 12”, 14” & 16”O.D.

CFM Range ……………………………………………………………………………………………………………………………………………… 30-2400

Materials ………………………………………………………………………………………………………… Aluminum, Stainless Steel, Heresite Coating

Sound Insulation ………………………………………………………………………………………………………………………………………… Optional

Actuation ………………………………………………………………………………………………………………………………… Electronic or Pneumatic

Part Number Guide

GENERAL

TRIATEK reserves the right to change product specifications without notice. TRIATEK reserves the right to change product specifications without notice.

FMS-1650L -1-0-1

Case Style # of Remote Sensors

T = thin (flush) 1 = single sensor

S = surface 2 = dual sensor

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 3-

FMS-1650L

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

The TRIATEK FMS-1650L Isolation Monitor

is an ultra-sensitive instrument used to control

and/or monitor air pressure in hospital rooms,

labs, and clean rooms. This unit is a precision

measuring system capable of measuring and

displaying air pressures down to 0.0001” WC.

It can be used to control pressures down to

0.001” WC. Features of the unit include:

• Digital display of pressure with a

programmable descriptor

• Full color touch screen

• audible and visual alarm annunciation

• Four relay outputs for transmitting alarm

conditions to a remote location such as a

central monitoring station

• Auxiliary analog inputs for use with

optional sensors

• Analog outputs used in control

applications

• Password protection of programmed

setup

• Optional keylock switch for isolation

select protection

• Optional LON communications.

The FMS-1650L is equipped with a full color

touch screen display and can be wiped clean

using a soft cloth without the use of harsh

chemicals. No decontamination requirements

are required for the proper operation of this

product.

There are three background screen colors

to indicate “Normal” when pressure is within

defined limits, “Caution” when pressure

is nearing an out-of-limits condition, and

“Alarm” when pressure is outside defined

acceptable limits. The pressure ranges for

these conditions are easily set by the user for

the specific installation when necessary. The

background screen colors provide overview of

room pressure conditions at a glance.

Alarm Conditions can be defined by the

user, in terms of desired pressure settings for

the room being monitored. When an alarm

condition occurs, it can be annunciated in

three user-definable ways: 1) on the display,

2) with an audible alarm, and 3) transmitted

via contacts to a remote monitoring station

and over network. The alarm can be set to

automatically reset when the unit has sensed

that the room pressure has returned to proper

limits, or it may be set to remain on until

manually reset. In either case, the attendant

can mute the audible alarm by touching the

OK button on the alarm popup.

The FMS-1650L provides four Relay

outputs that can be used for remote alarm

annunciation or pilot control functions. The

operation of each output can be configured by

the user to define the exact room air pressure

values above and below which the output will

operate. Delay times before activation can be

specified to minimize nuisance activation.

In many installations, it is important to have

other room variables such as temperature or

relative humidity to be displayed along with

room pressure.

The FMS-1650L provides for this by means

of Additional Analog Inputs which can be

configured for 4-20 ma current or for voltage

input signals. The input can be scaled as

needed to display correct values, and a

suitable descriptor can be applied.

The FMS-1650L provides Analog Outputs

which can be set up for voltage. It can be

programmed to be proportional output (AO-2,

AO-3 or AO-4) for providing a linear signal

to an automation system, or programmed

for PID floating point output (AO-1) for direct

control of damper actuators, speed drives,

etc.

The user can set up multiple access level

passwords to protect against unauthorized or

casual access to the FMS-1650L programmed

variables.

Room pressure selection of Positive,

Negative, or No Isolation is set using the

user menu or an optional Keylock Switch.

A LON Communications Interface enables

the unit to communicate room status

information to the building automation system.

GENERAL

Overview

TRIATEK reserves the right to change product specifications without notice.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

SUBHEAD

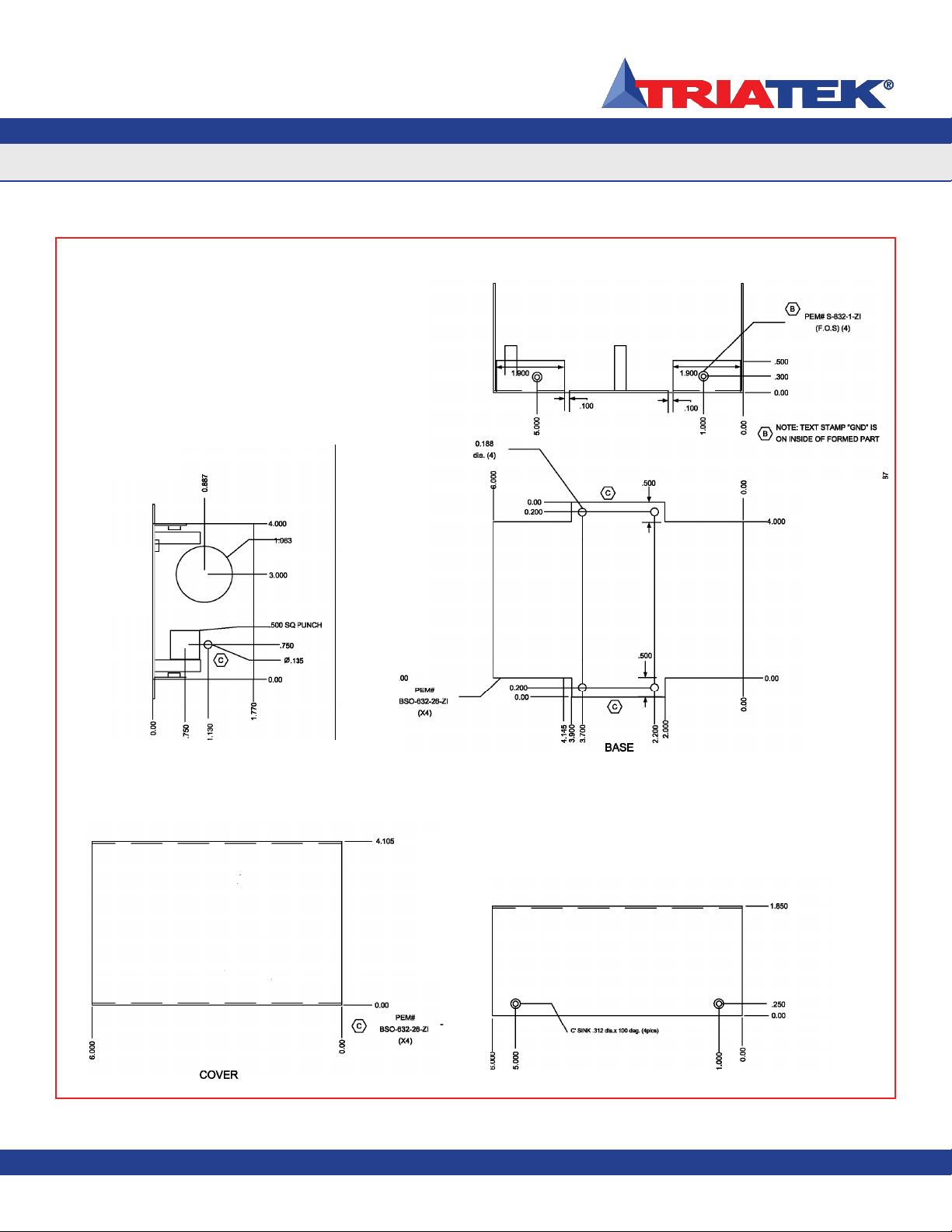

FMS Case Dimensions

FMS-1650L

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 4 -

3"

5"

3/4

"

3/4

"

®

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.TRIATEK reserves the right to change product specifications without notice.

PWR LED

— + GND +V

MOUNTING/WIRING

TRIATEK reserves the right to change product specifications without notice.

Right Side

View

Left Angle

Side View

Control Unit

Adapter

(Inside Control Unit)

Recommended Cable Type:

Belden 1325A

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

SUBHEAD

FMS-1650L

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 5 -

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.TRIATEK reserves the right to change product specifications without notice.

MOUNTING/WIRING

TRIATEK reserves the right to change product specifications without notice.

FMS Display Mounting Hole Pattern

The FMS-1650L display backplate may be mounted directly to a standard single-gang wall

box using the two slots along the centerline. Use the backplate as a template to mark the

mounting holes and the cable access hole at the center of the backplate.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

SUBHEAD

Controller Mounting Hole Pattern

FMS-1650L

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

- 6-

MOUNTING/WIRING

TRIATEK reserves the right to change product specifications without notice.TRIATEK reserves the right to change product specifications without notice. TRIATEK reserves the right to change product specifications without notice.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

FMS-1650L’s ordered with a remote sensor

must be installed in the wall between the isola-

tion room and the adjoining corridor. Port P1

must be oriented towards the isolation room

and Port P2 toward the corridor. Please see

illustration on page 13. With this sensor orien-

tation a positive pressure value indicates that

the isolation room is positive with respect to

the corridor. A three conductor cable must

be connected between the remote sensor

and the display processor unit. Maximum

length of this cable is 4000 feet. The display

unit can be installed outside the room, at the

nurses station, in the engineering office, or at

any other location as needed.

Mounting Steps:

1. Cut opening in the wall of the isolation

room to receive the mounting enclosure

for the remote sensor electronics.

Nominal hole dimensions are 3 1

/8” h x

2”w.

2. Drill a 7/16” hole through the opposite wall

for the flow tube as shown.

3. Bring the 2-conductor signal wire through

the cut-out.

4. Knock out the back and one bottom

knock-out, then with the signal wire pulled

through the bottom hole into the box.

Mount the enclosure box in the opening

provided and secure with screw and

anchors. Seal around the edges of the

box with UL Classified Fire Sealant.

5. Push a length of flow tube through the

back hole on through the 7/16” hole in the

opposite wall.

6. Attach the flow tube to the sensor port,

then push the tube and sensor module

into place and secure to the mounting

enclosure with two 6-32 x 3/4 screws

supplied.

7. Install the louvered cover plate.

8. On the opposite side (corridor) attach the

flow tube to the barbed fitting of the flow

tube mounting plate.

9. Press the mounting plate into place,

allowing the excess tube length to go into

the wall space. Secure with the screws

and anchors.

10. Install the louvered cover plate.

11. For 4-20mA operation - At the FMS-

1650L connect the three leads from the

remote sensor to the terminals marked

+V “, “AI-1” and “GND”. Remote Sensor

“Vin” goes to terminal “+V”; “GND”

connects to “GND” and “Io” connects with

terminal “AI-1”.

Install jumper on pin 1 JP6 and JP3 see

diagram on page 14. (If not installed at

the factory.)

Mounting/Wiring

Remote Sensor Option

FMS-1650L

- 7-

TRIATEK reserves the right to change product specifications without notice.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Mounting/Wiring

Remote Sensor Option

FMS-1650L

- 8 -

TRIATEK reserves the right to change product specifications without notice. TRIATEK reserves the right to change product specifications without notice.

NC

NC

GND

NC

NC

Io

NC

GND

+Vin

NC

NC

GND

NC

NC

Io

NC

GND

+Vin

~

~

~

~

Remote Sensor Installation Detail

(Side View)

ISOLATION

ROOM

CORRIDOR

Stainless Steel

Mounting Plate

Gasket

Louvered Cover

Plate

Stainless Steel

Flow Tube

Mounting Plate Gasket

Thin Silicone Caulking

(apply around tube and between

stainless steel plate and wall to seal

unit penetration)

Terminal

For connection of transmitter to

FMS-1650L

Flow Tube

When Flow Tube mounting plate

is located directly opposite the

sensor, flow tubing must be cut as

short as possible to prevent kinks.

To FMS-1650L Controller

Wall Section

(cutaway view)

Orange wall bracket

to be installed first

by using the rotating

clamps for secure

wall attachment.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Mounting/Wiring

Remote Sensor Option

FMS-1650L

- 9 -

TRIATEK reserves the right to change product specifications without notice.

NC

NC

GND

NC

NC

Io

NC

GND

+Vin

NC

NC

GND

NC

NC

Io

NC

GND

+Vin

~

~

~

~

Remote Sensor Installation Detail

(Bottom View)

ISOLATION

ROOM

CORRIDOR Stainless Steel

Mounting Plate

Gasket Louvered Cover

Plate

Stainless Steel

Flow Tube

Mounting Plate

Gasket

Thin Silicone Caulking

(apply around tube and

between stainless steel

plate and wall to seal unit

penetration)

Terminal

For connection of

transmitter to

FMS-1650L

Flow Tube

When Flow Tube mounting plate

is located directly opposite the

sensor, flow tubing must be cut as

short as possible to prevent kinks.

To FMS-1650L

Controller

Wall Section

(cutaway view)

Rotating clamps secure

assembly to wall board

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

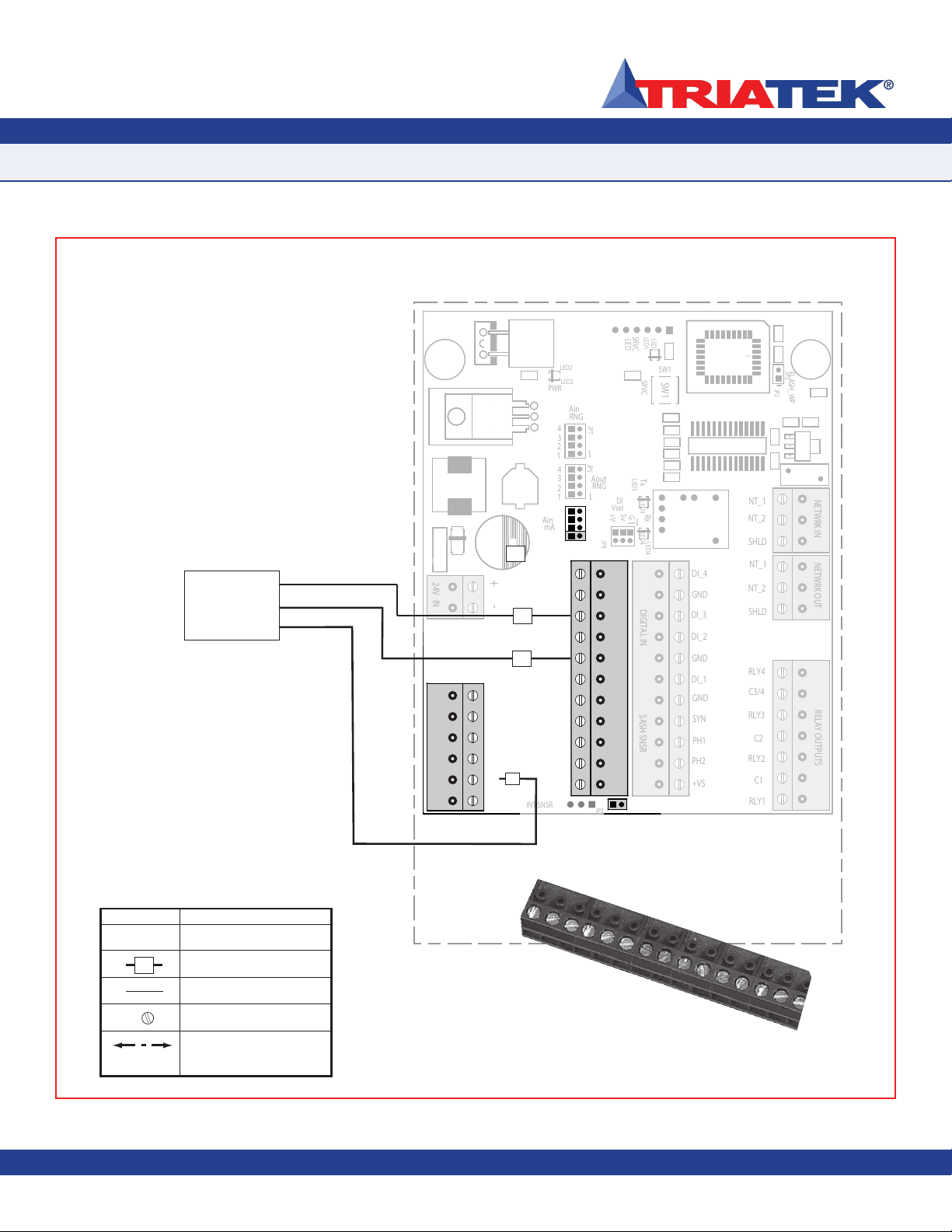

Mounting / Wiring

Remote Sensor Connector Strip

FMS-1650L

- 10 -

TRIATEK reserves the right to change product specifications without notice. TRIATEK reserves the right to change product specifications without notice.

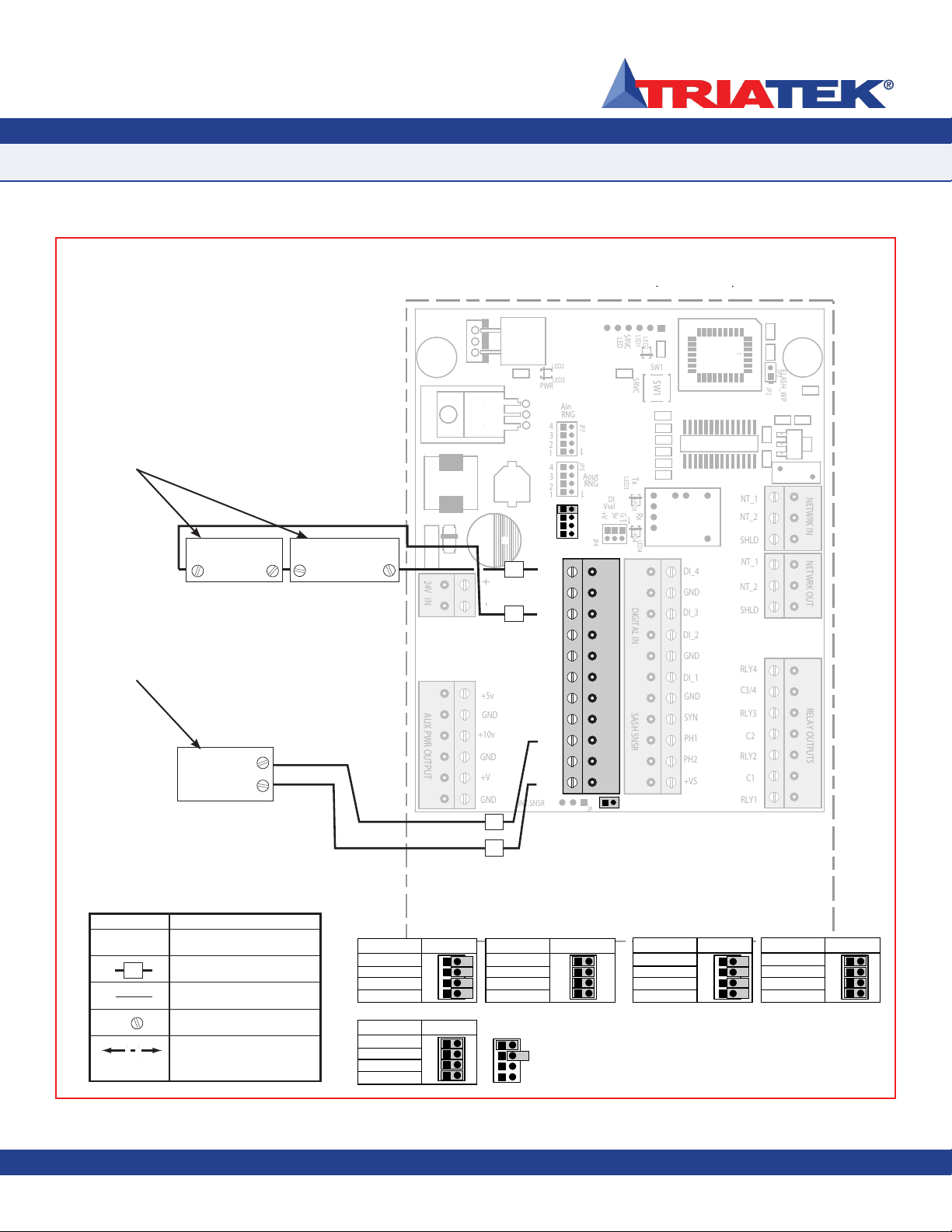

AO_1

AO_2

AO_3

AO_4

AI_1

AI_2

AI_3

AI_4

GND

GND

+10v

+V

ANALOG IN

NT_1

NT_2

NETWRK OUT

DI_1

DI_2

DI_4

GND

GND

GND

PH1

PH2

+VS

SYN

+

-

24V IN

SASH SNSR

DIGITAL IN

RLY1

RLY2

RLY3

RLY4

C3/4

C2

C1

RELAY OUTPUTS

SHLD

DI_3

1

2

3

EXT.SNSR

SELECT

INT.SNSR

G

5v

+V

DI

SRVC

EXT.

SRVC

SNSR

FLASH_WP

+5v

GND

GND

GND

GND

1

SHLD

NETWRK IN

NT_2

NT_1

AUX PWR OUTPUT

PWR

ANALOG OUT

Vsel

1

SW1

RNG

4

1

2

3

1

LED1

1

JP2

LED

Ain

4

Aout

LED2

1

JP4

1

2

JP5

1

4

RNG

1

Tx

mA 3

LED3

LED4

JP7

Ain

1

1

JP6

Rx

* * ** * *

SW1

LED1

1

JP3

11

JP2

LED2

1

1

1

1

1

LED3 LED4

1

1

NC

No Connection to Field Wiring

Field Wiring w/space for Number

Internal Wiring

Screw Terminal

Wiring Guide Legend

Symbol Description

Air Flow To and From Unit

Between Room and Corridor

Remote

Sensor/

Transmitter

GND

Io

+Vin

The electrical connections to the FMS-1650L are made

via a convenient removable terminal block as shown

below. All wiring should conform to the Local Regulations

and National Electrical Code. Take care not to run

Sensor wiring in the same conduit as linevoltage or other

conductors that supply highly inductive loads such as

generators, motors, solenoids, contactors, etc. Use 22

AWG or larger.

Removable

Connector

for easy installation

of field wiring. Note:

The FMS remote sensor is an option

which must be specified at time of

purchase from factory.

Remote Sensor

Connector

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Mounting / Wiring

Function Descriptions

FMS-1650L

- 11 -

TRIATEK reserves the right to change product specifications without notice.

Function Description

AUX Power Output Power supply outputs used for power auxiliary devices. Each is supply limited to 100

ma.

LON Communications LON FTT-10A Free Topology Network building automation system can access the sta-

tus and the configuration of the unit. Also used by configuration software to configure

unit.

Analog Output Unit has 4 Analog Outputs which can be configured for 0-5 VDC or 0-10VDC.

Analog Input Unit has 4 Analog Inputs which can be configured for 4-20 mA, 0-5VDC, or 0-10VDC.

Power The FMS-1650L Series can be powered by either 24 VAC or 24 VDC. A 120 VAC to

24 VAC Step Down Isolation Transformer is provided and recommended. This power

must be from a Class 2 supply only.

Digital Input The unit has 4 Digital Inputs with selectable pull-up voltages of 0V, +5V and +18V.

Relay Output The unit has 4 SPDT Relay outputs with normally open contacts.

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Mounting / Wiring Remote Sensor

Analog Output to Modulated Air Controller

FMS-1650L

- 12 -

TRIATEK reserves the right to change product specifications without notice. TRIATEK reserves the right to change product specifications without notice.

AO_1

AO_2

AO_3

AO_4

AI_1

AI_2

AI_3

AI_4

GND

GND

+10v

+V

ANALOG IN

NT_1

NT_2

NETWRK OUT

DI_1

DI_2

DI_4

GND

GND

GND

PH1

PH2

+VS

SYN

+

-

24V IN

SASH SNSR

DIGITAL IN

RLY1

RLY2

RLY3

RLY4

C3/4

C2

C1

RELAY OUTPUTS

SHLD

DI_3

1

2

3

EXT.SNSR

SELECT

INT.SNSR

G

5v

+V

DI

SRVC

EXT.

SRVC

SNSR

FLASH_WP

+5v

GND

GND

GND

GND

1

SHLD

NETWRK IN

NT_2

NT_1

AUX PWR OUTPUT

PWR

ANALOG OUT

Vsel

1

SW1

RNG

4

1

2

3

1

LED1

1

JP2

LED

Ain

4

Aout

LED2

1

JP4

1

2

JP5

1

4

RNG

1

Tx

mA 3

LED3

LED4

JP7

Ain

1

1

JP6

Rx

* * ** * *

SW1

LED1

1

JP3

11

JP2

LED2

1

1

1

1

1

LED3 LED4

1

1

NC

No Connection to Field Wiring

Field Wiring w/space for Number

Internal Wiring

Screw Terminal

Wiring Guide Legend

Symbol Description

Air Flow To and From Unit

Between Room and Corridor

CONNECTIONS FOR POWERED OUTPUT

~

~

-

+

Air

Control

Modulator

+

-

+

-

Optional External

Transmitter

Power Supply

0-5v (JP7)

Jumper Setting

AI 1

AI 2

AI 3

AI 4

1

2

3

4

= JUMPER ON

Analog Input

0-10v (JP7)

AI 1

AI 2

AI 3

AI 4

JP7

1

2

3

4

Analog Input

4-20mA (JP6)

AI 1

AI 2

AI 3

AI 4

Analog Input

JP6

0-5v (JP5)

AO 1

AO 2

AO 3

AO 4

Analog Output

0-10v (JP5)

AO 1

AO 2

AO 3

AO 4

JP5

Analog Output

Note: 4-20mA can only be used if the

corresponding JP7 Analog Input Jumper

is set to OFF.

Note: Each Analog Input or Output value can be set independent of one another.

Example:

AI 1 can be set to 0-5v jumper OFF (JP7 PIN 1)

AI 2 can be set to 0-10v jumper ON (JP7 PIN 2)

AI 3 can be set to 4-20mA jumper ON (JP6 PIN 3) and jumper OFF (JP7 PIN 3)

AO 1 can be set to 0-10v jumper ON (JP5 PIN 1)

AO 2 0-5v can be set to 0-5v jumper OFF (JP5 PIN 2)

= JUMPER OFF

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Purchased Separately

Purchased Separately

4-20mA Loop

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Mounting / Wiring

Analog Input to Remote Pressure Sensor - 0-10V Out

FMS-1650L

- 13 -

TRIATEK reserves the right to change product specifications without notice.

0-10V OUT

A

O

1

A

O

2

A

O

3

A

O4

A

I

A

I

A

I

A

I

G

ND

G

ND

+1

0v

+

V

A

NAL

OG

I

1

2

3

E

XT

S

N

SR

+

5v

G

ND

G

ND

G

ND

G

ND

AU

X PWR

OU

TP

U

A

NAL

OG

OUT

R

N

G

4

1

2

3

Ain

4

Aout

J

P

4

2

J

P

5

4

R

N

G

1

m

A

3

J

P

7

Ain

J

P

6

1

1

1

NC

No Connection to Field Wiring

Field Wiring w/space for Number

Internal Wiring

Screw Terminal

Wiring Guide Legend

Symbol Description

Air Flow To and From Unit

Between Room and Corridor

N

T

1

N

T

2

N

ETWRK

OUT

DI

DI

DI

G

ND

G

ND

G

ND

PH

1

PH2

+V

S

S

Y

N

+

-

24

V

I

N

S

A

S

H

S

N

S

DI

G

ITAL

R

LY

R

LY

2

R

LY

3

R

LY

4

C3

/4

C2

C1

R

ELAY

OU

TP

UT

S

HL

D

DI

E

XT

.S

N

S

S

ELE

C

INT

.S

N

S

G

5v

+

V

D

I

S

RV

C

S

RV

C

FLASH WP

1

S

HL

D

N

ETWRK

I

N

T

2

N

T

1

PWR

V

se

1

S

W

1

L

ED

1

J

P

2

L

E

D

L

ED

2

1

4

Tx

L

ED

3

L

ED

4

Rx

*

*

*

*

*

*

S

W

1

LED1

D

D

D

JP3

1

111111111111111111111111111

JP2

FL

FL

L

ED

2

1

LED3

E

E

E

LED4

E

E

E

1

111111111111111111111111111

-

IN

+

Pressure

Sensor

0-5v (JP7)

Jumper Setting

AI 1

AI 2

AI 3

AI 4

1

2

3

4

= JUMPER ON

Analog Input

0-10v (JP7)

AI 1

AI 2

AI 3

AI 4

JP7

1

2

3

4

Analog Input

4-20mA (JP6)

AI 1

AI 2

AI 3

AI 4

Analog Input

JP6

0-5v (JP5)

AO 1

AO 2

AO 3

AO 4

Analog Output

0-10v (JP5)

AO 1

AO 2

AO 3

AO 4

JP5

Analog Output

Note: 4-20mA can only be used if the

corresponding JP7 Analog Input Jumper

is set to OFF.

Note: Each Analog Input or Output value can be set independent of one another.

Example:

AI 1 can be set to 0-5v jumper OFF (JP7 PIN 1)

AI 2 can be set to 0-10v jumper ON (JP7 PIN 2)

AI 3 can be set to 4-20mA jumper ON (JP6 PIN 3) and jumper OFF (JP7 PIN 3)

AO 1 can be set to 0-10v jumper ON (JP5 PIN 1)

AO 2 0-5v can be set to 0-5v jumper OFF (JP5 PIN 2)

= JUMPER OFF

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Mounting / Wiring

Analog Input to Remote Pressure Sensor - 4-20mA Out

FMS-1650L

- 14 -

TRIATEK reserves the right to change product specifications without notice. TRIATEK reserves the right to change product specifications without notice.

AO_1

AO_2

AO_3

AO_4

AI_1

AI_2

AI_3

AI_4

GND

GND

+10v

+V

ANALOG IN

NT_1

NT_2

NETWRK OUT

DI_1

DI_2

DI_4

GND

GND

GND

PH1

PH2

+VS

SYN

+

-

24V IN

SASH SNSR

DIGITAL IN

RLY1

RLY2

RLY3

RLY4

C3/4

C2

C1

RELAY OUTPUTS

SHLD

DI_3

1

2

3

EXT.SNSR

SELECT

INT.SNSR

G

5v

+V

DI

SRVC

EXT.

SRVC

SNSR

FLASH_WP

+5v

GND

GND

GND

GND

1

SHLD

NETWRK IN

NT_2

NT_1

AUX PWR OUTPUT

PWR

ANALOG OUT

Vsel

1

SW1

RNG

4

1

2

3

1

LED1

1

JP2

LED

Ain

4

Aout

LED2

1

JP4

1

2

JP5

1

4

RNG

1

Tx

mA 3

LED3

LED4

JP7

Ain

1

1

JP6

Rx

* * ** * *

SW1

LED1

1

JP3

11

JP2

LED2

1

1

1

1

1

LED3 LED4

1

1

4-20mA OUT

NC

No Connection to Field Wiring

Field Wiring w/space for Number

Internal Wiring

Screw Terminal

Wiring Guide Legend

Symbol Description

Air Flow To and From Unit

Between Room and Corridor

Remote

Pressure

Sensor

Io

+Vin

GND

0-5v (JP7)

Jumper Setting

AI 1

AI 2

AI 3

AI 4

1

2

3

4

= JUMPER ON

Analog Input

0-10v (JP7)

AI 1

AI 2

AI 3

AI 4

JP7

1

2

3

4

Analog Input

4-20mA (JP6)

AI 1

AI 2

AI 3

AI 4

Analog Input

JP6

0-5v (JP5)

AO 1

AO 2

AO 3

AO 4

Analog Output

0-10v (JP5)

AO 1

AO 2

AO 3

AO 4

JP5

Analog Output

Note: 4-20mA can only be used if the

corresponding JP7 Analog Input Jumper

is set to OFF.

Note: Each Analog Input or Output value can be set independent of one another.

Example:

AI 1 can be set to 0-5v jumper OFF (JP7 PIN 1)

AI 2 can be set to 0-10v jumper ON (JP7 PIN 2)

AI 3 can be set to 4-20mA jumper ON (JP6 PIN 3) and jumper OFF (JP7 PIN 3)

AO 1 can be set to 0-10v jumper ON (JP5 PIN 1)

AO 2 0-5v can be set to 0-5v jumper OFF (JP5 PIN 2)

= JUMPER OFF

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Due to continuous improvement, TRIATEK reserves the right to change product specifications without notice.

Mounting / Wiring

Analog Input to 2 Remote Pressure Sensors - 0-10V Out

FMS-1650L

- 15 -

TRIATEK reserves the right to change product specifications without notice.

A

O

1

A

O

2

A

O

3

A

O4

A

I

A

I

A

I

A

I

G

ND

G

ND

+1

0v

+

V

A

NAL

OG

I

1

2

3

E

XT

.S

N

S

S

ELE

C

E

XT

S

N

SR

+

5v

G

ND

G

ND

G

ND

G

ND

AU

X PWR

OU

TP

U

A

NAL

OG

OUT

R

N

G

4

1

2

3

Ain

4

Aout

J

P

4

2

J

P

5

4

R

N

G

1

m

A

3

J

P

7

Ain

J

P

6

1

1

N

T

1

N

T

2

N

ETWRK

OUT

DI

DI

DI

G

ND

G

ND

G

ND

PH

1

PH2

+V

S

S

Y

N

+

-

24

V

I

N

S

A

S

H

S

N

S

DI

G

ITAL

R

LY

R

LY

2

R

LY

3

R

LY

4

C3

/4

C2

C1

R

ELAY

OU

TP

UT

S

HL

D

DI

.SNS

G

5v

+

V

D

I

S

RV

C

S

RV

C

FLASH WP

S

HL

D

N

ETWRK

I

N

T

2

N

T

1

PWR

V

se

1

S

W

1

L

ED

1

J

P

2

L

E

D

L

ED

2

1

4

Tx

L

ED

3

L

ED

4

Rx

*

*

*

*

*

*

S

W

1

LED1

D

D

D

JP3

1

111111111111111111111111111

JP2

FL

FL

L

ED

2

1

LED3

E

E

E

LED4

E

E

E

1

111111111111111111111111111

INT

NC

No Connection to Field Wiring

Field Wiring w/space for Number

Internal Wiring

Screw Terminal

Wiring Guide Legend

Symbol Description

Air Flow To and From Unit

Between Room and Corridor

T

~

~

-

+

Pressure

Sensor 1

IN

~

~

~

~

-

IN

Pressure

Sensor 2

+

0-10V OUT

0-5v (JP7)

Jumper Setting

AI 1

AI 2

AI 3

AI 4

1

2

3

4

= JUMPER ON

Analog Input

0-10v (JP7)

AI 1

AI 2

AI 3

AI 4

JP7

1

2

3

4

Analog Input

4-20mA (JP6)

AI 1

AI 2

AI 3

AI 4

Analog Input

JP6

0-5v (JP5)

AO 1

AO 2

AO 3

AO 4

Analog Output

0-10v (JP5)

AO 1

AO 2

AO 3

AO 4

JP5

Analog Output

Note: 4-20mA can only be used if the

corresponding JP7 Analog Input Jumper

is set to OFF.

Note: Each Analog Input or Output value can be set independent of one another.

Example:

AI 1 can be set to 0-5v jumper OFF (JP7 PIN 1)

AI 2 can be set to 0-10v jumper ON (JP7 PIN 2)

AI 3 can be set to 4-20mA jumper ON (JP6 PIN 3) and jumper OFF (JP7 PIN 3)

AO 1 can be set to 0-10v jumper ON (JP5 PIN 1)

AO 2 0-5v can be set to 0-5v jumper OFF (JP5 PIN 2)

= JUMPER OFF

1

2

3

4

1

2

3

4

1

2

3

4

1

2

3

4

Purchased Separately

Table of contents

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual