Tridekon Cropsaver User manual

OWNERS MANUAL

Tridekon

RR# 2

Neepawa, MB

R0J 1H0

Ph: (204) 966-3469

1-866-292-6115

Fax: (204) 966-3335

Email: [email protected]

www.tridekon.com

Read and understand this manual prior to installation or use of Tridekon Cropsavers

Statement of Policies

Shipping Claims

It is the original buyers/dealers responsibility to check that all goods have been received as ordered

Any claims for shipping errors, damage or loss upon delivery must be reported within 15 days of the

delivery date.

Warranty Information

• To obtain warranty service you must rst contact us to determine the problem and the most appropriate

solution for you.

• This warranty applies to the physical goods, and only for physical goods, purchased from Tridekon –

labour will not be covered.

• This warranty covers any defects in material or workmanship under normal use during the warranty

period.

• During the warranty period Tridekon will replace at no charge products or parts of a product that proves

defective because of improper material or workmanship under normal use and maintenance.

• The warranty period is one year after original purchase date.

• All item(s) returned for warranty consideration, inspection, repair, etc. must be shipped prepaid.

• All returns must be accompanied by a Return Authorization Form from Tridekon.

Shipping Charges

Customers are responsible for all shipping charges on any product. Tridekon uses multiple shipping

companies to ensure the lowest cost.

Acceptance

By placing an order with Tridekon the purchaser consents to the terms and conditions contained herein

and upon Tridekon providing the products ordered, these terms and conditions shall form an essential

part of the contract between the parties.

Installation Notice

The user of Tridekon Cropsavers are installing these products to their machines at their own risk.

Tridekon will not be responsible for damages resulting from improper installation.

Cropsavers® is a registered trade mark of Tridekon Ltd. © 2012 Tridekon Ltd. All rights reserved

Safety Signs

• Keep safety signs clean and legible at all times.

• Replace safety signs that are missing or have become illegible.

• Replaced parts that displayed a safety sign should also display the current sign.

• Safety signs are available from your authorized Dealer or from Tridekon.

TABLE OF CONTENTS

How Your Cropsavers Are Shipped ................................................................................................... Page 4

Lock-up Pin Warning ..............................................................................................................................Page 5

Crop Height Adjustment ......................................................................................................................Page 5

Fine Tuning Installation.........................................................................................................................Page 5

Cropsaver Parts Assembly Drawing..................................................................................................Page 6

Cropsaver Parts List ................................................................................................................................Page 7

Mounting Your Cropsavers ..................................................................................................................Page 8 to 12

Setting And Adjusting Your Cropsavers..........................................................................................Page 13

Removing Your Cropsavers..................................................................................................................Page 14

QR Code Link To Installation Video ...................................................................................................Page 15

Frequently Asked Questions ...............................................................................................................Page 15-16

Attached: Bolt-on information and instructions

Air lift kit instructions (if equipped)

HOW YOUR CROPSAVERS ARE SHIPPED

2.

4. 5.

7.

8.

9.

1. 3.

6.

1. Your Cropsavers will arrive at your location wrapped and strapped to a shipping skid. Note the sticker

and reference numbers on the shipment.

2. The shipping label tells you the location it was shipped to and the contents of the skid. It also tells you

the dealer purchase order number and the Tridekon reference number. These are important when

dealing with either party.

3. The marked Cropsaver cone contains the owners manual and extra accessories (ie: air lift kit ttings, if

ordered)

4. At the bottom of the skid under the Cropsaver cones are the mounting arms and deector arms.

5. Bolt-on brackets can be found on the bottom of the pallet as well. (note: larger bolt-on brackets may

be packed on top of the Cropsaver cones.

6. Remove the back panels of the Cropsavers to remove inner quick attach brackets.

7. Behind the back panel of the marked cone (in picture 3) you will nd the instruction manual and air

lift ttings (if equipped).

8. Outer quick attach brackets are found at the bottom of the skid.

9. Unwrapped Cropsaver order, note location of the various parts

Page 4

WARNINGS

1. Remove lock-up pin for eld position, damage will occur if pins are placed back in bracket.

Failure to remove pins during eld operation will restrict Cropsaver lift and void warranty.

2. Check the 3/8” by 7” lock bolt on a regular basis to ensure it is still intact.

It is required to keep the Cropsaver from bouncing out of the outer quick attach bracket.

If maximum lift is exceeded it will act as a shear pin.

k

CROP HEIGHT ADJUSTMENT

Run the bottom tip of the Cropsavers one third of the way up from the height of the plant. Allow a couple

of inches for tire impression. The lowest height of crop that Cropsavers can eectively divide is 20”.

2/3

1/3

Some sets of Cropsavers will come with extra length on the mounting arms to accommodate dierent

tire and rim sizes. Some trimming of the arms may be required to get the Cropsavers in their optimal

position. Cropsavers should be no closer than 1.5”away from the front of the tire and no further that 10” away.

Bending of the deector arms may be required to avoid interference with your sprayer.

Deector arms should be no closer than 4” from the tire to avoid contact.

FINE TUNING THE INSTALLATION

Page 5

k

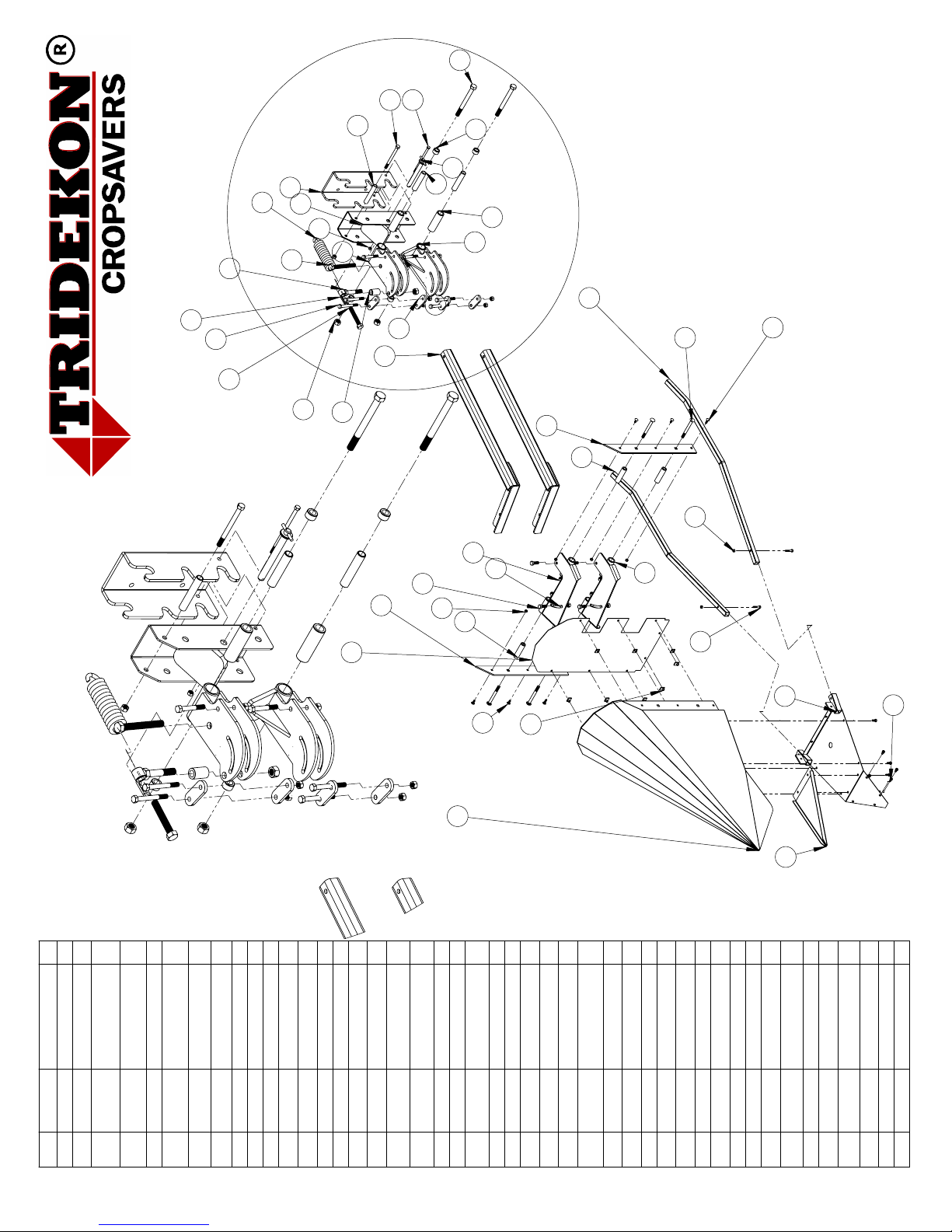

1.

2.

4

36

12

10

42

11

31

23

24

32

45

28

26

33

16

25

40

20

38

27

30

29

17

44

39

19

22

21

18

3

41

8

35

14

43

2

13

5

1

37

6

9

15

7

34

ITEM

NO.

PART

NUMBER

DESCRIPTION

QTY.

1

1-csp-07

Cropsaver Plus shell

1

2

8-csp-07

Cropsaver floor

panel

1

3

42-csp-07

reinforcement plate

2 1/2" x 22" right hand

1

4

41-csp-07

reinforcement plate

2 1/2" x 22" left hand

1

5

53-csp-07

reinforcement tip

1

6

52-csp-07

hinge plate for right

hand cropsaver

2

7

50-csp-07

1" d.o.m. .240 wall x 3

3/4" long

4

8

36-csp-07

1/2" carriage bolt x 5

1/2" long

4

9

37-csp-07

1/2" flat washer

4

10

13-csp-07

1/2" nylon locknut

15

11

43-csp-07

Right hand arm

2

12

45-csp-07

hexbolt 1/2" x 1 1/2"

long

4

13

34-csp-07

5/16" hexbolt x 3/4"

long

10

14

39-csp-07

5/16" nut

12

15

33-csp-07

Backwall Panel

1

16

25B-csp-07

Top hinged clevis

right

1

17

26A-csp-07

Lower hinged clevis

right

1

18

23-csp-07

1 1/2" nylon bushing

4 3/4" long

2

19

21-csp-07

1" d.o.m. x .120 wall x

4 7/8" long

2

20

20-csp-07

inner quick atach

1

21

24-csp-07

3/4" hexbolt 8" long

2

22

22-csp-07

1 1/4" d.o.m. bushing

x 3/4" long

4

23

10-csp-07

3/4" nylon locknut

3

24

7-csp-07

3/4" x4 1/2" long bolt

1

25

5-csp-07

coil spring hooked

3/4" nut

1

26

6-csp-07

Eyebolt 3/4" x 4" long

1

27

14-csp-07

1/2" pipe x 4 7/8"

long

1

28

9-csp-07

1 1/4" d.o.m. .240

bushing x 2" long

1

29

15-csp-07

1/2" hexbolt x 6" long

1

30

12-csp-07

1/2" bolt x 3 1/2" long

2

31

17-csp-07

1 1/2" clamp plate

4

32

16-csp-07

1/2" hexbolt x 4 1/2"

long

4

33

11-csp-07

3/4" adjustment bolt

x 6" long

1

34

40-csp-07

5/16" carriage bolt

4

35

46-csp-07

5/16" carriage bolt x

1" long

2

36

4-csp-07

5/16" nylon locknut

6

37

54-csp-07

Clip

8

38

19-csp-07

Outer quick attach

bracket

1

39

27-csp-07

3/8" hexbolt 7" long (

lock bolt )

1

40

28-csp-07

3/8" nylon locknut

1

41

2L-csp-07

Extention deflector

arm - left

1

42

2R-csp-07

Extention deflector

arm - right

1

43

3-csp-07

5/16" hexbolt x 1 1/2"

long

2

44

30-csp-07

3/4" lock pin

1

45

29-csp-07

#11 hitchpin

1

THE INFORMATION CONTAINED IN THIS DRAWING IS THE

SOLE PROPERTY OF TRIDEKON. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION

OF TRIDEKON IS PROHIBITED

Page 6

CROPSAVER PARTS LIST

Parts # # per cone

1-csp-07 1 Crop $aver Plus shell

8-csp-07 1 Crop $aver Plus floor panel

33-csp-07 1 backwall panel

53-csp-0 1 reinforcement tip (not shown on parts overview)

41-csp-07 1 reinforcement plate 2 1/2" x 22" left hand

42-csp-07 1 reinforcement plate 2 1/2" x 22" right hand

51-csp-07 2 hinge plates for left hand Crop $aver

52-csp-07 2 hinge plates for right hand Crop $aver

2L-csp-07 1 Extended deflector arms- left

2R-csp-07 1 Extended deflector arms- right

19-csp-07 1 Outer quick attach bracket

20-csp-07 1 Inner quick attach bracket

25-csp-07 1 top hinged clevis L/R

26-csp-07 1 Lower hinged clevis L/R

6-csp-07 1 eyebolt 3/4" x 4" long

5-cps-07 1 coil pull spring hooked 3/4" female thread

9-csp-07 1 3/4" ID bushing x 2"long

11-csp-07 1 Adjustment bolt 3/4"x6 with 3/4" jamnut

14-csp-07 4 1/2" ID bushing- spacer 4 7/8" length

17-csp-07 4 1 1/2" x 4" x 3/8" clamp plate

22-csp-07 4 steel 3/4" ID x 3/4" long spacers

27-csp-07 1

lockbolt 3/8" x 7" long

29-csp-07 1 # 11 hitchpin

30-csp-07 1 3/4" x 7" long lock pin

43-csp-07 2 arms for right hand Crop $aver *

44-csp-07 2 arms for left hand Crop $aver *

50-csp-07 1 1/2" ID x 4" long

21-csp-07 2 Nylon/ steel lined bushing

4-cps-07 2 5/16" nylon locknut

7-csp-07 1 3/4" x 4 1/2" long bolt

10-csp-07 3 3/4" nylon locknut

12-csp-07 2 1/2" bolt x 3 1/2" length

13-csp-07 11 1/2" nylon locknut

15-csp-07 1 1/2" hexbolt x 6" long + 1/2" nylon locknut

16-csp-07 4 1/2" hexbolt x 4 1/2" long

3-csp-07 2 5/16" x 1 1/2"

24-csp-07 2 3/4" hexbolt x 8" long

28-csp-07 1 3/8" nylon locknut

34-csp-07 8 5/16" x 3/4" hexbolt

35-csp-07 2 5/16" lock washers

36-csp-07 4 1/2" carriage bolts x 5 1/2" long

37-csp-07 2 1/2" flat washers

39-csp-07 14 5/16" nylon locknuts

40-csp-07 6 5/16" carriage bolts

45-csp-07 4 hexbolt 1/2" x 1 1/2" long

46-csp-07 1 5/16" carriage bolts X 1" long

54-csp-07 8 Back wall pins

Description

Page 7

MOUNTING YOUR CROPSAVERS

1.

Remove back panels of Cropsavers.

Parts and accessories stored in Cropsaver cone for shipping.

Remove top pivot plate to remove inner quick attach brackets.

2.

3.

Mount bolt-on kit to your sprayer. Note there will be additional mounting instructions

for each individual sprayers. Follow those instructions to mount the bolt-on kit.

Page 8

g

MOUNTING YOUR CROPSAVERS

4.

Using supplied bolts (specied in the bolt-on instruction page) bolt the outer quick attach bracket

to the bolt-on bracket. Bolt-on bolts are found in a hardware bag in cone shown in picture # 2.

5.

Place the Cropsaver cone on a 5 gallon pail and bring it close to the wheel.

6.

Lower the inner quick attach assembly into the outer quick attach. Secure in place with 3/8 lock bolt.

Page 9

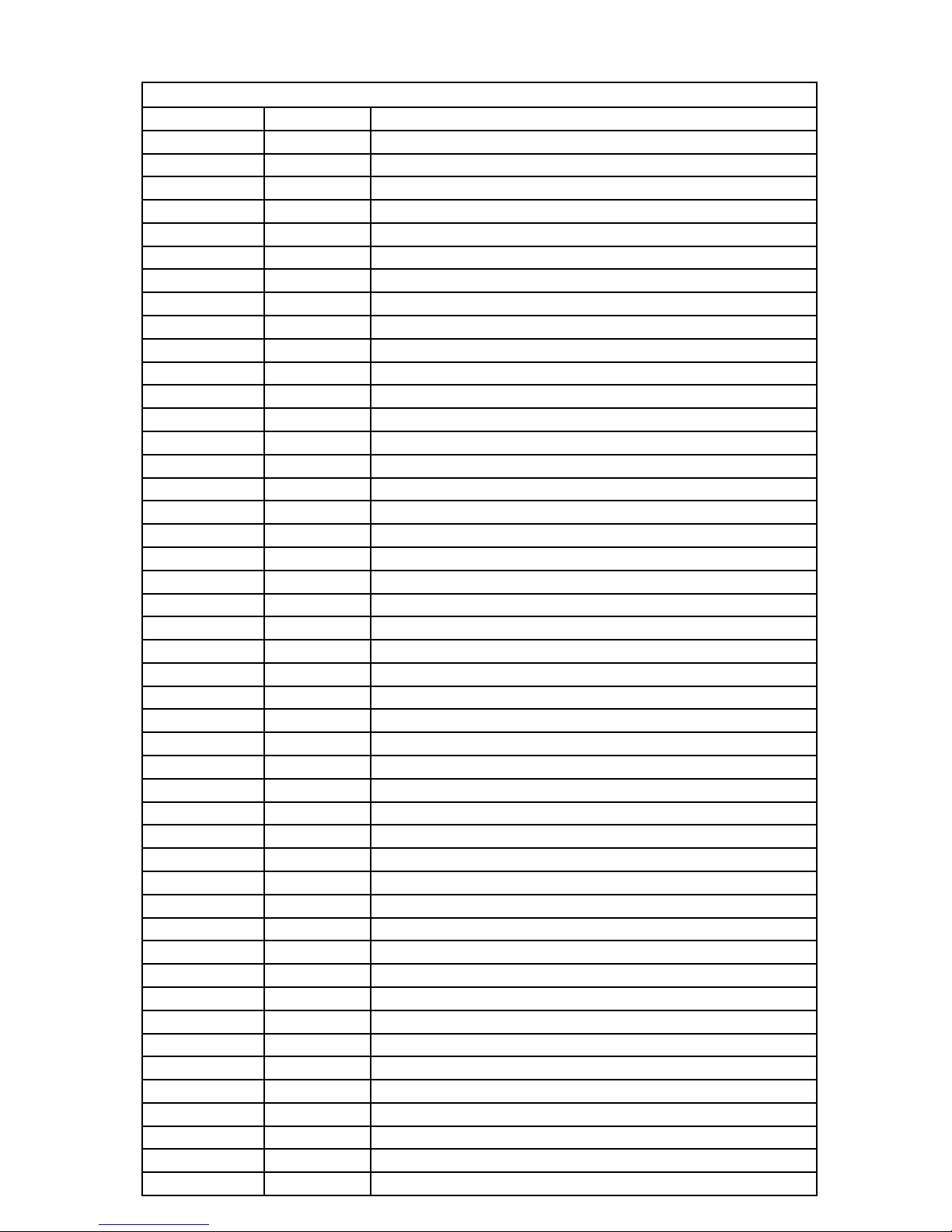

MOUNTING YOUR CROPSAVERS

7.

8.

Bolt arms into outer quick attach assembly. Arm and Deector arm bolts are found in a bag in each cone.

Leave these bolts loose temporarily until nal adjustments are complete.

Temporarily leave o clamp plates (shown above) until nal adjustments are complete.

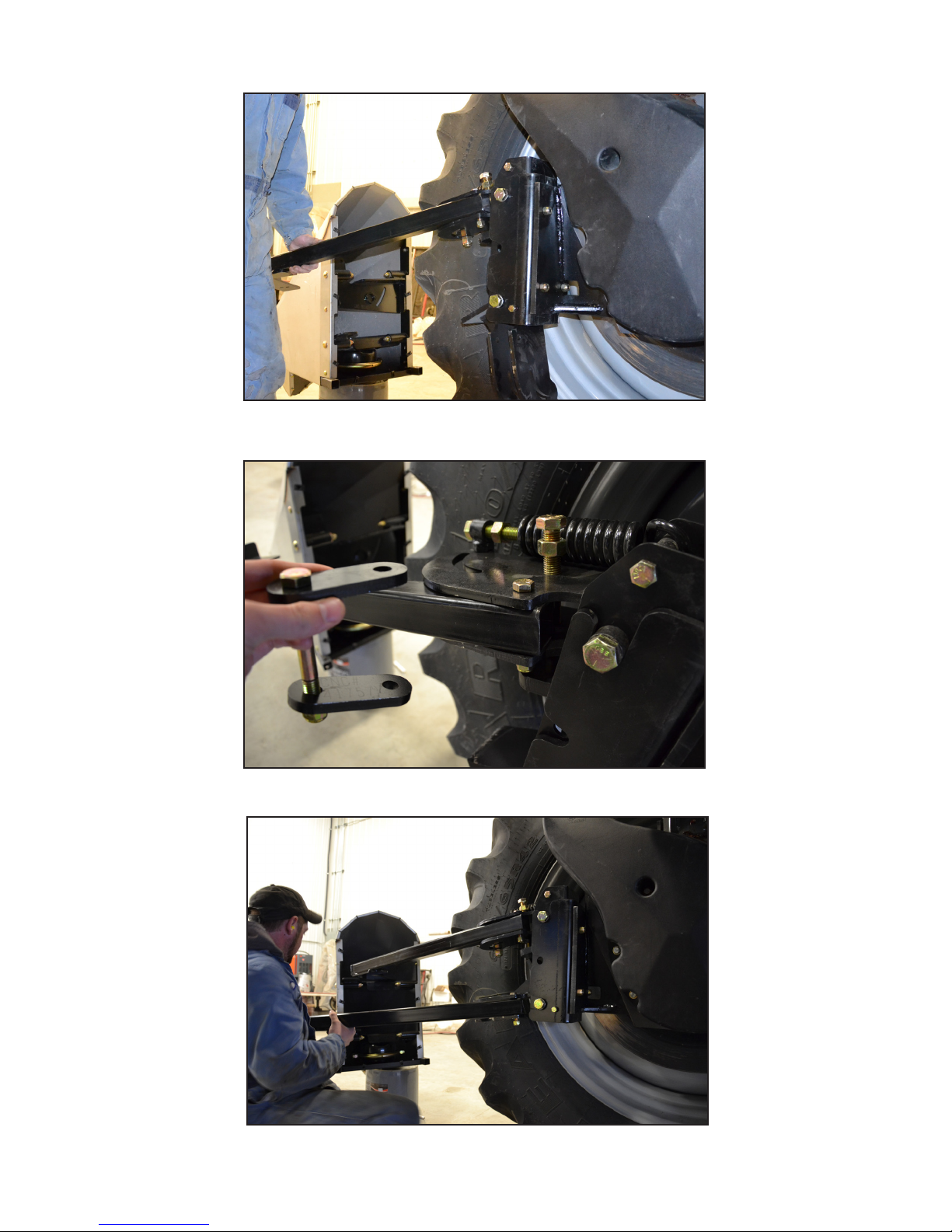

9.

Guide arms into Cropsaver cone.

Page 10

MOUNTING YOUR CROPSAVERS

10.

Bolt arms into hinge plates. Note bolts holding arms on are kept loose at this point in time to allow for alignment.

11.

12.

Adjust cone to align it to the sprayer tire – the cone end pivots where the arms

bolt to the pivot plates. Make adjustments as described in step 12 simultaneously.

Arms can be moved back and forth horizontally to align Cropsaver to wheel. Cropsaver is properly aligned when arms are

no closer that 1”away from the side of the tire, and cone is covering the entire width of the tire in the front. When Cropsaver

is in correct place use clamp plates to lock Cropsaver in required position. Tighten all bolts in picture 7 and 11 at this time.

k

k

Page 11

MOUNTING YOUR CROPSAVERS

13.

Ensure all bolts are tightened after adjustments.

Insert deector arms and bolt into place. Deector arms can be shortened or re-bent to

t individuals sprayers better. Bolts found in Arm and Deector arm bolts bag.

14.

15.

Install back panel to complete installation. If ordered with the air lift kit

option, leave back panel o until air installation is complete. Page 12

SETTING AND ADJUSTING YOUR CROPSAVERS

Adjust spring tension to set the oating weight of the Cropsaver. Tighten jam nut against

the spring as picture shows so the spring doesn’t slide and Cropsaver oats properly.

Although it depends on conditions Tridekon recommends the tension to be

set so it takes about 5lbs of lift to lift the tip of the cone.

Use this bolt to set the height of the Cropsaver. Set the height with this bolt before setting the spring tension.

See Crop Height Adjustment section (Page 5) for further instruction. Tighten jam nut once adjusted.

1.

2.

3.

Page 13

Note: Cropsaver doesn’t need to be centered in-front of the tire – as long as it covers the entire width

of the tire. The back panel of the Cropsaver should be 90° to the sidewall of the tire.

f

REMOVING CROPSAVERS USING QUICK ATTACH

Lay pin ahead of hole used for lock-up. This will reduce the amount you have to lift

the Cropsaver while keeping it unlocked and free to be removed.

Remove 3/8” lock bolt then with two people, lift the tip of the Cropsaver and on the

arms. Pivot the bottom out rst then pull the top out.

Note if equipped with air lift disconnect the quick couplers rst.

f

1.

2.

Page 14

FREQUENTLY ASKED QUESTIONS

Page 15

INSTALLATION VIDEO

You can nd installation videos on our website or

go directly to them by scanning this QR code.

tridekon.com

1. I am still trampling crop. What is wrong?

You may be running the Cropsaver too low, raise the divider up . See page 5 for instruction.

2. How fast can I drive with the dividers on?

Generally speed does not matter. In some crops (ie: oats and barley) slow down depending on how ripe the

crop is.

3. Does driving quickly with Cropsavers do damage to the crop?

With the Cropsavers set at the correct crop height no damage will occur. However if your Cropsavers are set

too low some damage may occur.

4. Doesn’t the canopy stay open after the rst cone?

No, the crop waves back. The rear dividers are required to reopen the canopy.

5. How high can the dividers lift?

To the centre of the wheel diameter.

LOCKING THE CROPSAVERS UP

Manually lift the Cropsaver and insert the lock up pin to hold the Cropaver up.

If airlift is installed raise the cones fully and insert the lock up pin. Lock up pin shown in diagram.

k

FREQUENTLY ASKED QUESTIONS

Page 16

6. How low of a crop can you divide?

Minimum crop height is 20 inches.

7. How heavy should I set the resistance of the cones?

It should take 5-10 lbs of force to lift the tip of the Cropsaver when set properly.

8. What happens if I set the resistance too light?

The dividers will bounce around and can cause damage.

9. I am snapping bolts.

The dividers may be set too light, they will bounce around. OR: Going through heavy canopy (eg: podded

canola) will snap bolts.

10. How far in front of the tire should the cone be?

No less than 1.5” and no further than 10”.

11. How high should we run the dividers?

1/3 of the height of the crop from the lowest point of the divider not the tip.

12. Can I follow tram lines from earlier in the season?

You have to be careful doing this as there may be ruts left from the original pass. Cropsavers will not

bottom out and lift up in a rut, they can catch on the sides of the rut and a run-over could occur.

13. When I turn the wheels of my machine the Cropsaver cones drop down?

The tires pivot when the wheel is turned, the Cropsavers will move down slightly this is normal on some

machines.

14. Does my Cropsaver cone have to be perfectly centered with the tire?

No, as long as the Cropsaver cone covers the entire width of the tire it can be o centre.

15. Do Cropsavers work in canola?

Yes, if the canola is owering or in the early podding stage it is dividable. However if the crop is tangled ie:

fully podded or lodged and you are unable to walk through it, it will not divide very well.

16. Is there an easy way to remove the Cropsavers?

Yes, please refer to page 14 of the owners manual or refer to the Cropsaver Video section of tridekon.com.

It’s also possible to nd a balance point on your Cropsaver arms and weld in a link so you can use a fork lift

to carry the Cropsavers.

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions