User's Manual

750 50 0045 03 2

CONTENTS

1. Safety regulations............................................................................................................... 4

1.1 Important Information ................................................................................................ 4

1.2 Security Symbols........................................................................................................ 4

1.3 General Warnings....................................................................................................... 4

2. Instrument Description ...................................................................................................... 5

2.1 Instrument................................................................................................................... 6

2.2 Interfaces/Connectors............................................................................................... 6

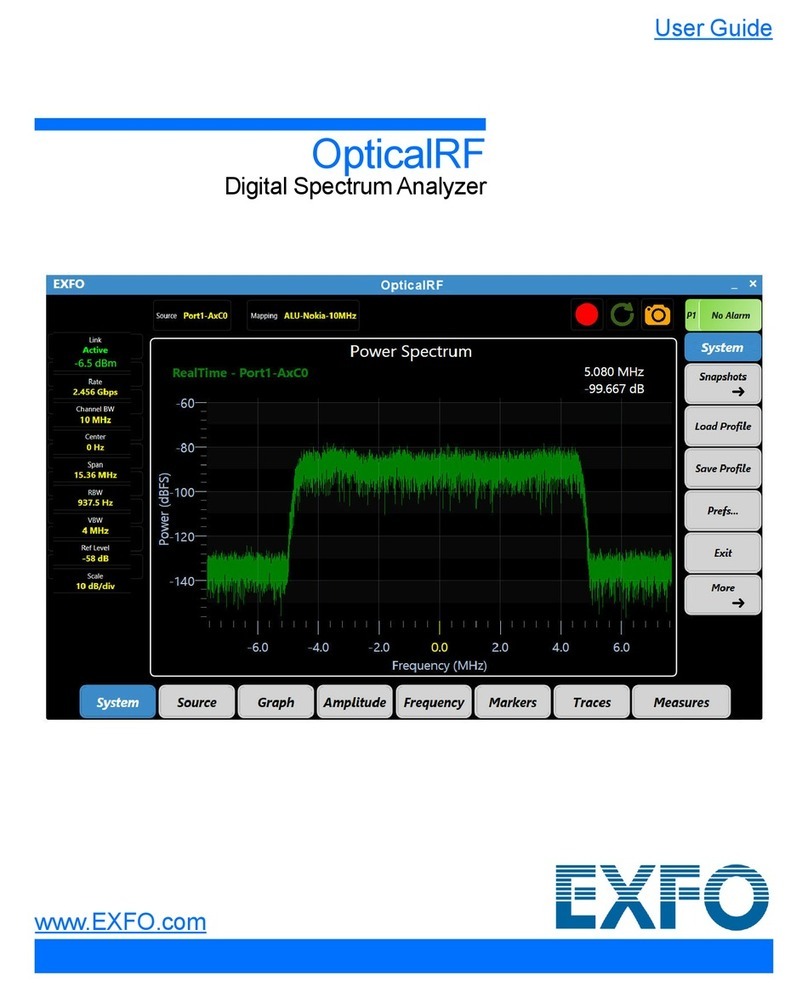

2.3 Display........................................................................................................................ 6

3. Setting up ............................................................................................................................ 7

3.1 Packing List ................................................................................................................ 7

3.2 Setting-up ................................................................................................................... 8

4. Getting Started.................................................................................................................. 10

4.1 Displacement Modes : Manual/Motorized.............................................................. 10

4.2 Setting into Operation ............................................................................................. 11

5. Main Functions.................................................................................................................. 13

5.1 Selection of Height and Diameter / Centerline Measurements .............................. 13

5.2 Height Measurements .............................................................................................. 13

5.3 Diameter and Centerline Measurements................................................................. 14

5.4 References................................................................................................................ 16

5.5 Selection of the Resolution ...................................................................................... 16

5.6 Setting / Memorizing of the Probe Constant .......................................................... 17

5.7 Selection of the Measuring Unit .............................................................................. 17

5.8 Measuring in Min / Max / Delta Mode .................................................................... 17

5.9 Average Between 2 Last Measurements ................................................................. 19

5.10 Difference Between 2 Last Measurements.............................................................. 20

5.11 Zero Setting of the Display ...................................................................................... 20

6. Secondary Functions........................................................................................................ 21

6.1 Perpendicularity Measurement ................................................................................ 21

6.2 Measurement History (Buffer).................................................................................. 23

6.3 Distance and Centerline Measurement ................................................................... 25

6.4 Inversion of the Measuring Direction....................................................................... 26

6.5 Probe Holder Change .............................................................................................. 27

6.6 Manual Recording of the Probe Constant............................................................... 27

6.7 Display Modes ......................................................................................................... 28

6.8 Shrinking Factor ....................................................................................................... 28

6.9 Temperature Compensation .................................................................................... 29