Introduction

Overview

Inspection

Preliminary Checks

Safety

DANGER

This product is designed to conform to IEC 61010 Safety Standards, and

has been thoroughly tested for safety prior to shipment. However,

mishandling during use could result in injury or death, as well as damage

to the product. Be certain that you understand the instructions and

precautions in the manual before use. We disclaim any responsibility for

accidents or injuries not resulting directly from product defects.

The symbol printed on the product indicates that the user

should refer to a corresponding topic in the manual (marked

with the symbol) before using the relevant function.

In the manual, the symbol indicates particularly important

information that the user should read before using the

product.

Indicates AC (Alternating Current).

DANGER

Indicates that incorrect operation presents an extreme

hazard that could result in serious injury or death to the

user.

WARNING

Indicates that incorrect operation presents a significant

hazard that could result in serious injury or death to the

user.

CAUTION Indicates that incorrect operation presents a possibility of

injury to the user or damage to the product.

NOTE Advisory items related to performance or correct

operation of the product.

Notes on Use

DANGER

To avoid short circuits and potentially life-threatening hazards,

never attach the clamp to a circuit that operates at more than the

600 Vrms, or over bare conductors.

Clamp-on probe should only be connected to the secondary side

of a breaker, so the breaker can prevent an accident if a short

circuit occurs. Connections should never be made to the primary

side of a breaker, because unrestricted current flow could cause a

serious accident if a short circuit occurs.

WARNING

To avoid electric shock, do not allow the product to get wet, and

do not use it when your hands are wet.

To avoid electric shock when measuring live lines, wear

appropriate protective gear, such as insulated rubber gloves,

boots and a safety helmet.

Before measurement, check the position of the range switches.

The unit may be damaged it current at levels in excess of the

measurement limit is applied for a long time.

Current measurements exceeding 500 A, 1 kHz should be of short

duration. Heat builds up in the core proportionate to the current

value, and will reach a dangerous level over a long period of time.

CAUTION

Do not store or use the product where it could be exposed to direct

sunlight, high temperature or humidity, or condensation. Under such

conditions, the product may be damaged and insulation may

deteriorate so that it no longer meets specifications.

To avoid damage to the product, protect it from vibration or shock

during transport and handling, and be especially careful to avoid

dropping.

NOTE

Accurate measurement may be impossible in the presence of strong

magnetic fields, such as near transformers and high-current conductors,

or in the presence of strong electromagnetic fields such as near radio

transmitters.

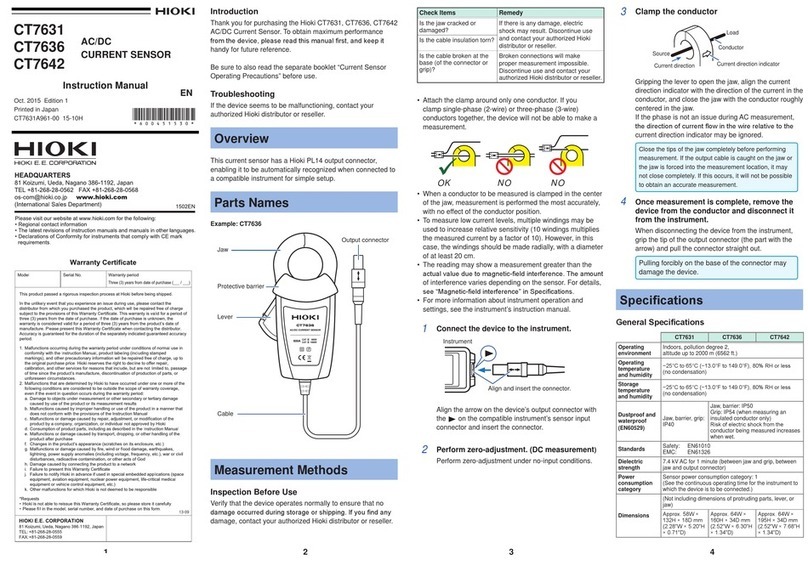

Part Names

Jaws

9010 SAFETY PLUG

Range select

rotary switch

9010-10 BNC CONNECTOR

Measurement Procedure (AC A)

CAUTION

To prevent damage to the product and sensor, never connect or

disconnect a sensor while the power is on.

When disconnecting the BNC connector, be sure to release the lock

before pulling off the connector. Forcibly pulling the connector without

releasing the lock, or pulling on the cable, can damage the connector.

Specifications

Measuring range AC 10/20/50/100/200/500 A

Output voltage 0.2 V AC f.s. (The output resistance is approx.

150Ω: in the range of 10 A)

Amplitude accuracy 3%f.s. (45 to 66 Hz, at the clamp core center)

Frequency

characteristics

At 40 to 1000 Hz (deviation from 55 Hz)

Within 6% (in10/20 A range)

Within 3% (in 50/100/200/500 A range)

Effect of conductor

position

Within 2% everywhere in the core.

Effect of external

magnetic field

1 A or less for 400 A/m external magnetic field.

Maximum rated

voltage to earth

Max. 600 Vrms

Maximum input

current

(in 45 to 66 Hz)

10/20/50 A range: 150 A continuous

100/200 A range: 400 A continuous

500 A range: 650 A continuous, 1400 A for a

minute

Withstand voltage 5550 VAC: For a minute (between electric circuit

and core, between case and core)

Operating temperature

and humidity range

0to40 (32 to 104 ), Max. 80%RH (no

condensation)

Storage temperature

and humidity range

-10 to 50 (14 to 122 ), Max. 80%RH (no

condensation)

Location for use Indoor, altitude up to 2000 m (6562 feet)

Diameter of

measurable conductors

Less than 46 mm (1.81") Possible to use the 50

mm (1.97") wide 20 mm (0.79") deep busbar

Cord length Approx. 3 m (118.11")

External dimensions

and mass

Approx. 74W 184H 37D mm

(2.91"W 7.24"H 1.46"D) (excluding protrusions)

Approx. 400 g (14.1 oz.)

Accessories Instruction manual

Applicable standards Safety EN61010-2-032:1995

Overvoltage Category III Pollution

Degree 2 (Anticipated transient

overvoltage 6000 V)

EMC EN61326:1997+A1:1998+A2:2001

Maintenance and Service

Thank you for purchasing the HIOKI "9010, 9010-10 CLAMP ON PROBE".

To obtain maximum performance from the product, please read this manual

first, and keep it handy for future reference.

The 9010, 9010-02, and 9010-10 are voltage output type clamp on probes,

which are applicable to 500A AC current measurements. The instrument can

be used to measure alternating current on a live power line without the need

to cut the wire. Easy operation and connection make them useful for

measuring alternating current and power in various fields.

Before using the product the first time, verify that it operates normally to

ensure that the no damage occurred during storage or shipping. If you find

any damage, contact your dealer or Hioki representative.

Before using the product the first time, verify that it operates normally to

ensure that the no damage occurred during storage or shipping. If you find

any damage, contact your dealer or Hioki representative.

Before using the product, make sure that the insulation on the test leads

and probes is undamaged and that no bare conductors are improperly

exposed. Using the product in such conditions could cause an electric

shock, so contact your dealer or Hioki representative for repair.

Overvoltage categories (CAT)

This product conforms to the safety requirements for CAT III measurement

products.

To ensure safe operation of measurement products, IEC 60664 establishes

safety standards for various electrical environments, categorized as CAT I to

CAT IV, and called overvoltage categories. These are defined as follows.

CAT I: Secondary electrical circuits connected to an AC electrical outlet

through a transformer or similar device.

CAT II: Primary electrical circuits in equipment connected to an AC electrical

outlet by a power cord (portable tools, household appliances, etc.)

CAT III: Primary electrical circuits of heavy equipment (fixed installations)

connected directly to the distribution panel, and feeders from the

distribution panel to outlets.

CAT IV:The circuit from the service drop to the service entrance, and to the

power meter and primary overcurrent protection device (distribution

panel).

Higher-numbered categories correspond to electrical environments with

greater momentary energy, so a measurement product designed for CAT III

environments can endure greater momentary energy than one designed for

CAT II. Using a measurement product in an environment designated with a

higher-numbered category than that for which the product is rated could

result in a severe accident, and must be carefully avoided.

Safety symbols

This manual contains information and warnings essential for safe operation

of the product and for maintaining it in safe operating condition. Before using

the product, be sure to carefully read the following safety notes.

The following symbols in this manual indicate the relative importance of

cautions and warnings.

Follow these precautions to ensure safe operation and to obtain the full

benefits of the various functions.

When input to our recorder or tester, use 0.2 VAC range.

1. Connect the safety plug (banana plug, BNC connector) to the input

terminal. When using the BNC connector, align the BNC connector with

the connector guide notch on the current input connector. While pushing

the connector in, turn it to the right to lock it.

2. When input the unknown amount of measuring current, set the range to

the largest one (500 A).

3. Open the jaws and clamp the conductor.

4. Confirm whether the core tip connection part is closed certainly.

5. Set the proper range of the clamp on probe according to the measurement

value. Do not set the range from the measurement equipment (the

recorder etc.)

NOTE

Make sure that only one conductor is in the core. Single-phase (2-wire) and

three-phase (3-wire) lines clamped together will not produce reading.

Accuracy is guaranteed for 1 year at 23 5 (73 9 ) and 80%RH.

(Opening and Closing of the Sensor: Maximum 10000 times)

Cleaning the unit

To clean the product, wipe it gently with a soft cloth moistened with water or

mild detergent. Never use solvents such as benzene, alcohol, acetone, ether,

ketones, thinners or gasoline, as they can deform and discolor the case.

Service

If the product seems to be malfunctioning, contact your dealer or Hioki

representative.

Pack the product carefully so that it will not be damaged during shipment,

and include a detailed written description of the problem. Hioki cannot be

responsible for damage that occurs during shipment.