Trine Axion Series User manual

Instruction Manual

AXION SERIES

MODEL EN400, EN400RP

- ELECTRIC STRIKE

TRINE ACCESS TECHNOLOGY

1440 Ferris Place, Bronx, NY 10461-3699

PH: 718-829-2332 -- FX: 718-829-6405

www.trineonline.com

Index No. Name Part Number

PARTS LIST

EN400RP LATCH

EN400

LATCH

1EN400 Latch EN-LCH

2EN400RP Latch EN- RPLCH

3Slider EN-SLR

4Coil Assembly (12V) EN-CA-12DC or EN-CA-12AC

Coil Assembly (24V) EN-CA-24DC or EN-CA-24AC

5Screws (2) #4-40 x 1/8" (Cover) EN-SCR 1/8

6Frame Cover EN-FR.C

7Screws #4-40 x 1/4" (Coil) EN-SCR 1/4

8Frame ** EN-FR400

9Assembly Pin* EN-ASS.PN

10 Spring EN-SPR

11 Latch Pivot Pin EN-LCH-PV-ST

12 Slider Guard EN-GRD

13

Mounting Screws (2) #12-24 x 1/2"

EN-MTS

14 Shim Kit (3) 1/16" Shim EN-UNV-SHIM

15 Shim Screws (2) #6-32 x 1/4" EN-SHIM-SCR-S

16 Shim Screws (2) #6-32 x 3/8" EN-SHIM-SCR-L

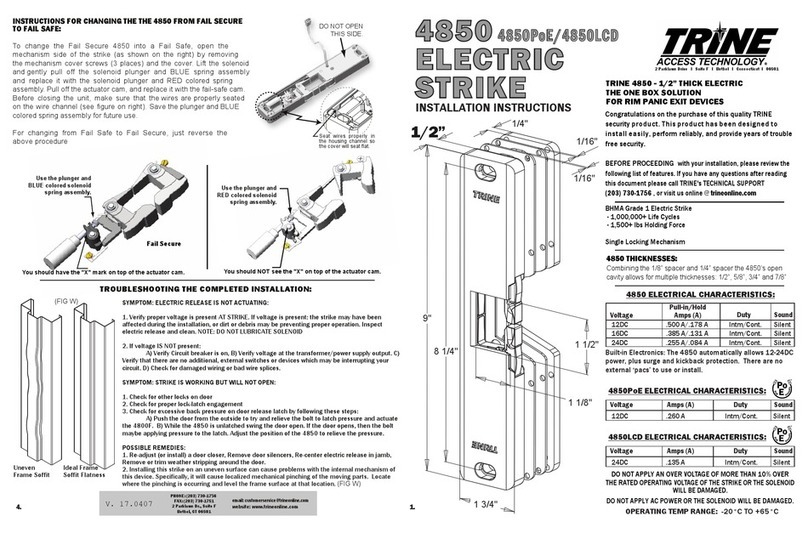

Figure 1

EN400 Electric Strike

NOTE: Number in parenthesis ( ) indicates part in Parts List.

UL LISTED - 10B fire rated (class A, 3-hour, Single Swing Doors)

[Except EN400RP]

UL LISTED - 1034 Burglary Resistant Locking

Mechanism for Indoor or Outdoor Use

ANSI/BHMA - A156.5 - 1992 - 4-7/8” x 1-1/4” Fits Cutout

Specification A115.1 (with Slight Jamb Modification)

BHMA - Grade 1

NYC MEA - 79-01-E

NOTE: UL fire listing is void when using fail safe action or

RP latch for Rim Panic Devices.

4

5

6

9

8

1

15 & 16

14

10

12

11 2

3

7

Voltage Amps Ohms Duty Sound

12AC 0.70 4.5 Intm. Buzz

24AC 0.37 18.0 Intm. Buzz

12DC 0.28 43.0 Intm./Cont. Silent

24DC 0.15 164.0 Intm./Cont. Silent

EN SERIES ELECTRICAL CHARACTERISTICS CHART

HANDING DETERMINATION

Door handing is determined by

the position of the hinges, as

viewed from the outside of the

room or building. If the door

hinges are on the left, the door

is termed left handed; if the

door hinges are on the right,

the door is termed right

handed. Also a door is either

inswinging (opens into the

room), or outswinging (opens

to the outside of the room).

LEFT HAND (LH) RIGHT HAND (RH)OUTSIDE

LEFT HAND

REVERSE (ORDER RH)

RIGHT HAND

REVERSE (ORDER LH)

OUTSIDE

DOOR HANDING GUIDE

HANDING OF DOOR IS ALWAYS DETERMINED FROM THE OUTSIDE.

Slider Guard

Prepare the Latch for

assembly. Position the

Latch and Latch

Spring as shown and

pass the assembly pin

through the two parts.

Insert the Slider as

Fail-Secure or

Fail-Safe position

as shown.

Disassemble the Back Cover and the

solenoid of the Left Hand configured

EN strike.

Using the Assembly Pin, push the

Latch Pivot Pin out.

Take the Latch & Spring and the

Slider Guard out of the frame.

Disassemble the Back Cover and the

solenoid of the Right Hand configured

EN strike.

Using the Assembly Pin, push the

Latch Pivot Pin out.

Take the Latch & Spring and the Slider

Guard out of the frame.

Pass the long leg of the Spring

through the rectangular hole on

the frame and let the Latch

assembly drop to position where

all the pivot holes lines up.

Pass the long leg of the Spring

through the rectangular hole on

the frame and let the Latch

assembly drop to position where

all the pivot holes lines up.

Assemble the Solenoid and

secure it with the solenoid Screw

as shown.

Finish the assembly by installing

the Cover and securing it with the

two assembly Screws.

Assemble the Solenoid and

secure it with the solenoid Screw

as shown.

Finish the assembly by installing

the Cover and securing it with the

two assembly Screws.

Fail-Secure

Slider position

HANDING THE STRIKE (RIGHT HAND) HANDING THE STRIKE (LEFT HAND)

Fail-Safe Slider

Slider position

Fail-Secure

Slider position

Dimple shows

Fail-Safe

Slider position

Fail-Safe Slider

Slider position

Dimple shows

Fail-Safe

Slider position

Assemble the Slider Guard over the Slider.Assemble the Slider Guard over the Slider.

Align the Slider with

the pick guard ribs

as shown.

Align the Slider with

the pick guard ribs

as shown.

1 1

2

2

3

3 3

4

5

A

below

A

below

7 7

8

LATCH ASSEMBLY

400 LATCH

FOR CYLINDRICAL

& MORTISE LOCKS

RP LATCH

FOR RIM PANIC

DEVICES

At 5 (Below) you

may switch out the

standard

Cylindrical/Mortise

Latch for the RP

(rim panic) Latch.

Note: RP Latch is

NOT Fire Rated

(it is Outdoor rated)

A

SWAP LATCHES

Latch Pivot Pin

Assembly Pin

Latch Pivot Pin

Assembly

Pin

66

Insert the Latch Pivot Pin

making sure that the flared pin

head is towards the right as shown.

Pass the Latch Pivot Pin through the

Frame, Latch and Spring.

(The assembly pin will fall off the opposite end.

Save this pin for future use.)

Insert the Latch Pivot Pin

making sure that the flared pin

head is towards the left as shown.

Pass the Latch Pivot Pin through the

Frame, Latch and Spring.

(The assembly pin will fall off the opposite end. Save

this pin for future use.)

Wire

Latch

Cont... Page 2 Door Handing Determination

The position of the Electric Strike in the door

jamb will be the same for a right-handed door

and a lefthanded door. For these installations,

the Electric Strike position in the door jamb

will be as shown in Figure 3.

In a similar manner, the position of the Electric

Strike in the door jamb will be the same for a

lefthanded reverse bevel door and a right

-handed door. For these installations, the

Electric Strike position in the door jamb will be

as shown in figure (4).

NOTE

The EN Electric Strike must be installed with

coil assembly up (wiring toward top of unit). In

this position, the Electric Strike will be locked

without power, Fail Secure, or locked with

power, Fail Safe action. Before performing

Handing Procedure, view Electric Strike in up

position (wire leads at top) to determine if a

handing change is required.

Figure 3.

Position of

Electric Strike

for Right Hand

Inswinging and

Left Hand

Outswinging

Door

Figure 4.

Position of

Electric Strike

for Left Hand

Inswinging and

Right Hand

Outswinging

Door

Wire

Latch

400RP

400RP

400

400

Figure 10a. USING DC TRANSFORMER

SAMPLE WIRING DIAGRAMS

FOR THE EN SERiES

Figure 10b. USING AC TRANSFORMER

24V DC OR 12V DC

TRANSFORMER

TO 120V AC LINE

PUSH

BUTTON

NORMALLY OPEN

** When wiring the optional buzzer, polarity must be

observed. Connect the (+ or RED) positive wire to the

(+) positive side of the circuit and the (- or BLACK)

negative side wire terminal to the negative side of the

circuit.

+

-

+

RED

-

BLACK

FAIL-SECURE

ELECTRIC

STRIKE

OPTIONAL**

BUZZER: BZ-12 OR BZ-24

OPTIONAL** BUZZER: BZ-12 OR BZ-24 BZ-6 FOR LC VERSION

FAIL-SAFE

ELECTRIC

STRIKE

RECTIFIER*

24V AC or 12V AC Transformer

TO 120V AC LINE

PUSH

BUTTON

NORMALLY OPEN

* The rectifier can be positioned before of after the push button in the circuit. The LC

module can ONLY be positioned after the push button as shown above.

*** When wiring the optional buzzer, polarity must be observed. Connect the (+ or

RED) positive wire to the (+) positive side of the circuit and the (- or BLACK) negative

side wire terminal to the negative side of the circuit.

+

-+

RED

-

BLACK

INSTALLATION PROCEDURE:

- For new or replacement installation in wood

or metal jambs.

1. Verify that voltage rating of Electric Strike is

compatible with supply voltages of installtion.

Coil voltages are color coded.

WIRE LEAD CODE/STRIPE

12AC Blue/Orange Stripe

12DC 2 Orange Stripe

24AC Blue/Black Stripe

24DC 2 Black Stripe

2. Using template supplied with Electric Strike,

mark door jamb for cutout and screw holes.

NOTE

For proper installation, center line of latches must

be aligned with center line of Electric Strike.

3. Prepare door frame (cut out jamb if

required) for Electric Strike. Leave sufficient

space for splicing between power supply

wiring and Electric Strike wiring.

4. If required, run new wiring to door frame

mounting hole. See figure 10 for typical wiring

installations. Refer to wiring chart below for

correct wire size. (Total wiring length includes

routing to door-release push button).

Total Wiring Length

To Transformer 12V 24V

Up to 50 Ft 18AWG 20AWG

50 to 150 ft 16AWG 18AWG

150 to 300 ft 14AWG 16AWG

300 to 600 ft 12AWG 14AWG

NOTE

For DC operation, to obtain an audible

signal when Electric Strike is energized,

install buzzer type BZ-12 for 12VDC

operation, or BZ-24 for 24VDC operation

(purchased seperately), as illustrated in

figure 10. 5. Hold Electric Strike upright

(wiring toward top) and determine if

handing is required. If so, perform handing

procedure.

6. Splice Electric Strike wiring to supply

wiring. Secure with wire nuts (supplied).

7. For wood and aluminum door jambs, drill

pilot holes for securing Electric Strike to

door jamb. For steel and aluminum door

jambs, secure Electric Stike to existing

mounting tabs.

8. Install Electric Strike into door jamb and

secure with flat head mounting screws

(supplied).

9. Verify that door operates correctly when

Electric Strike is energized and not

energized.

NOTE

1. Rectifier can be located either between

transformer and push button, or between

push button and electric strike.

2. Use either a silicon rectifier or a current

regulating rectifier for converting the AC

voltage at the transformer secondary to

the DC for operating the electric strike.

Door lockset is not

secured by Electric

Strike

Electric Strike

does no energize

(activate)

1) Centerline of lockset is not

properly aligned to the

centerline of the electric strike.

Check for proper cutout installation of Electric Strike by

referring to template and door frame and lockset position.

1) Wiring to electric strike is

open or shorted.

Check that electrical connections are secure and that no fraying has occurred during installation. Use voltmeter

to verify that Electric Strike is receiving energizing voltage and that wiring is not shorted.

2) Insufficient voltage to

electric strike.

Verify that voltage rating on Electric Strike label is compatiblewith voltage from secondary transformer

(12V or 24V). If voltages do not match, either replace transformer or change Electric Strike or Coil Assembly.

Use voltmeter to verify that Electric Strike is receiving proper voltage and that wiring is not shorted.

If voltage is too low because wire size is too small for length or wiring to Electric Strike (see

wiring-length data on previous page), either replace wiring or use transformer with higher VA rating.

2) Latch does not project

properly into the cavity of the

electric strike

Check for excessive gap between door and jamb.

Check that lockset is compatible with EN series cavity and requirements. If necessary, use other type of lockset

or Electric Strike (refer to Trine Catalog for more information).

3) Latch Spring broken

or missing

Hold Electric Strike so that wiring faces down and apply pressure to Latch. Verify that Latch releases and that

there is sufficient Spring tension to push it to closed positionwhen released. If Latch does not have Spring

tension, disassemble Electric Strike and inspect for improperly installed or broken Spring.

Possible TroubleProbable CauseSuggested Remedy

TROUBLESHOOTING

Electric Strike energizes

but does not disengage

the lockset

1) Lockset is applying pressure

to electric strike, preventing

latch from releasing.

Check for proper cutout installation of Electric Strike. Latch requires proper clearance to open correctly and

provide path for Lockset Latch to engage Strike.

Check that Lockset Latch is not binding to bottom of Strike cavity due to door sag.

Check if foam insulation or the materials around door jamb are preventing door from closing flush, causing

door to put pressure on Latch.

3) Slider does not move when

coil receives proper voltage

Using an OHM meter, verify that resistance of the Coils matches the chart on page 3. If Coil is open (burned out),

verify that transformer for Electric Strike has correct voltage current AC/DC and is wired correctly. AC Coils do

not operate at continuous duty, or on DC voltage.

Check that Slider (2) floats freely, as follows:

Remove Electric Strike from jamb and hold with wires facing up. Test that Strike is locked by applying pressure

to Latch. Then turn Strike upside down with wires facing down and verify that Latch opens freely by applying

pressure. The locking Slider (#2) must float freely for unit to operate properly.

TRINE ACCESS TECHNOLOGY

1440 Ferris Place, Bronx, NY 10461-3699

PH: 718-829-2332 -- FX: 718-829-6405

FOR ADDITIONAL INFORMATION, HELP, ACCESS TO SPECS ON

A OUR FULL LINE OF PRODUCST, OR ADDITIONAL

CONTACT OPTIONS PLEASE VISIT OUR WEBSITE

www.trineonline.com

This manual suits for next models

2

Other Trine Lock manuals

Popular Lock manuals by other brands

Abus

Abus KeyGarage 787 Smart-BT manual

LaGard

LaGard 3035 operating instructions

Itec

Itec iCylinder 05 instruction manual

Keyautomation

Keyautomation ALT3KF Series Instructions and warnings for installation and use

RCO

RCO R-COD 500 Installing, Commissioning, Using

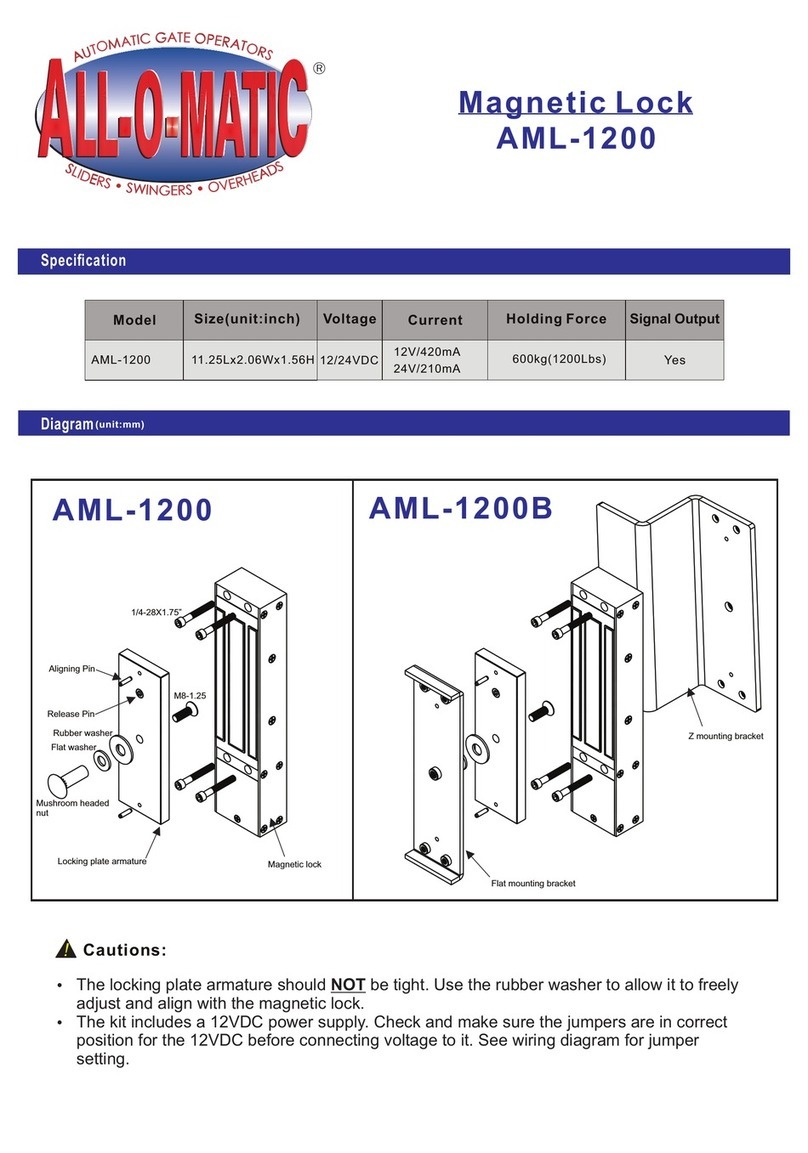

ALLOMATIC

ALLOMATIC AML-1200 quick start guide