SICK i15-EM0123 User manual

OPERATING INSTRUCTIONS

i15 Lock

Safety locking device

Described product

i15 Lock

Manufacturer

SICK AG

Erwin-Sick-Str. 1

79183 Waldkirch

Germany

Legal information

This work is protected by copyright. Any rights derived from the copyright shall be

reserved for SICK AG. Reproduction of this document or parts of this document is

only permissible within the limits of the legal determination of Copyright Law. Any modi‐

fication, abridgment or translation of this document is prohibited without the express

written permission of SICK AG.

The trademarks stated in this document are the property of their respective owner.

© SICK AG. All rights reserved.

Original document

This document is an original document of SICK AG.

2O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

Contents

1 About this document........................................................................ 5

1.1 Scope......................................................................................................... 5

1.2 Additional information.............................................................................. 5

1.3 Symbols and document conventions...................................................... 5

2 Safety information............................................................................ 7

2.1 General safety notes................................................................................ 7

2.2 Intended use............................................................................................. 7

2.3 Requirements for the qualification of personnel.................................... 7

3 Product description........................................................................... 8

3.1 Setup and function................................................................................... 8

3.2 Product characteristics............................................................................ 8

3.3 Symbols on the product........................................................................... 9

3.4 Manual unlocking..................................................................................... 9

4 Project planning................................................................................ 11

4.1 Manufacturer of the machine.................................................................. 11

4.2 Operator of the machine.......................................................................... 11

4.3 Design........................................................................................................ 12

4.4 Integrating into the electrical control....................................................... 12

4.5 Testing plan............................................................................................... 12

5 Mounting............................................................................................. 13

5.1 Safety......................................................................................................... 13

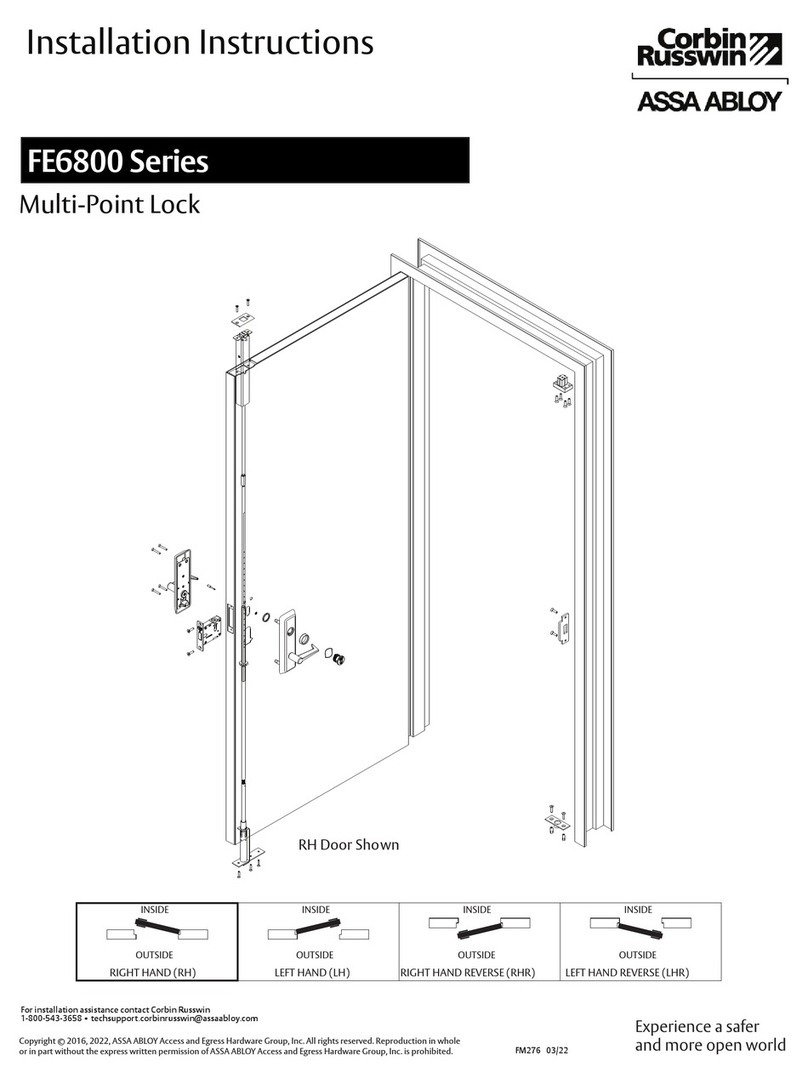

5.2 Converting the actuating head................................................................. 13

5.3 Mounting................................................................................................... 14

5.4 Protection from environmental influences.............................................. 14

6 Electrical installation........................................................................ 15

6.1 Safety......................................................................................................... 15

6.2 Pin assignment......................................................................................... 15

6.3 System connection (cable entry)............................................................. 15

7 Commissioning.................................................................................. 17

7.1 Check during commissioning and modifications.................................... 17

7.2 Recurring technical checks...................................................................... 17

8 Decommissioning............................................................................. 19

8.1 Disposal..................................................................................................... 19

9 Technical data.................................................................................... 20

9.1 Technical data........................................................................................... 20

9.2 Dimensional drawings.............................................................................. 21

CONTENTS

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 3

Subject to change without notice

10 Ordering information........................................................................ 23

10.1 Ordering information................................................................................. 23

11 Accessories........................................................................................ 24

11.1 Actuator..................................................................................................... 24

11.2 Additional accessories............................................................................. 24

12 Annex.................................................................................................. 25

12.1 Conformities and certificates................................................................... 25

CONTENTS

4O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

1 About this document

1.1 Scope

These operating instructions are valid for all i15 Lock safety locking devices.

This document is included with the following SICK part numbers (this document in all

available language versions):

8022220

1.2 Additional information

www.sick.com

The following information is available on the Internet:

•Data sheets and application examples

•CAD data and dimensional drawings

•Certificates (e.g. EU declaration of conformity)

•Guide for Safe Machinery Six steps to a safe machine

1.3 Symbols and document conventions

The following symbols and conventions are used in this document:

Safety notes and other notes

DANGER

Indicates a situation presenting imminent danger, which will lead to death or serious

injuries if not prevented.

WARNING

Indicates a situation presenting possible danger, which may lead to death or serious

injuries if not prevented.

CAUTION

Indicates a situation presenting possible danger, which may lead to moderate or minor

injuries if not prevented.

NOTICE

Indicates a situation presenting possible danger, which may lead to property damage if

not prevented.

NOTE

Indicates useful tips and recommendations.

Instructions to action

bThe arrow denotes instructions to action.

1. The sequence of instructions for action is numbered.

2. Follow the order in which the numbered instructions are given.

✓The check mark denotes the result of an instruction.

Terminology

Dangerous state

ABOUT THIS DOCUMENT 1

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 5

Subject to change without notice

A dangerous state is a status of the machine or facility, where people may be injured.

Protective devices prevent this risk if the machine is operated within its intended use.

The figures in this document always show the dangerous state of the machine as

movement of a machine part. In practice, there are different dangerous states, such as:

•Machine movements

•Electrical parts

•Visible and invisible beam

•A combination of multiple hazards

1 ABOUT THIS DOCUMENT

6O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

2 Safety information

2.1 General safety notes

The safety locking device must be configured and operated correctly by qualified safety

personnel according to the machine requirements.

2.2 Intended use

The safety locking device is a locking unit with a safety locking function and is suitable

for the following applications:

•Temporarily preventing access to a hazardous area

•Monitoring of movable physical guards

In conjunction with a movable physical guard and the machine controller, the safety

locking device prevents the protective device from being opened. The locking device

remains locked for as long as the hazardous machine function is performed or until the

production step has finished.

The product is only suitable for use in industrial environments.

Incorrect use, improper modification of or tampering with the safety locking device will

invalidate any warranty from SICK AG; in addition, any responsibility and liability of SICK

AG for damage and secondary damage caused by this is excluded.

2.3 Requirements for the qualification of personnel

The safety locking device must be planned in, installed, connected, commissioned, and

serviced only by qualified safety personnel.

Project planning

For project planning, a person is considered qualified when he/she has expertise and

experience in the selection and use of protective devices on machines and is familiar

with the relevant technical rules and work safety regulations.

Mechanical mounting, electrical installation, and commissioning

For the task, a person is considered qualified when he/she has the expertise and

experience in the relevant field and is sufficiently familiar with the application of the

protective device on the machine to be able to assess whether it is in an operationally

safe state.

Operation and maintenance

For operation and maintenance, a person is considered competent when he/she has

the expertise and experience in the relevant field and is sufficiently familiar with the

application of the protective device on the machine and has been instructed by the

machine operator in its operation.

SAFETY INFORMATION 2

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 7

Subject to change without notice

3 Product description

3.1 Setup and function

The safety locking device is an interlocking device consisting of a mechanically-actu‐

ated position switch and a coded actuator. The actuator has a lower coding level.

The position switch contains a rotating switching cylinder which the actuator grips

during closing. The switching cylinder is locked or unlocked electromagnetically (variant-

dependent).

When inserting and removing the actuator, switching contacts for door monitoring are

opened and closed. When locking and unlocking the locking device, switching contacts

for locking device monitoring are opened and closed.

If the locking device is locked, the actuator cannot be removed from the actuating head.

The locking device can only be locked when the protective device is closed.

3.2 Product characteristics

3.2.1 Product variants

The safety locking device is delivered in different variants. You will find an overview of

important distinguishing features of the variants in the following.

•Locking principle: operating or standby current

•Type of contacts for door monitoring

•Maximum locking force

Complete overview of all variants: see "Ordering information", page 23

Standby current locking principle

i15-M

•Locking locking device: close protective device, no voltage on the magnet

•Unlocking locking device: apply voltage to magnet

If voltage is interrupted at the magnet, the locking device remains locked and the

protective device cannot be opened immediately.

WARNING

The locking device locks even when voltage is not present

People could get trapped.

bIf people are in the hazardous area, do not close the protective device even

voltage is not present.

Operating current locking principle

i15-E

•Locking locking device: apply voltage to magnet

•Unlocking locking device: disconnect voltage from magnet

If voltage is disconnected at the magnet, the locking device is unlocked and the protec‐

tive device can be opened immediately.

3 PRODUCT DESCRIPTION

8O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

DANGER

Hazard due to lack of effectiveness of the protective device

In the event of a voltage drop, the safety locking device unlocks regardless of whether

the dangerous state of the machine has ended.

bAssess the risk of accident. Use for protecting people requires correct project

planning.

3.2.2 Locking device monitoring

All variants feature at least 1 positive opening normally closed contact for locking

device monitoring. The output state changes when locking or unlocking the locking

device.

3.2.3 Door monitoring

All versions feature at least 2 contacts for door monitoring. At least 1 contact is a

positive opening normally closed contact. Depending on the product variant, 1 contact

can be a normally open contact. The output state changes when opening or closing the

protective device.

3.3 Symbols on the product

Table 1: Symbols on the product

Symbol Meaning

Positive opening normally closed contact for locking device moni‐

toring

Positive opening normally closed contact for door monitoring

Mechanical unlocking mechanism actuated, safety locking device

unlocked

Mechanical unlocking mechanism not actuated, safety locking

device functions normally

3.4 Manual unlocking

In some situations, it necessary to unlock the locking device manually (e.g. is faults are

present). After unlocking, a function test must be performed.

Mechanical unlocking mechanism

With the mechanical unlocking mechanism, the safety locking device can be unlocked

regardless of the status.

When actuating the mechanical unlocking mechanism, the contacts for locking device

monitoring open. A stop command must be generated.

Actuating the mechanical unlocking mechanism

bEnsure tensile stress is not applied on the actuator.

bLoosen safety screw with the screwdriver.

bUse the screwdriver to rotate the mechanical unlocking mechanism in the direc‐

tion of the arrow to the following symbol:

✓The locking device is unlocked.

PRODUCT DESCRIPTION 3

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 9

Subject to change without notice

WARNING

Permanent actuation of the mechanical unlocking mechanism

Hazard due to lack of effectiveness of the protective device

bAfter use, put back the mechanical unlocking mechanism, screw in the safety

screw and seal (e.g. with locking varnish).

3 PRODUCT DESCRIPTION

10 O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

4 Project planning

4.1 Manufacturer of the machine

DANGER

Failure to comply with manufacturer’s obligations

Hazard due to lack of effectiveness of the protective device

bCarry out a risk assessment before using the safety locking device.

bDo not tamper with or modify the components of the safety locking device.

bMake sure that the safety locking device is only repaired by the manufacturer or by

someone authorized by the manufacturer. Improper repair can lead to a loss of the

protective function.

bMake sure that switch-on commands which bring about a dangerous state of the

machine are not enabled until the protective device is closed and the lock is

activated.

bMake sure that the lock is not deactivated until the dangerous state of the

machine has stopped.

bMake sure that closing a protective device and activating the lock does not cause

a dangerous machine function to start by itself. This must be controlled by a

separate start command.

bThe safety locking device must not be bypassed (contacts jumpered), turned

away, removed, or rendered ineffective in any other way. Take measures to reduce

bypassing options as necessary.

If several devices are switched in succession and the simplified process according to

ISO 13849 is used to determine the performance level (PL), the PL may be reduced.

A logical series connection of safe contacts may be possible up to PL d under certain

circumstances. For more detailed information, see ISO TR 24119.

The safety locking device is designed so that internal errors according to ISO 13849-2,

Table A4, can be ruled out.

Observe EN ISO 14119 for using interlocking devices associated with physical guards.

4.1.1 Application of the safety locking device to protect people

At least one safe contact must be used for locking device monitoring (contact assign‐

ment see table 2).

4.1.2 Application of the safety locking device for process protection

At least one safe contact must be used for door monitoring.

Contacts for locking device monitoring can also be used (pin assignment see table 2).

4.2 Operator of the machine

Changes to the electrical integration of the device in the machine controller and

changes to the mechanical mounting of the device necessitate a new risk assessment.

The results of this risk assessment may require the entity operating the machine to

meet the obligations of a manufacturer.

PROJECT PLANNING 4

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 11

Subject to change without notice

The device must not be tampered with or changed, except for the procedures described

in this document.

The device must not be repaired. Improper repair can result in the device not providing

correct protection.

Restrict access to replacement actuators, so they cannot be used for bypassing.

4.3 Design

DANGER

Bypassing the protective device

Hazard due to lack of effectiveness of the protective device

bEliminate any temptation to tamper with the safety locking device by implementing

measures such as the following:

°Attach safety switches with a cover or with shielding, or ensure they are out of

reach.

°Cover the safety switch and the actuator with additional equipment or protect

them against access. Cover the sensor and the actuator with additional

equipment or protect them against access.

4.3.1 Selection of the actuator

NOTICE

Selecting unsuitable actuators or improper mounting can damage the device.

bSelect the right actuator (see table 7).

bPay attention to the door radius and mounting options.

4.4 Integrating into the electrical control

Switch-on commands which bring about a dangerous state of the machine must not be

enabled until the protective device is closed and the lock is activated. The lock must not

be deactivated until the dangerous state has ended. Depending on the safety concept,

the signal is analyzed by, e.g., safety relays or a safety controller.

The connected controller and all devices responsible for safety must comply with

the required performance level and the required category (for example according to

ISO 13849-1).

4.5 Testing plan

The safety locking device must be tested by appropriately qualified safety personnel

when commissioning, after modifications, and at regular intervals.

The regular thorough checks serve to investigate the effectiveness of the safety locking

device and discover defects because of modifications or external influences (such as

damage or tampering).

The manufacturer and user must define the type and frequency of the thorough checks

on the machine on the basis of the application conditions and the risk assessment.

Determination of the thorough checks must be documented in a traceable manner.

4 PROJECT PLANNING

12 O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

5 Mounting

5.1 Safety

DANGER

Hazard due to unexpected starting of the machine

Death or severe injury

bMake sure that the dangerous state of the machine is and remains switched off.

DANGER

Bypassing the protective device

Hazard due to lack of effectiveness of the protective device

bEliminate any temptation to tamper with the safety locking device by taking at least

one of the following measures:

°Attach safety switches with a cover or with shielding, or ensure they are out of

reach.

°If possible, use permanent mounting methods for actuators (e.g., welding,

glue, disposable screws, or rivets).

CAUTION

Hot housing

Risk of burns

bAt ambient temperatures > 40 °C, protect the safety locking device from uninten‐

tional touching by people.

NOTICE

If incorrectly installed or the ambient conditions are not suitable, the safety locking

device can get damaged.

bArrange the safety switch and actuator so that damage due to unintentional out‐

side influences is prevented.

bDo not use safety switch and actuator.

bThe set-up and mounting of the safety switch and actuator must be stable enough

to maintain proper operation.

bUse only reliable mounting elements that can only be removed with tools.

bIf an opening is created in the physical guard due to alignment errors, it must not

impair the protective function.

bAt ambient temperatures > 40 °C, protect the safety switch from contact with

flammable materials.

bThe specified IP enclosure rating only applies if the housing screws, cable entries,

and plug connectors have been fastened correctly. Observe the tightening torque.

5.2 Converting the actuating head

1. Insert the actuator into the actuating head.

2. Loosen the screws on the actuating head.

3. Turn the actuating head in the desired direction.

MOUNTING 5

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 13

Subject to change without notice

4. Tighten the screws to 0.6 Nm.

5. Seal unused actuation slots with the supplied slot covers.

5.3 Mounting

1. Insert the actuator into the actuating head.

2. Connect the safety switch to the fixed part of the protective device with positive

locking with 2 M5 screws. Tightening torque: 1.4 Nm.

3. In addition, insert 2 M5 coiled spring pins to fasten the safety switch.

4. Connect the actuator permanently to the moving part of the protective device so it

cannot be disengaged.

5. Fit an additional stop for the moving part of the protective device.

5.4 Protection from environmental influences

The prerequisite for a proper and permanent safety function is protection of the actuat‐

ing head from foreign bodies such as chips, sand, beams of light, etc.

When doing painting work, cover the actuation slot, the actuator and the type label.

5 MOUNTING

14 O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

6 Electrical installation

6.1 Safety

DANGER

Hazard due to electrical voltage

Death or severe injury

bMake sure that the machine and the connecting cables of the safety locking

device are and remain disconnected from the power supply during the electrical

installation.

DANGER

Incorrect safety locking device connection

Loss of safety function

bWith insulation material or connection slots, pay attention to the temperature

resistance and mechanical load capability.

bIf different voltages are used between the contact pairs and the magnet coil (e.g.

230 V and 24 V), when wiring in the terminal compartment, make sure safe

separation is always present.

bFor safety functions, use only safe contacts for locking device monitoring and door

monitoring.

bTo ensure a secure contact, strip the individual wires back about 6 mm (± 1 mm).

6.2 Pin assignment

Table 2: Switching elements and switching functions

Actuator inserted Actuator removed

Locked Unlocked

E2

E1

E2

E1

E2

E1

i15-**0123 Lock

21

11

22

12 11 12

21

11

22

12 11 12

21

11

22

12 11 12

i15-**0133 Lock

23

11

24

12 11 12

23

11

24

12 11 12

23

11

24

12 11 12

All variants E1: +24 V DC magnet coil voltage supply (locking device)

E2: +0 V DC magnet coil voltage supply (locking device)

6.3 System connection (cable entry)

1. Open desired insertion opening with a suitable tool.

2. Mount the cable gland with corresponding enclosure rating.

3. Connect contacts (contact assignment see table 2).

°Operate all contact pairs in the same voltage range.

°Protect the magnet coil separately.

°Tighten terminals to 0.5 Nm.

ELECTRICAL INSTALLATION 6

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 15

Subject to change without notice

4. Pay attention to tightness of the cable entries.

5. Close switch cover and fasten it (tightening torque 0.8 Nm).

6 ELECTRICAL INSTALLATION

16 O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

7 Commissioning

7.1 Check during commissioning and modifications

DANGER

Hazard due to unexpected starting of the machine

Death or severe injury

bBefore carrying out the functional test, make sure that there are no people in the

hazardous area.

Approach

Check that the device is functioning properly after installation and after every fault. To

do this, proceed as follows:

Mechanical functional test

bOpen the protective device and close it again. The components of the safety

locking device must not collide with other parts. When the protective device is

closed, the actuator must be in a position which enables the lock to be actuated.

Electrical functional test

1. Switch on the supply voltage.

2. Close all protective devices and activate the locks. The machine must not start up

on its own.

3. Check the lock. It must not be possible to open the protective device.

4. Start the machine function.

5. Stop the machine function and deactivate the lock.

6. Check whether the protective device is kept locked until there is no more risk of

injury (e.g., due to run-on movements).

7. Repeat steps 3 to 9 individually for each protective device.

Complementary information

NOTE

You can simulate an active lock command, by applying the referred voltage to the “Lock

input” contact.

7.2 Recurring technical checks

DANGER

Insufficient checks or incorrect repair

Hazard due to lack of effectiveness of the protective device

bIn the event of wear or damage, replace the entire safety locking device with

actuator. Never replace individual parts or assemblies.

bCheck the safety locking device following the inspection intervals specified in the

national rules and regulations.

The following checks must be done to ensure permanent and proper function:

•Proper switching function

•Safe mounting for all components

•No damage, contamination, deposits or wear

•Tightness of cable entries

COMMISSIONING 7

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 17

Subject to change without notice

•No loose cable connections or plug connectors

•No manipulation by employees

7 COMMISSIONING

18 O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

8 Decommissioning

8.1 Disposal

Approach

bAlways dispose of unusable devices in accordance with national waste disposal

regulations.

Complementary information

SICK will be glad to help you dispose of these devices on request.

DECOMMISSIONING 8

8020548/1FVF/2022-04-27 | SICK O P E R A T I N G I N S T R U C T I O N S | i15 Lock 19

Subject to change without notice

9 Technical data

9.1 Technical data

Table 3: Features

Features

Housing material Fiberglass-reinforced thermoplastic

Enclosure rating (IEC 60529) IP 67

Mechanical service life 2 × 106 Switching operations

B10d (EN ISO 13849) at DC-13 100 mA / 24 V 2 × 106 Switching operation with small load

Type Type 2 (EN ISO 14119)

Coding level of the actuator Low coding level (EN ISO 14119)

Ambient operating temperature –20 °C … +55 °C

Connection type M 20

Max. actuation speed 20 m × min–1

Max. actuation frequency 1,200 × min–1

Pollution degree

(external, according to EN 60947)

3 × (industry)

Max. actuating force at 20 °C 35 N

Max. force against which unlocking is possible 20 N

Max. retaining force, unlocked 30 N

Locking force Fmax

i15-*M (metal actuating head)

i15-*M (metal actuating head) with angled

actuator

i15-*P (metal actuating head)

2,000 N

1,500 N

1,000 N

Locking force FZh according to (EN ISO 14119)

(FZh = Fmax /1.3)

i15-*M (metal actuating head)

i15-*P (metal actuating head)

1,500 N

700 N

Minimum door radii see table 7

Table 4: Electrical data

Electrical data

Thermal current lth 4 A

Switching principle Slow action switching element

Wire cross-section, (rigid/flexible) 0.34 mm²... 1.5 mm²

Rated insulation voltage Ui250 V

Rated impulse withstand voltage Uimp 2.5 kV

Utilization category (IEC 60947-5-1) AC-15: 230 V, 4 A; DC-13: 24 V, 4 A

Min. switching voltage 1) 12 V

Min. switching current at 24 V DC 1 mA

Conditional rated short-circuit current 100 A

Short-circuit protection (control fuse) (IEC

60269)

4 A gG

Solenoid supply voltage (+10% … –15%) AC/DC 24 V

Max. solenoid power 6 W

9 TECHNICAL DATA

20 O P E R A T I N G I N S T R U C T I O N S | i15 Lock 8020548/1FVF/2022-04-27 | SICK

Subject to change without notice

This manual suits for next models

15

Table of contents

Other SICK Lock manuals