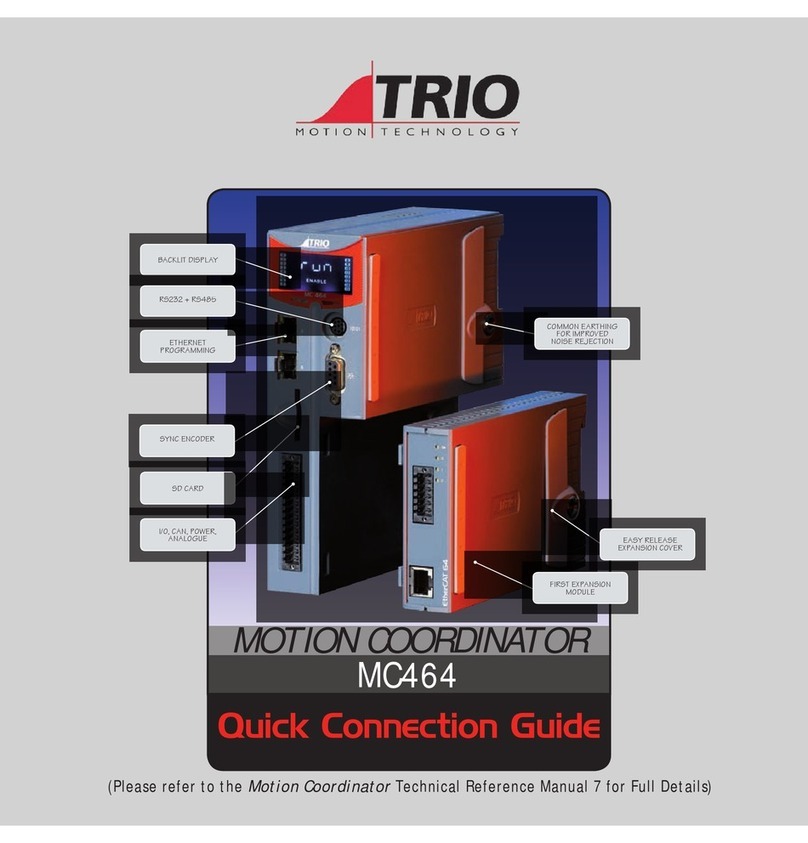

Trio MC4N-ECAT User manual

QUICK START GUIDE

PROGRAMMING PORT

ETHECAT PORT

STATUS LEDS

BACKLIT DISPLAY

FLEXIBLE AXIS PORT

RS 232 PORT

POWER - I/O - WDOG

CANBUS & SD CARD

CHASSIS EARTH

SCREW

MC4N-ECAT

P900 - P904

2

MINIMUM CONNECTIONS

PROGRAMMING

PORT

ETHECAT

PORT

0V

24V

OPTIONAL CONNECTIONS

Serial ports

Auxiliary Flexible Axis Port

I/O Connections

Enable (Watchdog)

CONNECTORS

I/O / Power (24V) connector:

Note: Use ferrules on all wires for best connection.

1. Connection: Push wire into hole of connector. Tighten

screw. Insert connector into MC4N.

2. Removal: Reverse the procedure.

SAFETY WARNING

During the installation or use of control systems, users of Trio products must ensure that there is no possibility of injury to any

person or damage to machinery.

Control systems, especially during installation, can malfunction or behave unexpectedly. Bearing this in mind, users must

ensure that even in the event of a malfunction or unexpected behaviour, the safety of an operator or programmer is never

compromised.

3

RJ45 ETHERNET CONNECTOR (TOP)

A standard Ethernet connector is provided for use as the primary programming interface.

The Trio programming software, Motion Perfect 4 and above, must be installed on a Windows based PC that

is tted with an Ethernet connection. The IP address is displayed on the MC4N display for a few seconds after

power-up or when an Ethernet cable is plugged in.

The Standard Ethernet connection may also be used for Ethernet-IP, Modbus and other factory communications.

ETHERCAT PORT

The MC4N acts as an EtherCAT master. EtherCAT drives and I/O devices are normally connected in a chain.

Ethernet standard pin assignment:

Pin Signal Description

1TD+ Transmission data +

2TD- Transmission data -

3RD+ Receive data +

6RD- Receive data -

Symetric or cross-over cables can be used between EtherCAT devices. Minimum CAT 5 shielded SF/UTPcable is recommended.

ETHERCAT NETWORK DETECTION

EtherCAT Intelegent drives Window in Motion Perfect

4

SERIAL CONNECTIONS (8 WAY MINI-DIN)

Pin Function Note

1 RS485 Data In A Rx+ Serial Port #2

2 RS485 Data In B Rx-

3 RS232 Transmit Serial Port #1

4 0V Serial

5RS232 Receive Serial Port #1

65V Output 150mA max*

7 RS485 Data Out Z Tx- Serial Port #2

8 RS485 Data Out Y Tx+

* Current shared with encoder port

FLEXIBLE AXIS PORT (9 WAY D-TYPE)

Pin Encoder Stepper Axis Absolute Encoder

1 Enc. A Step + Clock

2Enc. /A Step - /Clock

3 Enc. B Direction + --------

4Enc. /B Direction - --------

5 0V Serial/Encoder 0V Serial/Encoder 0V Serial/Encoder

6 Enc. Z Enable + Data

7Enc. /Z Enable - /Data

85V* 5V* 5V*

9Not Connected Not Connected Not Connected

*Current limit is 150mA max shared with serial port.

8

7

6

5

4

3

1

2

5

4

3

2

1

9

8

7

6

5

SHIELDING THE FLEXIBLE AXIS PORT

Ensure that:

1. The shield screw is grounded as close to the MC4N as possible.

2. 0V connection is NOT used for terminating screens.

3. Pin 5 of Encoder/Stepper plug is connected to 0V on drive.

4. Encoder cable screen is clamped to 9 way D shell.

5. The MC4N 24V supply has common 0V with the drive(s).

WHEN WIRING MC4N STEPPER OUTPUT TO A DIFFERENTIAL

INPUT STEPPER DRIVE, USE THE 0V AND SHIELD CONNECTIONS

SHOWN FOR THE ENCODER. THE STEPPER DRIVE MUST HAVE ITS

COMMON 0V CONNECTED TO THE MC4N.

5

1

2

3

4

6

7

0V

A+

A-

B+

B-

Z+

Z-

CONNECTOR SHELL

Enc 0V

Quadrature A

Quadrature B

Z Marker Pulse

SHIELD SCREW

ENCODER INPUT (9 WAY D-TYPE)

Encoder Output 0V MUST be connected to pin 5

*

*

6

I/O CONNECTOR

Not Used

Not Used

I/O 8

I/O 9

I/O 10

I/O 11

I/O 12

I/O 13

I/O 14

I/O 15

I/O 24V

24V

Input 0

Input 1

Input 2

Input 3

Input 4

Input 5

Input 6

Input 7

I/O 0V

0V

Enable

(Watchdog)

I/O CIRCUITS

Optical

Output

Control

Signal

Optical

Input

Signal

I/O 24V

I/O 0V

Protected

Switch

I/O Pin

6k8

Optical

Input

Signal

I/O 0V

Input Pin

2k7 on Inputs 0 - 3

6k8 on all other inputs

Inputs 0 - 3 have fast

opto-couplers for use as

axis registration inputs.

Inputs 4 - 7 may also

be used as registration

inputs.

Inputs / Outputs 8 - 15

7

AMPLIFIER ENABLE (WATCHDOG) RELAY OUTPUT

An internal relay may be used to enable external ampliers when the controller has

powered up correctly and the system and application software are ready. The amplier

enable is a single pole solid state relay with a normally open “contact”. The enable

relay contact will be open circuit if there is no power on the controller OR an axis

error exists OR the user program sets it open with the WDOG=OFF command.

ETHERCAT DRIVES WILL BE ENABLED VIA THE ETHERCAT NETWORK SO THE

“AMPLIFIER ENABLE” CONNECTION IS NOT NORMALLY REQUIRED.

ALL NON ETHERCAT STEPPER AND SERVO AMPLIFIERS MUST BE INHIBITED

WHEN THE AMPLIFIER ENABLE OUTPUT IS OPEN CIRCUIT.

An additional safety relay may be required so as to meet machine safety approvals.

Enable

Not Used

Not used

Input/Output 8

Input/Output 9

Input/Output 10

Input/Output 11

Input/Output 12

Input/Output 13

Input/Output 14

Input/Output 15

Input/Output 24V

24V

Input 0

Input 1

Input 2

Input 3

Input 4

Input 5

Input 6

Input 7

Input/Output 0V

0V

Amplier

Enable 1

Amplier

Enable 2

To other axis enables

24V 0V 0V

Enable

CONTROLLER SERVO AMPLIFIER

8

DISPLAY

The IP address and subnet mask of the MC4N is shown on the LCD display for a few seconds

after power-up. The factory default IP address is 192.168.0.250. This can be changed using

the IP_ADDRESS command via the Motion Perfect software tool.

Display

Example Description Details

SYS

Displayed on

controller

start

901

Model code :

Displayed on

power up

P900 : 2 axes

P901 : 4 axes

P902 : 8 axes

P903 : 16 axes

P904 : 32 axes

192.16 8.0.250 IP Address :

Displayed on power up OR after

ethernet connection for 15

seconds

Enable status

Error codes

Ann : Error on Axis nn

Unn : Unit error on slot nn

Caa : Conguration error on

unit nn, ie: too many axes

E04 : VR/TABLE corrupt entry

IP Address / Run / Error code

(see table below)

EtherCAT Communications active

EtherCAT detection (flashing)

EtherCAT detected (steady)

I/O channels On / OFF

Error

Enable status LED

Power LED

9

5-WAY CANBUS CONNECTOR

This is a 5 way 3.5mm pitch connector. The connector is used both to provide the 24 Volt power to

the MC4N CAN circuit and provide connections for I/O expansion via Trio’s CAN I/O expanders. A

24V dc, Class 2 transformer or power source should be used.

This 24V input is internally isolated from the I/O 24V and main 24V power.

THE CAN CONNECTOR MAY BE LEFT UNUSED. THE MC4N IS GROUNDED VIA THE METAL

CHASSIS. FIT A SHORT SHIELD CONNECTION BETWEEN THE CHASSIS EARTH SCREW AND

THE EARTHED METAL MOUNTING PANEL / PLATE.

SD CARD

The SD Card may be used for storing or transfering programs, recipes and data to and from the MC4N. The card must be FAT32

format and a maximum 16Gb size.

SD CARDS MAY BE FAT16 FORMATTED WHEN PURCHACED. RE-FORMAT IN A PC TO FAT32 PRIOR TO USE.

CAN 0V

C-Low

C-High

CAN 24V

10

NETWORK SETUP

Network connection

Set IP_ADDRESS in MC4N to an available unused address.

It MUST match the subnet in use. Set the PC to use

DHCP server.

Note: the MC4N always has a xed IP address.

Point-to-point or closed network

(No DHCP server)

The PC MUST be set to a xed IP_ADDRESS.

The rst 3 “octets” MUST be the same as the MC4N and

the last MUST be dierent, but not 000, 254 or 255.

Setting a xed IP address

In Windows 7. Open “Network and Sharing Centre” then change “Adapter

Settings”. Select the properties of the Local Area Network and the IPv4

properties. The IP Address is set to 192.168.0.100 with subnet mask set to

255.255.255.0. Assuming that the MC4N has IP_ADDRESS=192.168.0.250 or

similar.

SwitchPC Laptop

Controller

Controller

PC Laptop

DCHP Server

Example : 192.168.0.100 Example : 192.168.0.250

SwitchPC Laptop

Controller

Controller

PC Laptop

DCHP Server

Example : 192.168.0.100 Example : 192.168.0.250

11

CHASSIS MOUNTING DIMENSIONS (LOOKING FROM FRONT)

M4 screws should be used in 2 places to mount the MC4N to an unpainted metal

panel.

The best EMC performance is obtained when the MC4N is attached from the shield

screw (marked) using a at braided conductor with a cross section of 4mm x 1mm.

Do NOT use a circular section wire or run the braid to a central star point.

ENSURE THAT THE VENTILATION SLOTS AT THE TOP AND BOTTOM OF THE

MC4N ARE KEPT CLEAR TO ENSURE A FREE FLOW OF AIR THROUGH THE

MODULE.

38.6

19.3 19.3

4

145.8

4

4.5

4.5

Shield Screw

UK | USA | CHINA | INDIA

WWW.TRIOMOTION.COM

THE MOTION SPECIALIST

CAD data Drawings to aid packaging and mounting are available in various formats from the Trio web site. Products should be

wired by qualied persons.

Specications may change without notice. E & OE

Quick Start v4 October 2020

154mm

184mm

56mm

186mm

122mm

35mm

226mm

132mm

35mm 135mm

122mm

35mm

270.97mm

212.97mm

40mm

200.35mm

146.35mm

34.0mm

120mm

157mm

107mm

40mm

147mm

15mm15mm15mm

17mm17mm

120mm

157mm

40mm

120mm

157mm

40mm

170mm

129mm

25mm

130mm

26mm 85mm

120mm

157mm

40mm

This manual suits for next models

2

Table of contents

Other Trio Control Unit manuals

Popular Control Unit manuals by other brands

Microsemi

Microsemi DVP-102-000512-001 Demo guide

Grundfos

Grundfos PM 1 Installation and operating instructions

Pilz

Pilz PSS u2 ES 8DI operating manual

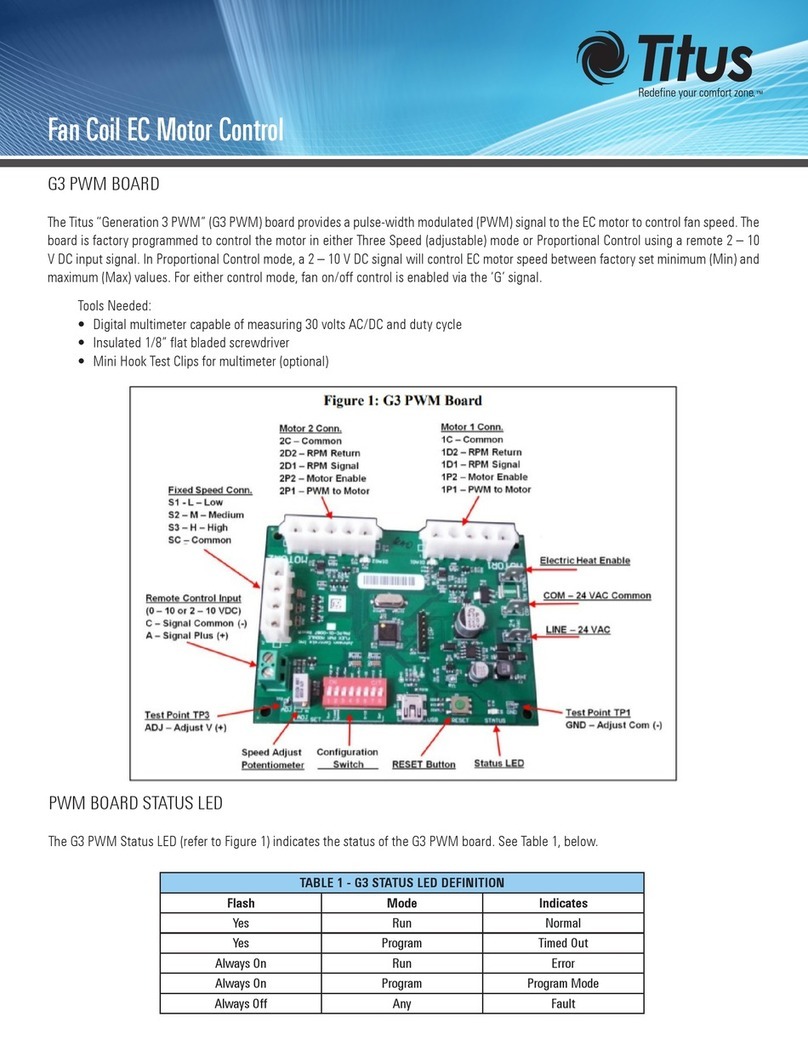

Titus

Titus G3 PWM BOARD manual

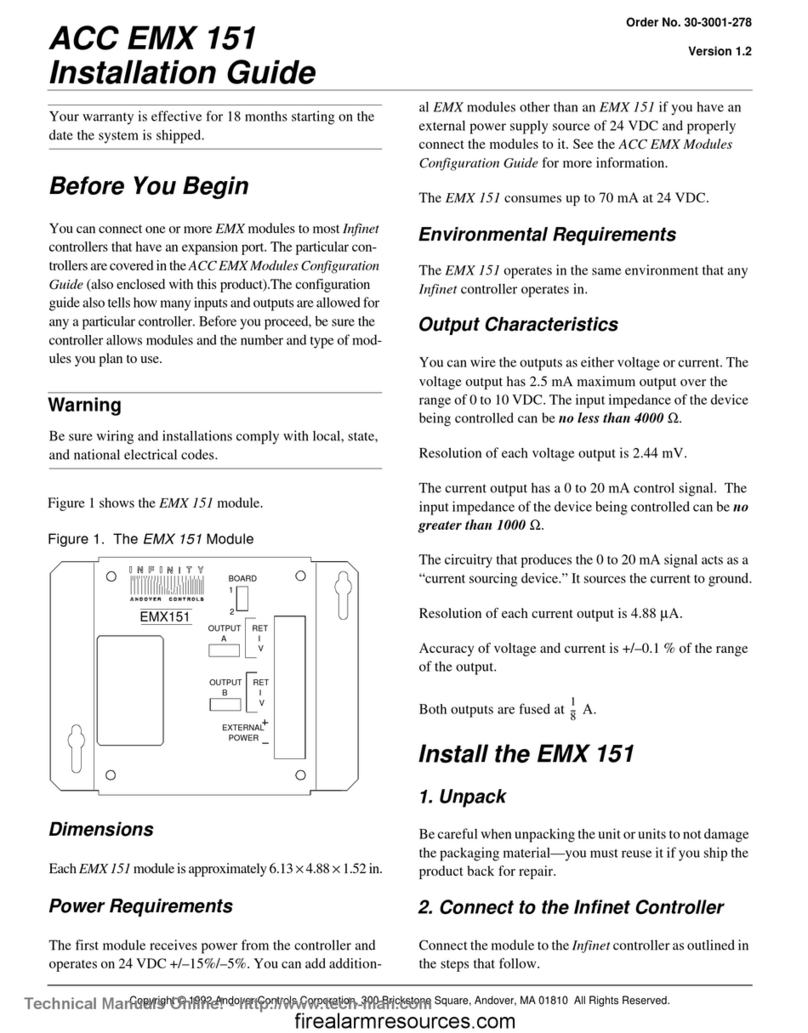

Andover Controls

Andover Controls Infinity ACC EMX 151 installation guide

ProSoft Technology

ProSoft Technology PLX51-HART-4I quick start guide