Trio Motion Coordinator MC216 Product manual

Trio Motion Technology

Motion Coordinator

Technical Reference Manual

Sixth Edition • 2004

Revision 4

All goods supplied by Trio are subject to Trio's standard terms and conditions of sale.

This manual applies to systems based on the Motion Coordinator MC202, Euro 205 and MC216 with sys-

tem software version 1.52, or higher. Or MC206 and MC224 with system software version 1.62, or

higher.

The material in this manual is subject to change without notice. Despite every effort, in a manual of

this scope errors and omissions may occur. Therefore Trio cannot be held responsible for any malfunc-

tions or loss of data as a result.

Revision 6.4 April 2004

Copyright (C) 2000-2004 Trio Motion Technology Ltd.

All Rights Reserved

UK

Trio Motion Technology Ltd.

Shannon Way

Tewkesbury

GL20 8ND

United Kingdom

Phone: +44 (0)1684 292333

Fax: +44 (0)1684 297929

USA

Trio Motion Technology LLC.

1000 Gamma Drive, Suite 206

Pittsburgh

PA 15238,

USA

Phone: +1 412 968 9744

Fax: +1 412 968 9746

SAFETY WARNING

During the installation or use of a control system, users of Trio products must

ensure there is no possibility of injury to any person, or damage to

machinery.

Control systems, especially during installation, can malfunction or behave

unexpectedly. Bearing this in mind, users must ensure that even in the event

of a malfunction or unexpected behaviour the safety of an operator or

programmer is never compromised.

!!

Motion Coordinator Technical Reference Manual

i

CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Setup and Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

System Building . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

System Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Features and Typical Applications . . . . . . . . . . . . . . . . . . . . 1-15

The Trio Motion Technology Website . . . . . . . . . . . . . . . . . . 1-16

HARDWARE OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . 2-1

Motion Coordinator MC202 . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Connections to the MC202 . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Serial Port Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

MC202 - Feature Summary . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Motion Coordinator Euro205(X) . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Axis Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Connections to the Euro 205(X) . . . . . . . . . . . . . . . . . . . . . . 2-12

Euro 205(X) Backplane Connector . . . . . . . . . . . . . . . . . . . . 2-13

Euro205 - Feature Summary . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Euro205X - Feature Summary . . . . . . . . . . . . . . . . . . . . . . . 2-20

Motion Coordinator MC206 . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-22

Connections to the MC206 . . . . . . . . . . . . . . . . . . . . . . . . . 2-25

Amplifier Enable (Watchdog) Relay Output . . . . . . . . . . . . . . 2-28

Reference Encoder Input . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

Universal Serial Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-29

MC206 - Stepper Outputs / Encoder Inputs . . . . . . . . . . . . . . 2-30

MC206 - Feature Summary . . . . . . . . . . . . . . . . . . . . . . . . . 2-31

Motion Coordinator MC216 . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33

Connections to the MC216 . . . . . . . . . . . . . . . . . . . . . . . . . 2-35

MC216 - Feature Summary . . . . . . . . . . . . . . . . . . . . . . . . . 2-40

Motion Coordinator MC224 . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-41

Connections to the MC224 . . . . . . . . . . . . . . . . . . . . . . . . . 2-43

MC224 - Feature Summary . . . . . . . . . . . . . . . . . . . . . . . . . 2-48

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Motion Coordinator MC202 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Motion Coordinator Euro 205 . . . . . . . . . . . . . . . . . . . . . . . 3-5

Motion Coordinator MC216 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Motion Coordinator MC206 . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

ii

Trio Motion Technology

EMC Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-9

Installation Requirements to Ensure Conformance . . . . . . . . . .3-11

Motion Coordinator MC202 . . . . . . . . . . . . . . . . . . . . . . . . .3-11

Motion Coordinator Euro 205 . . . . . . . . . . . . . . . . . . . . . . . .3-11

Motion Coordinator MC206 . . . . . . . . . . . . . . . . . . . . . . . . .3-12

Motion Coordinator MC216 . . . . . . . . . . . . . . . . . . . . . . . . .3-13

DAUGHTER BOARDS . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Fitting and Handling Daughter Boards . . . . . . . . . . . . . . . . . . . . .4-4

MC216 + Axis Expander Slot Sequence . . . . . . . . . . . . . . . . . .4-6

Fitting Daughter Boards to the Euro205 . . . . . . . . . . . . . . . . . . . .4-7

Fitting Daughter Boards to the MC206 . . . . . . . . . . . . . . . . . . . . .4-9

Servo Encoder Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . .4-11

Servo Resolver Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . .4-14

Reference Encoder Daughter Board . . . . . . . . . . . . . . . . . . . . . .4-16

Stepper Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-18

Stepper Encoder Daughter . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-20

Hardware PSWITCH Daughter Board . . . . . . . . . . . . . . . . . . . . . .4-23

Analog Output Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . .4-25

SSI Servo Encoder Daughter Board . . . . . . . . . . . . . . . . . . . . . . .4-26

Differential Stepper Daughter Board . . . . . . . . . . . . . . . . . . . . . .4-29

CAN Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-31

SERCOS Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-32

SLM Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-33

USB Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-35

Ethernet Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-36

Profibus Daughter Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-37

EXPANSION MODULES . . . . . . . . . . . . . . . . . . . . . . . .5-1

Input/Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

CAN 16-I/O Module (P315) . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

CAN Analog Inputs Module (P325) . . . . . . . . . . . . . . . . . . . . . . . .5-11

Operator Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Membrane Keypad (P503) . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Mini-Membrane Keypad (P502) . . . . . . . . . . . . . . . . . . . . . . .5-19

Programming the Membrane Keypad . . . . . . . . . . . . . . . . . . .5-20

Keypad KEY ON - KEY OFF Mode . . . . . . . . . . . . . . . . . . . . . .5-24

FO-VFKB Fibre Optic Keypad/Display Interface . . . . . . . . . . . . . . .5-26

FO-VFKB Keypad Interface . . . . . . . . . . . . . . . . . . . . . . . . . .5-26

Communications Adaptors . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-28

Serial to RS485 Adapter: (P348) . . . . . . . . . . . . . . . . . . . . . .5-28

P349 - Serial to RS485 adapter to an MC202: . . . . . . . . . . . . . .5-30

Motion Coordinator Technical Reference Manual

iii

P435 - Serial to Fibre-Optic Adapter . . . . . . . . . . . . . . . . . . 5-31

SYSTEM SETUP AND DIAGNOSTICS . . . . . . . . . . . . . . . . . 6-1

Preliminary Concepts: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

System Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Preliminary checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Checking Communications and System Configuration . . . . . . . 6-4

Input/Output Connections: . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Setting Servo Gains . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Proportional Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Integral gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Derivative gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-10

Output Velocity Gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Velocity Feed Forward Gain . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Diagnostic Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

PROGRAMMING . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

What is a program? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Iteration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Controller Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Identifiers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Expressions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Command Line Interface . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

TRIO BASIC

COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Motion and Axis Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Input / Output Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-45

Program Loops and Structures . . . . . . . . . . . . . . . . . . . . . . . . . 8-65

System Parameters and Commands . . . . . . . . . . . . . . . . . . . . . . 8-78

Process Parameters and Commands . . . . . . . . . . . . . . . . . . . . . 8-129

Mathematical Operations and Commands . . . . . . . . . . . . . . . . . . 8-133

Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-150

Axis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-152

PROGRAMMING EXAMPLES . . . . . . . . . . . . . . . . . . . . . 9-1

Example Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

iv

Trio Motion Technology

SUPPORT SOFTWARE . . . . . . . . . . . . . . . . . . . . . . . .10-1

Motion Perfect 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

System Requirements: . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

New Features for Motion Perfect 1 Users . . . . . . . . . . . . . . . .10-5

Connecting Motion Perfect to a controller . . . . . . . . . . . . . . . . . .10-6

Motion Perfect 2 Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

The Project Check Window . . . . . . . . . . . . . . . . . . . . . . . . .10-7

Project Check Options . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-8

The Motion Perfect Desktop . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12

Controller Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-13

Controller Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

Feature Enable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-15

Loading New System Software . . . . . . . . . . . . . . . . . . . . . . .10-17

Flashstick support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-19

Lock / Unlock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-20

Motion Perfect Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Axis Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-23

Oscilloscope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-26

Keypad Emulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-35

Table / VR Editor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-37

Jog Axes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-38

Digital IO Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-42

Analogue Input Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-44

Linking to External Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-45

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-47

Creating and Running a program . . . . . . . . . . . . . . . . . . . . . . . .10-52

The Motion Perfect Editor . . . . . . . . . . . . . . . . . . . . . . . . . .10-53

Editor Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-56

Program Debugger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-58

Running Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-61

Making programs run automatically . . . . . . . . . . . . . . . . . . . . . .10-62

Set Powerup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-62

Storing Programs in the Flash EPROM . . . . . . . . . . . . . . . . . . . . .10-63

Configuring The Motion Perfect 2 Desktop . . . . . . . . . . . . . . . . . .10-64

Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-64

Changing Comms Port Parameters . . . . . . . . . . . . . . . . . . . . .10-65

Editor Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-67

General Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-67

Saving the Desktop Layout . . . . . . . . . . . . . . . . . . . . . . . . . .10-68

Running Motion Perfect 2 Without a Controller . . . . . . . . . . . . . .10-69

v

Trio Motion Technology

MC Simulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-69

CAD2Motion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-72

DocMaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-73

Project Autoloader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-74

Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-75

Running the program . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-76

Script Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-77

Script File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-82

FIBRE-OPTIC NETWORK . . . . . . . . . . . . . . . . . . . . . . .11-1

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-3

Connection of Network . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-4

Network Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-6

Examples of network programming . . . . . . . . . . . . . . . . . . . .11-8

Network Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-12

USING THE TRIO

ACTIVEX CONTROL . . . . . . . . . . . . . . . . . . . . . . . . .12-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-3

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-3

Installation of the ActiveX Component . . . . . . . . . . . . . . . . . .12-3

Using the Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-3

Connection Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-4

Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-7

Motion Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-9

Process Control Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-18

Variable Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-19

Input / Output Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-22

General commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-28

Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-30

TrioPC status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-31

COMMUNICATIONS PROTOCOLS . . . . . . . . . . . . . . . . . . .13-1

MODBUS RTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-3

Initialisation and Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . .13-3

Modbus Technical Reference . . . . . . . . . . . . . . . . . . . . . . . .13-4

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-7

Profibus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-8

Installation and Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-8

vi

Trio Motion Technology

DeviceNet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-13

Installation and Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-13

DeviceNet Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-13

Connection Types Implemented . . . . . . . . . . . . . . . . . . . . . .13-14

DeviceNet Objects Implemented . . . . . . . . . . . . . . . . . . . . .13-14

MC Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-20

DeviceNet Status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-25

Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-26

Default IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-26

The Subnet Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-27

Connecting to the Trio Ethernet Daughter Board . . . . . . . . . . .13-28

REFERENCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

ATYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

AXISSTATUS / ERRORMASK . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4

CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Communications Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

Communications Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

MTYPE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

NETSTAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Data Formats and Floating-Point Operations . . . . . . . . . . . . . . . .1-8

Single-Precision Floating Point Format . . . . . . . . . . . . . . . . . .1-8

Product Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

CHAPTER

CHAPTER0INTRODUCTION

Motion Coordinator Technical Reference Manual

Introduction 1-3

Trio Motion Technology’s range of Motion Coordinator products are designed to

enable the control of industrial machines with a minimum of external compo-

nents. The products may be combined to build a control system capable of driv-

ing a multi-axis machine and its auxiliary equipment. The Motion Coordinator

system allows you to control up to 16 servo or stepper motors, Digital I/O and

additional equipment such as keypads and displays from a single master. Up to

fifteen masters can be networked together using the Trio fibre optic network

allowing up to 180 axes of control. The controller is programmed using the Trio

BASIC programming language. This may be used to build stand-alone programs or

commands can be sent from an external computer.

Typical System Configuration

The

Motion

Coordinator system is modular, allowing the user to tailor the controller

to their specific needs, but also allowingthe flexibility to incorporate new modules if

needs should change.

ENCODER V+ V- R 0v

54321

9876

ENCODER V+ V- R 0v

54321

9876

IO8

IO9

IO10

IO11

IO12

IO13

IO14

IO15

I0

I1

I2

I3

I4

I5

I6

I7

24v

0v

Trio

8

9

10

11

12

13

14

15

0

OKNET

0

1

STATUS

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

4

8

16

32

OFF

MS NS

PR

DR 10 11 12 13 14 15 24v Ov98

765432100v 24v

NODE

ADDRESS

CAN16 -I/O

Trio 0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

2

4

8

16

32

OFF

MS NS

PR

DR 10 11 12 13 14 15 24v Ov98

7654 32100v 24v

NODE

ADDRESS

CAN16 -I/O

Trio

7

4

1

-

8

5

2

0

9

6

3

.

Y

N

CLR

TrioMo tion Technology

PCforProgramming

OperatorInterface

MotionCoordinator

CANI/O

ServoDrive

PCforProgramming

ServoDrive

Motor

Motor

1-4 Introduction

Setup and Programming

Trio Motion Technology

Setup and Programming

To program the

Motion

Coordinator a PC is connected via an RS-232 or USB serial

link. The dedicated

Motion

Perfect program is normally used to provide a wide

range of programming facilities, on an IBM PC or 100% compatible microcomputer

running Windows.

Motion Perfect

Once connected to the

Motion

Coordinator, the user has direct access to

Trio

BASIC, which provides an easy, rapid way to develop control programs. All the

standard program constructs are provided; variables, loops, input/output, maths

and conditions. Extensions to this basic instruction set exist to permit a wide

variety of motion control facilities, such as single axis moves, synchronized multi

axis moves and unsynchronised multi axis moves as well as the control of the

digital I/O.

The

Motion

Coordinator range currently consists of the MC202, MC206, Euro 205X,

MC216 and MC224. These controllers feature multi-tasking BASIC. Multiple

Trio

BASIC programs can be constructed and run simultaneously to make programming

complex applications much easier.

Motion Coordinator Technical Reference Manual

Introduction 1-5

Products

Products

The range of Trio

Motion

Coordinator products covered by this manual:

Motion Coordinator Master Controllers

Product

Code Name Description

P165 MC202 Compact, low cost DIN-rail mounting module features 1 1/2

servo or 2 stepper axes. 4 Opto-isolated Inputs and 4 Opto-

isolated I/O channels are built in. Multi-tasking Trio BASIC. I/O

expansion is via CAN bus.

P135 MC206 Low cost, high performance DIN-rail mounting controller for 1-6

axes. 8 Opto-isolated Inputs and 8 Opto-isolated Input/Output

channels,1 Opto-isolated analogue input, USB and memory stick

socket are built in. Multi-tasking Trio BASIC. I/O expansion is

via CAN bus.

P150 Euro 205 For OEM applications, Trio offer a 3U Eurocard format controller

featuring 4 onboard axes plus the option for a further axis via a

standard Trio daughter board. 16 Opto-isolated Inputs and 8

Opto-isolated Output channels are built in. Multi-tasking Trio

BASIC. I/O expansion is via CAN bus.

P140 MC216 Flexible high performance master controller for 1-16 axes. 8

Opto-isolated Inputs and 8 Opto-isolated Input/Output channels

are built in. Multi-tasking Trio BASIC. I/O expansion is via CAN

bus.

P170 MC224 Flexible high performance master controller for 1-24 axes. 8

Opto-isolated Inputs and 8 Opto-isolated Input/Output

channels,2 Opto-isolated analogue inputs, USB and memory

stick socket are built in. Multi-tasking Trio BASIC. I/O

expansion is via CAN bus.

1-6 Introduction

Products

Trio Motion Technology

Daughter Boards

The Daughter Board concept

is a one of the key features

which give the

Motion

Coordinator system enormous

flexibility in its configuration.

The Daughter Boards provide

the interface to many types

of Servo or Stepper Axes, plus

a number of advanced

communications options as well.

There are 13 types of daughter boards currently available:

Product

Code: Name Description

P200 Servo Encoder +/- 10v Output, Differential Encoder Input

plus Hardware Registration Input

The servo encoder daughter board provides the inter-

face to a DC or Brushless servo motor fitted with an

encoder or encoder emulation.

P210 Servo Resolver +/- 10v Output, Resolver Input

plus Hardware Registration Input

The servo resolver daughter board provides the inter-

face to a DC or Brushless servo motor fitted with a

resolver. The resolver port provides absolute position

feedback within one motor turn.

P220 Reference

Encoder Differential Encoder Input

plus Hardware Registration Input

The encoder daughter board provides an encoder input

without any servo feedback facility for measurement,

registration and synchronization functions on convey-

ors, drums, flying shears, etc.

P230 Stepper Open-collector Step, Direction, Boost and Enable out-

puts

The stepper daughter board generates pulses to drive

an external stepper motor amplifier. Single step, half

step and micro-stepping drives can be used with the

board.

1-7 Introduction

Products

Trio Motion Technology

P240 Stepper

Encoder Open-collector Step, Direction, Boost and Enable out-

puts plus Differential Encoder Input.

The stepper daughter board with position verification

has all the features of the simpler stepper daughter

board. Position verification is added to a stepper axis

by providing encoder feedback to check the position of

the motor.

P242 Hardware

Pswitch Differential Encoder Input

plus Hardware Position Switch Outputs

The hardware PSWITCH daughter board allows 4 open-

collector outputs to be switched ON and OFF at pro-

grammed positions. This function is similar to the

PWITCH command which is implemented in the system

software and allows outputs to be switched ON and OFF

over defined position sectors. The Hardware PSWITCH

daughter board performs the position comparison in

electronic hardware on the daughter board. This allows

the pulses generated to be very accurately timed.

P260 Analogue Out-

put +/- 10v Output with direct DAC control

The voltage output daughter board provides a 12 bit +/-

10v voltage output for driving inverters and other

devices. The board is a simplified servo daughter board

and the connections are similar.

P270 SSI Absolute

Servo +/- 10v Output, Differential Encoder Input

plus Hardware Registration Input

The servo resolver daughter board provides the inter-

face to a DC or Brushless servo motor fitted with an

absolute encoder fitted with a Synchronous Serial Inter-

face (SSI).

P280 Differential

Stepper Differential Line Driver outputs for Step, Direction,

Boost and Enable, plus Hardware Registration Input

The differential stepper daughter board is a stepper

daughter board with the output signals provided as dif-

ferential 5 volt signals on a 15 way 'D' connector. The

daughter board does not feature an encoder port for

position verification, but does have a registration input

to allow for capture of the number of step pulses when

a registration signals arrives.

Product

Code: Name Description

1-8 Introduction

Products

Trio Motion Technology

*

(Available for use with MC206 and MC224 only)

Custom Daughter Boards

Trio can produce custom daughter boards for specific customer applications where

required.

P290 CAN Digital Link to CANBus drives

The combination of the motherboard CAN channel and

the ability to add up to 4 CAN daughter boards allows

the MC216 to potentially control up to 5 CAN channels.

P291* SERCOS Digital Link to SERCOS drives

The SERCOS daughter board provids digital control to

appropriate servo drives via a Fibre Optic loop. Up to 8

axes can be connected to each P291, which allows the

MC224 to control up to 24 axes.

P292 SLM (Drivelink) Digital Link to SLM drives

The SLM daughter board is aimed at providing digital

control channels for servo drives utilising the SLM proto-

col.

P295 USB Interface Universal Serial bus interface for high-speed PC

communications

The USB daughter board provides a very high speed

interface between the motion coordinator and a host

PC fitted with a USB port. Support for this high speed

interface is included in Trio's MotionPerfect 2 applica-

tion and software libraries are in development to allow

developers to support the interface within their own

programs.

P296* Ethernet Ethernet LAN Interface

The Ethernet daughter board enables the Motion Coor-

dinator to be connected to a local factory or office net-

work. Supports TCP/IP using the 10Base-T physical

layer.

P297 Profibus Profibus Fieldbus Interface

With the Profibus Daughter Board and appropriate soft-

ware on the Motion Coordinator, it is possible to con-

nect to external devices using the Profibus protocol.

Product

Code: Name Description

1-9 Introduction

Products

Trio Motion Technology

I/O Expansion options

MC216 Shown with P300 Axis Expander

Prod.

Code Name Description

P315 CAN 16 IO DIN Rail mounted 24v I/O expander module pro-

vides 16 opto-isolated channels each of which may

be used as an Input or an Output.

P325 CAN Analog Inputs DIN Rail mounted +/- 10v Analog Input module pro-

vides 8 opto-isolated channels.

P300 Axis Expander Expansion module provides housing for up to 4

additional axisdaughter boards. Up to 3 connect to

the MC216

P315 - CAN-16 I/O P325 - CAN-8 Analog Inputs

1-10 Introduction

Products

Trio Motion Technology

Operator Interfaces

Name Name Description

P502 Mini-Membrane

Keypad Compact operator keypad/display

P503 Membrane Keypad High performance general purpose operator key-

pad/display

This manual suits for next models

4

Table of contents

Other Trio Controllers manuals

Trio

Trio MC508 Instruction Manual

Trio

Trio MC664 User manual

Trio

Trio MC664 Instruction Manual

Trio

Trio MC405 Instruction Manual

Trio

Trio MC403-X User manual

Trio

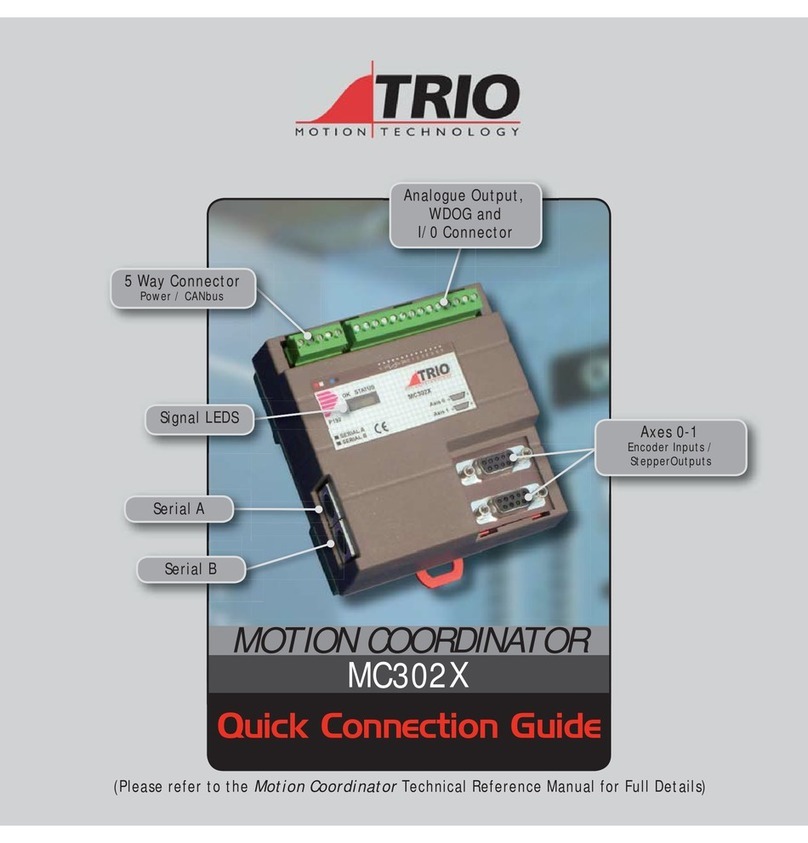

Trio MC302X Instruction Manual

Trio

Trio MC508 P848 User manual

Trio

Trio MC302X Product manual

Trio

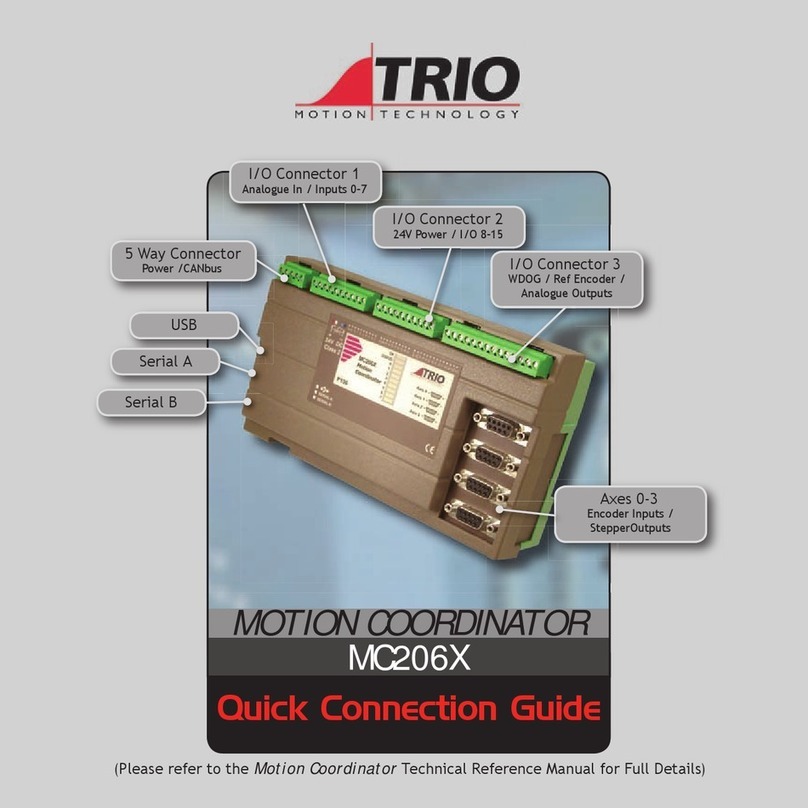

Trio MC206X Instruction Manual

Trio

Trio Flex-6 Nano P601 User manual