Trio SafeTcheck Pro Logger II User manual

Pro Logger II & NaNto

oPerator's MaNuaL

SAFETCHECK OPERATOR'S MANUAL

2Introduction

2

ABOUT THE SAFETCHECK

PRO LOGGER II AND NANTO

ASafeTcheck ensures that mains powered portable appliances are compliant with the current Australian and New Zealand

Standard AS/NZS 3760 (In–service safety inspection and testing of electrical equipment).

ASafeTcheck is unique in that ensures an appliance is correctly connected prior to running a test sequence.

Most, if not all other testers, will pass an appliance even if it is not connected in accordance with the standard.

With a SafeTcheck , testing Electrical Safety of Appliances is simple, fast, accurate, thorough and safe.

You can test the safety of Class 1 (earthed) appliances, Class 2 (double insulated) appliances, 3 Phase appliances,

Fixed and Portable RCD's and Extension Leads in accordance with the standard, simply and efficiently. There is no

interpretation, no ambiguity, just a simple PASS or FAIL.

N1913N2068

A SafeTcheck is an electrical Portable Appliance Tester

(PAT), designed and manufactured in Australia. It has

been designed to comply with Australian Standards

AS3100 & AS3760 to maximise user safety.

TRIO TEST & MEASUREMENT

3

Copyright 2015 all rights reserved

General Information

Testing of appliances with a SafeTcheck 04

Frequency of electrical safety testing 05

Function and basic technical specification 06

Available options and accessories 08

Preparation of the appliance prior to safety testing 09

Operating a SafeTcheck

Operating a SafeTcheck 10

Safety testing earthed appliances 11

Safety testing double insulated appliances 13

Safety testing mains leads 15

Safety testing other appliances (Other Appliance menu) 16

Run testing (Leakage current test) 18

Run testing earthed (class 1) appliances 19

Run testing double insulated (class 2) appliances 20

Run testing 3 Phase appliances (Option – Pro Logger II only) 21

RCD Tester 22

High current earth test (Option - Pro Logger II only) 24

Battery Power (Standard on Nanto; Option on Pro Logger II) 25

Utilities Menu (F2 key) 26

Info display (F1 key) 29

Other Information

Data Logger operating instructions 30

Scanner Setup 34

Appendix A: Important Information regarding the Probe & Stainless Steel Cloak 35

For more information regarding the electrical testing of Portable Electrical Appliances such as Frequently Asked Questions

(FAQs), information relating to the standard AS/NZS 3760, more options for the SafeTcheck, the most recent updates in relation

to the SafeTcheck and for general information relating to Portable Appliance Testing go to our Appliance Testing website:

www.safetcheck.com.au

For all other general Test & Measurement Instrumentation go to our TRIO Test & Measurement website:

www.triotest.com.au

Contents

SAFETCHECK OPERATOR'S MANUAL

4General Information

A SafeTcheck will test most 240V 50Hz single phase class

1 and 2 electrical appliances and extension leads to comply

with the current electrical safety standard AS/NZS 3760. It

will also test, RCDs (both fixed and portable) and 3 Phase

appliances (option for Pro logger II only). Appliances with

characteristics which may require modified test parameters

(in accordance with the standard) may be found in the

OTHER APPLIANCE menu.

If you experience difficulties or doubts in testing certain

appliances please contact TRIO Test & Measurement.

SafeTchecks are designed & manufactured in Australia to

comply with Australian Standards AS3100 & AS3760 to

maximise user safety.

TRIO Test & Measurement

Sales, Technical & Service Enquiries

Phone 1300 852 402

Fax 1300 853 409

safety@triotest.com.au

www.SafeTcheck.com.au

General Test & Measurement enquiries

Phone 1300 853 407

sales@triotest.com.au

www.triotest.com.au

The testing of appliances with a SafeTcheck

SafeTcheck Models

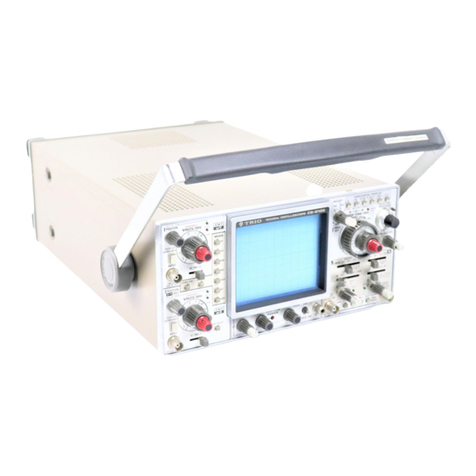

Pro Logger II Nanto

5

Copyright 2015 all rights reserved

Frequency of electrical safety testing

Guide only

The minimum recommended frequency of safety testing of electrical equipment is specified in Australian Standard for in service

testing AS/NZS 3760.

Type of environment in which

equipment is used

Earthed

Appliance

Double Insulated

Appliance

Extension

Cords

Factories, shops & places of work manufacturing,

repair, maintenance or construction

6 months 12 months 6 months

Office environment where equipment is not subject

to constant flexing of the supply cord

5 years 5 years 12 months

Other commercial environments, e.g. tea rooms, office,

kitchens, health care studios, with no protection

12 months 12 months 6 months

Construction and Demolition sites 3 months 3 months 3 months

Hire equipment Before each hire Before each hire Before each hire

Note: Some organisations may alter these periods based on a documented risk assessment, undertaken in accordance

with the process specified in AS/NZS 4360 (see AS/NZS 3760 for details).

SAFETCHECK OPERATOR'S MANUAL

6General Information

Mains Power Outlet Check (may be factory disabled for

some situations)

The mains power outlet supplying a SafeTcheck is checked

for the existence of an Earth, Active-Neutral transposition and

Mains voltage tolerance.

Earthed appliances are tested for:

Note: If the appliance requires mains power to energise

its On/Off switch (and the switch must be “on” to

complete the mains electrical circuit), a SafeTcheck can

conduct a Current Leakage Test (Run Test) to ensure

Leakage Current is <= 5mA.

Double insulated appliances are tested for:

(unique to a SafeTcheck and an alternative

to Probe Mode) ensures the stainless steel cloak is correctly

in place to provide a return path for any leakage current

during the insulation resistance test

Note: If the appliance requires mains power to energise

its On/Off switch (and the switch must be “on” to

complete the mains electrical circuit), a SafeTcheck can

conduct a Current Leakage Test (Run Test) to ensure

Leakage Current is <= 1mA.

Extension/Mains leads are tested for:

Test duration

Electrical stress test parameters

Run test (leakage current test)

earth – compliant with AS3100)

RCD Tester conducts a Lead Test and then an RCD Test

(measured at 0° and 180° crossing)

3 Phase Appliance Testing (when fitted – Pro Logger II only)

available)

Note: *0.2, 10 & 25A test currents are available with

the High Current Earth Bond Option (Pro Logger II only).

Minimum Order Quantities (MOQ) apply for this option.

Function and basic technical specification

ASafeTcheck has been designed and manufactured

to comply with Australian Standards AS3100 & AS3760

to maximise user safety

TRIO TEST & MEASUREMENT

7

Copyright 2015 all rights reserved

Display LCD to indicate:

LEDs to indicate:

Run Test sockets)

Data Logging

- Logging can be switched on/off

- Individual Fields can be switched on/off

SafeTcheck's

memory or in real time via 'Data Dump'

to the USB port (real time is for use with 3rd party software)

accidental loss of data (i.e. no over writing of stored data)

Power requirements

240V AC +/–10% @ 50Hz (115V AC model available)

Battery power standard on the Nanto and an option on the

Pro Logger II – see section Battery Power

The mains power outlet supplying the SafeTcheck is checked

for (Mains Power Outlet Check):

Test inlets

standard 240V Plug on the Pro Logger II only), protected

from accidental application of 240V 50Hz mains voltage

indicate active Test Socket

Operating instructions

Warranty

24 months warranty against faulty workmanship and parts

(Batteries are not included in this warranty).

Lifetime warranty available – conditions apply (check online

at www.SafeTcheck.com.au).

Lifetime warranty

Check online at www.SafeTcheck.com.au for a lifetime

Calibration period

Recommended every 12 months (or 24 months with a

verification at alternate 12 months – contact TRIO for details)

Repairs and calibration (Cradle to Grave care)

SafeTcheck PATs can only be calibrated (with adjustment)

by TRIO Test & Measurement Service Centres. Continued

calibration at a TRIO Service Centre ensures a Lifetime

Warranty.

We recommend that a SafeTcheck is returned to a

TRIO Test & Measurement Service Centre for repair and/

or calibration. In doing so you are assured that any recent

enhancements to the Hardware & Firmware, where applicable

to your SafeTcheck,will be included in the calibration

and/or repair.

Note 1: Tolerance on all stated values is ±5% unless

otherwise stated.

Note 2: TRIO Test & Measurement reserves the right to

change specifications at any time without notice.

Function and basic technical specification

Contact TRIO Test & Measurement

or go to www.SafeTcheck.com.au

for more detail

SAFETCHECK OPERATOR'S MANUAL

8General Information

We have developed options and have a range of accessories to complement the SafeTcheck

Accessories

3 Phase Appliance Tester (20 & 32A Sockets - Pro Logger II only)

(Standard on Nanto, option on the Pro Logger II)

Batteries and Batter Charger (suitable for the Nanto only)

Carry Case & Accessories for the Nanto only

Stainless steel cloak (350 x 600mm)

Figure 8 & Clover Leaf to IEC Mains adaptors

Large 'suitcase' style carry cases

Scanner and/or memory upgrade to 2000 records

Data & Asset Management Software

Tag Printers (mains or battery)

Test tags (with optional company logos & barcodes)

Barcoded item stickers, tested labels and danger tags

Removable lid (Pro Logger II with Pelican Case only)

Note: *Pro Logger II only. Minimum quantities apply for

these options

Available options and accessories

For more information please

contact TRIO Test & Measurement

on 1300 852 402 or visit

www.SafeTcheck.com.au

9

Copyright 2015 all rights reserved TRIO TEST & MEASUREMENTS

General visual inspection

1 Ensure the appliance to be safety tested has no obvious

mechanical faults and is free from external damage.

2 Inspect the mains lead for any damage, defects or loose

terminals

in

the

accessories,

connectors,

plugs or outlet

sockets. Common faults encountered:

a) Frayed, cracked or otherwise damaged mains lead.

b) Exposed conductors and/or covered by insulation tape.

c) Abrasions in the outside insulation jacket.

d) Mains lead anchorage at plug or appliance entry.

3 Check that any controls, alarms and replaceable protective

devices accessible to the user, are of correct rating and in

good working order.

4 Inspect all switches and speed controls for mechanical

operation; ensure switches and controls are clear of any

obstruction, e.g. filings, swarf, metal particles, grease, etc.

5 Confirm all identity tags/labels etc. pertaining to the

frequency of safety testing are correctly attached and

records of all test/inspections are kept to ensure the safety

integrity and history of the appliance.

6 Unroll extension leads and inspect as above.

Identify the type of appliance to be tested

Examine the appliance to be tested and identify whether the

appliance is an earthed appliance, a double insulated appliance

or an extension cord.

Earthed appliances will always have an earth pin on their plug,

and may have exposed metal components.

Double insulated appliances may be identified by the double

insulation symbol, and/or by the absence of an earth pin on

a moulded socket (if not misssing or deliberately removed).

Note 1: Many double insulated tools are colour coded blue.

Note 2: If any doubt exists about the Class of an appliance

(Class I or II), the appliance should be tested as an earthed

appliance first (see also OTHER APPLIANCE menu).

Preparation of an earthed appliance to be safety tested

1 Switch any/all switches ‘ON’.

2 Set any speed control or thermostat to ‘FULL ON’

(Maximum speed).

3 Preparation for earthed appliance to be safety tested is now

complete and may be connected to the SafeTcheck.

(see Safety Testing Earthed Appliances)

Preparation of a double insulated appliance to

be safety tested

1 Switch any or all switches to the ‘ON’ position.

2 Set any speed control or thermostat to ‘FULL ON’

(Maximum speed/temperature).

3 If not in Probe Mode, preparation for a double insulated

appliance to be safety tested requires the appliance to

be wrapped in a stainless steel cloak taking care to make

contact with all metal components and the exterior of the

appliance where hand contact is normally possible.

4 The double insulated appliance is now ready to be safety

tested and may be connected to the SafeTcheck.

(see Safety Testing Double Insulated Appliances)

Note: The above description regarding the inspection

and testing of electrical appliances is a guide only.

Please refer also to the current standard AS/NZS 3760.

WARNING

Upon completion of a safety test and subsequent

removal of test lead and/or stainless steel cloak, please

ensure all switches, speed and thermostat controls are

returned to their ‘OFF’ or minimum position.

Preparation of the appliance prior to safety testing

SAFETCHECK OPERATOR'S MANUAL

10 Operating Instructions

Place the SafeTcheck on a convenient non–conductive

working surface. Insert the mains plug into a correctly wired and

earthed mains power outlet. The following sequence will occur:

1 Thereareaseriesofshortbeeps,apauseandasingle shortbeep;

2 The Start Prompt appears on the Liquid Crystal Display (LCD);

(If the Data Logging function is turned on then the Time

and Date and Memory used is displayed. Pressing reset

after each of these screens will display the Start Prompt). To

3 The TEST and FAIL LEDs flash momentarily.

The SafeTcheck is now ready to perform Appliance

Safety Testing.

ANY DEPARTURE FROM THESE CONDITIONS MAY

MEAN THE SAFETCHECK HAS A FAULT AND SHOULD

BE RETURNED TO A TRIO TEST & MEASUREMENT

SERVICE CENTRE FOR SERVICE.

(F1 & F2)

INFO DISPLAY (F1)

UTILITIES MENU (F2)

LCD

DISPL AY

APPLIANCE

SELECTION

START TEST

RESET

(RUN TEST) COMPLIES

WITH AS 3100

INSULATION

ACCESSORY

WELL

(3 PHASE OPTION)

ONLY

STANDARD

ONLY – NANTO

COMES WITH

ADAPTOR CABLE

STANDARD IEC

COMPUTER I/F

USB PORT

SCANNER (USB PORT)

MAINS POWER

Note: a Test Socket's

LED will flash to indicate

which socket is active

Note 1: If a message appears on the LCD indicating an

Active/Neutral reversal or an Earth fault then there is a

problem with the power outlet supplying the SafeTcheck.

At this point the tester will cease to function, preventing

any appliance testing being performed under fault

conditions. Either the power outlet fault must be corrected

prior to proceeding or an alternate power outlet used to

power the SafeTcheck.

*Note 2: In some earlier models of the Pro Logger II

with dual USB ports, when using the Scanner together

with the Keyboard, connect the Keyboard to the Scanner’s

“Keyboard Wedge Cable” via the PS/2 connection.

Connecting the keyboard and scanner via separate USB

ports will occasionally cause the keyboard to send spurious

characters to the Pro Logger II while scanning barcodes.

Operating a SafeTcheck

(shows Pro Logger II layout only – Nanto features are similar)

TRIO TEST & MEASUREMENT

11

Copyright 2015 all rights reserved

1 Ensure the SafeTcheck is in the ready to test mode

i.e. the Start Prompt appears on the LCD Display.

2 Plug the appliance to be tested into the socket labelled

INSULATION RESISTANCE provided on the front panel

of the SafeTcheck. The appliance should be connected

directly and not via an extension lead.

3 Connect the Return Lead to the unit via the Earth Return

Socket

4 Connect the Return Lead to a convenient metal (conductive)

point of the appliance under test.

If any earthed appliance has one or more metal components

which are possibly not connected together, the overall test

must be repeated with the Return Lead connected to each

metal component in turn.

5 Switch the appliance to be tested ‘ON’

Note: Any or all switches must be "on" to ensure testing

of the appliance's complete electrical circuit.

6 If the appliance to be tested has a variable speed or

thermostat control fitted, turn the control to its highest

setting, this will connect Active/Neutral direct to the internal

windings.

7 Select EARTHED APPLIANCE. The SafeTcheck is now

ready to test the appliance.

5 Switch the appliance to be t

ested ‘ON’

Note: If Data Logging is switched on then additional

information will be requested. See section entitled

”Data Logging”

The green indicator alongside "Start" will now be flashing.

5 Switch the appliance to be t

ested ‘ON’

Note: During the test cycle the user should apply stress to

the supply lead and plug in order to detect any intermittent

faults. This is a ‘real world’ dynamic test.

8 Test results will be displayed on the LCD along with audible

tones and flashing LEDs.

a) Pass – 'Thumbs Up' and PASS indication on LCD

along side "Start".

b) Fail – 'Thumbs Down' and/or LCD Prompt indicating

the most probable reason for failure with:

The measured value (if enabled), a continuous BEEP

and a RED indicator flashing alongside "Reset".

Note 1: A FAIL indicating “poor continuity” denotes lack

of a circuit path between the Active and Neutral of the

appliance. If the appliance switch is on and this error

occurs then go to the RUN TEST.

WARNING

To avoid uncertain results when testing an earthed

appliance, ensure that:

1 The earth clip is securely attached to the

metal frame.

2 The appliance under test has been disconnected

from all other equipment.

3 The test is conducted on an insulated or

(non metallic) benchtop.

Note 2: For a FAILED earthed appliance known to be

fitted with surge protection i.e. metal oxide varistors

(MOVs), test again using Class 2 (250V) test, see

OTHER APPLIANCES.

Note 3: For appliances with no class identification, no

accessible earth and having 3 pins on the plug, a standard

earthed appliance test may fail, see OTHER APPLIANCE

menu.

Evaluation of in–service testing results for

erthed appliances

Evaluation of in–service testing results for earthed appliances

Where the SafeTcheck identifies an appliance which fails

to comply with the test criteria, the equipment shall be:

1 Withdrawn from service immediately and have a label

attached to it warning against further use.

2 Repaired by the appropriately qualified

person and retested after repair.

3 Refit test identity tags/labels etc. and log

test in safety history records.

WARNING

Upon completion of a safety test and subsequent removal

of test lead and/or stainless steel cloak, please ensure all

switches, speed or thermostat controls are returned to

their ‘OFF’ or minimum position.

Safety testing earthed appliances

SAFETCHECK OPERATOR'S MANUAL

12 Operating Instructions

SWITCH APPLIANCE ON AND

SET THERMOSTAT OR SPEED

CONTROL TO MAXIMUM

RETURN LEAD

AND CLAMP

(CLASS I & II)

SELECT

EARTHED

APPLIANCE

TEST

Safety testing earthed appliances

TRIO TEST & MEASUREMENT

13

Copyright 2015 all rights reserved

SELECT DOUBLE INSULATED

APPLIANCE TEST

1 Ensure the SafeTcheck is in the ready to test mode

i.e. the Start Prompt appears on the LCD Display.

2 Plug the double insulated appliance to be tested

into the socket labelled INSULATION RESISTANCE

provided on the front panel of the SafeTcheck.

Note: The appliance should be plugged in directly,

and not via extension leads, unless instructed to do so

3 Switch the appliance to be tested, 'ON'

5 Switch the appliance to be tested ‘ON’

Note: Any or all switches must be "on" to ensure

testing of the appliance's complete electrical circuit.

4 If the appliance to be tested has a variable speed or

thermostat control fitted, turn the control to its highest

setting, this will connect Active/Neutral direct to the internal

circuit.

5 if in mode, wrap the appliance in the

stainless steel cloak, taking care to make contact with all

metal components and the exterior of the appliance where

human hand contact is normally possible.

If the SafeTcheck is set to Probe Mode then see section

entitled Probe Mode at the end of this section

The stainless steel cloak may also be woven metal cloth

mesh, conductive braid, aluminium foil, or other suitable

flexible conductor with low resistance.

Note: The wrapped appliance should be on an

insulated bench to avoid earthing the measurement

circuit in the SafeTcheck.

6 Connect the Clamp of the Return Lead to the stainless

steel cloak as shown. ensures the

Clamp is connected to the stainless steel cloak.

7 Select DOUBLE INSULATED.

The SafeTcheck is now ready to test the appliance.

5 Switch the appliance to be t

ested ‘ON’

Note: If Data Logging is switched on

then additional information will be requested.

See section entitled ”Data Logging”

The green indicator alongside "Start" will now be flashing.

8 Switch the appliance to be tested ‘ON’

Note: During the test cycle the user may apply stress to

the supply lead and plug in order to detect any intermittent

faults

RETURN LEAD AND

CLAMP OR PROBE

Safety testing double insulated appliances

Note: Use the probe to make contact with

metal exposed parts and insulated surfaces.

See section entitled "Utilities Menu" for more

information about the Probe Mode

Note: Switch appliance on & Set appliance thermostat

or speed control to maximum. See also Appedix A for

details relating to using the Stainless Steel Cloak.

STAINLESS

OR PROBE

ON SURFACE

SAFETCHECK OPERATOR'S MANUAL

14 Operating Instructions

9 During the test cycle the SafeTcheck's

will check that the stainless steel cloak and return lead are

correctly connected. This will ensure that the correct test

environment is present to measure the insulation resistance

of a double insulated appliance. is a unique

feature of the SafeTcheck Portable Appliance Testers.

10 If the verification test passes the SafeTcheck will continue

with the double insulated appliance test.

If the verification test fails then it maybe for one or more of

the following reasons:

a) has found the double insulated

appliance is not correctly wrapped or connected to the

return lead for double insulated appliances.

b) The assumed double insulated appliance is in fact an

earthed appliance.

c) The double insulated appliance is connected to the

SafeTcheck via a non–compliant extension cord.

d) The appliance is earthed via another path

such as a metal earthed bench.

e) Both active (A) and neutral (N) leads are open circuited

in the appliance e.g. failure to turn ‘ON’ appliance

switch(es).

f) The resistance of the stainless steel cloak around the

appliance is too high.

g) The appliance has low capacitive coupling between the

external surface (the stainless steel cloak) and the internal

electrical circuit. Place some of the mains cable under the

Cloak to overcome this problem. This may apply to some

appliances with minimum internal circuitry e.g. a plastic

bedlamp, a vacuum cleaner where the motor is separated

by a relatively large distance from the case, or a mobile

phone charger.

11 Test results will be displayed on the LCD along with audible

tones and flashing LEDs.

a) Pass – C'Thumbs Up' and PASS indication on LCD

along side "Start".

b) Fail –

C

'Thumbs Down' and/or LCD Prompt indicating

the most probable reason for failure with: The measured

value (if enabled), a continuous BEEP and a RED indicator

flashing along side "Reset".

A FAIL indicating “poor continuity” denotes lack of

a circuit path between the Active and Neutral of the

appliance. If the appliance switch is on and this error

occurs then go to the RUN TEST.

For a FAILED double insulated appliance known to be

fitted with surge protection i.e. metal oxide varistors

(MOVs), test again using Class 2 (250V) test, see

OTHER APPLIANCE menu.

For appliances with no class identification, no accessible

earth and having 3 pins on the plug, a standard double

insulated test may fail, see OTHER APPLIANCE menu.

PROBE MODE

If for some reason it is not practical to use the stainless

steel cloak, then Probe Mode may be used. In

Probe Mode a test may proceed without a return lead

connected. This will ensure a 'Pass" for the test but

a valid test will not have been performed. To

bypass , switch to Probe Mode, see

OTHER APPLIANCE menu.

Evaluation of in–service testing results

Where the SafeTcheck identifies an appliance/tool which fails

to comply with the test criteria the equipment shall be:

1 Withdrawn from service immediately and have a label

attached to it warning against further use.

2 Repaired by the appropriately qualified person and retested

after repair.

3 Refit test identity tags/labels etc. and log test in Safety

History records.

WARNING

Upon completion of a safety test and subsequent removal

of test lead and/or stainless steel cloak, please ensure all

switches, speed or thermostat controls are returned to their

‘OFF’ or minimum position.

Note: may be turned off by switching to

Probe Mode. See the UTILITIES MENU.

Safety testing double insulated appliances

TRIO TEST & MEASUREMENT

15

Copyright 2015 all rights reserved

1 Plug the extension lead into the plug and socket labelled

LEADS provided on the front panel of the SafeTcheck. An

adaptor lead (IEC to Aust. plug) is provided for the Nanto.

2 Select LEADS. The SafeTcheck is now ready to test the

appliance. The green indicator alongside "Start" will now be

flashing.

Note 1: The appliance should be on an insulated

bench to avoid earthing the measurement circuit in the

SafeTcheck.

Note 2: If Data Logging is switched on then additional

information will be requested. See section entitled ”

Data Logging”

Note 3: During the test cycle the user may apply stress

to the supply lead and plug in order to detect any

intermittent faults

3 Test results will be displayed on the LCD along with audible

tones and flashing LEDs.

a) Pass – C'Thumbs Up' and PASS indication on LCD

side "Start".

b) Fail –

C

'Thumbs Down' and/or LCD Prompt indicating

the most probable reason for failure with: The measured

value (if enabled), a continuous BEEP and a RED indicator

flashing along side "Reset".

SELECT

LEADS

TEST

Note 1: If the extension lead has a fixed socket (as in

extension reels), this must be connected to the fixed test

plug on the SafeTcheck with a short TEST extension lead

of rated voltage and current, which has been previously

tested and verified SAFE. Normally, extension leads must

be tested individually and not cascaded.

Note 2: If EPODs are fitted with surge protection i.e.

metal oxide varistors (MOVs), they may fail the LEADS

test. If so, test again using EPOD (250V) test, see

OTHER APPLIANCES.

Note 3: Each socket of the EPOD must be tested in turn.

Note 4: Long extension lead may fail if it is left coiled. Be

sure to uncoil leads prior to testing. This must be done to

visually inspect the lead in any case.

Note 5: Additional Two (2) Wire Lead Test

Many modern appliances use a two wire mains power

lead with a figure 8 style socket i.e. no earth conductor.

The SafeTcheck’S Lead Test tests this style lead as a

Class 2 appliance (requires a Figure 8 adaptor; a Clover

Leaf adaptor is also available). The SafeTcheck will

conduct an Insulation Resistance (IR) Test if the lead is

found to have no earth (requires confirmation by the user).

The IR is measured between the inner mains conductors

and the SafeTcheck’S Cloak which should be wrapped

around the length of the lead or touched with the Probe

over its length.

For the Pro Logger II this feature is available on all testers

with Firmware Version V4.64 and above

Lead under test EPOD under test

Safety testing mains leads

SAFETCHECK OPERATOR'S MANUAL

16 Operating Instructions

The SafeTcheck is capable of testing many electrical

appliances with unusual characteristics. The Other Appliance

menu is used to select the test suitable for any of these

appliances. The user may scroll though the list by using the

F1 and F2 keys.

1 Appliances such as those fitted with surge protection

or MOVs (Metal Oxide Varistors) may be tested at 250V

(instead of 500V) by selecting one of the following:

2 Appliances requiring the mains voltage to be applied to

activate the On/Off switch, shall have their leakage current

checked by selecting one of the following:

(see also Run testing)

3 An earth continuity test may be conducted by selecting:

SELECT

OTHER

APPLIANCE

4 Appliances employing Mineral Insulated Metal Sheath

(MIMS) such as stoves and electric jugs may be tested

using a run test by selecting:

5 As for appliances in 1 above EPODs with surge protection

may be tested at 250V by selecting:

6 RCDs rated at 10mA, 30mA either portable or fixed

may be tested by selecting one of the following:

7 Appliances employing a PIEZO starter such as the starter

on a portable gas stove may be tested by performing a:

Safety testing other appliances (OTHER APPLIANCE menu)

TRIO TEST & MEASUREMENT

17

Copyright 2015 all rights reserved

8 Appliances connected to the mains via a 3 pin plug with

no Double Insulated (Class 2) symbol visible, should be

considered Earthed Appliances (Class 1), however, with

some appliances of this kind, the earth conductor provides

not only a degree of electrical safety but also a path to

conduct EMI currents, to reduce noise. This EMI current

may cause an appliance to fail due to, what the

Pro Logger sees, as excessive leakage. Also, with some

other appliances, there is simply no practical way of

finding a connection to the Earth Conductor i.e. it has

no exposed earthed metal parts.

The first phase of this test, while running the appliance,

looks for 1mA of leakage current between the Pro Logger’s

Cloak and the appliance’s case i.e. a standard Double

Insulated Run Test. If the Pro Logger measures more

than this, it will try again with an increased 5mA threshold

(because the appliance is Earthed, up to 5mA of Leakage

Current is permissible).

The person conducting the test will be warned that the

1mA threshold has been exceeded and that a 5mA test will

be conducted. Any more than 5mA of leakage current will

cause the test to fail.

To test these appliances use:

9 Where a Class I earthed appliance requires a longer than

normal run time (approximately 2 minutes), the following

test may be used:

†

10 For a 3 phase appliance Run Test, select:

Note 1: New tests may be added to the Other Appliance

menu from time–to–time. For details regarding upgrades

contact TRIO.

*Note 2: The 3 Phase Run Test is an option for the

Pro Logger II (see also Run testing 3 Phase appliances)

†Note 3: Available only on Pro Logger II's with firmware

version 4.04 or later.

WARNING

This test does not look for the presence of an Earth

Conductor. It should only be used if the normal Earthed

Appliance Insulation Resistance Test has continually failed.

Safety testing other appliances (OTHER APPLIANCE menu)

SAFETCHECK OPERATOR'S MANUAL

18 Operating Instructions

Overview

The Run Test is primarily for performing safety tests on

appliances that require a mains voltage applied to operate

their mains switch (on/off switch). In these cases the Insulation

Test will fail due to poor continuity though the mains switch or

associated circuitry (speed controls, remote controls, etc)

Run testing (Leakage current tests)

ABOUT THE SafeTcheck

PRO LOGGER II AND NANTO

TRIO Test & Measurement recommends that the

following Run tests are used only if the insulation testing

of an appliance fails or is unsuitable for that type of

appliance. Run tests apply the mains voltage (240V) to

the appliance under test, exposing the user to the risk of

personal injury (e.g. electric shock or electrocution).

Remember, until proven otherwise the appliance under

test should be considered unsafe for use.

TRIO TEST & MEASUREMENT

19

Copyright 2015 all rights reserved

1 Ensure the appliance is switched off.

2 Plug the appliance into the separate Run Test socket.

3 Connect the return lead to the SafeTcheck via the

Earth Return Socket.

4 Connect the Clamp of the Return Lead to a convenient

earthed metal point on the appliance under test.

WARNING

Upon completion of a safety test and subsequent

removal of test lead, please ensure all switches, speed

or thermostat controls are returned to their ‘OFF’ or

minimum position.

5 Switch the appliance on.

6 Select Class 1 Run Test under Other

APPLIANCE menu (F1 and F2 keys move the

selection of mode up or down respectively)

7 Press START button and follow the screen

instructions. The appliance will operate for

up to 20 seconds during the run test.

8 For Class I appliances requiring a longer than

normal run test duration, move to Long Class I

Run under OTHER APPLIANCE menu.

Note 1: Pressing RESET at any point during the Run

Test will shorten the test duration. This does not invalidate

the test result.

Note 2: If Data Logging is switched on then additional

information will be requested. See section entitled

”Data Logging”

WARNING

The appliance will operate for up to 20 seconds in the

run test mode. Ensure rotating parts or heating elements

are able to operate safely. Appliances such as drills, angle

grinders etc should be firmly restrained during the run test.

Run testing earthed (class 1) appliances

SWITCH APPLIANCE ON & SET

APPLIANCE THERMOSTAT OR

SPEED CONTROL TO MAXIMUM

SAFETCHECK OPERATOR'S MANUAL

20

Note 1: Pressing RESET at any point during the test

will shorten the test duration. This does not invalidate

the test result.

Note 2: The

SafeTcheck

does not use

to test for the presence of a return lead/probe in the Run

Test mode. Failing to use the return lead/probe while

running the appliance invalidates the test.

Note 3: If Data Logging is switched on then additional

information will be requested. See section entitled

'Data Logging'

Operating Instructions

1 Ensure the appliance is switched off.

2 Plug the appliance into the separate Run Test socket.

4 Connect the return lead/probe to the SafeTcheck via the

Earth Return Socket. Use the Probe to wipe over the

surface of the appliance and make contact with metal parts

during the test.

WARNING

The appliance will operate for up to 20 seconds in the run

test mode. Ensure rotating or heating elements are able to

operate safely. Appliances such as drills, angle grinders etc

should be firmly restrained during the run test.

5 Switch the appliance on.

6 Select Class 2 Run Test under Other APPLIANCE menu

using the F1 and F2 keys.

7 Press START button and follow the screen instructions. The

appliance will operate for up to 20 seconds during the run test.

WARNING

Upon completion of a safety test and subsequent

removal of test lead, please ensure all switches, speed

or thermostat controls are returned to their ‘OFF’ or

minimum position.

Run testing double insulated (class 2) appliances

Note: Use the probe to make contact with metal

exposed parts and insulated surfaces. See section

entitled "Utilities Menu" for more information about

the Probe Mode

This manual suits for next models

1

Table of contents

Other Trio Test Equipment manuals

Popular Test Equipment manuals by other brands

pico Technology

pico Technology TA041 user guide

PCB Piezotronics

PCB Piezotronics 480E09 Installation and operating manual

PEMTECH

PEMTECH PT301N Reference manual

Amprobe

Amprobe AMB-25 instruction manual

Cascade Microtech

Cascade Microtech IZI Probe Quick reference guide

SIRETTA

SIRETTA SNYPER-LTE graphyte quick start guide

Honeywell

Honeywell Posi 3 Setup guide

Proceq

Proceq Pundit PL-200PE operating instructions

Niigata seiki

Niigata seiki LHT-400 instruction manual

Nidec

Nidec Shimpo DT-315AEB-230V-NIST instruction manual

Reach Technology

Reach Technology RT-PoE4N manual

Bante Instruments

Bante Instruments ECscan40 user manual