GASTRON GIR-3000 User manual

GIR-3000

Instruction Manual

Read in detail for correct use.

Gas & Flame

Detection System

GIR-3000

Instruction Manual

When abnormalities occur after purchasing the product,

please contact the following address.

·Address : 23 Gunpo Advanced Industry 1-ro,

Gunpo-si, Gyeonggi-do

·Tel : 031-490-0800

·Fax : 031-490-0801

·URL : www.gastron.com

·e-mail : [email protected]

We sincerely thank you for purchasing the product of Gastron Co. Ltd.

Our Gastron Co.Ltd. is a company specialized in Gas detector and Gas Monitoring System, being

recognized by many consumers due to the best quality and use convenience. We always enable you

consumers to find desired products nearby and are ceaselessly studying and striving for development

of Gas detectors satisfying customers. From now on, solve all anguishes concerning Gas detector with

the products of Gastron Co. Ltd, We Gastron Co. will take a responsibility and give you satisfaction.

In the present instruction manual, operation method for Gas detector as well as simple methods for

maintenance and repair, etc. are recorded If you read it in detail and keep it well, for reference when

you have questions, then it will give you much help.

* KOSHA GUIDE : P-135-2013

Calibration should be executed at the periods required by the manufacturer, and should be executed

every quarter unless there are separate calibration periods.

www.gastron.com

02_03

The present product and the product manual can be changed without advance notice for performance improvement and

use convenience of the product.

■ For accurate operation of Gas detector, check up and calibrate for more than once in every 6 months.

( * See No. 13 of KOSHA GUIDE : P-135-2013 / 8.3 paragraph on qualification and calibration)

■ For accurate operation of Gas detector, checkup and calibration with calibration gas before measurement

is recommended.

■

When not calibrated, it may cause malfunction of the equipment due to problems resulting from Sensor aging.

■ When the present instrument should be dismantled, those with professional skills for Gas detector should

conduct the operation.

■ For power supply cable, wire specifications should be determined by referring to the item of "Length of

installed cable".

■ For the contents on checkup and calibration of Gas detector, please use our company's engineering

department , e-mail, or web site.

Greetings

Contents

GIR-3000

Instruction Manual

1. Overview ·························································································· 6

2. Structure ·························································································· 6

3. Specification ······················································································· 7

3.1. Basic Specifications ········································································ 7

3.2. Mechanical Specifications ·································································· 7

3.3. Electrical Specifications (Standard Type) ··················································· 8

3.4. Environmental Specifications ······························································· 8

4. Name and description of each part ································································ 9

4.1. Components ················································································ 9

4.2. Components of infrared sensor ····························································· 11

5. Installation ························································································· 12

5.1. Separation of Housing Cover······························································· 12

5.2. Configuration of Main PCB ·································································· 12

5.3. Configuration of power supply and 4-20mA terminal ······································· 14

5.3.1. Wire connection diagram of driving method for 4~20mA Source ··················· 14

5.3.2. Wire connection diagram of driving method for 4~20mA Sink ······················ 14

5.3.3. Wire connection diagram of driving method for 4~20mA 3Wire Sink ················ 16

5.4. Configuration of Relay terminal and communication terminal ······························· 16

5.4.1. Configuration of terminal ···························································· 16

5.4.2. Setting for Relay mode ······························································ 17

5.4.3. Setting for RS485 MODBUS ························································· 17

5.5. Configuration of sensor connecting terminal ··············································· 18

5.6. Configuration of Remote Type connection ················································· 19

5.7. Length of installed cable ···································································· 20

6. Operation Flow for sensor ········································································ 21

6.1. Initial operation state (Power On) ··························································· 21

6.2. Gas measuring state (Measuring Mode) ····················································· 21

www.gastron.com

04_05

Contents

6.3. Operation Flow ············································································· 22

6.4. Menu Configuration Table ·································································· 23

7. System Mode ······················································································ 25

7.1. PROGRAM MODE ············································································· 25

7.2. CALIBRATION MODE ·········································································· 26

7.2.1. Zero Calibration ····································································· 26

7.2.2. Span Calibration ···································································· 27

7.3. ALARM MODE ················································································ 28

8. Troubleshooting ··················································································· 30

8.1. Fault List ···················································································· 30

8.2. Recovery List ··············································································· 31

9. Interface configuration ············································································· 32

9.1. MODBUS RS485 ·············································································· 32

9.1.1. Interface setting····································································· 32

9.1.2. MODBUS RS485 Register map ························································· 32

10. Outline drawing and Dimensions ··································································· 33

10.1. Standard Type ··············································································· 33

10.2. Upon coupling of warning light ····························································· 34

10.3. Upon coupling of Raincover ································································ 35

10.4. GIR-3000 Remote Type ····································································· 36

11. Notes before installation ··········································································· 37

11.1. Selection of installation place(Data from occupational safety and health regulations) ······· 37

11.2.

Selection of installation place (Data from safety management regulations for high-pressure gas)

····· 37

11.3. Notes upon installation······································································ 38

12. Revision record ···················································································· 39

The GIR-3000 infrared Gas detector has been developed to prevent accidents beforehand by detecting various

leaked gases generated in industry fields such as plants producing or using combustible gas, carbon monoxide,

carbon dioxide, gas storage place, manufacturing processes, etc.

The GIR-3000 infrared Gas detector is installed in areas with a risk of gas leakage to display measured values

with LCD, OLED installed in the detector by continuous detection of gas leakage, providing DC 4~20mA standard

output, Isolation RS-485 communication signal, HART communication, and Relay contact signal of gas Alarm. Also,

DC 4~20mA standard output can connect up to the maximum of 500m (upon using CVVS or CVVSB 1.5sq↑ Shield

Cable) in transmission distance of output signals of Gas detector and receiving unit while RS-485 communication

signal can be transmitted up to1,000m (upon using RS-485 exclusive line).

The GIR-3000’s body is made of aluminum alloy material in a structure of complete pressure-resistant explosion-

proof type(Ex d IIC T6), can be installed in the areas with a risk of leakage and explosion of all combustible gases,

displaying leakage situation of gas at the installed field by embedding LCD, OLED in the Gas detector. Inside structure

is comprised of liquid crystal unit displaying measured values, connector unit outputting measured values (DC

4~20mA) or Isolation RS-485 communication (Option) Signal, HART

communication signal, and Alarm Signal to outside, and 2 PCB Boards. Outside structure is comprised of Sensor

unit for detection of gas leakage and Cable lead-in unit (2ea). Calibration operation can be conducted outside of Gas

detector body by using Magnet-bar, making maintenance and repair operation convenient.

[Figure 1. GIR-3000 Overview]

Infrared Gas

Sensor Module

(GSA920)

Main Board

(Transmitter)

+24V DC

4-20mA Analog

Signal Output

Display Board

(User Interface)

Transmitter enclosure

Safety Power Supply Unit

(24VDC)

Safety Controller

(PLC or DCS)

GIR-3000 Gas Detector

Hazardous Area (Filed) Safe Area

2. Structure

1. Overview

GIR-3000

Instruction Manual

www.gastron.com

06_07

3. Specications

3.1. Basic Specifications

3.2. Mechanical Specifications

ITEMS SPECIFICATION

Measuring Type Diffusion type

Measuring Value Display Local Digital LCD or OLED Display

Measuring Method Non-Dispersive Infrared(NDIR)

Detectible Gas

Combustible Gas

Carbon dioxide (CO2)

Carbon monoxide(CO)

Measuring Range Combustible:

0~9,999ppm / 0~100% LEL /

0~100% VOL

CO₂: 1.0% ~ 100% VOL

CO: 5% ~ 100% VOL

Accuracy ≤ ±3% / Full Range

Zero Drift ≤2% / Full Range

Response Time 90% of full scale in less than 10 sec

Approvals Classification

KCs: Ex d llC T6,T4, IP65

ATEX/IECEX: II 2 G Ex d IIC Gb T4,T6

SIL2, MED, ABS, DNV

Basic Interface Analog 4-20mA current interface

HART Interface HART REV7(Option)

Option

HART Board

MODBUS RS485 Board

GTL-100 warning light

Rain Cover

Warranty Body (Transmitter) 2Year

Sensor 1Year

ITEMS SPECIFICATION

Explosion Proof type Pressure-resistant, explosion-proof enclosure

Dimension 156(W) × 322(H) × 110(D) mm

Weight including Sensor App. 3kg

Mounting type Wall mount

Mounting Holes Ø 7 ±0.1

Cable inlet 3/4" PF ( 1/2"or 3/4" NPT )

Body material Body (Transmitter)

aluminum alloy

Sensor

Stainless Steel (STS316)

3.3. Electrical Specifications (Standard Type)

ITEMS SPECIFICATION

Input Voltage(Standard)

※ Customer supplied PSU must meet

requirements IEC1010-1 and CE

Marking requirements.

Absolute min:

Nominal:

Absolute max:

Ripple maximum allowed:

18V

24V

31V

1V pk-pk

Wattage Max. wattage:

Max. current:

9.6W @+24 VDC

400mA @+24 VDC

Analog output Current

0-20mA(500 ohms max load)

All readings ± 0.2mA

Measured-value signal:

4mA(Zero) to 20mA(Full Scale)

Fault:

0-100% LEL:

100-109%LEL:

Over 110% LEL:

Maintenance:

0mA

4mA - 20mA

21.6mA

22mA

3mA

Analog output current ripple & noise max ±20uA

Relay contact Alarm1, Alarm2, Fault Relay

Rated 1.0 A @ 30VDC or 0.5 A @ 125 VAC

Wiring requirement

Power CVVS or CVVSB with shield

Analog CVVS or CVVSB with shield

RS485 STP(Shielded Twisted Pair)

Signal transmission distance

(Cable Connection Length)

Analog 2500m

RS485 1000m

EMC Protection: Complies with EN50270

3.4. Environmental Specifications

ITEMS SPECIFICATION

Operation Temperature Transmitter -40 to 80 ℃

Sensor -40 to 80 ℃

Storage Temperature Transmitter -40 to 80 ℃

Sensor -40 to 80 ℃

Operation Humidity Transmitter 5 to 99% RH (Non-condensing)

Sensor 5 to 99% RH (Non-condensing)

Pressure Range 90 to 110KPa

Max. air velocity 6m/s

3. Specications

GIR-3000

Instruction Manual

www.gastron.com

08_09

4. Name and description of each part

4.1. Components of transmitter

No ITEMS SPECIFICATION

1Housing Protect PCB Board embedded inside Sensor and Housing from change of

outside environments and impact.

2Main PCB

Amplify output signals produced by Sensor, and convert to standard output of DC 4~20mA for

transmission, and output Isolation RS- 485 communication Signal and Alarm relay contact signal.

Also, send Data to be displayed in Display unit.

3Display PCB Display Data received from MAIN PCB in LCD or OLED, and

display the current Event situations by Power lamp, Alarm lamp, Trouble lamp

4Power/Signal

Terminal

CN12 is comprised of power supply of DC18-31V and DC 4~20mA standard output Connection

terminal (VISO, +V, mA, -V, ETH).

5Alarm signal

Terminal

CN8 is Alarm signal connection terminal, as a terminal where Trouble, Alarm1, Alarm2 Relay

contact are outputted.

6RS-485 signal CN3 is Isolation RS-485 communication signal connection terminal(A, B).

7Sensor terminal CN10 is Sensor connection terminal. (RD, WH, BK, BE)

8Program Downloading

Connector Connector that allows downloading of product program.

[Figure 2. Components of GIR-3000]

4.1. Components of transmitter

No ITEMS SPECIFICATION

9Power lamp Lamp is lighted when .power switch is turned On

10 Trouble lamp Lighted when abnormality occurs in circuit or sensor sensitivity, etc.

11 Alarm1 lamp Lighted when gas is leaked to become higher than Alarm1 level

12 Alarm2 lamp Lighted when gas is leaked to become higher than Alarm2 level

13 Function key

When contact is made for more than 2sec by using Magnet-bar upon parameter setting, it is

converted to Program mode. (Program mode, Calibration mode, Test mode, etc.) Also, it is

used when Data is inputted for setting.

14 Reset key

Converted when cancelled during parameter setting or touched for more than once by using

Magnet bar to return to the previous state. (Converted to the previous mode by one stage at

a time upon every touch.

15 ↑(Up) key Converted or transformed by one stage at a time when touched once by using Magnet-bar

upon mode conversion or figure transformation (transformed to the higher stage)

16 ↓(Down) key Converted or transformed by one stage at a time when touched once by using Magnet-bar

upon mode conversion or figure transformation(transformed to the lower stage)

17 External earth - Outside grounding for protection from outside noise or strong electric field

- For grounding cable, use conductor larger than 4mm upon coupling connection

18 Mount hole Hole to mount Gas Detector onto outer wall and other installation place.

19 Cover fixed screw(M4) Fix with a hexagonal lens bolt to prevent drop-off due to outside impacts after assembly of

Detector Housing Body and Detector Housing Cover

20 Sensor thread Mounting port for mounting of infrared gas sensor (Detector)

21 Cable inlet Basically PF 3/4" is provided for power supply to Gas detector and lead-in of measurement

output signals upon installation operation.

22 Internal earth - Inside grounding of Detector for protection from outside nose or strong electric field

- For grounding cable, use conductor larger than 4mm upon coupling connection.

23 RS-485 Module /

HART Module

Connector to connect Isolation Type RS-485 communication Module for communication with

PC or PLC and HART communication Module. For RS-485 communication, communication

Address should be set, and the basic value is set for No.1. For HART communication,

Polling-Address and Tag No. etc. should be set. (Optional specifications)

24 Relay Contact

Type Selection

Configured so as to allow selection of A, B contact. If not in ENERGIZER MODE, it operates

as contact A (Normal Open) when Jumper is connected to the part displayed as silk A, while

it operates as contact B (Normal Close) when Jumper is connected to the part displayed as

silk B. On the contrary, if in ENERGIZER MODE, it operates as contact B when Jumper is

connected to A, while it operates as contact A when Jumper is connected to B.

25 Warning Light

Connector Connecting connector when the warning light is used(Optional)

[Table 1. Description on components of GIR-3000 transmitter]

4. Name and description of each part

GIR-3000

Instruction Manual

www.gastron.com

10_11

4. Name and description of each part

No ITEMS SPECIFICATION

1Power & Signal cable

Comprised of power supply input, 4-20mA analog signal, and transmitter communication cable.

2Detector fixed screw Screw processing part for mounting of transmitter

3Earth Ground Outside grounding for protection from outside noise or strong electric field

4Housing Protect PCB Board embedded inside from change in outside environment or impact

5IR Sensor Sensor device for transformation of IR wavelength to electric signals

6IR Tube Lock Screw for fixing of IR tube

7IR Tube Optical path passing infrared wavelength generated in IR lamp

8Filter Filter device for protection of inside optical paths from outside contaminants

9IR Source Lamp for generation of infrared signals

10 Calibration port Inlet for calibration gas upon gas calibration

11 Filter fixing screw Screw for fixing of filter

4.2. Components of infrared sensor

5. Installation

GIR-3000

Instruction Manual

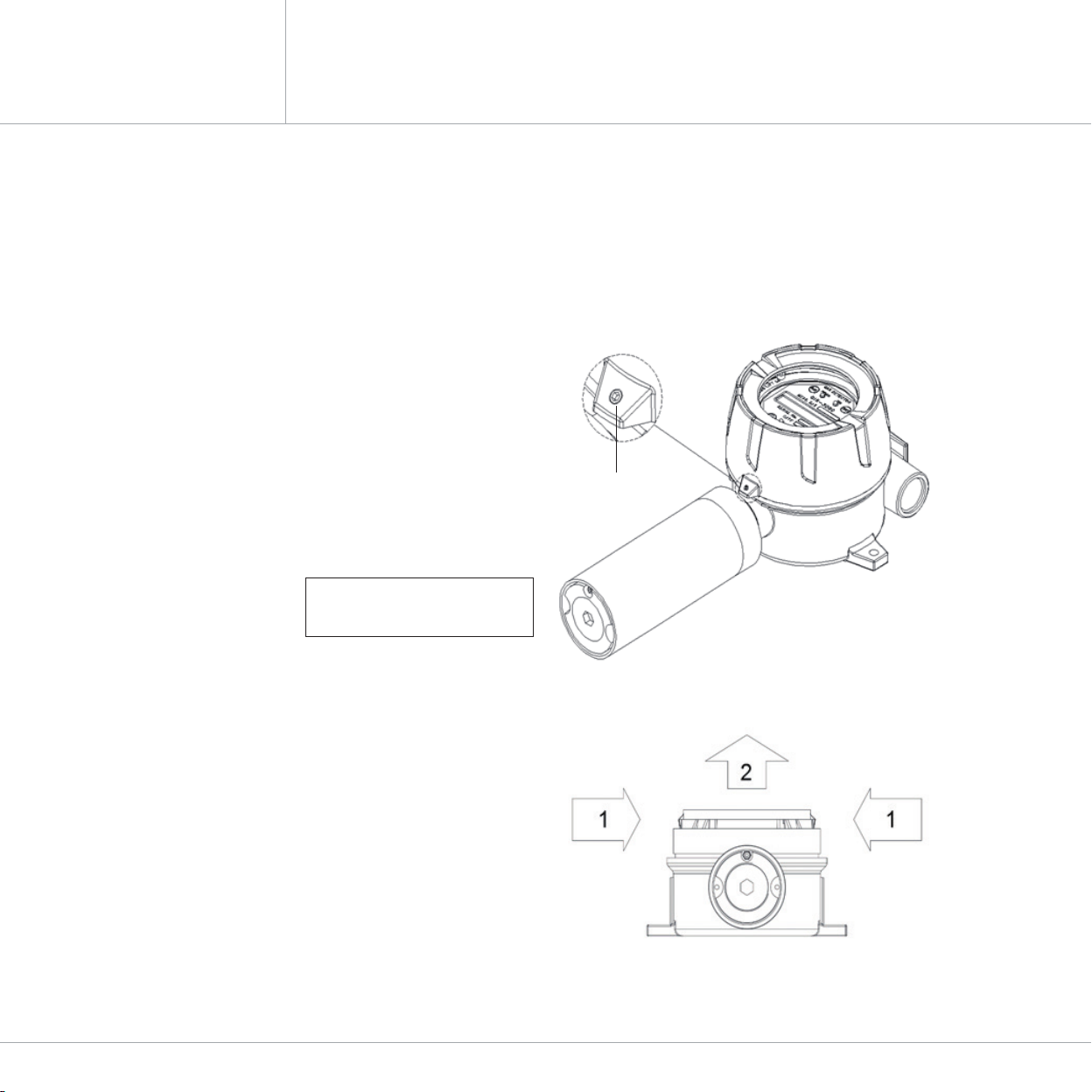

5.1. Separation of Housing Cover

■ When Cover is separated, separate Display Parts in the

following order.

① Simultaneously push inward the fixing chains on

left side and right side on the front face of LCD unit.

② Separate from Gas detector body by pulling Display

Parts forward in the pushed state.

③ Main PCB is installed below Detector Body after

separation of Display Parts .

Absolutely no one other the approved users or those of the headquarters in charge of installation and repair should

be allowed to install in the field, open or operate Cover of the installed gas leakage detector. Otherwise serious

damages to life and property may be inflicted. Also, make sure to shut off the power supply and conduct operation

after checking whether explosive GAS remains or flammable substances are present in the surroundings.

■ <Warning - Do not open during current supply.>

■ Cover can be separated when the cover for gas

leakage detector is turned counterclockwise after

slotted set

■ screw for fixing of body's cover (M4 x 1ea) is turned

3~4 turns clockwise by using a hexagonal wrench (M2).

When Cover is separated, LCD unit is displayed.

Slotted set

screw (M4)

Figure when infrared

Sensor(Detector) is mounted

[Figure 4. Separation method for Display Part]

[Figure 3. Slotted set screw]

[Table 3.Description on major parts of Main PCB]

[Figure 5.Layout diagram for Main PCB terminals]

www.gastron.com

12_13

5. Installation

5.2. Configuration of Main PCB

■ When Display Parts are separated, the layout diagram for Main PCB terminal as follows can be seen.

■ By using OC1, OC2, OC3 of the above layout diagram, HART Option or RS485 MODBUS board can be mounted,

and is fixed by using 3 Ø Screw hoe on the to[ left side of Option board.

No NAME DESCRIPTION

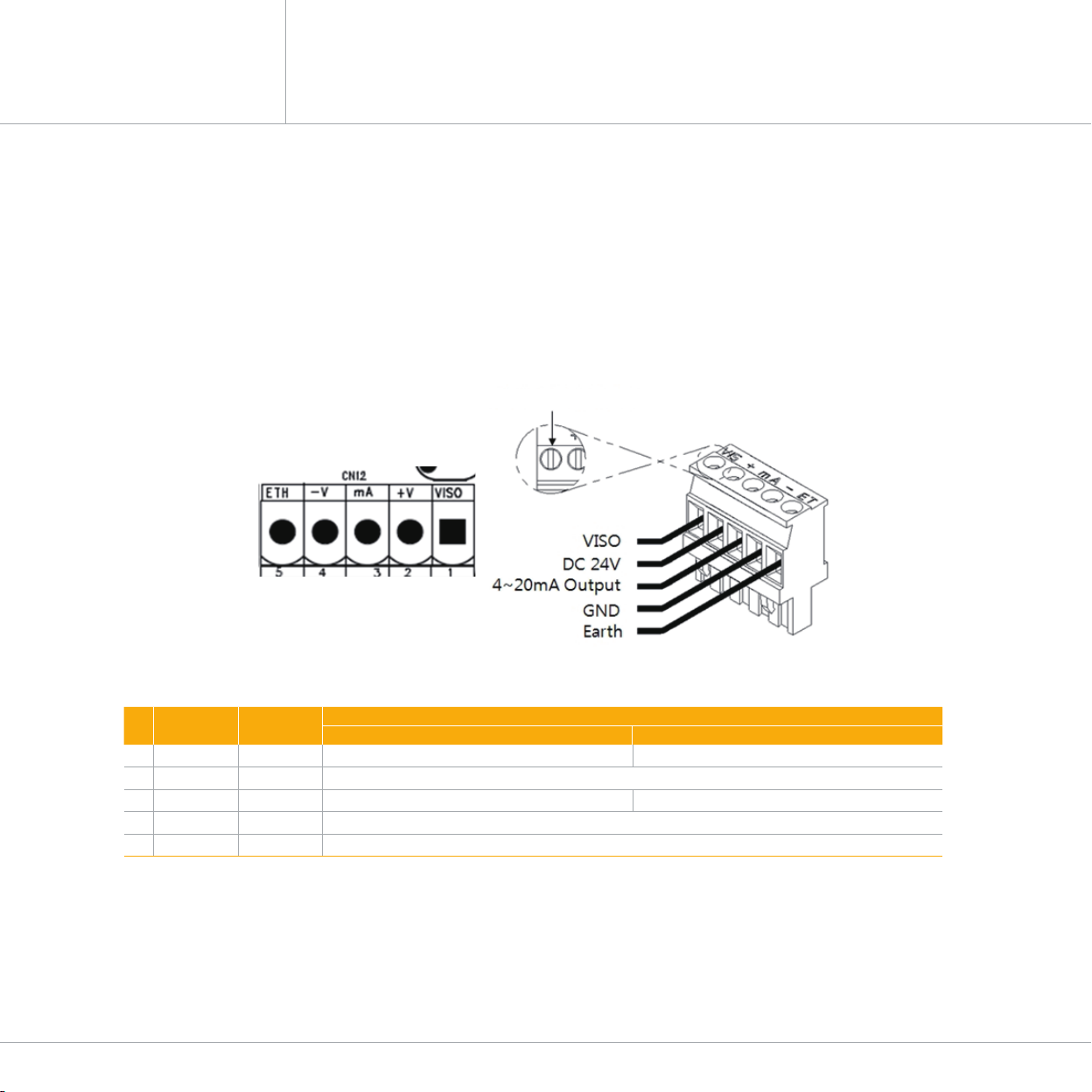

1CN12 Power & Output Signal Terminal

2J4 4~20mA Source / Sink selection jumper (ON: Source Type, OFF: Sink Type)

3CN11 Display LCD Connector

4CN10 Sensor Connector

5CN6 Program download Connector

6D1 Status LED (Blinks by the unit of 11 sec in the case of normal operation)

7OC1, OC2, OC3 HART Option Board Connector

8CN5 Warning light (GTL-100) Interface Connector

5.3. Configuration of power supply and 4-20mA terminal

■ <Warning - Conduct operation after shutting off the power supply upon connection of power supply terminal.>

■ When Display Parts are separated, Terminal Block in Main PCB can be seen as show in the following figure,

which is separated from Main PCB when held by hand and pulled up.

■ Loosen by turning counterclockwise the terminal-fixing screws at 5 places in the upper part of the separated

Terminal Block CN12 (VISO, +V, mA, -V, ETH) Connector by using Θ driver, connect DC18-31V power supply

to +, - , and Signal Cable to mA , followed by locking terminal-fixing screws at 5 places clockwise to prevent

terminal from breaking away, and fit it in Main PCB as before separation.

5. Installation

GIR-3000

Instruction Manual

No PCB Silk PIN NAME DESCRIPTION

4~20mA Source Drive (J1 Jumper ON) 4~20mA Sink Drive (J1 Jumper OFF)

1VISO VIS N.C 4~20mA Sink In(+)

2+V ++24V / POWER (+)

3mA mA 4~20mA Source Out 4~20mA Sink Out(-)

4-V -GND / POWER (-)

5ETH ET EARTH

[Table 4. Detailed description on CN12 terminal]

[Figure 6. Configuration of CN12 terminal]

■ Upon configuring the Terminal, use CVVS or CVVSB 2.0sq↑ Shield Cable.

■ To connect 4Pin Terminal of the existing old-style GIR-3000, fasten the terminal based on +24V as No.2 plate.

<Terminal-fixing Screw>

www.gastron.com

14_15

5. Installation

5.3.1. Wire connection diagram of driving method

for 4~20mA Source

5.3.2. Wire connection diagram of driving method for

4~20mA Sink

[Figure 7.Configuration of 4-20mA Source]

[Figure 8. Configuration of 4-20mA Sink]

■ Connect 4-20mA Signal terminal on PLC side to

GIR-3000의 'mA', while GND terminal is used in

common with the power supply. And then turn

the J1 Jumper ON.

■ HART Communicator can be used only in the model

using HART Option board

■ Connect 4-20mA Sink output (+) terminal on PLC

side to VISO terminal, and (-) terminal to 'mA'

terminal. And then turn the J1 Jumper OFF.

■ HART Communicator can be used only in the model

using HART Option board.

5. Installation

GIR-3000

Instruction Manual

[Figure 9. Configuration of 4-20mA 3Wire Sink]

■ Connect 4-20mA Sink output (+) terminal on PLC

side to VISO terminal, and (-) terminal to (24V DC)

(-) terminal. Connect 'mA' terminal of GIR-3000 to

'GND' terminal. Then connectturn the J1 Jumper

OFF.

5.4.1. Configuration of terminal

5.3.3. Wire connection diagram of driving method for

4~20mA 3Wire Sink

5.4. Configuration of Relay terminal and communication terminal

TER. NO. PIN NO. TERMINAL NAME DESCRIPTION

CN8

1TRB OUT

Output mode is determined by TROUBLE RELAY OUTPUT terminal and J3 Jumper setting

2TRB COM TROUBLE RELAY COMMON terminal

3AL1 OUT Output mode is determined by ALARM1 RELAY OUTPUT terminal, J2 Jumper setting.

4AL1 COM ALARM1 RELAY COMMON terminal

5AL2 OUT

Output mode is determined by ALARM2 RELAY OUTPUT terminal and J1 Jumper setting.

6AL2 COM ALARM2 RELAY COMMON terminal

CN3 7RS485 A RS485 A terminal

8RS485 B RS485 B terminal

[Figure 10. Relay and RS485 Terminal]

[Table 5. Description on Relay and RS485 terminal]

5.4.2. Setting for Relay mode

5.4.3. Setting for RS485 MODBUS

■ MODBUS of GIR-3000 product is an Optional item, and is connected to the receiver unit by the following method.

■ For driving of Relay of GIR-3000 product, 2 types of Normal open and Normal close are operated. To allow

setting of Main PCB에 Relay driving method, Jumper is configured with operation setting as follows.

www.gastron.com

16_17

5. Installation

TER. NO. PIN NO. TERMINAL NAME MODE 설정

CN8

1TRB OUT J3 A-C connection : Contact A ( Normal Open )

J3 B-C connection : Contact B ( Normal Close )

2TRB COM

3AL1 OUT J2 A-C connection : Contact A ( Normal Open )

J2 B-C connection : Contact B( Normal Close )

4AL1 COM

5AL2 OUT J1 A-C connection : Contact A ( Normal Open )

J1 B-C connection : Contact B ( Normal Close )

6AL2 COM

TER. NO. PIN NO. TERMINAL NAME RECEIVER TERMINAL NAME NOTE

CN3 7485A 'TRXD+' or 'A' or 'P'

8485B 'TRXD-' or 'B' or 'N'

[Table 6. Setting for Relay Mode]

[Table 7. Description on RS485 terminal]

[Figure 11.Setting for Relay Mode]

■ When power is supplied to the power supply terminal on MAIN PCB board after wiring, the following contents can

be checked in LCD unit. After the initial operation power is supplied, stabilization time of about 30 minutes is required,

and normal operation occurs from the time of sufficient stabilization.

5. Installation

GIR-3000

Instruction Manual

5.5. Configuration of sensor-connecting terminal

■ IR sensor module (to be referred to as GSA920A hereafter) is connected to the transmitter by using CN No.10

terminal.

TER. NO. PIN NO. TERMINAL NAME COLOR OF SENSOR CABLE REMARKS

CN10

1TRB OUT TROUBLE RELAY OUT is determined +24V sensor power supply

2TRB COM TROUBLE RELAY COMMON terminal Sensor communication with transmitter

3RS485 A RS485 A terminal

Sensor power supply GROUND

4RS485 B RS485 B terminal

EARTH

[Table 8. Description on sensor-connecting terminal]

[Figure 13. Configuration of connection for GSA920A]

■ Configuration of the cable with wire connection to

GSA920A is as follows.

- GSA920A module allows configuration of

extension cable, and is connected by using

CN10 terminal of transmitter.

- GSA920A Option1 is an exclusive output of

4-20mA, while the relevant option is used

upon sole installation of GSA920A

- GSA920A Option2 is an exclusive Zero port,

while the relevant option is used upon sole

installation of GSA920A.

[Figure 12. Sensor-connecting terminal]

www.gastron.com

18_19

5. Installation

■ To remotely configure GSA920A, the sensor is installed by using Junction Box(GDH-1010) of the following form,

and connection is made to GIR-3000 transmitter by using component terminal inside Junction Box.

5.6. Configuration of Remote Type connection

[Figure 14. Configuration for GSA-920A Remote Type]

Wire connection

diagram for Cable

(GSA-920A)

Wire connection

diagram for Cable

(Receive Unit)

5. Installation

GIR-3000

Instruction Manual

5.7. Length of installed cable

[Table 9. Installation length for GIR-3000 power supply cable]

PIN NO. mm

2

COPPER RESISTANCE(ohms/m) METERS

12 3.31 0.00521 1439

14 2.08 0.00828

905

16

1.31 0.01318 569

18 0.82 0.02095

357

20 0.518 0.0333

225

[Figure 15. Calculation of length for GIR-3000 installation cable]

■ The maximum length between GIR-3000 and power supply is determined by the wire specifications.

■ Maximum installation length= VMAXDROP ÷ IMAX ÷ WIRER/m ÷ 2

■ VMAXDROP: Maximum Power Loop Voltage Drop (=Power Supply voltage - min operating voltage)

■ IMAX: Maximum current value of GIR-3000

■ WIRER/m: The resistance of the wire (ohms/meter value available in wire manufacturer's

specification data sheet),

■ An example for installation length using 24V power supply and 16AWG is as follows.

■ GIR-3000 minimum operating voltage = 18 Vdc

■ VMAXDROP = 24 - 18 = 6V

■ IMAX = 0.4A(400mA)

■ 6÷ 0.4÷0.01318÷ 2 = 569.044m ≒ 569m

Other manuals for GIR-3000

1

Table of contents

Other GASTRON Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

EIJKELKAMP

EIJKELKAMP Scuba Blue Green Algae Buoy user manual

Emerson

Emerson Daniel Ultrasonic 100 Series INSTALLATION PROCEDURE

UINICS

UINICS SP-564A Series instruction manual

National Instruments

National Instruments FD-11613 user guide

Endress+Hauser

Endress+Hauser Liquiline System CA80AM Brief operating instructions

Laserworld

Laserworld GREEN-200E user manual