5.2 Indoor Installation Notes, Clearances and Chimney

Note: Installation is to be performed by a qualified installer and will comply with all

requirements of the AJH (Authority having jurisdiction). All installations must be

done following applicable building, plumbing, electrical and fire codes.

•

Check with your insurance provider on coverages, inspection requirements and

restrictions for solid fuel heating appliances when placed indoors.

•

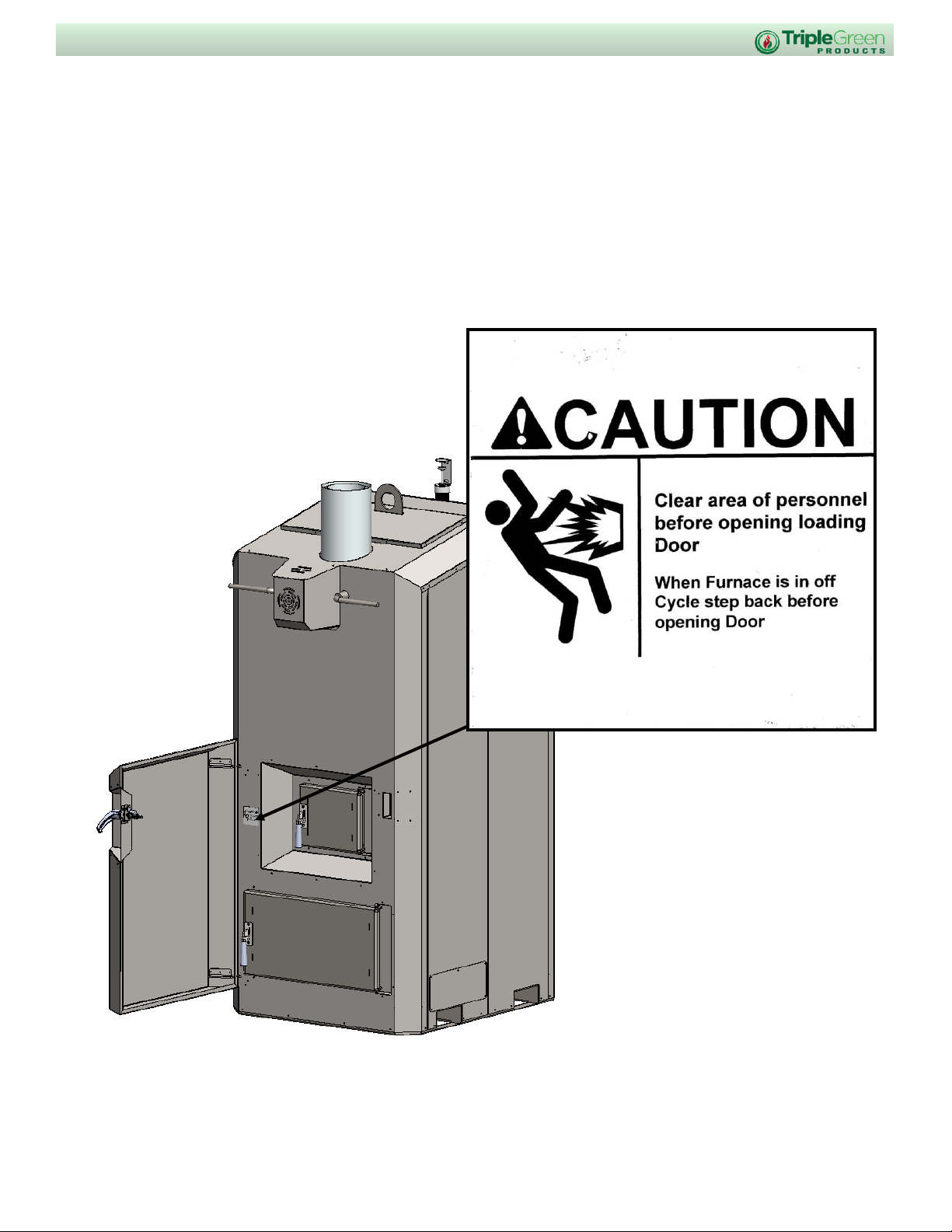

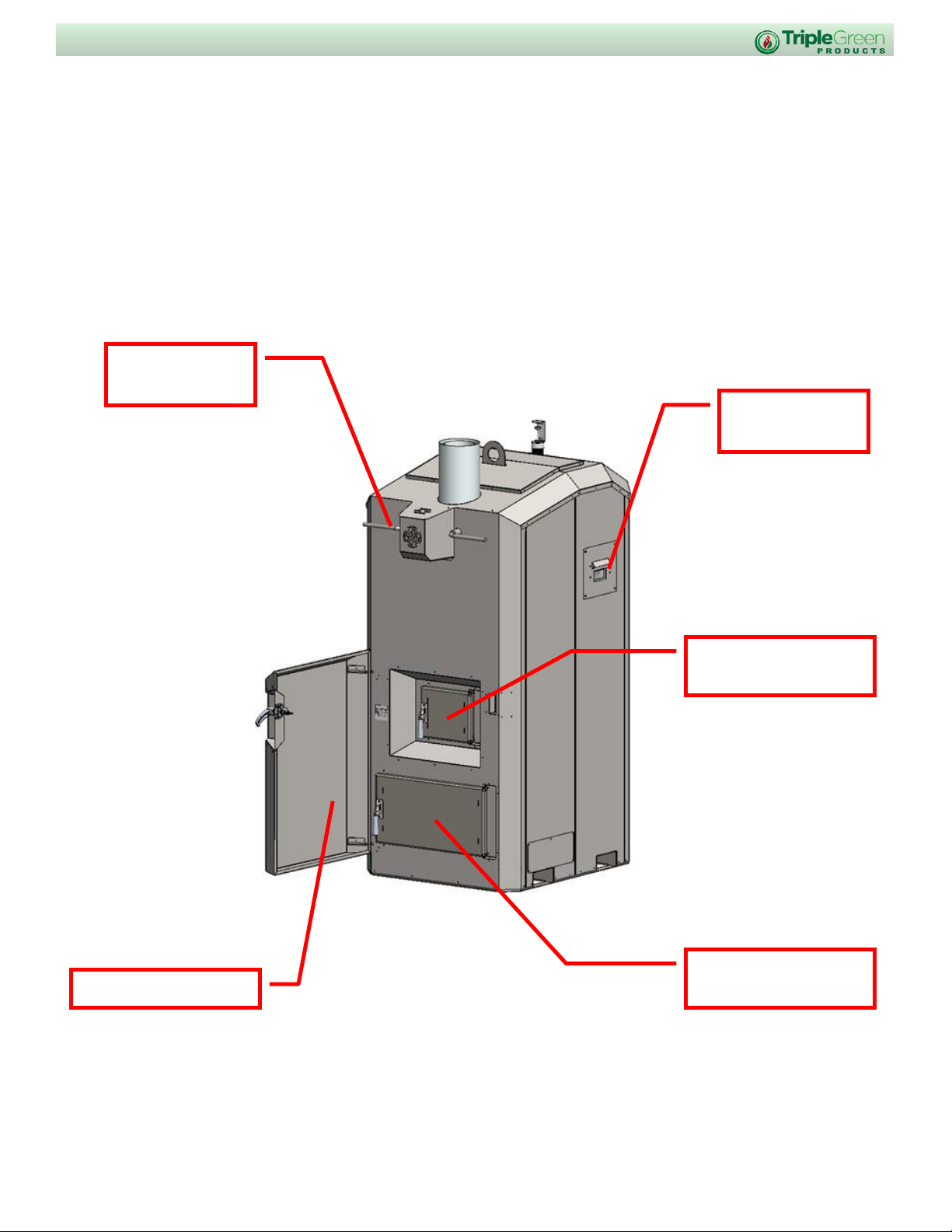

Indoor installations will require clearance to access the front and back doors as well as

installation clearances to combustibles.

Back and Front = 60 inches (152 cm) Required for opening exterior doors and

access.

Top = 18 inches (46 cm)

Sides = 18 inches (46 cm)

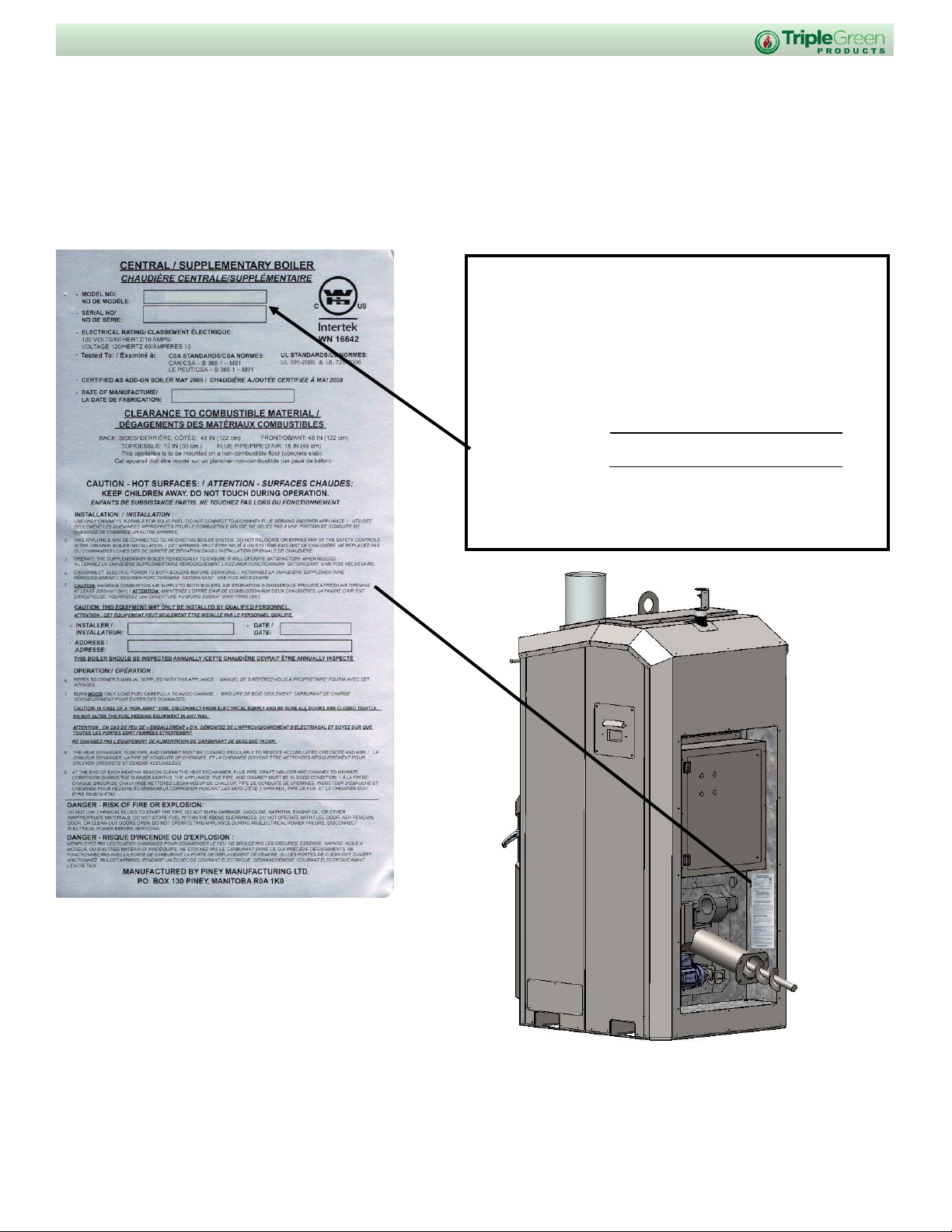

Minimum distance to any walls, please refer to certification Label

•

A concrete slab on a compacted granular base is recommended for a foundation. The

foundation design must be capable of supporting the weight of the heater. (See

Specifications,)

•

Installation on combustible floors (not recommended). If the boiler is to be installed

on combustible floor areas, the floor area around the front of the furnace must be

protected from spillage of burning fuel particles. The protective materials must be non-

combustible, these include masonry materials or sheet metal. Areas to be covered are:

1. Underneath the boiler.

2. At least 16 inches (400 mm) in front and 8 inches (200 mm) on either side of the fuel

loading and ash removal doors,.

3. Underneath the chimney connector and extending at least 2 inches (50 mm) on

either side of the chimney connector.

•

Install the furnace downstream of prevailing winds relative to any residences. i.e., not too

close to neighbors or in valleys that would cause unhealthy air quality or nuisance

conditions.

•

Insulated chimney may be added (beyond the starter section provided). The chimney

size is 6 inches inside diameter. The recommended chimney type is UL listed, HT

prefabricated insulated stainless steel. Please consult the chimney manufacturer for

Indoor installation lateral support recommendations.

•

Chimney height. The recommended height is 4 feet above any roof or immediate

structures (walls, buildings etc. closer than 50 feet away).

•

Do not connect this chimney flue to other appliances. The chimney is to serve this heater

only.

•

Installation of a tight fitting rain cap onto the chimney is recommended in the off season to

help reduce internal corrosion.