Trolex Sentro Vortex Wireless TX5952 User manual

TX5952 User Manual

TX5952-UM-EN-01a 3

TX5952 Sentro Vortex Wireless Air Flow Sensor

Contents

1. Product Overview 4

1.1 Operating Features 5

1.2 Application 5

1.3 Product Options 6

1.3.1 Side Projecting Sensor 6

1.3.2 Remote Mounted Sensor 6

1.4 Dimensions 7

1.4.1 Side Projecting Sensor 7

1.4.2 Remote Mounted Sensor 8

1.5 Technical Information 9

1.6 Electrical Details 10

1.7 Sentro Module 11

2. Certification 12

3. Installation 13

3.1 Tools and Test

Equipment Required 13

3.2 Siting Recommendations 14

3.2.1 Fitting in Pipes and Ducts 14

3.2.2 Fitting in Roadways and

Tunnels 16

3.3 Connections 17

4. Setup and Calibration 18

4.1 Controls and Indicators 18

4.2 Software Menus 20

4.3 Navigation 21

4.4 Power-up 22

4.5 Main Menu 23

4.5.1 Sentro Setup 24

4.5.2 Output Setup 29

4.5.3 Module Setup 31

4.5.4 CommTrac 41

4.5.4 Exit 46

4.6 Support 46

5. Operation 47

6. Diagnostics and

Maintenance 48

6.1 Diagnostic Messages 48

6.2 Maintenance 49

6.2.1 Introduction 49

6.2.2 Sentro Vortex Wireless

- Check 50

6.2.3 Sentro Vortex Wireless

Batteries - Replace 50

6.2.4 Sentro Vortex Wireless

Sensing Probe - Clean 51

6.2.5 Sentro Vortex Wireless

Sensing Probe - Calibrate 52

6.3 Disposal 53

6.4 Maintenance Records 53

6.5 Maintenance and

Calibration Log 54

Disclaimers 55

Trademarks 55

Contact Details 55

Document History 55

www.trolex.com

4 TX5952-UM-EN-01a

1. Product Overview

TX5952 . . . XX

Sentro Vortex Wireless air flow sensor with side projecting

sensing probe for open flow monitoring in tunnels, roadways

and process systems.

TX5952 . . . XX

Sentro Vortex Wireless air flow sensor with remote mounted

sensor. For use where fitting space is limited or is difficult to

access.

www.trolex.com

TX5952 User Manual

TX5952-UM-EN-01a 5

1.1 Operating Features

• Fully wireless operation

• Powered by commercially available batteries giving up to 200 hours of operation

• Powered by the Strata CommTrac wireless network

• High stability air flow monitoring

• Vortex monitoring principle with no moving components

• Output signal linearly proportional to flow velocity

• Integral LCD screen with large easy to read characters and back light

illumination

• Easily programmable function and display configuration

• Rangeable flow velocity from 0.5 m/sec to 30 m/sec

• Integral LED indicators for General and High alarms

• Auxiliary analogue output signal to drive a local audio visual alarm unit, if

required

1.2 Application

Fixed point wireless air flow velocity measurement in pipes, ducts and open

roadways. Ventilation, cooling systems and process condition monitoring in heavy

duty industrial applications and hazardous areas. Output data linearly proportional to

air flow velocity.

www.trolex.com

6 TX5952-UM-EN-01a

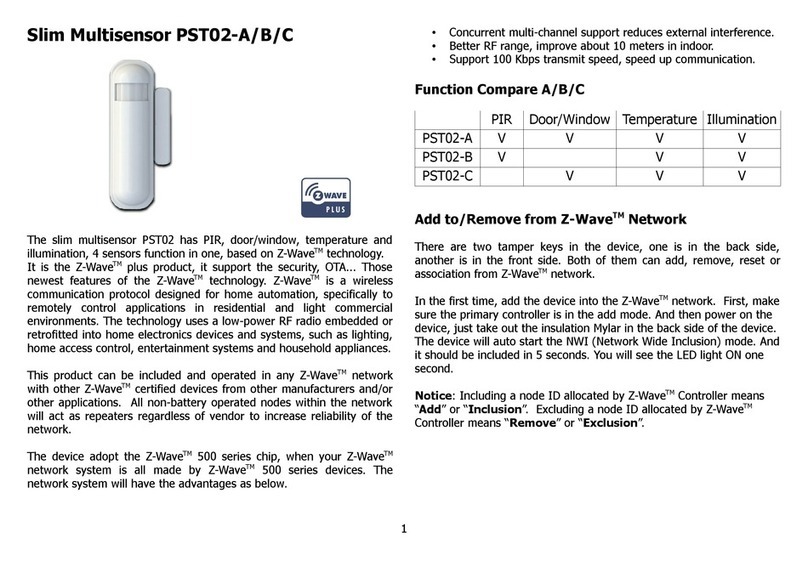

1.3 Product Options

1.3.1 Side Projecting Sensor

Side Projecting Sensor

Order Reference

Mining Ex ia General Purpose

TX5952.XX.XX.XX.XX TX5952.XX.XX.XX

Please specify the probe length when ordering, probes available from 160 mm to

2000 mm insertion length, in 100 mm increments.

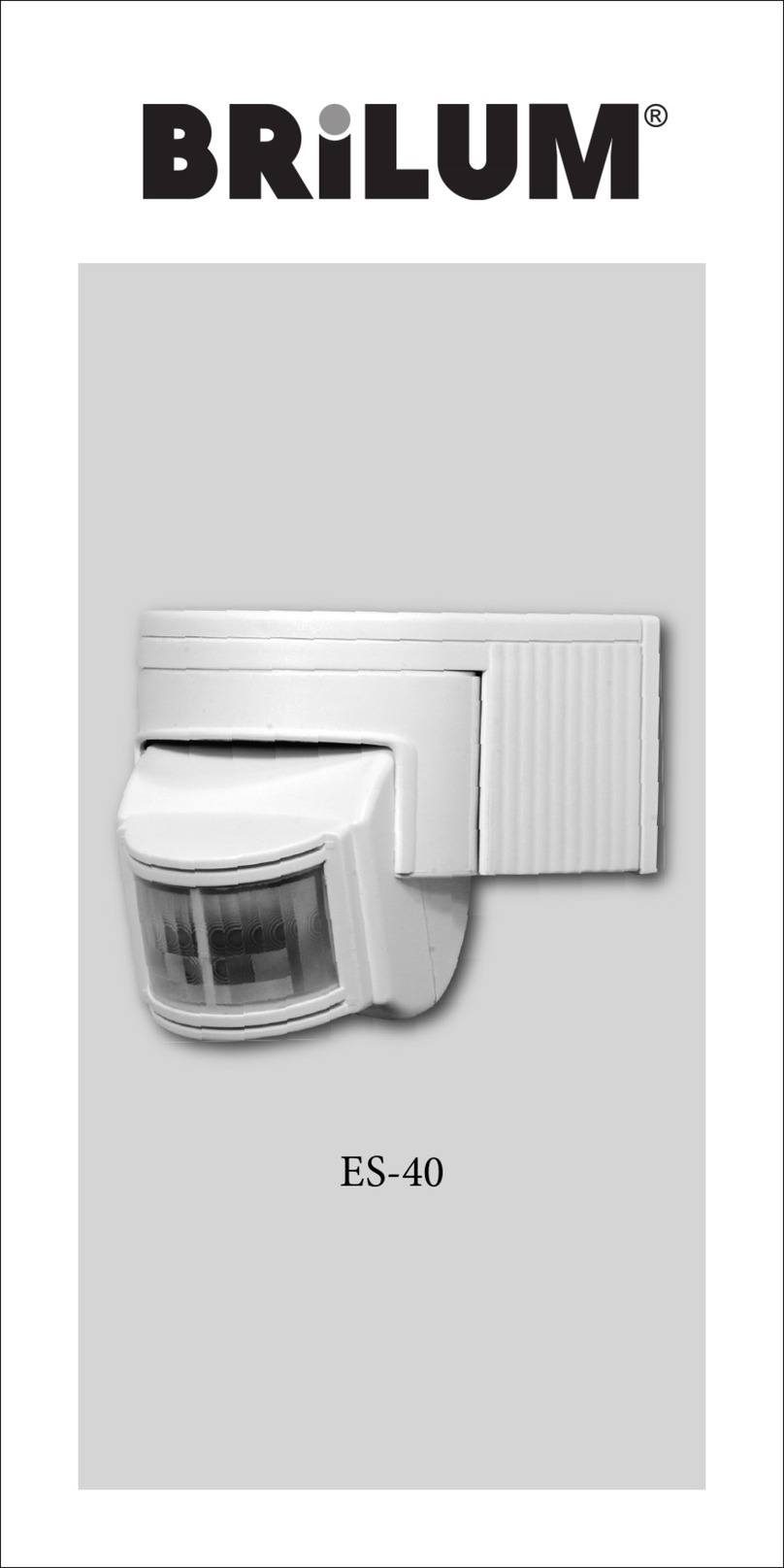

1.3.2 Remote Mounted Sensor

Remote Mounted Sensor With 50 mm ANSI Mounting Flange

Order Reference

Mining Ex ia General Purpose

TX5952.XX.XX.XX.XX TX5952.XX.XX.XX.XX

Please specify cable length and non-standard process fittings when ordering.

Please specify the probe length when ordering, probes available from 160 mm to

2000 mm insertion length, in 100 mm increments.

Remote Mounted Sensor With 11/2” BSP Mounting Bush

Order Reference

Mining Ex ia General Purpose

TX5951.XX.XX.XX.XX TX5952.XX.XX.XX.XX

Please specify cable length and non-standard process fittings when ordering.

Please specify the probe length when ordering, probes available from 160 mm to

2000 mm insertion length, in 100 mm increments.

www.trolex.com

TX5952 User Manual

TX5952-UM-EN-01a 7

1.4 Dimensions

1.4.1 Side Projecting Sensor

www.trolex.com

8 TX5952-UM-EN-01a

1.4.2 Remote Mounted Sensor

www.trolex.com

TX5952 User Manual

TX5952-UM-EN-01a 9

1.5 Technical Information

Flow measuring range Rangeable from 0.5 to 5 m/s up to 0.5 to 30 m/s

Accuracy +/- 2% within 12.5° rotation of flow axis

Linearity +/- 1%

Ambient temperature limits -20 to +40°C

Sensor temperature limit -20 to +150°C

Humidity 0 to 95% non-condensing

Protection classification Dust and waterproof to IP65

Process media Air, steam or saturated vapour

Housing material Reinforced polymer

Sensor material Stainless steel - grade 316

Flexible cable (remote

sensor)

PVC coated armoured flexible conduit

Maximum static pressure 20 bar

Process fittings • 11/2” BSP mounting bush

• 50 mm ANSI mounting flange

Cable entry • Side projecting sensing probe - 1 x M20

• Remote mounted sensing probe - 1 x 2M20

Nett weight • Side projecting sensing probe - 1.5 kg

• Remote mounted sensing probe - 2.5 kg

Information display 128 x 64 dot graphic backlit LCD screen

Vibration limits Vibration limits (EN 60079-29-1):

• 10 to 30 Hz - 1.00 mm total excursion

• 31 to 150 Hz - 19.6 m/s2acceleration peak

Impact limits 20 joules (housing)

Output Signals • CommTrac wireless proprietary signal

• Auxiliary analogue output signal (4 to 20 mA)

to drive a local audio visual alarm

Alarms Programmable General and High alarm levels

with built-in LED indicators

www.trolex.com

10 TX5952-UM-EN-01a

Menu configuration • Security code protection

• Scale factor selection (linear/volume/time)

• Setpoint level and mode adjustment

• Data output protocol configuration

• Flow units selection

• Duty display text entry

• Wireless network configuration and

information

Fault indication • Loss of communications

• Sensing module absent

• Sensor over-range

1.6 Electrical Details

Description

Mining Ex General Purpose

Supply voltage

6 V dc (+/- 5%) 6 V dc (+/- 5%)

Supply current

10 mA - no backlight

30 mA - with backlight

50 mA with 2 alarm signals

and backlight

10 mA - no backlight

30 mA - with backlight

50 mA with 2 alarm signals

and backlight

Output relays

None

None

www.trolex.com

TX5952 User Manual

TX5952-UM-EN-01a 11

1.7 Sentro Module

Plug-in pre-calibrated sensing module with standardised output data.

• The sensing module stores all the necessary data about its type identification,

sensing range and specific calibration. This data is automatically recognised by

Sentro Vortex Wireless when the sensing module is loaded into the module

bay

• The sensing modules are pre-calibrated so they can be replaced at any time by

a replacement sensing module

• The sensing module will identify itself when plugged into the sensor housing

and auto configuration will take place

• All Sentro sensing modules have two output alarm signals for General alarm

and High alarm. Default values are entered during manufacture and these can

be changed to preferred values

• The two alarm signals can be set to illuminate built-in flashing LED indicators

• Two auxiliary analogue output signals (4 to 20 mA) to drive a local audio visual

alarm unit, if required

www.trolex.com

12 TX5952-UM-EN-01a

2. Certification

Pending

www.trolex.com

TX5952 User Manual

TX5952-UM-EN-01a 13

Certification - continued

Pending

www.trolex.com

14 TX5952-UM-EN-01a

3. Installation

3.1 Tools andTest Equipment

Required

No special tools are required:

• Metric spanner set

• Metric hexagon key set

• Standard electrical test meter

Trolex recommends that the Sentro Wireless

Gas Detector is positioned a minimum of

6 m (20 ft) and no more than 245 m

(800 ft) from a Strata CommTrac C node for

the Sentro Wireless Gas Detector to work

effectively.

Checkpoint

Where the process cannot be interrupted

to remove the Sentro Vortex Wireless

from a pipeline, an isolating ball valve

may be fitted to the process connection

at the installation. This is also useful

in installations that have a high level

of contamination or moisture in the air

stream. Build up of debris or water vapour

will cause deterioration of the output

signal.

3.2 Siting Recommendations

3.2.1 Fitting in Pipes and Ducts

To attain the best accuracy of response,

select a position that is at least twenty pipe

diameters down-stream from bends or

obstructions, and approximately five pipe

diameters from down-stream intrusions.

Similarly, the sensor should be mounted

www.trolex.com

TX5952 User Manual

TX5952-UM-EN-01a 15

at least fifteen pipe diameters from a pipe

reducer and fifty pipe diameters from valves.

If this is not possible then the installation

of a standard flow straightener will improve

performance.

Fit a corresponding threaded boss or flange

at the monitoring point and install the sensor,

ensuring a air tight seal.

Checkpoint

High pressure versions, above 2 bar, will be

supplied with a welded bush or flange and

will require dedicated process fittings.

Release the clamping ring on the mounting

bush or flange.

The centre of the flow path of the sensing

head should be positioned as shown.

Checkpoint

Ensure that pressurised systems have

been completely vented before installation

or removal of the sensor.

Position the sensing head with the smaller

opening facing the flow, within a rotational

deviation of no more than 12.5° from the

axis of flow. Tighten the clamping ring with

moderate force.

Avoid fitting the sensor at low points

in pipework structures to prevent the

sensing head from being affected by large

accumulations of moisture.

www.trolex.com

16 TX5952-UM-EN-01a

3.2.2 Fitting in Roadways and

Tunnels

To attain the best accuracy of response,

select a position away from adjacent

structures with a clearance of at least 200

mm.

The version with a side projecting sensor can

be mounted on to a suitable support using

the mounting holes.

Alternatively use a standard mounting bush

or flange for fitting to a suitable bracket.

www.trolex.com

TX5952 User Manual

TX5952-UM-EN-01a 17

3.3 Connections

The Sentro Vortex Wireless is battery

powered and has wireless communications,

therefore no wiring is required to install it.

However, there are two analogue output

signals. These can be used to connect to

local audio visual alarms, if required.

If you decide to use local audio visual alarms

you will need to wire them to the Sentro

Vortex Wireless. Connections are as follows:

1. Alarm output 1

2. 0 V

3. Alarm output 2

4. Battery + V (no user connection)

5. 0 V Battery - V (no user connection)

6. Reserved for future use (no user

connection)

The terminals are located behind the front

cover. Use a cross head screwdriver to

remove the four screws securing the front

cover and move it out of the way.

www.trolex.com

18 TX5952-UM-EN-01a

4. Setup and Calibration

4.1 Controls and Indicators

www.trolex.com

TX5952 User Manual

TX5952-UM-EN-01a 19

www.trolex.com

20 TX5952-UM-EN-01a

4.2 Software Menus

www.trolex.com

Table of contents

Other Trolex Accessories manuals

Popular Accessories manuals by other brands

Pepperl+Fuchs

Pepperl+Fuchs UC2000-L2-E6-V15-Y277310 manual

POWERMOD

POWERMOD BPCPAP12V-KT Operation manual

La Crosse Technology

La Crosse Technology TX8U instruction manual

Vega

Vega VEGAPULS 61 operating instructions

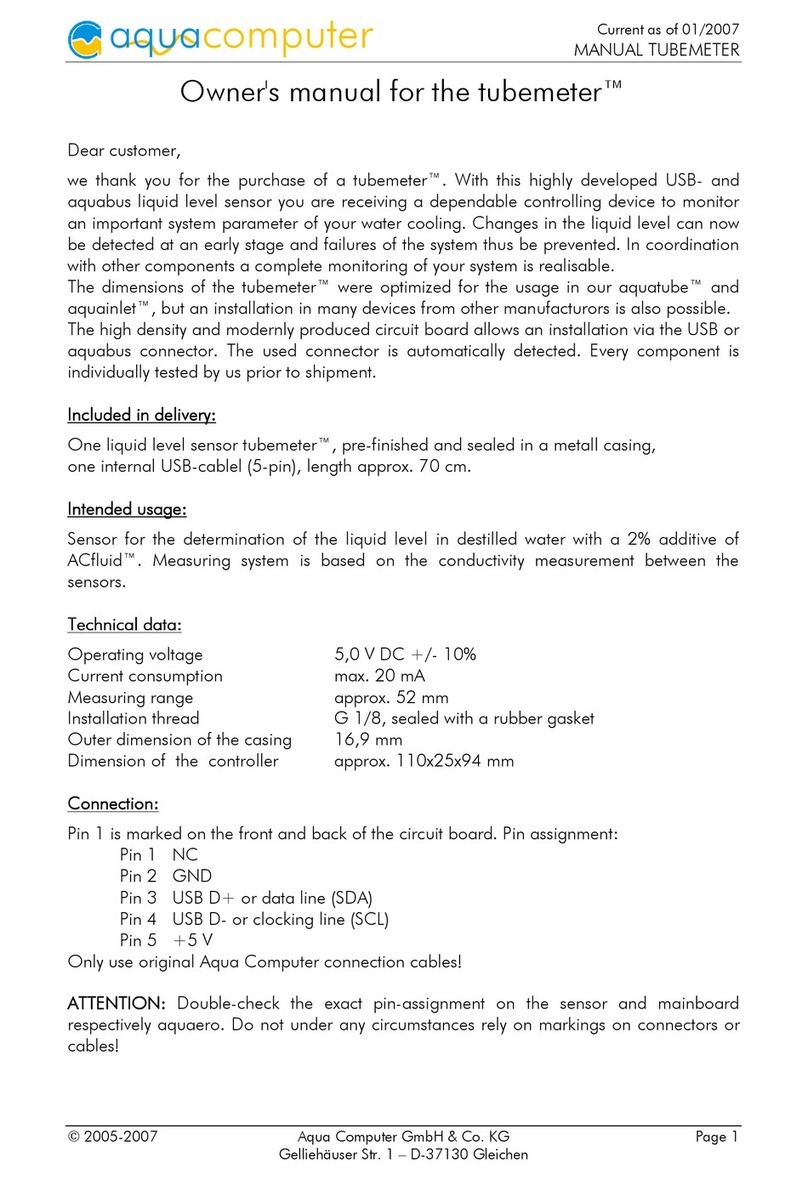

Aqua Computer

Aqua Computer TUBEMETER owner's manual

Vision

Vision ZF 5201 IN Installation & operation manual