Trolex TX9042 User manual

TX9042-UM-EN-A • P5423.1600-A2

TX9042 Programmable Sensor Controller (PSC)

Contents

1. Product Overview 4

1.1 Operating Features 4

1.2 Application 5

1.3 Product Options 6

1.3.1 TX9042 PSC Input Module Types 6

1.4 Dimensions 7

1.5 Technical Information 7

1.6 Electrical Details 9

2. Certication & Conformity 10

3. Functional Safety 13

3.1 Overview of Safety Integrity Level 13

3.2 SIL Suitability 13

3.3 Summary of the Veried

Functional Safety Data 14

3.4 Conditions or Restrictions for

use in SIL Applications 15

3.5 Proof Test 16

3.6 System Conguration Drawing 17

4. Installation 18

4.1 Precautions 18

4.2 Labelling 18

4.3 Tools & Test Equipment Required 19

4.4 Mechanical Installation 19

4.5 Connections 20

4.6 Input Channel Conguration 22

4.6.1 Analogue Input Modules 23

4.6.2 Display of Connection Details 28

4.6.3 Replacing an Input Module 28

4.6.4 Cable Distance for Loop Powered

4 to 20 mA Sensors 28

4.6.5 Cable Distance for Voltage 28

Inputs (0.4 to 2 V) 29

4.6.6 Dual Input Signals (Dierential) 29

5. Setup and Calibration 30

5.1 Controls and Indicators 30

5.2 Power-up 32

5.3 Signal Display 32

5.4 Reviewing the Input Module

Conguration 33

5.5 Close-up Information Display 33

5.5.1 Close-up1 Display 34

5.5.1.1 Close-up 1 Display for an

Analogue Input Module 34

5.5.1.2 Close-up 1 Display for a

Digital Input Module 36

5.5.2 Close-up 2 Display 37

5.5.2.1 Close-up 2 Display for an

Analogue Input Channel 37

5.5.2.2 Close-up-2 Display for a

Digital Input Channel 38

5.6 Menu of Functions 39

5.6.1 Default Values 39

5.6.2 Programming the Operating

Values 39

5.7 Main Menu 40

5.7.1 Main Setup 41

5.7.2 Escape/Return

5.7.3 Communications Setup 42

5.7.4 Clock 44

5.7.5 Keycode Security 44

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 3

5.7.6 Datalog Interval Period 45

5.7.7 Datalog Display Review 45

5.7.8 Clear the Data in the Datalog 46

5.7.9 Relay Reset Mode Options 47

5.7.10 Relay Voting 48

5.7.11 Relay Operation 50

5.7.12 Software Version 50

5.7.13 Self Test 50

5.7.14 Display Cycling 51

5.8 Contrast Control 51

5.9 Channel Function and

Calibration 52

5.9.1 Power On Delay (POD) Period 53

5.9.2 Scale and Display Settings 55

5.9.2.1 Reset Peak 56

5.9.2.2 Constant 56

5.9.2.3 Update 57

5.9.2.4 Units 59

5.9.2.5 Decimal Points 59

5.9.2.6 Lower 60

5.9.2.7 Upper 60

5.9.2.8 Calibrate (Temperature Input Module) 61

5.9.2.9 Identication 63

5.9.2.10 Connections 63

5.9.3 Setpoint Characteristics 64

5.9.3.1 Level 65

5.9.3.2 Hysteresis 65

5.9.3.3 Alarm (Rising/Falling) 66

5.9.3.4 Setpoint On Delay 66

5.9.3.5 Setpoint O Delay 67

5.9.3.6 Operation 67

5.9.3.7 Relays 69

5.9.4 Fault Signal Alarm Assignation 70

5.9.5 Threshold Acceptance Level 71

5.9.6 Keycode Security for Each

Channel - 1 to 8 72

5.9.7 Digital Level 74

5.9.8 Setting a Digital Failsafe

Input Module 75

5.9.9 Channel Display Mode 78

5.10 Datacommunications 79

5.10.1 RS485 79

6. Maintenance 81

6.1 TX9042 PSC Planned

Preventative Maintenance 81

6.1.1 Overview 81

6.1.2 TX9042 PSC

- Physical Check 81

6.1.3 TX9042 PSC

- Replace the battery 83

6.1.4 TX9042 PSC - Proof Test 83

6.2 TX9042 PSC - Repair 86

6.3 Maintenance Records 86

6.4 Maintenance Log 87

7. Disposal 88

Disclaimers 89

Trademarks 89

Document History 89

Contact Details 89

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A4

1. Product Overview

TX9042.55

Up to 8 analogue or digital inputs.

Up to 16 On/O inputs

RS485 data communications

Data logging facility for up to 26,000 input readings per

channel

1.1 Operating Features

• Up to eight channels of analogue or digital inputs or sixteen on/o inputs

• Input and output functions are programmed directly using the keypad

• RS485 data protocol for integrating multi-point sensor collecting into mine wide

systems

• Accepts analogue or digital inputs from a variety of source types

• Simple to use, just four keys to programme the TX9042 PSC, no special

software and no software programming skills required

• Full functional compatibility with the entire range of Trolex sensors

• Up to 32 TX9042 PSC can be connected to a single mine wide data system

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 5

1.2 Application

The TX9042 Programmable Sensor Controller (PSC) is for sensor management and

data communications in arduous industrial environments and hazardous areas.

It is suitable for use in SIL 1 and SIL 2 applications, in accordance with specic

conditions or restrictions.

The uses of the TX9042 PSC include:

• Underground machinery protection

• Environmental monitoring using a combination of gas sensors and ow sensors

• Gas detection systems

• Conveyor control

• Pump and compressor monitoring

• Machine condition monitoring

• Fan vibration monitoring

• ITP monitoring

• On-board underground machinery monitoring

• Plant protection

• Data collection from groups of diverse sensors

• Area network sensor collection and monitoring

The data logging facility can be used to record operational trends and to analyse

events where serious incidents may have occurred. All data acquired can also be

transmitted over a communication link to a remote point. The system can also be

used for collecting sensor information from several distributed monitoring stations

on a mine wide sensor network. Up to 32 sensor collectors can be networked on

a data link and communicated to a central control and monitoring computer via the

data link.

Intrinsically Safe:

TX9042.55

Supply Voltage:

12 V dc from an approved intrinsically

safe power source

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A6

1.3 Product Options

TX9042 PSC General Purpose Mining Ex ia

12 V dc - TX9042.55

1.3.1 TX9042 PSC Input Module Types

Input Module Description Mining Ex ia

Order Code

Current - 0 to 20 mA P5423.516

Current - 4 to 20 mA P5423.508

Voltage - 0.4 to 2 V P5423.509

Flow TX6023 - not lo limited P5423.552

Flow TX6023 - 4 to 20 mA lo limited P5423.556

Flow TX6022 - Flow P5423.528

Flow TX6022 - Pressure P5423.518

PT100 - -50 to +200°C P5423.510

ac RMS - 500 Hz to 10 kHz - TX5630 P5423.506.01

ac RMS - 15 to 100 Hz - TX5630 P5423.506.02

Digital 12 V/24 V P5423.523

Digital Failsafe P5423.522

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 7

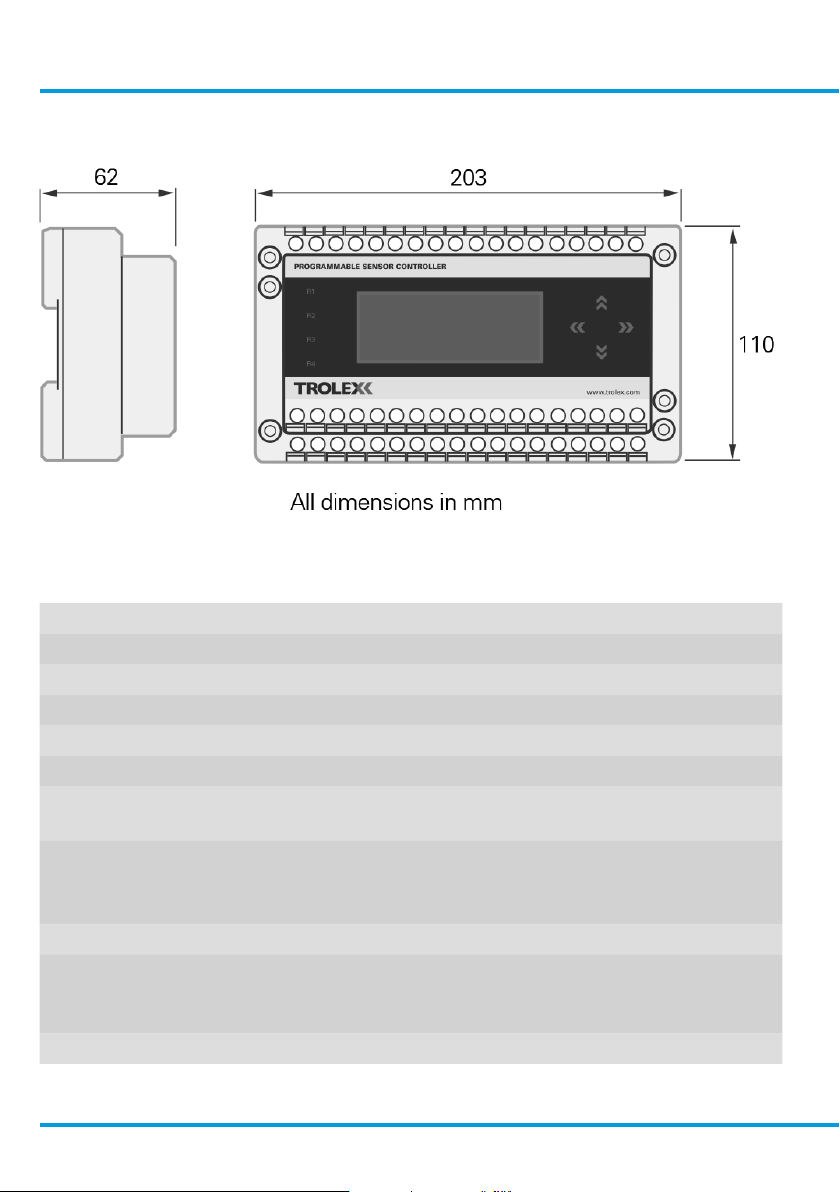

1.4 Dimensions

1.5 Technical Information

Display accuracy +/-0.25% (analogue channels)

Setpoint accuracy +/-0.5%

Ambient temperature limits -10 to +40°C

Electrical connections 4 mm barrier/clamp terminals

Housing material ABS

Nett weight 800 g

Environmental protection Must be housed in a protective metal enclosure

to comply with Intrinsically Safe requirements

Information display LCD screen

20 characters x 4 lines

6 mm high characters

Mounting DIN rail

Microprocessor Microprocessor controlled menu operation, with

non-volatile data retention and 10 bit analogue to

digital conversion (analogue channels)

Setpoints 2 per channel plus Fault signal

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A8

Output relays 4 encapsulated reed relays with function

programming

Relay contact rating 200 V

0.25 A

3 W absolute maximum

Checkpoint

Circuits switched by the contacts of the

output relays MUST emanate from a certied

Intrinsically Safe power source and the circuit

parameters must be within Intrinsically Safe

requirements.

Setpoint adjustment 0 to 99% of full scale

Hysteresis adjustment 0 to 99%

Power on delay adjustment 0 to 255 seconds for each channel

Output delay adjustment 0 to 18 hours for each setpoint in one second

steps

Input update period

adjustment

0 to 60 seconds for each channel in 0.05 second

steps

Engineering units menu V, mV, mA, °C, °F, K, g, kg, mbar, bar, Pa, kPa,

PSI, %, ppm, %RH, mm, m, mm/s, m3/s, rpm,

pps, Hz, kHz, secs, m:s, h:m, m/s, m3/H, m3/m,

A, l/m, g/m, l/s, g/s, l/h and g/h

Fault signal Open or short circuit signal line or sensor fault,

will generate a fault signal, the fault will be

identied and displayed on the LCD screen

Data communications RS485 Modbus

Data logging Up to 26,000 readings with on-demand down

loading

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 9

1.6 Electrical Details

TX9042.55 - Programmable Sensor Controller (PSC)

Supply voltage: 12 V dc +20%/-2.5% at 125 mA

Output: Modbus protocol

Supply current: 125 mA at 12 V

Relay contact rating: 200 V

0.25 A

3 W absolute maximum

Checkpoint

Circuits switched by the contacts of the output relays

MUST emanate from a certied Intrinsically Safe

power source and the circuit parameters must be

within Intrinsically Safe requirements.

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A10

2. Certification and Conformity

ATEX (European Union) certification for use in underground mines (Group I).

Complies with ATEX Directive 2014/34/EU.

Standards:

EN IEC 60079-0:2018

IEC 60079-11:2023

IECEx (International) certification for use in underground mines (Group I).

Standards:

IEC 60079-0:2017

IEC 60079-11:2013

ANZEx certification for use in underground mines (Group I) in Australia.

MASC IA certification for use in underground mines (Group I) in South Africa.

EAC certification for use in underground mines in Eurasian Customs Union (including

Russia).

Product Code:

Ex Certificate Number:

Ex Certification Code:

TX9042.xx.xx.19

Programmable Sensor Controller

Baseefa03ATEX0292X

IECEx BAS 15.0065X

I M1

Ex ia I Ma

Ta = -20oC to +40oC

TX9042.xx.xx.10

Programmable Sensor Controller ANZEx 06.3057X Ex ia I

Ta = -20oC to +40oC

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 11

TX9042.xx.xx.05

Programmable Sensor Controller

MASC M/11-359X

Baseefa03ATEX0292X

I M1

Ex ia I Ma

Ta = -20

o

C to +40

o

C

TX9042.xx.xx.14

Programmable Sensor Controller

RU C-GB.AA87.B.00137/19

PO Ex ia I Ma X

Ta = -20

o

C to +40

o

C

The following Special conditions for Use apply to the certificates listed above:

Specific Conditions of Use pertaining to Baseefa03ATEX0292X and IECEx BAS 15.0065X are reproduced

below. For conditions associated with other certificates listed above, please refer to individual

certificates. Copies of certificates are available on www.trolex.com.

i. The Programmable Sensor Controller Type TX9042 must be mounted in a secondary

enclosure as shown on drawing P5423.02 or in an alternative metal enclosure (not light

alloys) which is appropriately certified as providing a degree of protection of IP54.

ii. Up to 11 RS485 Comms Modules (in separate Programmable Sensor Controllers type TX9042)

may be daisy-chained together (i.e. terminals B1 all linked together, terminals B2 all linked

together and terminals B3 all linked together). Provided that the number of daisy-chained

PSC’s is reduced to 10, these comms lines may be connected to unspecified safe area

equipment via an appropriately certified shunt zener diode safety barrier (dual channel a.c.),

whose output parameters do not exceed the following per channel:

U

o

= 9 V, I

o

= 100 mA, P

o

= 225 mW

OR

U

o

= 12 V, I

o

= 80 mA, P

o

= 240 mW

e.g. suitably certified MTL 761, MTL766 to BAS01ATEX7202 or MTL7761ac, MTL7766ac to

BAS01ATEX7217.

For the purposes of this certificate, these shunt zener safety barriers may be considered

equivalent to Category I (M1) equipment.

The cable parameters shall not exceed the following: C

c

= 2.8 µF, L

c

/R

c

= 222 µH/Ω.

iii. For the purpose of this certificate, a P+F Cylindrical Inductive Proximity Sensor Type NC… and

NJ…. to PTB00ATEX2048X to Category II 1G Ex ia IIC T6 connected to terminals T1 to T4 of a

Digital Input Module may be considered equivalent to Category I M1 EPL Mb (ATEX) or Ex ia I

Mb (IECEx). In this instance, the power supply selected to power the PSC must have an output

voltage not exceeding 16 V.

Intrinsic safety parameters

For intrinsic safety parameters associated with certificates listed above, please refer to individual

certificates. Copies of certificates are available on www.trolex.com.

Installation of equipment

The installation of the product must only be carried out by competent personnel. Each installation

needs to be considered with reference to the local safety regulations and authorities. Refer to the

following standards for additional guidance:

-IEC/EN 60079-14

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A12

-IEC/EN 60079-25

Refer to the Certification Section of this User Manual and to the relevant certificates for any

installation parameters and special conditions of safe use.

Commissioning / verification tests prior to first use.

Prior to commissioning and first use, the product shall be inspected for any visible damages and

integrity of the enclosure. Never use the product that has damaged housing in hazardous locations.

Maintenance

The maintenance of the product must only be carried out by competent personnel. Maintenance shall

be considered with reference to the local safety regulations and authorities. Refer to the following

standards for additional guidance:

-IEC/EN 60079-17

It is recommended to periodically check the condition of the product.

The product shall only be serviced and repaired by Trolex Ltd. or a local Trolex service agent approved

by Trolex Ltd in order to maintain the explosion protection of the product.

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 13

3. Functional Safety

3.1 Overview of Safety Integrity Level

The following instructions are applicable when the TX9042 Programmable Sensor

Controller (PSC) is used as an element in a safety instrumented function that is

specied to achieve a Safety Integrity Level (SIL), eg. SIL 1, 2, etc.

The reliability of the TX9042 Programmable Sensor Controller (PSC) has been

independently assessed in accordance with IEC 61508 for use in SIL applications.

The compliance with IEC 61508 includes hardware reliability (probabilistic type

failures) and measures to address systematic type failures.

The information that follows forms the ‘Safety Manual’ required by IEC 61508-2

and is intended to allow correct product selection, system integration, installation,

operation and maintenance to enable the SIL specied for the safety instrumented

function to be achieved and maintained, as far as the TX9042 Programmable Sensor

Controller (PSC) is concerned.

The actual SIL will depend on many system considerations that are outside the

scope of the TX9042 Programmable Sensor Controller (PSC) and will rely on

personnel who are competent in the functional safety aspects of the various

lifecycle activities mentioned above.

3.2 SIL Suitability

The versions and congurations of the TX9042 Programmable Sensor Controller

(PSC) identied in Table 1 in Section 3.3 below and are suitable for use in safety

functions that have a specied Safety Integrity Level (SIL) in accordance with IEC

61508 or IEC 61511 up to and including:

SIL 2 - when used in a ‘Low Demand’ safety function [1]

with proof test interval of 3 months

SIL 1 - when used in a ‘Low Demand’ safety function [1]

with proof test interval of 12 months

SIL 1 - when used in a ‘High Demand’ safety function [1]

The functional safety data in Tables 1 and 2 in Section 3.3 must be taken into

account by integrators and end-users, including compliance with the restrictions in

use (Section 3.4) and all other provisions and conditions in this User Manual.

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A14

System integrators and end users responsible for other lifecycle phases (system

specication, integration, installation, commissioning, operation, maintenance, etc)

need to perform assessments on the complete scope of their activities to ensure a

target SIL for the safety function is and continues to be met.

[1]

Low Demand and High Demand modes of operation are dened in IEC 61508-4, 3.5.16

3.3 Summary of the Veried Functional Safety Data

The product, conguration and Safety Manual that have been assessed are shown

in Table 1.

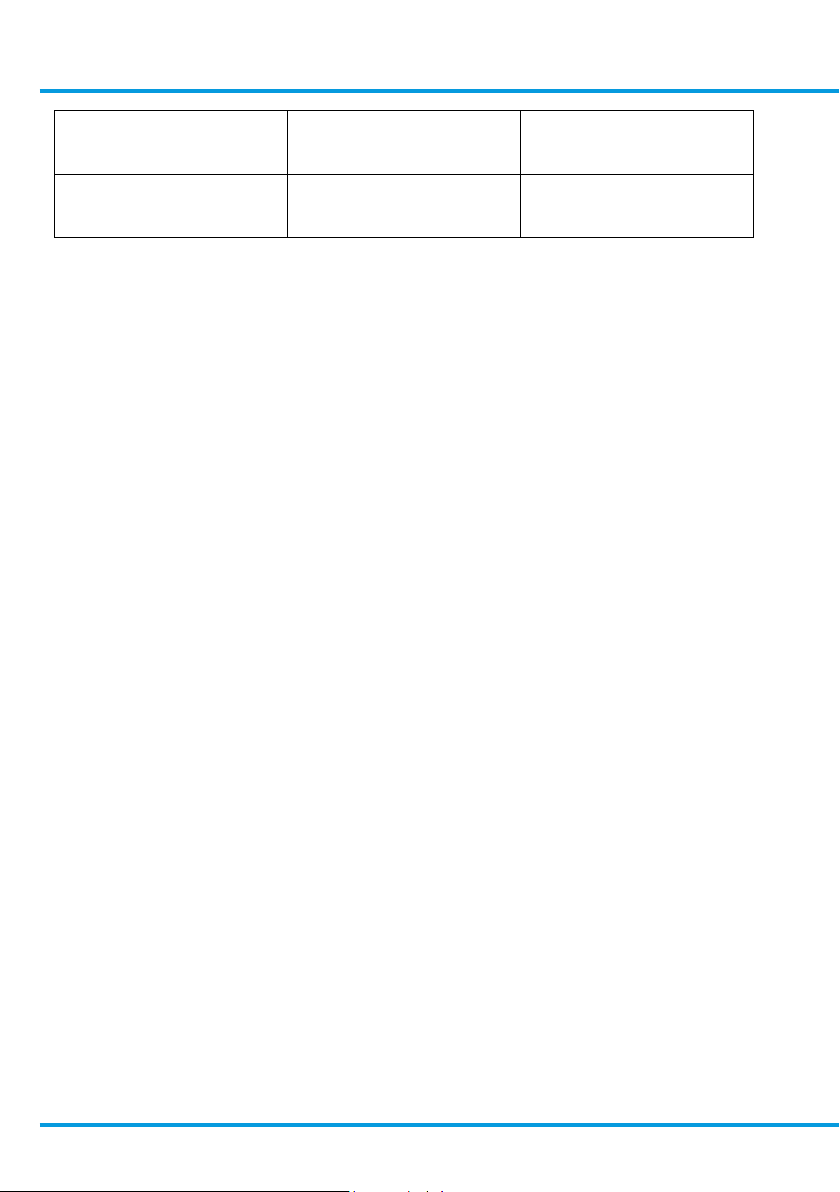

Product Information Details

Product identication TX9042.55 Programmable Sensor Controller

Product specication See Section 1.5 of this User Manual

Product conguration

4 to 20 mA input conditioning modules tted

OR

0.4 to 2 V input conditioning modules tted

To achieve SIL the TX9042 with 4 to 20 mA or

0.4 to 2 V input conditioning modules tted, must be

congured to de-energise an output channel relay if

either the input signal transitions a pre-determined

alarm threshold or an internal fault is indicated.

Neither the display nor the RS-485 data link are part

of the specied safety function.

System conguration

Monitoring of signals from devices congured as

2/3-wire current loop devices, 4-wire current inputs

with separate power connection, or voltage inputs.

Element safety function

To de-energise an output channel relay (open relay

contacts) if either the input signal transitions a pre-

determined alarm threshold or an internal fault is

indicated.

Safety Manual See Section 3 of this User Manual

Table 1 Basic Element Information

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 15

The hardware failure data for the TX9042 element safety function based on an

extensive analysis of eld failure data with a 90% single sided condence limit is

shown in Table 2.

Parameter Value

Dangerous failure rate (λD)2.3E-06

Safe failure rate (λs)N/R [1]

Safe failure fraction (SFF) N/R [1]

Element type Type B

Hardware fault tolerance (internal architecture) 0

Diagnostic coverage (DC) 60%

Diagnostic test interval N/A [2]

Probability of Failure on Demand (PFDAVG) [12 month proof test; 24hr MTTR] 1.0E-02 [2]

Probability of Failure on Demand (PFDAVG) [3 month proof test; 24hr MTTR] 2.6E-03 [2]

Probability of dangerous Failure per Hour (PFH) 2.3E-06

Table 2 Hardware Failure Data

[1] Not required by Route 2H

[2] To be conservative, no credit has been taken for the diagnostics

3.4 Conditions or Restrictions for use in SIL Applications

The sections of this User Manual shall be strictly complied with to ensure validity of

the failure data and systematic safety integrity. The following additional restrictions

and conditions apply when the unit is used in SIL applications:

1. The TX9042 must be repaired within the MTTR assumed in the PFD

calculations shown in the table above if an internal fault is detected in the unit.

2. If the MTTR or the proof test interval (T1) is dierent from those assumed in

this User Manual, then the PFDAVG must be re-calculated and the SIL capability

re-veried accordingly (refer to the Safety Manual in Section 3.5 of this User

Manual).

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A16

3. The display is for indication only and is not part of the safety function; likewise

the RS485 communications are not part of the safety function.

4. The environmental limits are restricted to:

•+20 to +40°C

•relative humidity <90%

5. IEC 61508-2, 7.4.4.3.1c limits use to SIL 1 in high or continuous mode of

operation when used in a non-redundant conguration.

3.5 Proof Test

Periodic Proof Tests of the element safety function must be carried out to identify

any dormant failures, particularly when used in ‘low demand’ safety functions

– refer to Section 6.1.4 of this User Manual, for the Proof Test procedure. Faults

identied by this Proof Test must be repaired within the MTTR and the unit returned

to full working order.

A suitable Proof Test interval (T1) should be used in order to achieve the required

average probability of failure on demand (PFDAVG). A nominal interval of 8,760 hrs

(1 year) and Mean Time To Repair (MTTR) of 24 hours has been used in the

derivation of PFDAVG for illustration purposes. If dierent values are used, the PFDAVG

for a non-redundant arrangement (i.e., where the safety function relies on a single

element) can be re-calculated as follows:

PFDAVG = (λDU + λDD) tCE

Where tCE (the channel equivalent down time) = (λDU/λD) (T1/2 + MTTR) + (λDD/λD) MTTR

For redundant arrangements refer to IEC 61508-6 for the equations.

Checkpoint

Those responsible for specifying proof testing of safety functions should refer to

IEC 61508-6:2010 clause B.3.2.5 for considerations of the eect of non-perfect

proof tests.

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 17

3.6 System Conguration Drawing

The illustration below shows how the TX9042 is to be used with other system

elements.

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A18

4. Installation

4.1 Precautions

Do not disassemble the TX9042 PSC whilst in the hazardous area or use a TX9042

PSC that has a damaged housing in the hazardous area.

The TX9042 PSC must be installed within a metal protective enclosure to ensure

compliance with certication requirements. It is permissible for the enclosure to

incorporate a polycarbonate window to allow visibility of the TX9042 PSC LCD

screen. However, window area may be no greater than 100 cm2.

4.2 Labelling

When the TX9042 PSC is supplied tted into a standard Trolex TX9204 metal

enclosure, two channel identication labels will be tted to the enclosure near

to the connecting terminals. Connection details can also be viewed on the LCD

screen, refer to Section 5.9.2.21 for details.

If a TX9042 PSC is supplied to be tted into a customer supplied metal enclosure,

the two channel identication labels will be provided loose and must be tted

adjacent to the connecting terminals in a visible position in order to comply with

certication requirements.

Before installation check for the correct channel functions and supply voltage on the

channel identication label on the rear of the TX9042 PSC housing.

www.trolex.com

TX9042 User Manual

TX9042-UM-EN-A • P5423.1600-A 19

4.3 Tools and Test Equipment Required

No special tools are needed to assemble or install the TX9042 PSC.

4.4 Mechanical Installation

The TX9042 PSC is installed on a TS35 low prole DIN rail as follows:

1. Loosen the two securing screws, one each at the end of the TX9042 PSC

housing.

2. Swing the plastic tabs out of the way.

3. Locate the TX9042 PSC on the DIN rail.

4. Ensure that the plastic tabs can engage behind the DIN rail ange.

5. Tighten the two securing screws.

Do not overtighten the two securing screws.

www.trolex.com

TX9042-UM-EN-A • P5423.1600-A20

4.5 Connections

The terminals are divided on two horizontal planes. The lower level is used for

all input connections and the upper level is used for output signals and data

connections.

Each of the input channels has four connecting terminals available, and these

are utilised in accordance with the type of input module that is tted (refer to the

diagram on the following page).

Channel 1 sensor signal enters on terminals A2 and A3 and if a power supply is

required to feed the sensor, then this is available at terminals A1 and A4. The input

signal is fully oating and dierential, giving high immunity to electrical interference.

This conguration is repeated for channels 1 to 8.

www.trolex.com

Other manuals for TX9042

1

Table of contents

Other Trolex Controllers manuals