Trolex TX9042 User manual

Other manuals for TX9042

1

Table of contents

Other Trolex Controllers manuals

Popular Controllers manuals by other brands

WindowMaster

WindowMaster WMS 409 Installation instructions manual

BOSSCO

BOSSCO MPD-4 instructions

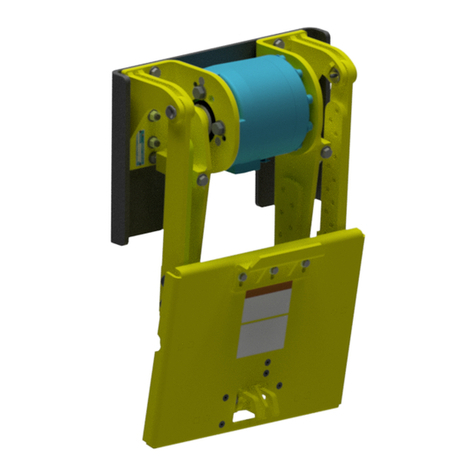

MICROMATIC

MICROMATIC ROTAC LONG ARM Installation, Service, and Use Manual

KEBCO

KEBCO COMBIVERT F5 Series Installation guide & operation manual

Metropolitan Industries

Metropolitan Industries Sump Boss BP2000 Installation & service manual

ACE RC

ACE RC BLC-40 instruction manual

Contro l4

Contro l4 EA-5 installation guide

wattstopper

wattstopper DRD8 v2 installation instructions

System air

System air TControl EASY 3S Installation and maintenance manual

Promise

Promise FastTRAK66 user manual

Allen Organ Company LLC

Allen Organ Company LLC Classic R-10 quick start guide

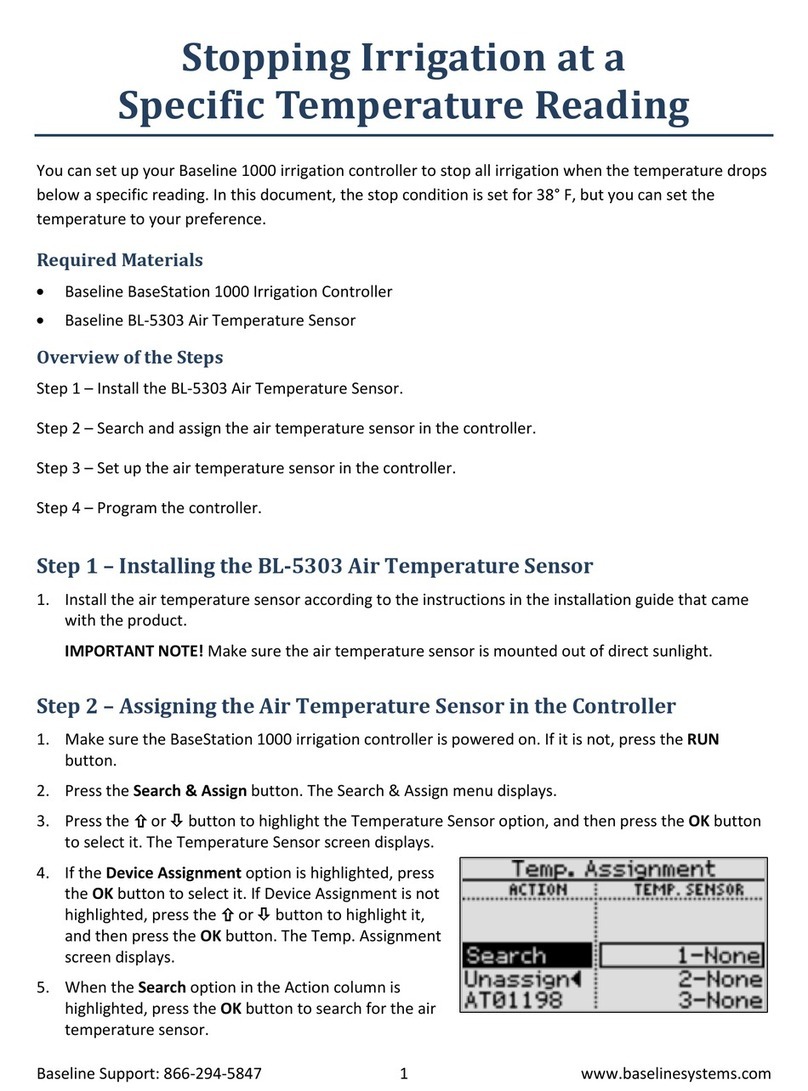

Base Line

Base Line BaseStation 1000 manual

Uni-Mig

Uni-Mig UNI-FLAME REG Operation manual

digitalview

digitalview DD-1920-HDMI-EDPT instructions

Smart system

Smart system DIGIDRIVE BASIC Quick reference guide

Ink Bird

Ink Bird ITC-306T-WIFI manual

red lion

red lion CSMSTRSX manual

Ebmpapst

Ebmpapst VTD-60.05-K5C-S Translation of the original operating instructions