Trolex Sentro Wireless TX6355 User manual

TX6355

Sentro Wireless

TX6355 User Manual

www.trolex.com

P5596.1600 rev B

3

TX6355 Sentro Wireless

Contents

1. Product Overview 4

1.1 Operating Features 4

1.2 Application 5

1.3 Product Options 5

1.4 Dimensions 6

1.5 Technical Information 7

1.6 Electrical Details 8

1.7 Sentro eModules 9

1.7.1 Sentro eModules 9

1.7.2 MSHA Certified eModules 9

2. Certification 12

2.1 United States of America

(MSHA) 12

2.2 South Africa (MASC) 13

2.3 Australia -IECEx 13

3. Installation 15

3.1 Safety Precautions 15

3.2 Tools and Test

Equipment Required 16

3.3 Siting Recommendations 16

3.4 Connections 17

3.5 Connecting in Hazardous

Areas 17

4. Setup and Calibration 18

4.1 Controls and Indicators 18

4.2 Software Menus 20

4.3 Navigation 21

4.4 Power-up 22

4.5 Main Menu 23

4.5.1 Calibrate 24

4.5.2 TX6355 Setup 27

4.5.3 Modbus Address 32

4.5.4 Module Setup 34

4.5.5 CommTrac 38

4.5.6 Exit 44

4.6 Support 44

5. Diagnostics and Maintenance 45

5.1 Diagnostic Messages 45

5.1.2 Sensor Negative Drift 46

5.1.3 Recovery from Display

Freeze 46

5.2 Maintenance 47

5.2.1 Introduction 47

5.2.2 Sentro Wireless Gas Inlet

Port - Check and Clean 48

5.2.3 Sentro Wireless - Bump Test 48

5.2.4 Sentro Wireless Batteries –

Replace 49

5.2.5 Sentro eModule - Calibrate 49

5.2.6 Sentro Wireless - Safety

Check 50

5.2.7 Sentro eModule - Replace 50

5.3 Recommended Test Gas

Concentrations 51

5.4 Disposal 52

5.5 Maintenance Records 52

5.6 Maintenance and

Calibration Log 53

Disclaimers 54

Trademarks 54

Document History 55

Contact Details 55

4

P5596.1600 rev B

www

.tr

olex.com

1. Product Overview

TX6355

Digital wireless output signal

Can be used with any Sentro eModule

Built in battery pack

1.1 Operating Features

•Fixed sensor for the detection of toxic gases and flammable gases

•Exclusive pre-calibrated plug-in gas sensing modules for many types of gas and

climatic conditions

•LCD readout and visual LED alarm indicators

•Strata specific digital wireless output signal

•Battery powered operation from built in battery pack

•Heavy duty housing to IP65, EMC compliant

•Simple, easy to use menu structure

•Easy integration into legacy wireless networks

TX6355 User Manual

www.trolex.com

P5596.1600 rev B

5

1.2 Application

Fixed point gas detection for safety monitoring in hazardous areas and general

purpose applications.

Underground Mining and Tunnelling

Ex ia

TX6355

Supply Voltage: 6 V dc from built in

battery pack

Type of protection:

Intrinsically safe. Ex ia

1.3 Product Options

Mining Ex: Supply Voltage:

TX6355.03 General Purpose - 6V dc from built in battery pack

TX6355.04.01 MSHA Approved - 6V dc from built in battery pack

TX6355.04.02 MSHA Approved and QPS Performance Approved 6V dc

from built in battery pack

TX6355.05 MASC Approved - 6V dc from built in battery pack

TX6355.06 Australia certified - 6V dc from built in battery pack

A choice of Sentro eModules for sensing a range of toxic and flammable gases.

See pages 9 to 14 for details of compatible Sentro eModules.

TX6355 User Manual

www.trolex.com

P5596.1600 rev B

7

1.5 Technical Information

Ambient temperature limits -20°C to +40°C

Storage temperature -20°C to +60°C

Ambient pressure 800 to 1100 mbar

Humidity 90% non-condensing

Protection classification Dust and waterproof to IP65. Gas Port: IP54.

Housing material Reinforced polymer

Nett weight 1400 g

Cable entries None

Information display 128 x 64 dot graphic backlit LCD

Vibration limits

Vibration limits (EN 60079-29-1):

• 10 to 30 Hz - 1.00 mm total excursion

• 31 to 150 Hz - 19.6 m/s2acceleration peak

Impact limits 20 joules (housing)

Calibration and setup

Digitally controlled ZERO and SPAN pushbutton

setting

Signal fix

The analogue output signal of the sensor is fixed

during calibration to prevent false alarms from

being initiated

Fault indication

Under range signal transmitted and fault display

for:

• Loss of communications from the sensing

module

• Sensing module absent for more than 10

seconds

• Negative drift below zero, 10% full scale

• Sensor over-range protect

Key coding

Coding stops prevent insertion of a non-valid

sensing module.

Alarms

Programmable General alarms and High alarms

with an LED indicator.

The two adjustable alarm setpoints are preset

during manufacture to default values appropriate

to the type of sensor, determined by the sensing

module being used.

8

P5596.1600 rev B

www

.tr

olex.com

Output signals Strata specific digital wireless output signal

Supply voltage 6V dc from internal battery pack

Current consumption 40 to 45 days life from internal batteries when

suitable eModules fitted. (see section 1.7.2)

Mounting By attachment point on the top of the Sentro

Wireless housing - will accept a standard 25 mm

strap

1.6 Electrical Details

Output signals

Strata specific digital wireless output signal

Supply voltage

6 V dc from internal battery pack

Current consumption

40 to 45 days life from internal batteries when

suitable eModules fitted. (see section 1.7.2)

Mounting By

attachment point on the top of the Sentro Wireless

housing - will accept a standard 25 mm strap

TX6355 User Manual

www.trolex.com

P5596.1600 rev B

9

1.7 Sentro eModules

Plug-in pre-calibrated eModules with standardised output data.

• Each eModule stores all the necessary data about its type identification, sensing

range and specific calibration. This data is automatically recognised by Sentro

when the eModule is loaded into the module bay

• The eModules are pre-calibrated so they can be replaced at any time with a

replacement sensing module - usually of the same type, but an alternative may

be inserted if required

• User configurable coding slots at each module bay can be individually configured

using coding stops to prevent invalid sensing module combinations

• The eModule will identify itself when plugged into the sensor housing and auto

configuration will take place

• All Sentro eModules have two output alarm signals for General alarm and High

alarm. Default values are entered during manufacture and these can be changed

to preferred values

•The alarm signals can be set to illuminate built-in flashing LED indicators

eModule Gas Sensor

1.7.1 Sentro eModules

For information and advice on the full range of Sentro eModules contact the Trolex

Sales Team: sales@trolex.com

1.7.2 MSHA Certified eModules

Sentro Wireless TX6355 is certified by MSHA for use with the following eModules:

12

P5596.1600 rev B

www

.tr

olex.com

2. Certification

2.1 United States of America

2.1.1 MSHA Approval

Meets the applicable requirements of Title 30 Code of Federal

Regulations, Part 18 (30 CFR Part 18). Approval No. 18-A150002-0.

For conditions of use refer to the MSHA controlled drawing no.

P5596. 1800.

2.1.2 Pennsylvania Approval

Pennsylvania Approval no. BFE 43-15 has been assigned to the

equipment. Pennsylvania State has determined that the minimum

safe blasting distance is 16.7 feet.

2.1.3 Gas Performance Approval

QPS certification covers the following:

•Sentro Wireless fixed point CO gas detector, model no.

TX6355.04.02, when fitted with a CO sensing eModule with part

no. TX6350.04.250.50 (0 to 50 ppm range) or eModule part no.

TX6350.04.250.500 (0 to 500 ppm range).

•Powered by 4 Energizer E95 D-cell type batteries.

•Indoor use and CO gas only.

•Ambient temperature range of -20°C to +40°C

Note: Only the display and local alarm indications were assessed

during the performance verification. The wireless output function was

not assessed during the performance verification but may be used

for data collection and record keeping functions or other non-safety

related functions.

Applicable Standards

•ANSI/ISA-92.00.01-2010 “Performance Requirements for Toxic

Gas Detectors, Approved 13 January 2011”

•UL 61010-1 “UL Standards for Safety Electrical Equipment for

Measurement, Control, and Laboratory Use; Part 1: General

Requirements –Third Edition; Reprint with revisions through and

including July 15, 2015”.

P5596.1600 rev B

13

www

.tr

olex.com

TX6355

User

Manual

This warning symbol on the equipment’s marking plate, Represents,

“Attention – consult accompanying documents”:

Refer to Section 1.7.2 for the list of approved eModules for

Sentro Wireless.

2.2 South Africa (MASC)

Ex certificate number: MASC M/15-0133X Ex certification code:

Ex ia I

Special Conditions of Safe Use (X)

1. May only be used with Energizer EN95/E95 D-type batteries.

2. Outputs #1 and #2 (P5596.01-M sheet 3 of 4) on the Sentro

Wireless configuration must be evaluated for intrinsic safety in its final

configuration when connected to other devices or equipment.

2.3 Australia IECEx

Model TX6355.06.nn is evaluated against the following standards:

IEC 60079-0:2011 Edition: 6.0

IEC 60079-11:2011 Edition: 6.0

Ex certificate numbers: IECEx TRA 16.0016X Ex certificate code: Ex ia I

Ma

Ingress Protection: IP65 except for gas inlet port (IP54)

Conditions of Use / Warnings:

1. Use only with Energizer E95/EN95 D-type Alkaline Cells. These

are wired to screw terminals 4, 5 on J6 Output Board only.

2. The other screw terminals 1, 2, 3, 6 on J6 Output Board shall not

be used in the hazardous area.

3. Only Trolex manufactured gas sensing modules (“eModules”)

identified by the top level part number “TX6350.06” shall be fitted.

The use of these eModules have been assessed for compatibility as

part of this certification and are suitable for use in Group I hazardous

location.

14

P5596.1600 rev B

www

.tr

olex.com

4. The cover screws must be torqued to a value of 1.24N*m (10in*lbs)

following replacement of the eModules (gas sensor) or batteries.

5. Do not open when coal dust is present.

6. Extreme care must be taken to protect the equipment from impact. In the

event the unit is dropped or impacted, a competent person must inspect it for

any damage that would impair the Ingress Protection (IP54).

7. The batteries must be removed to de-energise the unit before it is

transported /

relocated.

Ex-Certified e-Modules: Appropriate TX6350 e-Modules may be fitted as

assessed

P5596.1600 rev B

15

www

.tr

olex.com

TX6355

User

Manual

3. Installation

3.1 Safety Precautions

Hazardous areas

Do not disassemble the sensor whilst in the hazardous area or use a sensor that has a

damaged housing in the hazardous area. It is permissible to change the Sentro

Wireless batteries whilst in the hazardous area.

Evacuation

If a dangerous level of gas concentration is detected by the instrument, leave the area

immediately.

Flammable

Be aware that some toxic gases are also ‘flammable’ at high percentage

concentrations.

Operating Limits of Catalytic Combustion Sensors

Catalytic combustion sensors positively detect the presence of flammable gas. They

rely upon the presence of oxygen in the atmosphere and should only be used for gas

concentration up to the Lower Explosive Limit (LEL).

After this point, the output becomes non-linear and may erroneously indicate that the

gas concentration is below the LEL. They should not be used in oxygen enriched or

deficient atmospheres.

Discrimination

Catalytic combustion sensors can detect a wide range of flammable gases but they

cannot discriminate between individual gases. They will respond to most, or all,

of the flammable components present in the atmosphere without distinguishing

between them.

Infrared sensors are highly specific to the defined gas type and may not respond to

other similar gases.

Contamination

The response of catalytic combustion gas sensors can be affected by air borne

contaminants which will reduce the sensitivity. Substances such as silicones,

tetraethyl lead, sulphur compounds and phosphate esters can cause permanent

degradation (poisoning). Halogenated hydrocarbons may also cause temporary

inhibition.

16

P5596.1600 rev B

www

.tr

olex.com

Interference

If the atmosphere to be monitored contains a gas that dilutes or displaces the air,

this may reduce the response of catalytic sensors. Similarly, steam laden

atmospheres and condensation can reduce the stability.

High Concentrations of Flammable Gas

Exposure of low concentration catalytic combustion sensors to concentrations of

flammable gas greater than the LEL can affect the sensitivity and zero stability of

catalytic elements and the calibration should be checked after such an exposure.

Toxicity

Be aware that most flammable gases and vapours are also toxic at low

concentrations of LEL.

3.2. Tools and Test Equipment Required

No special tools are needed.

3.3. Siting Recommendations

Location of Gas Detectors

Each installation needs to be considered in its own right, with reference to safety

authorities and in compliance with mandatory local safety regulations. The

sensor must be operated in accordance with the User Manual to maintain safety,

reliability and to preserve safety integrity where applicable.

It is important that sensors are located in positions determined in consultation

with those who have specialised knowledge of the plant or installation and of the

principles of gas dispersion. Reference should also be made to those

responsible for the engineering layout and topology of the plant as they will be

most familiar with the nature of the potential dangers and the most likely sources

of gas release.

It is also important to recognise that the characteristics of the gas source can be

influenced by many factors; including the relative density or buoyancy of the gas,

the pressure at the point of release, the ambient temperature and the ventilation

of the site.

P5596.1600 rev B

17

www

.tr

olex.com

TX6355

User

Manual

Sensor coverage cannot be simply expressed in terms of ‘number per unit area’.

Sensors need to be sited where they are capable of monitoring those parts of a plant

where gas may accumulate or where a source of gas release is expected

to occur. This way, the earliest possible warning of a gas release can be given to

initiate shutdown functions, alarm functions or safe evacuation of the premises.

Trolex recommends that the Sentro Wireless Gas Detector is positioned a minimum of

6 m (20 ft) and no more than 245 m (800 ft) from a Strata CommTrac C node for the

Sentro Wireless Gas Detector to work effectively.

Sensor Management

A very important part of an efficient gas monitoring system is the training of plant

personnel in operation and maintenance of the sensors and the complete monitoring

system. Training can be provided by qualified Trolex application engineers. Once a

sensor installation is complete, the sensor locations and types should be formally

recorded and a planned test and maintenance procedure instituted.

STEL and TWA

Selected toxic gas sensors are equipped to automatically calculate STEL and TWA

limits in accordance with COSHH standards. If the facility is selected for use, ensure

that all accumulated data is reset to zero before the commencement of a working

period.

Checkpoint

STEL: Short term exposure limit of total accumulated units over a rolling fifteen

minute period. TWA: Time weighted average of gas concentration over a working

eight our period.

3.4 Connections

The Sentro Wireless sensor connects wirelessly to the Strata CommTrac mine wide

wireless network. Power is provided by batteries contained within the housing. No

hard wiring is required.

3.5 Connecting in Hazardous Areas

Certified Intrinsically Safe for use in underground mine hazardous areas.

The installation must be in accordance with the Sentro Wireless certification

parameters.

Table of contents

Other Trolex Gas Detector manuals

Popular Gas Detector manuals by other brands

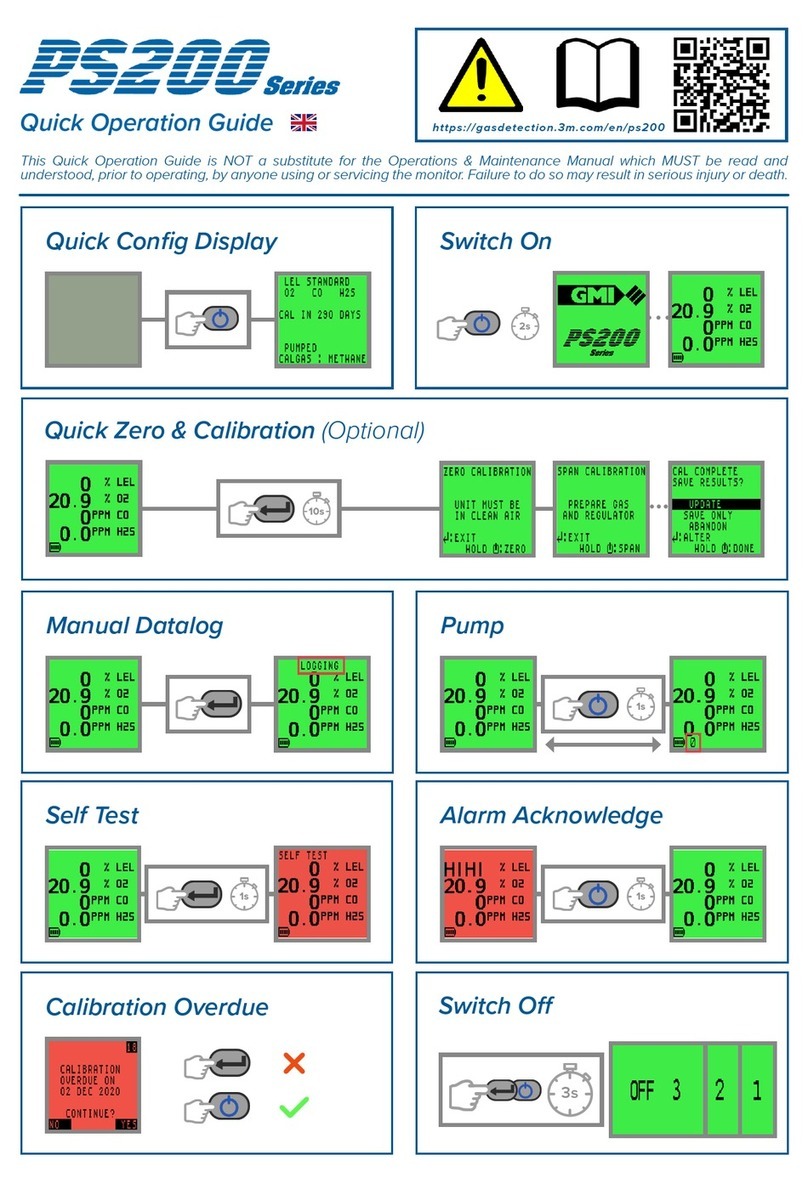

3M

3M GMI PS200 Series Quick operation guide

Riken Keiki

Riken Keiki SD-1DGH-AS operating manual

S+S Regeltechnik

S+S Regeltechnik AERASGARD ALQ-C02 Operating Instructions, Mounting & Installation

Honeywell

Honeywell BW GasAlertMicroClip XT user manual

König

König SAS-GD100U manual

GST

GST C-9602LW Installation and operation manual