Trox Technik ATVC-100 User manual

Installation manual

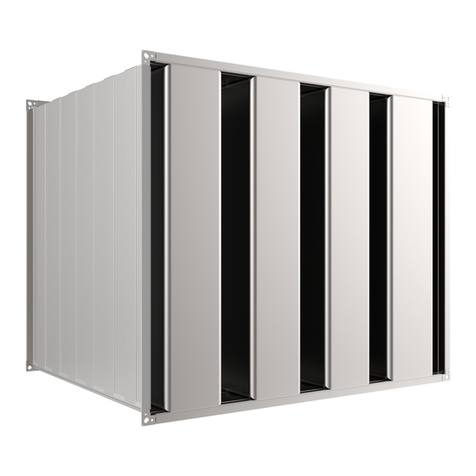

Automatic exhaust valve

Type ATVC-100

Subject to change · All rights reserved ·

L-50-7-02e

Installation manual for automatic exhaust valve ATVC-100

2

Contents

1. General information 2

2. Safety and correct use 3

General safety notes 3

Standards and guidelines 4

Repair and replacement parts 4

Environmental protection / disposal 4

Staff qualifications 4

Limitation of liability 4

Personal protective equipment 4

Correct use 4

3. Transport, storage and packaging 5

Delivery check 5

Transport on site 5

Storage 5

Packaging 5

4. Product description 6

Brief description 6

Special features of ATVC-100 6

How it works 6

Dimensions 6

5. Technical data 6

6. Installation / commissioning 7

Device selection 7

Performance diagram 7

Setting the basic volume flow rate V08

Assembly 9

7. Electrical installation 9

Electrical connection 9

Connection diagram 9

8. Maintenance 10

Maintenance and cleaning 10

1. General information

This installation manual describes the automatic exhaust valve

type:

ATVC-100

To ensure correct functioning of the automatic exhaust valve,

it is essential to read the provided installation manual before

starting any work, and to comply with it. The manufacturer

does not accept any liability for any malfunction or damage

resulting from non-compliance with these instructions or non-

compliance with relevant statutory regulations. This installati-

on manual is intended for specialist consultants, developers,

and owners of the ventilation systems in which the automatic

exhaust valve is to be installed. This installation manual is also

intended for people conducting the following work:

- Transport and storage

- Installation

- Electrical connection

- Commissioning

- Maintenance

- Cleaning

For details on the ATVC-100, see:

- Brochure L-07-2-05d

The installation manual and the brochure can be downloaded

from

www.troxhesco.com.

Installation manual for automatic exhaust valve ATVC-100

3

2. Safety and correct use

General safety notes

VORSICHT!

Verletzungsgefahr an scharfen Kanten, Graten, spitzen

Ecken und dünnwandigen Blechteilen!

– Bei allen Arbeiten vorsichtig vorgehen.

– Schutzhandschuhe, Sicherheitsschuhe und

Schutzhelm tragen.

GEFAHR!

Stromschlag beim Berühren spannungsführender

Teile. Elektrische Ausrüstungen stehen unter

gefährlicher elektrischer Spannung.

Nichtbeachtung kann Tod, schwere Körperschäden

oder Sachschaden verursachen!

– An den elektrischen Komponenten dürfen nur

Elektrofachkräfte arbeiten.

– Vor Arbeiten an der Elektrik die Versorgungs-

spannung ausschalten.

WARNUNG!

Gefahr durch Fehlgebrauch! Fehlgebrauch des

Produktes kann zu gefährlichen Situationen führen.

Das Produkt darf nicht eingesetzt werden:

– in Ex-Bereichen.

– im Freien ohne ausreichenden Schutz gegen

Witterungseinflüsse.

– in Atmosphären, die planmässig oder ausserplan-

mässig aufgrund chemischer Reaktionen eine

schädigende und/oder Korrosion verursachende

Wirkung auf das Produkt ausüben.

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation!

Unsachgemässer Umgang kann zu erheblichen Personen-

und Sachschäden führen.

– Alle Tätigkeiten nur durch dafür qualifiziertes Personal

in der Gebäudetechnik-Branche durchführen lassen.

VORSICHT!

Beschädigung des Produktes durch unsachgemässe

Behandlung! Gerät vor Inbetriebnahme auf Schäden

und Verunreinigung prüfen und beheben!

Unsachgemässer Umgang kann zu erheblichen

Sachschäden am Produkt führen.

– Keine säurehaltigen oder scheuernden Reinigungs-

mittel verwenden.

– Klebstoffe von Klebebändern können Farbschäden

verursachen.

– Unverhältnismässige Feuchtigkeit kann zu

Farbschäden und Korrosion führen.

– Nur ausdrücklich spezifizierte Reinigungsmittel,

Fette und Öle benutzen.

Installation manual for automatic exhaust valve ATVC-100

4

Standards and guidelines

For all work on the automatic exhaust valve, the following regu-

lations and guidelines must be observed among others:

- Product Safety Laws (PrSG)

- EKAS provisions

The local regulations for health and safety at work and general

safety regulations also apply.

Repair and replacement parts

To maintain the function, use only original TROX HESCO

Schweiz AG replacement parts.

Environmental protection / disposal

To protect the environment keep the following in mind:

- The packaging of the automatic exhaust valve must be dis-

posed of in an environmentally- friendly

manner.

- The automatic exhaust valve must be disposed of properly

by an authorised agent after its final decommissioning.

- Dispose of electronic components according -

to the national electronic waste regulations.

Qualied sta

Skilled qualied electrician

Skilled qualified electricians are individuals who have sufficient

professional or technical training, knowledge and actual ex-

perience to enable them to work on electrical systems, under-

stand any potential hazards related to the work under conside-

ration, and recognise and avoid any risks involved.

Specialist personnel

Specialist personnel are individuals who have sufficient profes-

sional or technical training, knowledge and actual experience to

enable them to carry out their assigned duties, understand any

potential hazards related to the work under consideration, and

recognise and avoid any risks involved.

Limitation of liability

The information in this manual has been compiled with refe-

rence to the applicable standards and guidelines, the state of

the art, and our expertise and experience of many years.

The manufacturer does not accept any liability for damages

resulting from:

- Non-compliance of these instructions

- Improper use

- Operation or handling by untrained individuals

- Unauthorised modifications

The actual supply package may differ from the information in

this manual for special versions, additional order options or as

a result of recent technical changes.

Personal protective equipment

Personal protective equipment must be worn for any work in

order to reduce health or safety hazards to the minimum.

The appropriate protective equipment for a job must be worn

for as long as the job takes.

Industrial safety helmet

Industrial protective helmets protect the head from falling ob-

jects, suspended loads and knocks against

stationary objects.

Protective gloves

Protective gloves protect hands from friction, abrasions, punc-

tures, deep cuts, and direct contact with hot surfaces.

Safety shoes

Safety shoes protect the feet against crushing, falling parts,

and from slipping on slippery ground.

Correct use

The automatic exhaust valve ATVC-100 is suitable for installati-

on in multi-storey residential and commercial buildings, hotels,

schools, etc. with central exhaust air systems.

The ATVC-100 can be installed in new buildings and in refur-

bishment projects.

Installation manual for automatic exhaust valve ATVC-100

5

3. Transport, storage and packaging

Delivery check

Upon delivery, carefully remove the packaging and check the

unit for transport damage and completeness. In case of any

damage or an incomplete shipment, contact the shipping com-

pany and the supplier immediately. Put the product back into

its packaging after the delivery check to protect it from dust

and contamination.

Transport on site

Please note:

- When unloading the delivery and transporting on-site,

proceed with care and observe the symbols and notices-

on the packaging.

- Devices should preferably be transported to the installation

location in their

original packaging.

- Use only lifting and transport gear

designed for the required load.

- Always secure the load against tipping and falling.

- Cumbersome equipment should be transported with at least

two people to

prevent injury and damage.

Storage

Please note:

- Store the product only in its original packaging.

- Protect the product from the effects of weather.

- Protect the product from humidity, dust and contamination.

- Storage temperature: -10 °C to +30 °C..

- Relative humidity: maximum 95%, no condensation

Packaging

Properly dispose of packaging material.

Befestigungs- und Montagematerial

Befestigungs- und Montagematerialien sind, soweit nicht

anders angegeben, kein Bestandteil der Lieferung und

müssen bauseits, abgestimmt auf die jeweilige Einbausitua-

tion beigestellt werden.

Installation manual for automatic exhaust valve ATVC-100

6

4. Product description

Brief description

The automatic exhaust valve is an exhaust air device control-

led by an electric external power supply. It is normally closed

or only slightly open to enable a basic volume flow rate. Air is

only extracted at a higher operating volume flow rate when the

corresponding switch contact is closed.

Special features of the ATVC-100

- Heating energy can be saved thanks to targeted ventilation

(basic volume flow rate/operating volume flow rate).

- No high volume flow rate during brief occupation of the

room thanks to the installed start delay.

- Silent opening and closing of exhaust valve.

- Exhaust valve and electro-thermal drive made from proven

components.

- Easy assembly.

- Taking the diversity factor into account,

a smaller roof fan and riser duct

can be selected.

- The exhaust valve can be closed tightly.

- Connection to the normal lighting network 230V 50Hz wit-

hout

additional delay relay (follow-up ventilation) or transformers.

How it works

When the circuit is closed, the electro-thermal drive heats up

and causes the valve disc to open within 2 to 4 minutes (delay

during brief occupation of the room). Air is exhausted through

the opening between the valve housing and the valve disc.

The valve stroke (6 mm) is always the same, i.e. the valve disc

always moves from the minimum setting to the maximum valve

opening. In the minimum setting, the exhaust valve can either

be closed or opened. Since the valve stroke is always the

same, the operating volume flow rate cannot be freely selected,

but is dependent on the minimum setting. The exhaust valve

stays open at the maximum valve stroke for as long as the

circuit is closed. Once the circuit has been interrupted, the

automatic exhaust valve remains open for follow-up ventilati-

on for approx. 5-8 minutes before it starts to move back to its

minimum setting slowly and silently.

Dimensions

1 Valve casing

2 Valve disc

3 Electro-thermal actuator

4 Tappet

5 Knurled nut

6 Electrical connection

7 Spring element (3 pieces)

8 Foam seal

5. Technical data

Nominal voltage 230V 50 Hz

Power consumption – initial 60 W

Power consumption – when run-

ning

8 W

Max. ambient temperature 30° C

Opening time 2 to 3 min.

Closing time 5 to 8 min.

Device for connection opening Ø 100 mm

Installation manual for automatic exhaust valve ATVC-100

7

6. Installation / commissioning

Device selection

The exhaust valve is determined by the following data:

- Stat. pressure loss ps(Pa)

- Basic volume flow rate (m3/h)

- Operating volume flow rate (m3/h)

Using this data, the stat. pressure loss and only one of the two

volume flow rates can each be freely selected.

The performance diagram (see below) is used to determine the

following:

- Number of rotations

- Residual volume flow rate

- Acoustic data.

Note that, if the minimum setting is selected, then the corre-

sponding operating volume curve must be taken into account.

Performance diagram

Example (as plotted)

Given:

- Stat. pressure drop ps= 40 Pa

- Operating volume flow rate V = 80 m3/h

Solution:

- Rotations for minimum setting 1

- Basic volume flow rate: Vo = 10 m3/h

- Sound power level for:

Basic volume flow rate <25 dB(A)

Operating volume flow rate approx. 38 dB(A)

10

20

30

40

50

100

Druckabfall ps[Pa]

15

60

80

LwA = 25 dB(A)

30 dB(A)

0

1

2

3

4

5 10 15 20 30 40 50 60 30 40 50 100 150 200

Grundvolumenstrom

‡

o[m³/h] Betriebsvolumenstrom

‡

[m³/h]

10

20

30

40

50

100

Druckabfall ps[Pa]

15

60

80

35 dB(A)

40 dB(A) 45 dB(A)

40 dB(A)

35 dB(A)

LwA = 30 dB(A)

ps

10

20

30

40

50

100

Perte de pression ps[Pa]

15

60

80

LwA = 25 dB(A)

30 dB(A)

0

1

2

3

4

5 10 15 20 30 40 50 60 30 40 50 100 150 200

Débit d'air de base ‡o[m³/h] Débit d'air de service ‡[m³/h]

10

20

30

40

50

100

Perte de pression ps[Pa]

15

60

80

35 dB(A)

40 dB(A) 45 dB(A)

40 dB(A)

35 dB(A)

LwA = 30 dB(A)

ps

10

20

30

40

50

100

Pressure drop ps[Pa]

15

60

80

LwA = 25 dB(A)

30 dB(A)

0

1

2

3

4

5 10 15 20 30 40 50 60 30 40 50 100 150 200

Basic air volume rate ‡o[m³/h] Operating air volume rate ‡[m³/h]

10

20

30

40

50

100

Pressure drop ps[Pa]

15

60

80

35 dB(A)

40 dB(A) 45 dB(A)

40 dB(A)

35 dB(A)

LwA = 30 dB(A)

ps

Installation manual for automatic exhaust valve ATVC-100

8

Setting the basic air volume ow rate V0

The automatic exhaust valve is delivered ex-works in a closed

condition (basic volume flow rate V0 = m3/h). If a basic volume

flow rate is required, this must be set as follows:

1 Valve casing

2 Valve disc

3 Electro-thermal actuator

4 Tappet

5 Knurled nut

Place the exhaust valve on a firm base as shown, e.g. on a

table, and loosen the brass knurled nut "5" by turning it one

rotation in a clockwise direction.

Hold the exhaust valve at the electric drive as shown and, using

one finger of your free hand, open the valve disc "2" by turning

it the required number of rotations in an anticlockwise direction.

Place the exhaust valve on a firm base as shown, e.g. a table,

hold it firmly with one hand against the base and tighten the

knurled screw "5" in an anticlockwise direction up to the tappet

"4".

Note: It is important that the valve disc does not rotate during

this operation.

The exhaust valve is now set.

1

5

2

4

3

5

2

45

Installation manual for automatic exhaust valve ATVC-100

9

Assembly

Once the required volume flow rate has been set and the

electric connection has been completed, the automatic exhaust

valve can be inserted into the appropriate opening so that the

casing is flush with the wall. The exhaust valve is held in the

opening by 3 spring elements.

Initial commissioning

Before you start commissioning:

- Check that the air terminal devices are seated correctly.

- Remove protective film.

- Ensure that all air terminal devices are clean and free from

residues and foreign matter.

- Check that electrical connections (if any) have

been correctly made.

- Check that the fixing and connection -

with the air duct is correct.

Volume ow rate balancing

When several diffusers are connected to just one volume flow

controller, it may be necessary to balance the volume flow

rates.

7. Electrical installation

GEFAHR!

Stromschlag beim Berühren spannungsführender

Teile. Elektrische Ausrüstungen stehen unter

gefährlicher elektrischer Spannung.

Nichtbeachtung kann Tod, schwere Körperschäden

oder Sachschaden verursachen!

– An den elektrischen Komponenten dürfen nur

Elektrofachkräfte arbeiten.

– Vor Arbeiten an der Elektrik die Versorgungs-

spannung ausschalten.

Electrical connection

Location of the electric cable

It is best to lead the electrical cable into the round air extract

opening.

Connection diagram

A 2-pin plug-in connector with protective contact is provided

for the electrical connection on site. Plug "A" can be removed

from the connector plate "C" after loosening the central screw

"B". With the central screw "B" removed from the plug "A", the

insert "F" can be pressed out with a screwdriver at the point

marked "D".

Installation manual for automatic exhaust valve ATVC-100

10

8. Maintenance

Maintenance and cleaning

Please note:

- Clean surfaces with a damp cloth.

- Only use commercially available, non-corrosive cleaning

agents-

for cleaning.

- Do not use cleaning agents that contain chlorine.

- The use of cleaning tools for removing persistent

contamination, e.g. scrubbing sponges and scouring agents,

can damage the surface and is not permitted.

- All technical components can be replaced

if defective.

GEFAHR!

Stromschlag beim Berühren spannungsführender

Teile. Elektrische Ausrüstungen stehen unter

gefährlicher elektrischer Spannung.

Nichtbeachtung kann Tod, schwere Körperschäden

oder Sachschaden verursachen!

– An den elektrischen Komponenten dürfen nur

Elektrofachkräfte arbeiten.

– Vor Arbeiten an der Elektrik die Versorgungs-

spannung ausschalten.

Design subject to change (06/2017)

Table of contents

Other Trox Technik Control Unit manuals

Trox Technik

Trox Technik Auranor FMS-A User manual

Trox Technik

Trox Technik XS User manual

Trox Technik

Trox Technik EM-BAC-MOD-01 User manual

Trox Technik

Trox Technik EM-IP Instruction sheet

Trox Technik

Trox Technik TROX UNIVERSAL User manual

Trox Technik

Trox Technik HESCO HFA User manual

Trox Technik

Trox Technik EM-TRF User manual