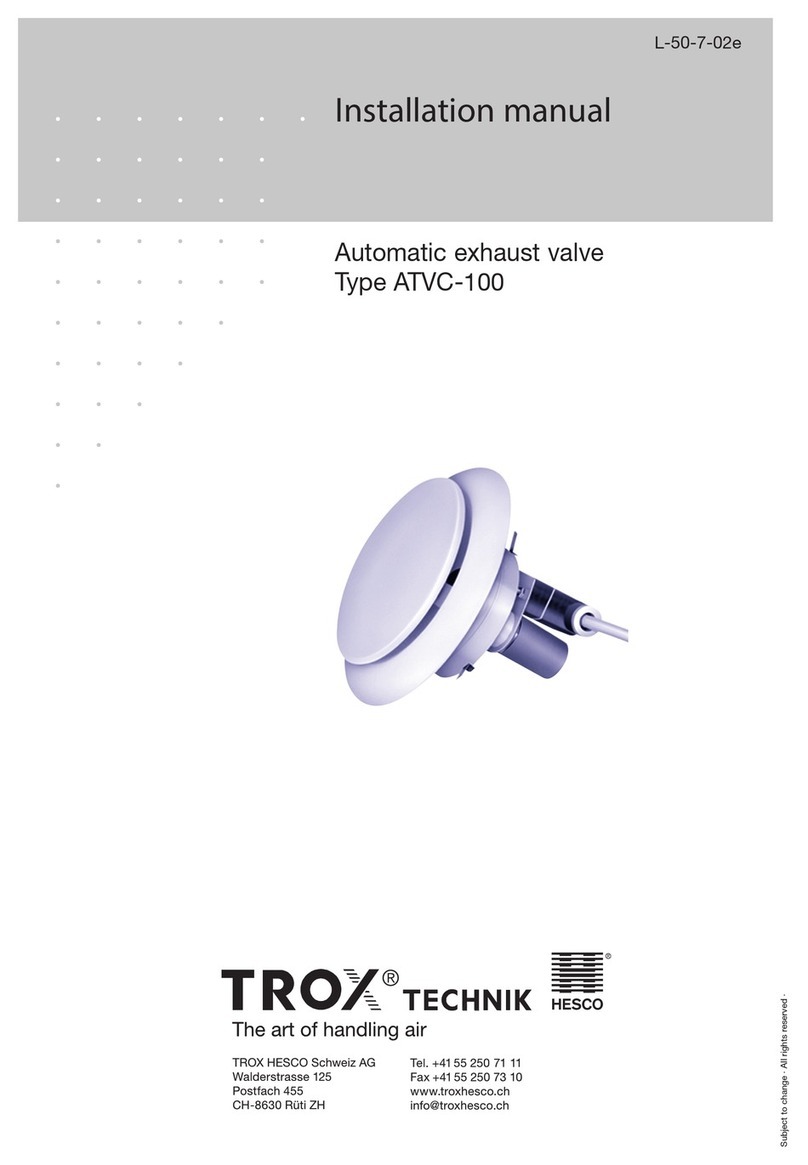

Installation manual for automatic extract air valve

4

Standards and guidelines

For all work on the automatic extract air valve, the following

provisions and guidelines among others must be observed

- Product Safety Law (PrSG)

- EKAS provisions

The local regulations for health and safety at work and general

safety regulations also apply.

Repair and replacement parts

To maintain the function, use only original TROX HESCO

Schweiz AG replacement parts.

Environmental protection / disposal

To protect the environment keep the following in mind:

- Dispose of packaging for the automatic extract air valve in

an environmentally sound manner.

- The automatic extract air valve must be disposed of pro-

perly- by an authorised agent after its final

decommissioning.

- Dispose of electronic components according -

to the national electronic waste regulations.

Qualied sta

Skilled qualied electrician

Skilled qualified electricians are individuals who have sufficient

professional or technical training, knowledge and actual ex-

perience to enable them to work on electrical systems, under-

stand any potential hazards related to the work under conside-

ration, and recognise and avoid any risks involved.

Specialist personnel

Specialist personnel are individuals who have sufficient profes-

sional or technical training, knowledge and actual experience to

enable them to carry out their assigned duties, understand any

potential hazards related to the work under consideration, and

recognise and avoid any risks involved.

Limitation of liability

The information in this manual has been compiled with refe-

rence to the applicable standards and guidelines, the state of

the art, and our expertise and experience of many years.

The manufacturer does not accept any liability for damages

resulting from:

- Non-compliance of these instructions

- Improper use

- Operation or handling by untrained individuals

- Unauthorised modifications

The actual supply package may differ from the information in

this manual for special versions, additional order options or as

a result of recent technical changes.

Personal protective equipment

Personal protective equipment must be worn for any work in

order to reduce health or safety hazards to the minimum.

The appropriate protective equipment for a job must be worn

for as long as the job takes.

Industrial safety helmet

Industrial protective helmets protect the head from falling ob-

jects, suspended loads and knocks against

stationary objects.

Protective gloves

Protective gloves protect hands from friction, abrasions, punc-

tures, deep cuts, and direct contact with hot surfaces.

Safety shoes

Safety shoes protect the feet against crushing, falling parts,

and from slipping on slippery ground.

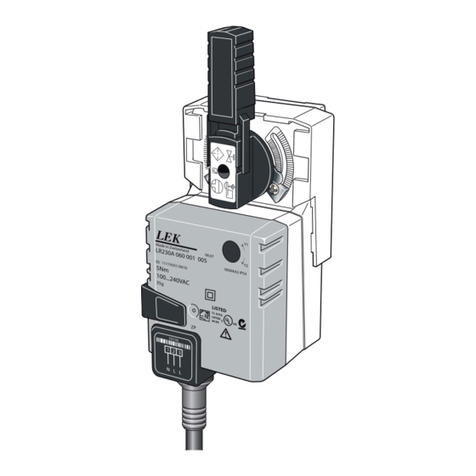

Correct use

The automatic extract air valve is used for central, energy-

saving extract air systems.