Tru-Test LactoCorder T-T User manual

__________________________________________________________________________

System LactoCorder T-T

Operating Manual

Development and production

WMB AG

Wegenstrasse 6 - CH-9436 Balgach

Tel. +41(0)71 727 18 30 - Fax +41(0)71 727 18 31

Internet www.wmb.ch

________________________________________________________________________

1

Table

Page

1 General.... ................................................... ... .1

1.1 Table........................................................................ .... 1

2 INTRODUCTION.......................................... ..... .2

2.1 Note........................................................................... ... 2

2.2 Used abbreviations................................................ 2

2.3 Special regulations...................................................... ... 3

2.4 Care note.. .................................................................. .. 3

2.5 Appropriate use....................................... . 4

2.6 Transport................................................................................. 4

2.6.1 Packaging............................................................ . 4

2.6.2 Unpacking / Entrance control.................................... 4

2.6.3 Transport damage............................................. ...... . . 4

2.7 Safety................................................................................. 5

2.7.1 General............................................................ . 5

2.7.2 Special note.......................................... . 5

2.7.3 Selection of operating personnel........................................... 5

3 Test fluid for water tests.............................. 6

4 Setting up the LC T-T in the stable........................... ...... 6

5 One-time settings........................................ 6

6 Problem of a not completely empty LC T-T ................ 7

7 Add the amount of the gap to the total quantity of milk? 8

8 Calculation of the amount of milk when

measured without emptying. 9

9 Battery management........................................................... .10

10 Possible errors and their solutions................................... .10

11 Transfer of data to LactoPro............................................... 11

________________________________________________________________________

2

2 Introduction

2.1 Note

Read these operating

instructions before unpacking

and before commissioning the

device and pay close attention!

The device may only be used

by persons familiar with the

operating instructions and the

applicable regulations on

occupational safety and

accident prevention.

2.2 Uses Abbreviations

LC T-T= LactoCorder T-T

The following names or signs are used in the operating instructions for

particularly important information:

Attention Indications of risk of injury to persons or risk of

damage to equipment parts

________________________________________________________________________

3

2.3 Special provisions

Attention The LactoCorder T-T is an electronic high-tec

measuring instrument that has to be treated

with care.

The following actions and applications are

prohibited and release the manufacturer from

any warranty:

1. Immersion or cleaning with high pressure

cleaning equipment, compressed air and

direct water jet (IP 64)

2. Use of solvents or solvent-based substance

and non-standard cleaning products not

approved for milking machines

3. Separate mechanical or chemical cleaning

of the probes (e.g. brushes with abrasives

or similar)

4. Mechanical force effects due to impacts and

improper handling

5. Falls and transport damage

6. Processing of the equipment different from

the maintenance and repair instructions

7. Tighten screws without paying attention to

the pre-written torques (Ncm)

2.4 Care notice

The following care instructions are required to maintain

the functionality of the LC T-T.

After measuring carry out internal cleaning

with the cleaning program.

Then remove the blowpipe and clean it separately.

________________________________________________________________________

4

2.5 Appropriate use

The LC T-T is only used to check the quality and quantity of

animal milk.

Any other use or in excess is considered improper

as intended. The resulting damages the manufacturer is not liable.

The user bears the risk alone.

The intended application also includes the observance of

instructions and compliance with the inspection and

Maintenance conditions.

2.6 Transport

2.6.1 Packaging

Keep the carton and packaging material for a

later transport so that the device can be transported safely.

2.6.2 Unpacking / Entrance Control

The shipping container for machines and equipment keeps normal

stresses during transport on roads, rails and in

the air.

Before you put the device into operation, check whether the

parts listed on the delivery note are completely and undamaged

in the scope of delivery. If the scope of delivery is

faulty - please contact our customer service.

2.6.3 Transport Damage

For damage caused during transport, the transport company

is responsible. A full report that assesses the damage

described in detail, the transport company must be submitted to them

and serves as the basis for the claim for damages.

Damage or loss of the goods delivered by us are to be reported to us

immediately and has to be confirmed by a copy of the above-

mentioned report.

________________________________________________________________________

5

2.7 Safety

2.7.1 General

The design of the LC T-T corresponds to the current state of

technology and is reliable.

The individual modules as well as the complete device are

tested by our quality assurance.

Only use the device when it is in perfect condition and in

accordance with its intended purpose, consciously taking

into account the operating instructions.

Faults that may affect operational safety,

eliminate immediately.

2.7.2 Special note

Before commissioning the device, read the operating instructions

carefully.

Lack of knowledge about the operation and support of the system

can cause damage to the LC T-T.

Keep the operating instructions always at the place of use!

Changes or modifications to the device are not permitted

without the approval of the supplier.

No program changes (software) to programmable

control systems!

2.7.3 Selection of operating personnel

Work on the LC T-T may only be carried out by well-instructed

personnel.

Use only well-trained personnel. Regulate the responsibility

of the staff for equipping, operating, maintenance,

and repairing clearly.

________________________________________________________________________

6

3 TEST FLUID FOR WATER TESTS

To preserve the test liquid for the water tests, mix 45 ml Neoagrar with 15 l

Water. This mixture should have a conductivity between 5.5 and 6.5mS.

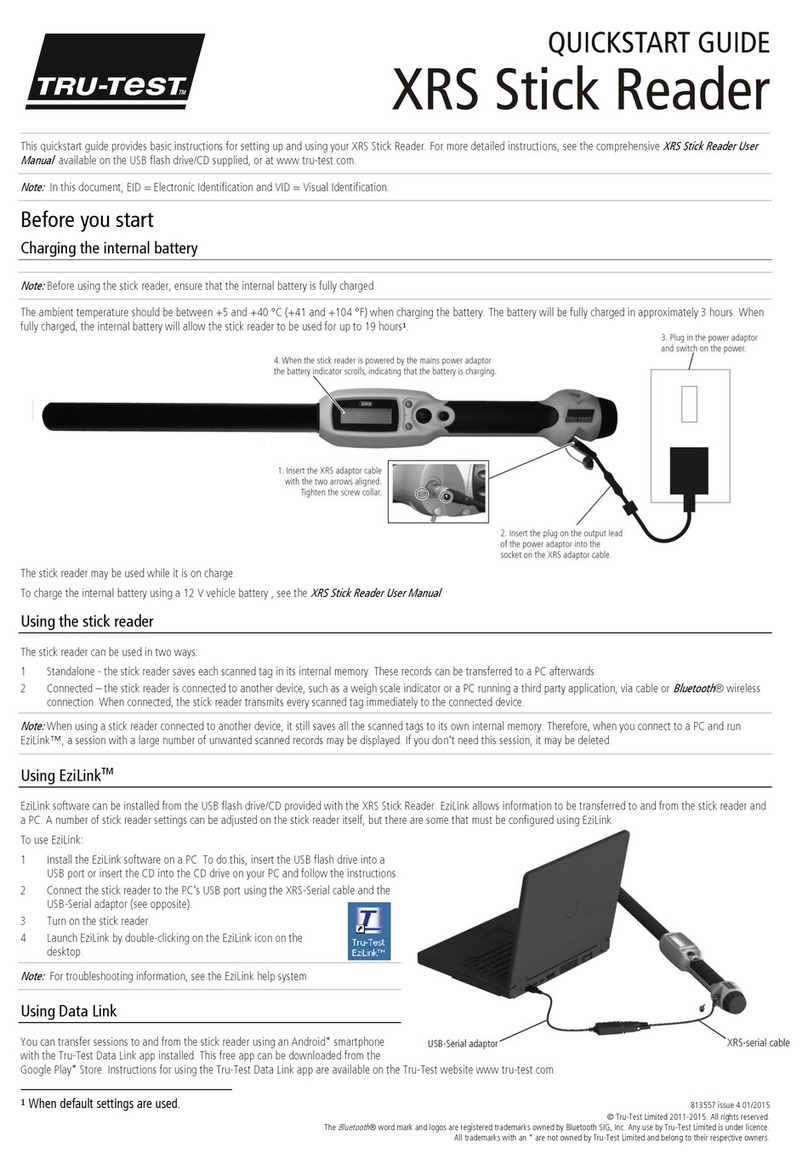

4 SETTING THE LC T-T IN STABLE

The LC T-T can be hung with hanging brackets or plug-in brackets or

positioned in the stable.

The devices should hang as vertically as possible.

The hose guide is important. The hoses should be as short as possible. The

Milk must always be able to drain completely. Standing milk would distort

the result of the measurement of the LC T-T.

5 One-time setting

The following settings must be made once.

5.1 Turn on LC T-T

5.2 Put in the USB stick on the LC T-T

5.3 In the main menu, press the button "9" twice in quick succession. It

appears the password entry for the hidden service menu.

5.4 Enter the six digits password (complementary value 9) to the device number

e.g.: LC T-T Device number: 070086

Password: 929913

5.5 Confirm with the "ENTER" button.

5.6 Press the "3" button (settings).

Activate measurement online data

5.7 Press button "1" (Online b. Measurement). The selection appears

if you want to measure with or without online data.

In the first line appears the selected option.

5.8 Press button "2" (with online data).

Activate cleaning online data

5.9 Press button "2" (Online b. Clean)

5.10 Press button "2" (with online data) or button “1” (without online data)

Setting language

5.11 Press button "4" (select language)

5.12 Press button "1" (German) » Select your language

5.13 Press the "CLEAR" button, Back to the settings menu

5.14 Switch to the next menu with the "ENTER" button

________________________________________________________________________

7

LC T-T_empty after each measurement

5.15 Press button "5" (empty after measurement)

Select if the LC T-T should be emptying or not after each measurement.

(Our proposal is to choose for milk quantity measurement without emptying)

Press the "1" button (without emptying), the LC T-T will not be

emptied.

Enter a weighted quantity of milk for online measurement

5.16 Press button "8" (weighted milk quantity)

5.17 Press button "2"

5.18 Switch to the next menu with "ENTER".

Enter the sampling during online measurement

5.19 Press button "9" (Enter sample)

5.20 Press the "2" button

Then, press four times "CLEAR" to get back to the main menu.

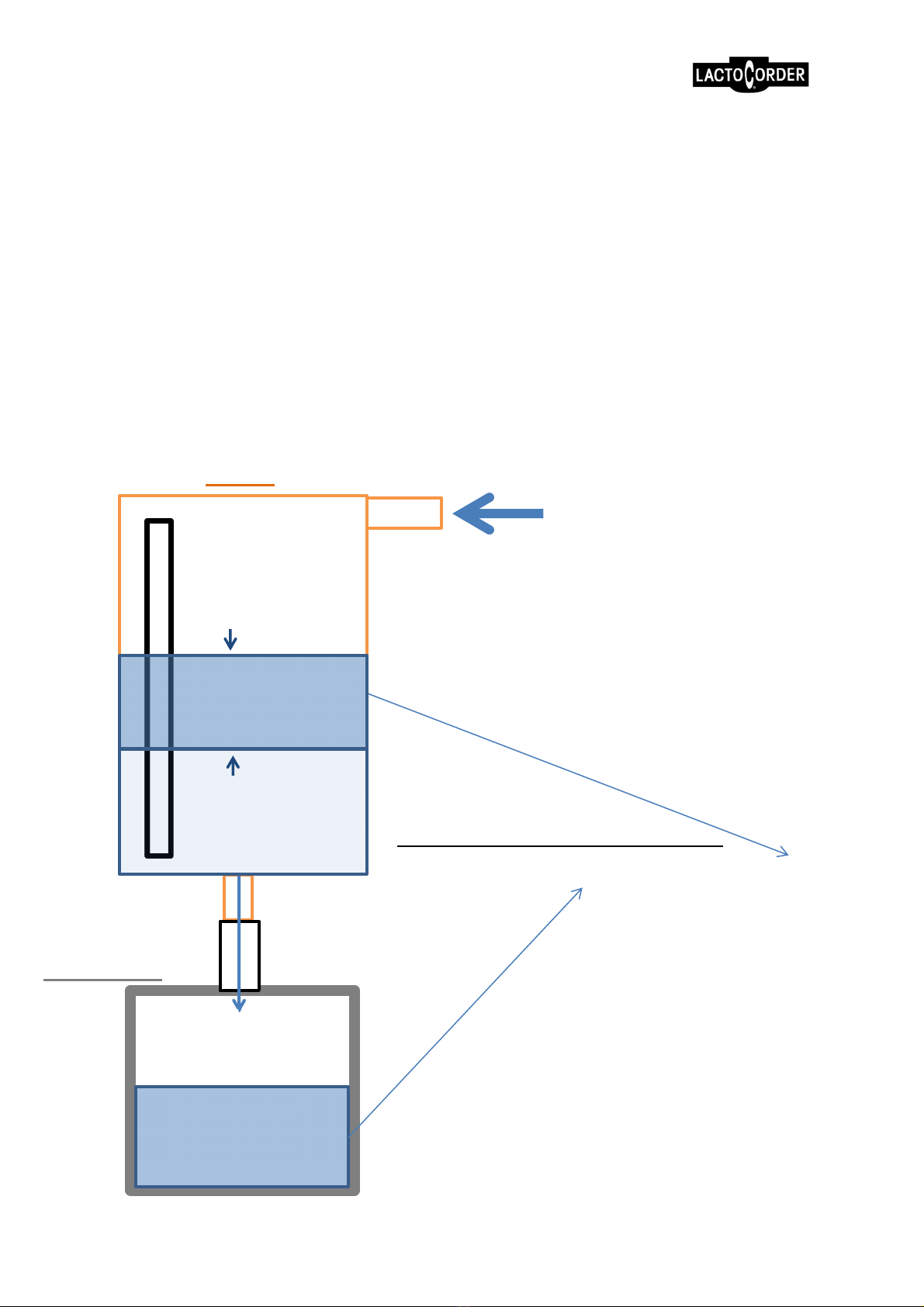

6 Problem of a not completely empty LC T-T

Very low levels cannot be measured exactly, as the output of the pressure pipe is not

completely covered with liquid. After emptying, an empty LC T-T is assumed. If the LC T-T

is not empty at the start of the measurement, errors in the milk quantity measurement will

result.

Residual milk

and milk foam

Pressure pipe for

measuring the level

of the milk

Fluid Cover LC T-T

________________________________________________________________________

8

7 Add the amount of the gap to the total quantity of milk?

It depends on the measurement procedure if the content of the sampling may be added on

the LC T-T for the total or not.

7.1 Milk quantity measurement and sampling at the same time

Where sampling and milk quantity measurement are carried out jointly, the

amount of milk split off from LC T-T may be added to the quantity of milk.

7.2 Checking the quantity of milk

The test of the quantity of milk may be carried out without sampling.

If the milk quantity measurement is carried out with sampling, usually the milk in the

sampler will be emptied in the bucket of the current milking. In this case,

the addition of the release quantity to the quantity of milk must be active.

________________________________________________________________________

9

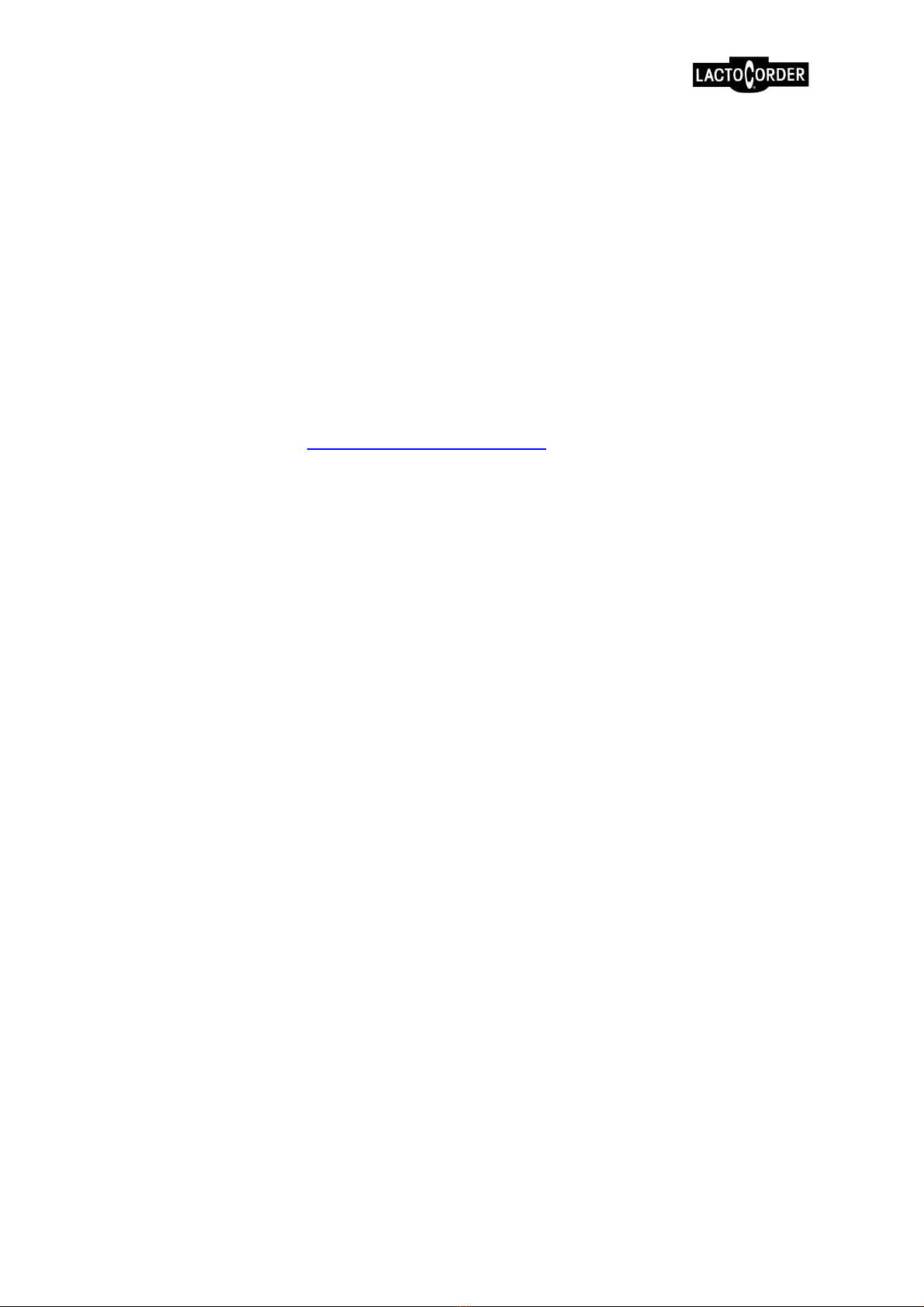

LC T-T

Total amount of milk from the animal

Milk quantity Animal = "Milk in bucket" + "Difference

quantity"

Milk poured into

the bucket

Milk bucket

Milk from the animal

Milk through the

aperture

Level at the

start of

measuring

Difference quantitiy

Level at the end

of measuring

8 Calculation of the amount of milk when measured without

emptying

If the milk quantity measurement is checked without emptying, the remaining volume

(difference volume) in the LC T-T has to be taken into account.

The storage level in the LC T-T is always different at the end of a measurement. This milk

quantity difference that must be taken into account.

The LC T-T measures the storage level of the milk at the beginning (starting level) and at

the end of the Measurement (final level). In this manner the weight of the milk, which

remain in the LC T-T, will be added to the amount in the bucket. When counterweighing, it

is necessary to add this milk, which is left inside in the LC T-T, is taken into account in

order to guarantee the effective quantity of milk from the animal. The LC T-T quantity and

the weigh can be compared as follows:

Lc T-T Quantity = "milk in a bucket" + difference = quantity of milk of the animal

________________________________________________________________________

10

9 Battery management

The LC T-T uses a lithium-ion battery with 4400 mAh. The battery indicator above

on the right provides information about the capacity state of the battery.

The following states are distinguished:

Icon Batter

y

condition Measures

Battery 100% charged

No measures

Battery 85% charged

No measures

Battery 75% charged

No measures

Battery 60% charged

No measures

Battery 50% charged

No measures

Battery 35% charged

Replaced and charged battery on occasion

Battery 25% charged

Replace the battery after milking and

Load

Battery 10% charged

Immediately replace and charge the

battery

no more milking

Table 1: Battery capacity indicator

10 Possible errors and their solution

10.1 Error: No filter inserted. Measurement not possible without filter

This error is displayed when starting up and starting the measurement when in the

LC T-T no filter is inserted. Either the filter is missing or the magnet in the filter is not

inserted.

10.2 Display by measurement: Storage Online. Failed!

For computing capacity reasons, the LC T-T does not have the option of making a PC

error in USB communication. Therefore, it may be possible that a USB stick on the PC

can still be read, but the LC T-T displays an error message. In this case, the USB stick

should be replaced.

If there is an error when writing the online data to the USB stick, it must be repeated or

canceled. If this has been aborted, it can be transferred to the measurement data on the

USB stick. Only then new online data can be recorded.

________________________________________________________________________

11

10.3 Cleaning takes longer than there is space in the online data

A maximum of 90 min. online values can be recorded during a cleaning process.

If a cleaning takes more than 90 min. it will indicate that a RAM overflow has occurred and

that the online readings are not complete. In this case, the first 90 min. of the cleaning

were recorded. This only applies to online values. Cleaning continues normally.

11 Data transfer to LactoPro

The measured data can be analyzed in LactoPro.

This should be used with LactoPro version 6.0.90. This version can be obtained from

WMB or from the website: www.wmb.ch/LCT-T/lactopro

11.1 Data on the USB stick

The measurement data from the LC T-T is displayed on the USB stick in the folder "LCS

measurement data". If this folder is not already available, the LC T-T will automatically

create one. The measurement data file is made up of the abbreviation MD for

measurement data, the operating number and the date when operating data was written to

the LCS. If no operating data has been used, 0 is entered.

e.g.: MD_1234567890123456_121115.DAT

MD: Identification for a measurement data file

1234567890123456: Operating number

121115: On 12/11/2015 the operating data on the LC T-T

were loaded

11.2 Transferring data to the PC

The desired measurement data file must be copied manually in the LactoPro folder in the

following path:

".. "LactoPro\Daten\Datapack"LCS_Messdaten"

The LCS_Messdaten folder must be created manually once.

The program "LactoPro" can then be started. The reading of the LC T-T measurement

data is now the same as reading data from a data pack.

Under "Data- Telepack -> Measurement and Operating Data DP -->PC"

The LC T-T data can be viewed like the data from the LactoCorder in LactoPro.

The following values are currently stored correctly:

- Operating number

- Animal number 2

- Bottle ID

- Device number

- Time

- Date

- Milking place number

________________________________________________________________________

12

- expected milk quantity

- Battery status (0: full, 1: 2/3, 2: 1/3, 3 almost empty, 4 empty)

- Total milking

- Species

11.3 Write data to USB stick:

11.3.1 Turn on LC T-T

11.3.2 Insert the USB stick on the LC T-T

11.3.3 Switch to the next menu with the "Enter" button

11.3.4 Button "5" (data transfer)

11.3.5 Button "2" (data write)

Table of contents

Other Tru-Test Test Equipment manuals