Truckman Roll-Top Xtreme User manual

Tools Required for Assembly ..................................... 1

Before You Start .......................................................... 1

Drain Hole Locations.................................................... 1

STEP 1: Remove From Packaging, and

Hardware and Packaging Contents ............................. 1

STEP 2: Positioning Canister ..................................... 2

STEP 3: Installing Rails .............................................. 2

STEP 4: Installing Top Cover ...................................... 4

STEP 5: Installing Clamps........................................... 5

STEP 6: Installing Rail Kickstands .............................. 6

STEP 7: Installing Tailgate Drain Tubes...................... 7

STEP 8: Lubricating Sweep Seals .............................. 8

STEP 9: Installing Canister Drain Tubes .................... 8

STEP 10: Attach the Pull Strap .................................. 8

Operating Instructions .................................................. 9

Maintenance ................................................................ 9

Warranty Statement ..................................................... 10

ARV1-1705

INSTALLATION INSTRUCTIONS

VOLKSWAGEN AMAROK

TABLE OF CONTENTS

Truckman

Unit 14 Narrowboat Way

Dudley

West Midlands

DY2 0EZ

Telephone: +44 (0) 1384 485405

http://www.truckman.co.uk

UNCONTROLLED DOCUMENT

1

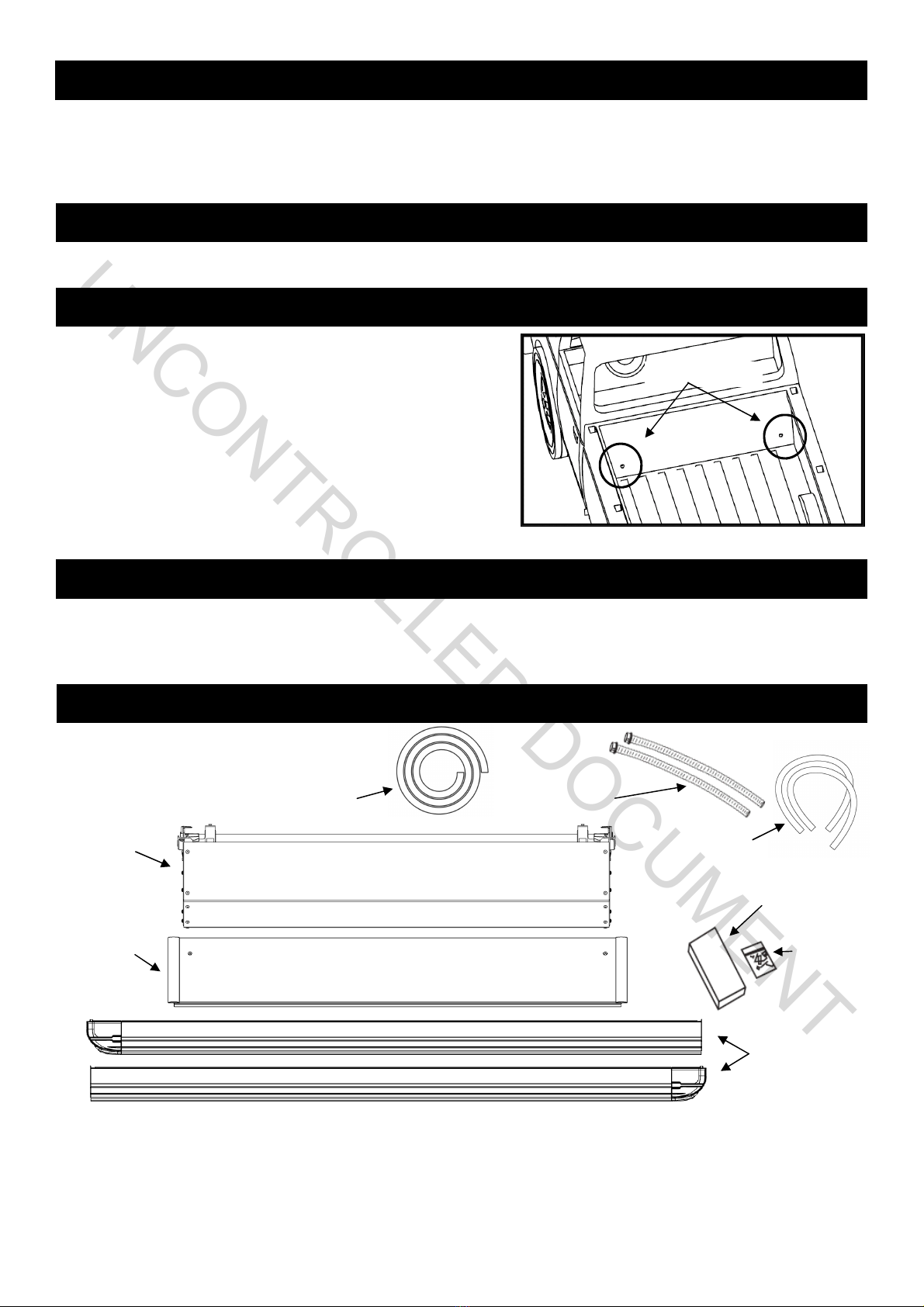

This tonneau cover is designed to carry rainwater from the cover

into the canister and then out through the drains. Most truck

models have standard OE drain holes or plastic/rubber access

ports in the front of the truck bed. Check to make sure your truck

has the OE drain holes so that drilling into the sheet metal is not

required. If drilling is necessary, be sure to check the underside

of the truck bed for the best location. The holes should be

located near the side and as far forward as possible. Use a drill

bit suitable for sheet metal (such as a taper drill or step drill). Drill

drain tube clearance holes at 3/4” (19mm). This will need to be

done before installing the cover.

TOOLS REQUIRED FOR ASSEMBLY

BEFORE YOU START!

CANISTER DRAIN HOLE LOCATIONS:

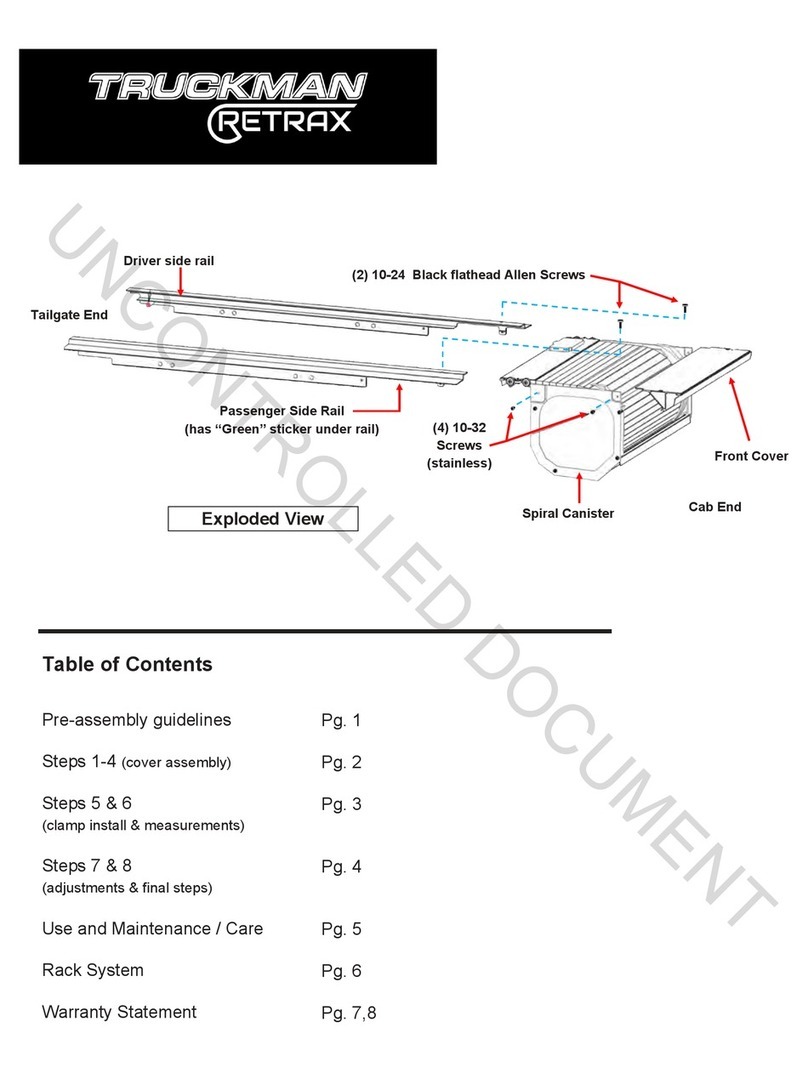

STEP 1: REMOVE FROM PACKAGING AND REVIEW CONTENTS

Tape Measure Side Cut or Needle Nose Pliers Masking tape 7/16” (11mm) Nut Driver

#2 Phillips Screwdriver Utility Knife

Note: There should be no drilling into the truck body needed on most standard or full-size trucks.

PACKAGING CONTENTS:

Complete

Canister

Assembly

Top Cover

Canister Drain

Tubes

Clamp Pack

Rails (Left

and Right)

Hardware

Pack

Drain Tube

Read the instructions carefully before you start. If you have any questions regarding the installation please call

Truckman at +44 (0) 1384 485405.

Top Cover

Foam

Tailgate Drain

Tubes

A complete unit will consist of the Rails, Top Cover, Canister Assembly, Clamp Pack, Hardware Pack, Foam and

Drain Tubes. Remove the components from the packaging carefully in order to avoid loss or damage. Perform a

quick inventory of the packaging contents to ensure the kit is complete.

UNCONTROLLED DOCUMENT

2

Use the Pull Strap and the canister body to lift and steady the

unit. Wrap the Pull Strap around the center of the canister a

couple times and double it up in your hand. (If you have

someone to help you, you can jump to step 3 and install the

assembled canister and rails on the truck)

Place the Canister in truck bed just behind the cab

and center it from side to side. You will need to

place the canister on elevating objects, such as the

box the canister came in or buckets. Note:

Ensuring that the canister is centered in the bed

will help with rail installation in the next step.

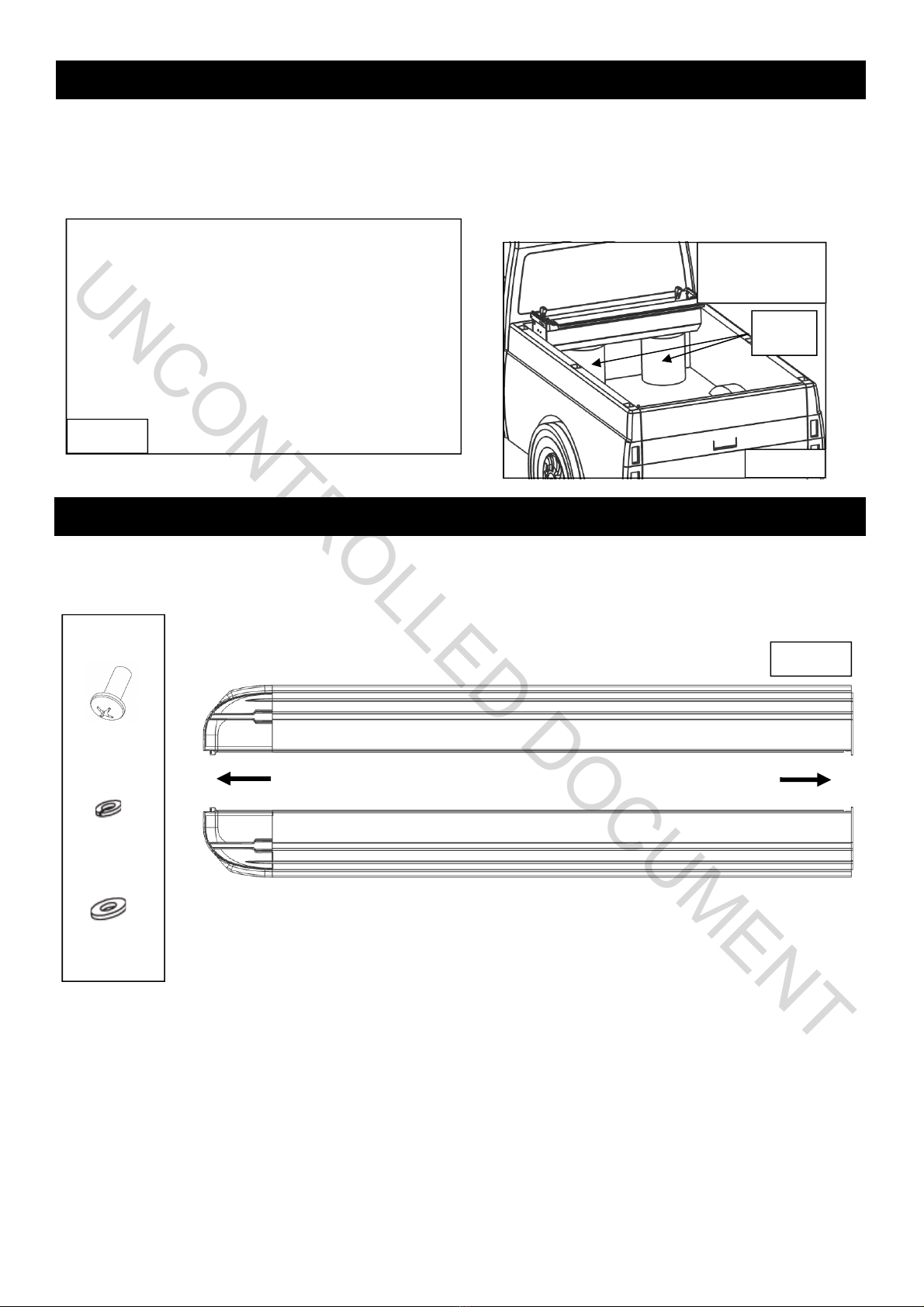

STEP 2: POSITIONING CANISTER

STEP 3: INSTALLING RAILS

FIG. 2A

FIG. 2B

Elevating

Canister needs to be

high enough to have

rail install clearance

Remove the protective paper from the foam on the underside of the Rail flanges. This is for packaging purposes

only.

Next identify the left and right side rails (FIG 3A). The rail flange and foam go towards the outside of the truck bed.

Left Rail

Right Rail

Tailgate End Cab End

HARDWARE

USED:

1/4-20 X 5/8”

RAIL SCREW

1/4” FLAT

WASHER x 2

1/4” LOCK

WASHER x 2

FIG. 3A

Note: Figure above is for reference

only and your supplied rails may be

slightly different.

UNCONTROLLED DOCUMENT

3

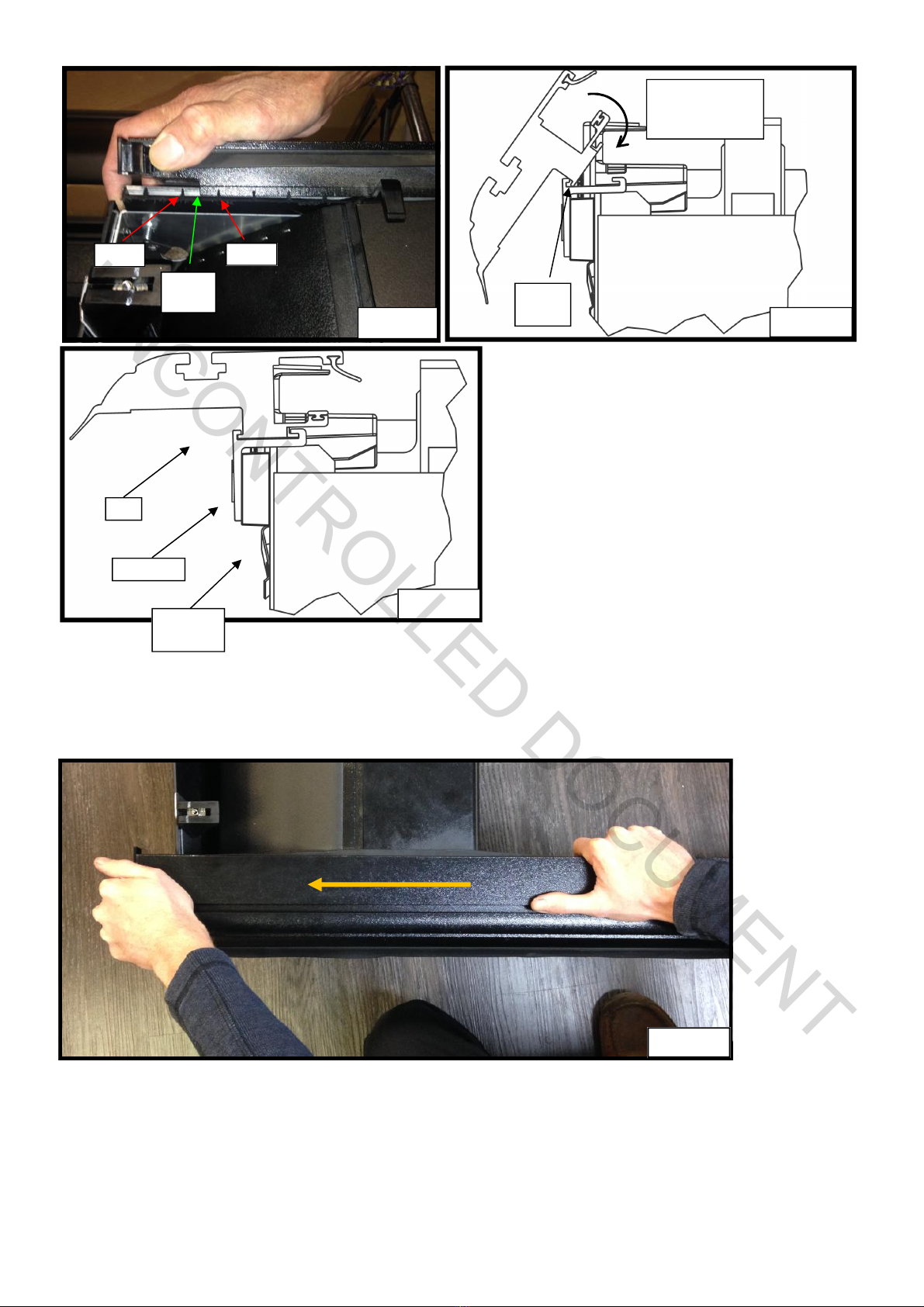

FIG. 3C

FIG. 3D

FIG. 3E

FIG. 3B

3rd Rib 4th Rib

Rail Sill

Vertical Outside

Groove

First make sure your handle latches are in, this

makes the rail install much easier (FIG 3F).

WARNING: IF YOU DO NOT HAVE THE LATCHES

IN, THE HANDLE WILL CATCH THE RAIL AS YOU

ATTEMPT TO SLIDE IT IN.

Next line up the Rail sill vertical between the 3rd and

4th Rib of the Rail Guide Spacer (FIG 3B). Then

hook the Outside Groove of the rail into the Rail

Guide and rotate down until the rail and rail guide are

level (FIG 3C & 3D). Now push the rail all the way

forward (FIG 3E). Finally you can install the Rail

Screw, Flat and Lock Washer securing the rail to the

canister (FIG 3G).

Rail Guide

Spacer

Rotate Down while

remaining in

Outside Groove

Rail Guide

Rail

UNCONTROLLED DOCUMENT

4

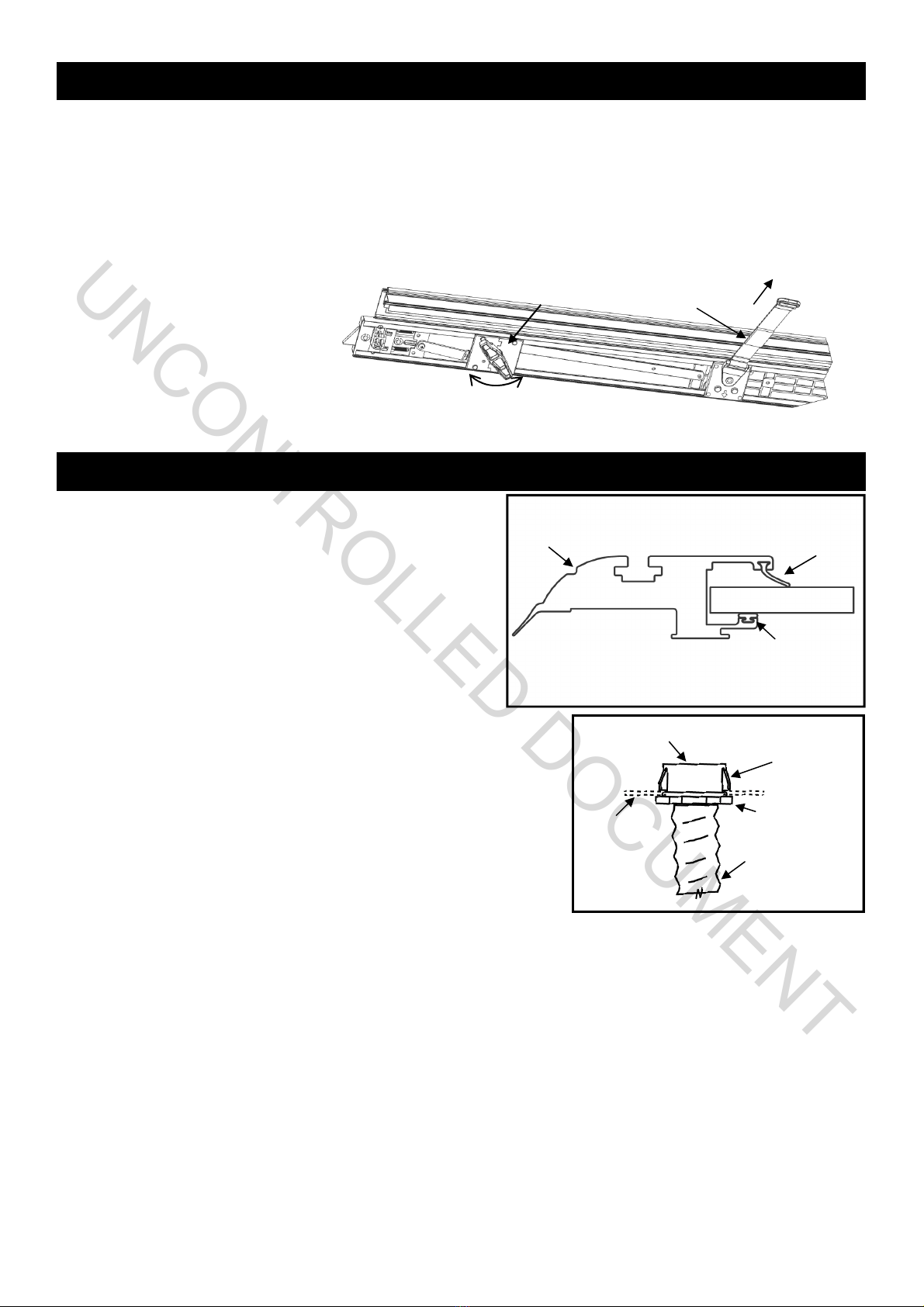

STEP 4: INSTALLING THE TOP COVER

Shut the tailgate and pull the rails back until the tailgate cap seals have good engagement

with your tailgate. A good way to check for proper engagement is to make sure the bottom

cap and tailgate have a 6mm gap (FIG 4A).

FIG. 4A

Tailgate

Bottom Cap

Tailgate

Cap Seal

The Rail shown is for

REFERENCE and may

not exactly match your

particular Rail geometry.

Canister Groove

Left Rail

Flat Washer

Lock Washer

Rail Screw

Canister

FIG. 3G

BLACK TOP COVER

SCREW x 2

180cm OF FOAM

INSTALLATION

TOOL x 1

FIG. 4C

Another way to set the tailgate cap seals is to use

the Tailgate Seal Gauge as shown in figure 4B &

4C. You should be able to just slide the Tailgate

Seal Gauge in between the Tailgate Cap Seal and

the Bottom Cap.

WARNING: Proper Tailgate Cap Seal

Engagement is important for getting the best

possible water resistance out of your cover!

BR Gauge

Tailgate Seal

Gauge

FIG. 4B

FIG. 3F

Installing the rails is easier with the handle latches

in. For information on handle operation reference

Figure 11A.

Latches In

Latches Out

6mm

UNCONTROLLED DOCUMENT

5

First assemble 4 clamp assemblies as shown in Figure 5A. Then Push the rails so that the brackets are resting

on the truck bed rail. Next Slide the pinch clamps on all 4 brackets (FIG 5B). Lightly Tighten the turn knobs

making sure that the pivot is in the orientation shown in Figure 5C so that is rotates up and reacts off the bottom

of the truck side sill. Figure 5D shows a cross section of how the clamps should look.

FIG. 5A

FIG. 5B

FIG. 5C

Flat

Washer

Lock

Washer

FIG. 5D

Pinch Clamp

Rail

Bracket

Truck

Bed Rail

Turn

Knob

Pivot

Shim

STEP 5: INSTALLING THE CLAMPS

Next mark where the front of the rails sit and mark this position with masking tape, this will be a guide for placing

your foam. (FIG 4D). Now pull the cover back until there is room to apply the foam. Lay the foam on the front sill of

the truck from rail to rail, trimming the excess with a utility knife (FIG 4E).

Now move the rails and canister back on the foam and double check that your tailgate seal engagement is good.

You can now install your top cover with the two included screws while making sure it aligns with the front of your

rails (FIG 4F).

WARNING: Proper top cover foam installation is important for getting the best possible water resistance out

of your cover!

FIG. 4E

FIG. 4D

Foam

Rail

Top Cover

FIG. 4F

UNCONTROLLED DOCUMENT

6

Once the clamps are lightly tightened,

measure the Between-the-Rail dimension at

the front and rear of the truck (FIG. 5E).

Another way to ensure proper fit is to check

the side to side play of the handle assembly

at the canister and at the tailgate end of the

rails. There should be, at the minimum,

enough play to allow the cover to move

freely with no drag and at a maximum 3mm

per side. If you push the cover you one side

you should not be able to fit the Between-the

-Rail gauge between the Rail metal and

Handle Stop on the opposite side. More than

3mm per side may result in the cover

opening unintentionally and in severe cases

it may fall between the rail tracks and

damage the cover. There are “Stick on

Shims” in the hardware pack that can be

added to the brackets if too loose.

Part number is on the

serial number label in

the upper left corner of

the canister (looking

from tailgate).

Rail

Metal

Handle

Stop

FIG. 5F

Slide the 4 Grip pieces on the rails as shown in Figure 6A. Position The Grip piece so that it is just beyond the

Relief Machining Figure 6B. Kickstands should go on the Tailgate and canister end of each rail (FIG. 6C).

STEP 6: INSTALLING THE RAIL KICKSTANDS

Grip

Rail

FIG. 6B

FIG. 6A

Relief Machining

BR Front

BR Rear

FIG. 5E

TAILGATE END

CANISTER END

FIG. 6C

PART BETWEEN

NUMBER THE RAILS

AR and AM2083 54 1/16 (137.3 cm)

BTR

UNCONTROLLED DOCUMENT

7

STEP 7: INSTALLING TAILGATE DRAINTUBES

To install the tailgate drain tubes you need to find suitable holes in

the rear stiffener of your truck bed. Figure 7B shows possible hole

locations.

Next you will screw the drain tube onto the drain fitting and slide it

on the tailgate cap as shown in figure 7C. There is an interference

bump on the cap that will lock the drain fitting in place. Next you will

need to thread the drain tube in the desired hole and trim the length

of the tube if needed. If there are no holes on the tailgate side of

your truck you will need to drill holes (5/8” or 16mm), make sure to

check for wires you could damage first.

FIG. 7A

FIG. 7B

Tailgate Drain

Fitting

Tailgate Drain

Tube

Tailgate Cap

TAILGATE DRAIN

TUBES X 2

DRAIN FITTINGS

X 2

Fasten the pre assembled Kickstand Assembly on the Grip using the provided mounting bolt, flat washer, lock

washer and wingnut (FIG. 6E). Next swing up the kickstand so that the adjusting bolt is as perpendicular to the Truck

Bed wall as possible (FIG. 6F). If you need more or less engagement you can change the length of the Kickstand by

flipping Kickstand Base (FIG. 6G). Tighten the Adjusting Bolt first by using the vinyl cap for quick adjustment, fine

tuning and higher torque can then be applied using the Turn Knob. Once the rails are level double check that your

Between-the-Rail dimension is still good and you can fully tighten the clamps.

FIG. 6F

Truck Bed

Wall

Adjusting

Bolt

Turn

Knob

Vinyl

Cap

Kickstand

Base

Flipping

Base

FIG. 6G

Longer Orientation Shorter Orientation

Mounting

Bolt Lock

Washer Wingnut

FIG. 6E

Flat

Washer

UNCONTROLLED DOCUMENT

8

Possible Hole

Locations

FIG. 7C

Locate the sweep seals (rubber weather strips) on the rails.

Open the provided 303 brand protectant sponge pack (find it

adhered to the underside of the top cover) and wipe the

underside of the sweep seal and the top of the wear strip.

Extend the cover to the tailgate. Use an Allen wrench if

needed to carefully draw out the sweep seal (seal should be

angled outwards toward the cover – not rolled in toward the

bed rail). (Fig. 8A)

Proper care and placement of the sweep seal will ensure the

smooth operation of the cover. Alcohol, petroleum based or

silicon-based UV Protectants such as Armor-All® should be

avoided and ARE NOT recommended for our covers.

STEP 8: LUBRICATING & PLACING THE SWEEP SEALS

Rail

Cover/Fabric Panel

Wearstrip

Sweep Seal

FIG. 8A

First, ensure that the Foam Washer is in place on the Drain Fitting as this washer

will help prevent water leakage. Next, test fit the drain tube to determine the length

you want to trim it. Always caution on the long side. Trim the end that will be

inserted through the truck bed using the wire cutters or a utility knife.

With the cover opened, insert the drain tube fittings into the pre-drilled holes on the

underside of the canister by pushing them in place from under the canister. Drain

Fitting should click into place.

Place the other end of the drain tube through the plastic/rubber access port or

through the pre-drilled holes in the floor or the front wall of the truck bed. If routing

through the front wall, ensure that the drain tubes are inserted and directed down

so water flows out of the truck.

To remove the drain tubes reach under the canister, grab the drain tube fitting and

turn it while applying light downward pressure. When the retaining tabs align with

notches in the bottom of the canister the Drain Tube and Fitting will drop out.

STEP 9: INSTALLING CANISTER DRAIN TUBES

Notch

Feature

Foam

Washer

Drain Fitting

Drain

Tube

FIG. 9A

Retract the cover the fully open position. Attach the

10cm Velcro strip onto the Velcro strip already

attached to the pull strap. Pull the pull strap over to

the driver’s side rail and remove the tape from the

10cm Velcro strip. Then apply the Velcro strip onto the

underside of the rail at your desired position. This will

hold the pull strap off of the floor and out of the way

when cargo is being stored in the truck bed.

STEP 10: ATTACH THE PULL STRAP

10cm VELCRO

STRIP

FIG. 10A

UNCONTROLLED DOCUMENT

9

To help keep your Retractable Tonneau Cover looking it’s best,

we recommend washing it the same as caring for your truck

finish. However you should not wax your cover. Using a citrus-

based vinyl cleaner and protectant such as 303 brand

protectant will keep your cover looking like new.

To assure quiet, smooth operation, periodically apply a

generous amount of the same 303 brand or equivalent

protectant to a rag and wipe out the inside of the rails the

underside of the sweep seal and the top of the wear strip.

Repeat as needed until these components are cleaned of debris

and well lubricated.

Ensure proper placement of the sweep seal as shown in step 8. Re-apply

protectant/lubricant if the cover begins squeaking or sticking during use.

(FIG. 8A)

Alcohol, petroleum based or silicon-based cleaners such as

Armor-All® should be avoided and ARE NOT recommended for our

covers.

It is important to open and close the cover regularly; the spring that

operates the cover is self-lubricated and regular use assures that it stays

in proper working condition.

Periodically remove the Top Cover and clean out the inside of the canister.

Drain tubes may become clogged overtime and should be removed and cleaned. To remove the drain tubes reach

under the canister, grab the drain tube fitting and turn it while applying light downward pressure. When the retaining

tabs align with notches in the bottom of the canister the Drain Tube and Fitting will drop out. (FIG. 9A and FIG. 12A)

Drain Tube Fitting

Retaining Tab

Foam Washer

Canister

Drain Tube

FIG. 12A

MAINTENANCE

Rail

Cover/Fabric Panel

Wearstrip

Sweep Seal

FIG. 8A

1. To open the cover, turn the actuator knob clockwise 90o until it clicks in the open position. This retracts the

latches into the handle and the cover is free to roll open into the canister. A tug on the pull strap will release the

latch and allow the cover to lock into the rails.

2. To latch the cover in one of the mid-range positions, pull it back just beyond the position desired and allow the

cover to retract until it latches into place. Latching positions are located every 30cm along the rails. The clicking

sound is the spring-loaded latches mounted inside the handle. The latches are designed to bypass the latching

positions as the cover is being closed and to stop the cover as it is being retracted.

3. To close the cover, pull on the

strap to draw it back toward the

tailgate. When it is within easy

reach, grasp the handle by the

hand grip and pull the cover to

the latching position against

the tailgate.

OPERATING INSTRUCTIONS

ACTUATOR KNOB PULL

STRAP

FIG 11A

UNCONTROLLED DOCUMENT

10

On your purchase of a Roll-Top Xtreme by Truckman. We are confident that you will get many years of trouble

free service from this accessory on your truck.

Truckman (hereinafter referred to as the MFG.) warrants each new

Roll-Top Xtreme retractable truck bed cover to the original owner as

follows:

FOR A PERIOD OF 3 YEARS FROM THE DATE THE UNIT IS

DELIVERED TO THE FIRST PURCHASER:

• Delamination of the Fabric Panel Assembly

• Failure of the Continuous Tension Spring

• All hardware and components

ITEMS NOT COVERED UNDER WARRANTY FOR ANY PERIOD

OF TIME:

• Rips, tears, or discoloration of the Fabric Panel material

• Seals and gaskets

• Water intrusion from any source

• Dealer and/or purchaser installed parts and accessories

CERTAIN CONDITIONS WILL VOID ALL WARRANTY.

These conditions include:

• Use for any purpose other than normal private use including

rental and promotion

• Altering the retractable truck bed cover in any manner without

written approval of the MFG

• Misuse, negligence or accident

• Installation of any part or accessory without written approval from

the MFG

CONGRATULATIONS!

CLAIMS:

If you have any warranty issues, please contact Truckman at +44 (0) 1384 485405 with the original invoice, the Unit Model and Serial Number.

After determining the validity of the warranty claim, Truckman will ship a replacement part prepaid to the customer. Labour costs to replace

defective parts are the responsibility of the purchaser.

CONDITIONS AND LIMITATIONS

This warranty is subject to certain conditions and limitations including,

but not limited to, the following:

• Any part of a Roll-Top Xtreme by Truckman retractable tonneau

that is found to be defective under the terms of this warranty will

be repaired or replaced using either new or reconditioned parts at

the discretion of the MFG.

• In determining what constitutes a failure under the terms of this

warranty the decision of the MFG shall be final.

• This warranty is extended to the original purchaser only and is not

transferable to subsequent purchasers.

• The MFG does not accept any responsibility in connection with

the installation of any of its products by its dealers or agents.

• The MFG does not undertake responsibility to any purchaser for

warranty express or implied by any of its dealers, distributors or

agents beyond that which is contained herein.

• Without regard to an alleged defect of its products the MFG under

any circumstances does not assume responsibility for loss of

time, inconvenience, revenue, or other consequential damage

including, but not limited to, expenses for telephone, food,

lodging, travel, loss or damage to the vehicle the products are

installed on or loss or damage to personal property of the

purchaser or user of the products.

• The MFG reserves the right to make changes in the design of,

improvements to, or warranty of its products without imposing any

obligation upon itself to provide the same for any products

theretofore manufactured.

Some jurisdictions do not allow limitations on or exclusions to

warranties, therefore some of the exclusions may not apply to you.

This warranty affords you specific legal rights. You may have other

legal rights that may vary from jurisdiction to jurisdiction.

TRUCKMAN PRODUCT WARRANTY

Truckman

Unit 14 Narrowboat Way

Dudley

West Midlands

DY2 0EZ

Telephone: +44 (0) 1384 485405

http://www.truckman.co.uk

UNCONTROLLED DOCUMENT

UNCONTROLLED DOCUMENT

Table of contents

Other Truckman Automobile Accessories manuals

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction