............ www.truemfg.com ............

True Food Service Equipment, Inc.

33

SAFETY INFORMATION

Thepowercordofthisapplianceisequippedwitha

groundingplugwhichmateswithastandardgrounding

walloutlettominimizethepossibilityofelectricshock

hazardfromthisappliance.

Havethewalloutletandcircuitcheckedbyaqualified

electriciantomakesuretheoutletisproperlygrounded.

Iftheoutletisastandard2-prongoutlet,itisyour

personalresponsibilityandobligationtohaveitreplaced

withtheproperlygroundedwalloutlet.

Theheatedcabinetshouldalwaysbepluggedintoit’s

ownindividualelectricalcircuit,whichhasavoltage

ratingthatmatchestheratingplate.

Thisprovidesthebestperformanceandalsoprevents

overloadingbuildingwiringcircuitswhichcouldcausea

firehazardfromoverheatedwires.

Neverunplugyourcabinetbypullingonthepowercord.

Alwaysgripplugfirmlyandpullstraightoutfromthe

outlet.

Repairorreplaceimmediatelyallpowercordsthathave

becomefrayedorotherwisedamaged.Donotuseacord

thatshowscracksorabrasiondamagealongitslengthor

ateitherend.

Whenremovingthecabinetawayfromthewall,be

carefulnottorolloverordamagethepowercord.

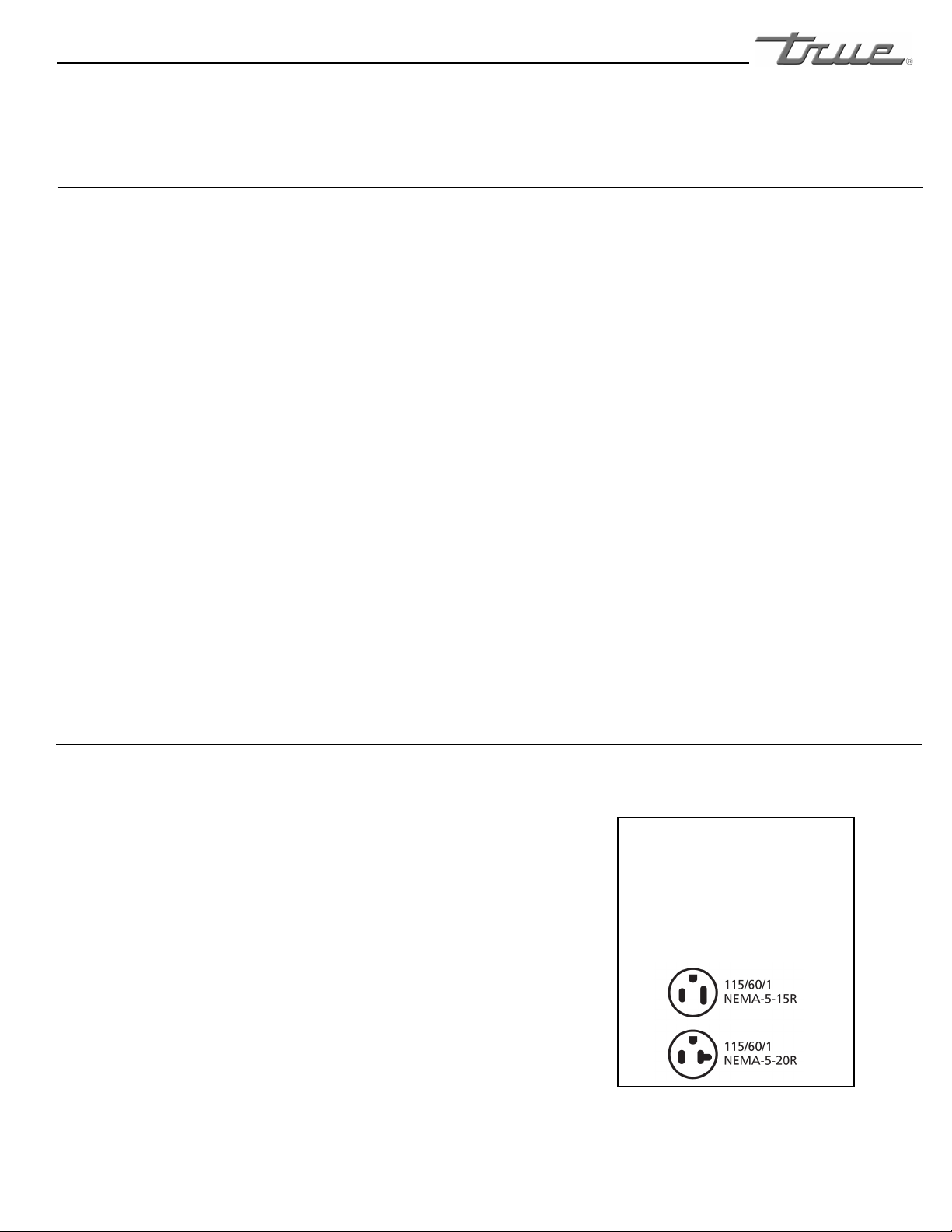

HOW TO CONNECT ELECTRICITY

Do not, under any circumstances, cut or remove the ground prong from the power cord.

For personal safety, this appliance must be properly grounded.

WARNING!

USE OF EXTENSION CORDS / ADAPTER PLUGS

Do not use adapter plugs or extension leads as these can cause safety issues and early failure of electrical components.

The use of adapters and extension cords will invalidate your warranty. NEVER USE AN EXTENSION CORD! NEVER USE AN

ADAPTER PLUG!

WARNING

Power supply cord ground should not be removed!

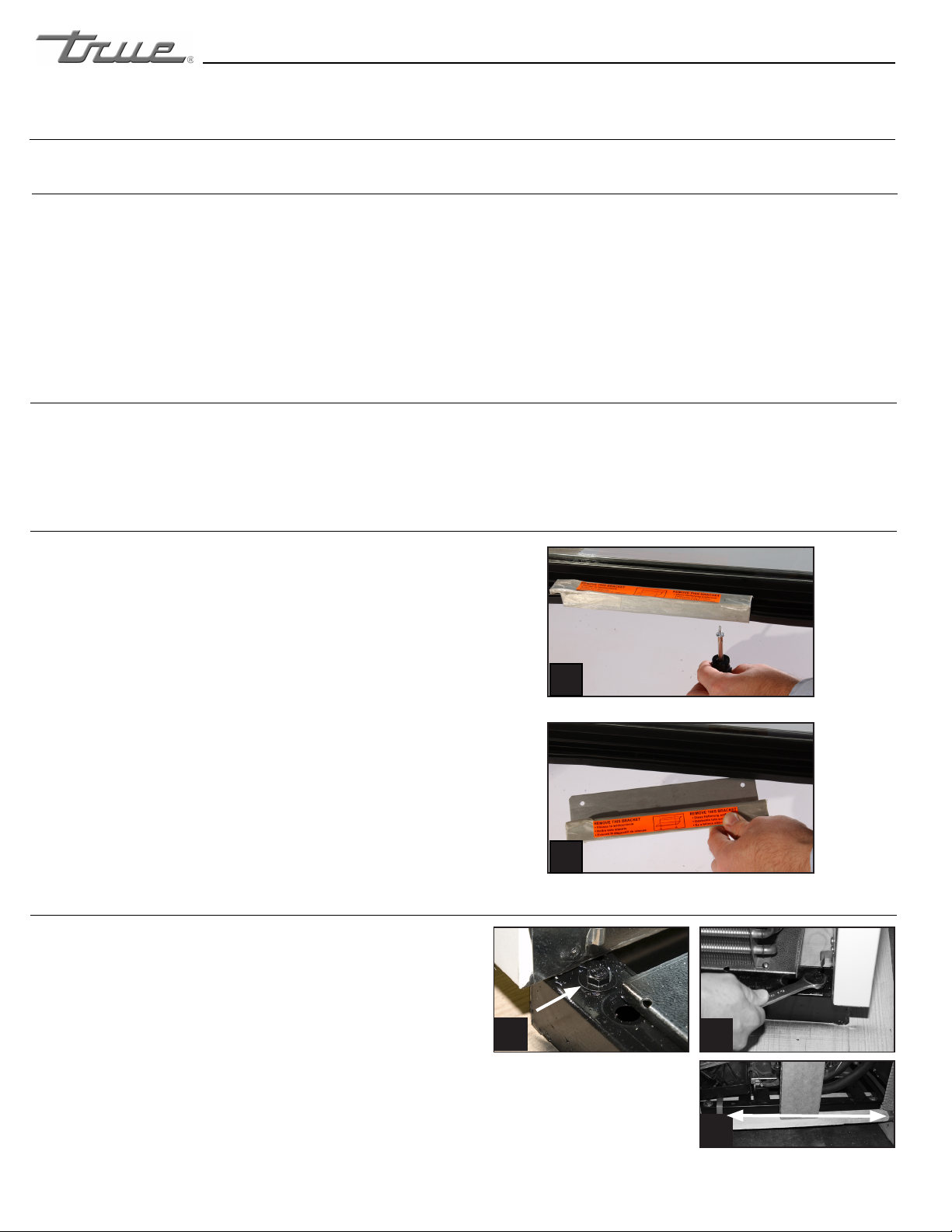

NOTE

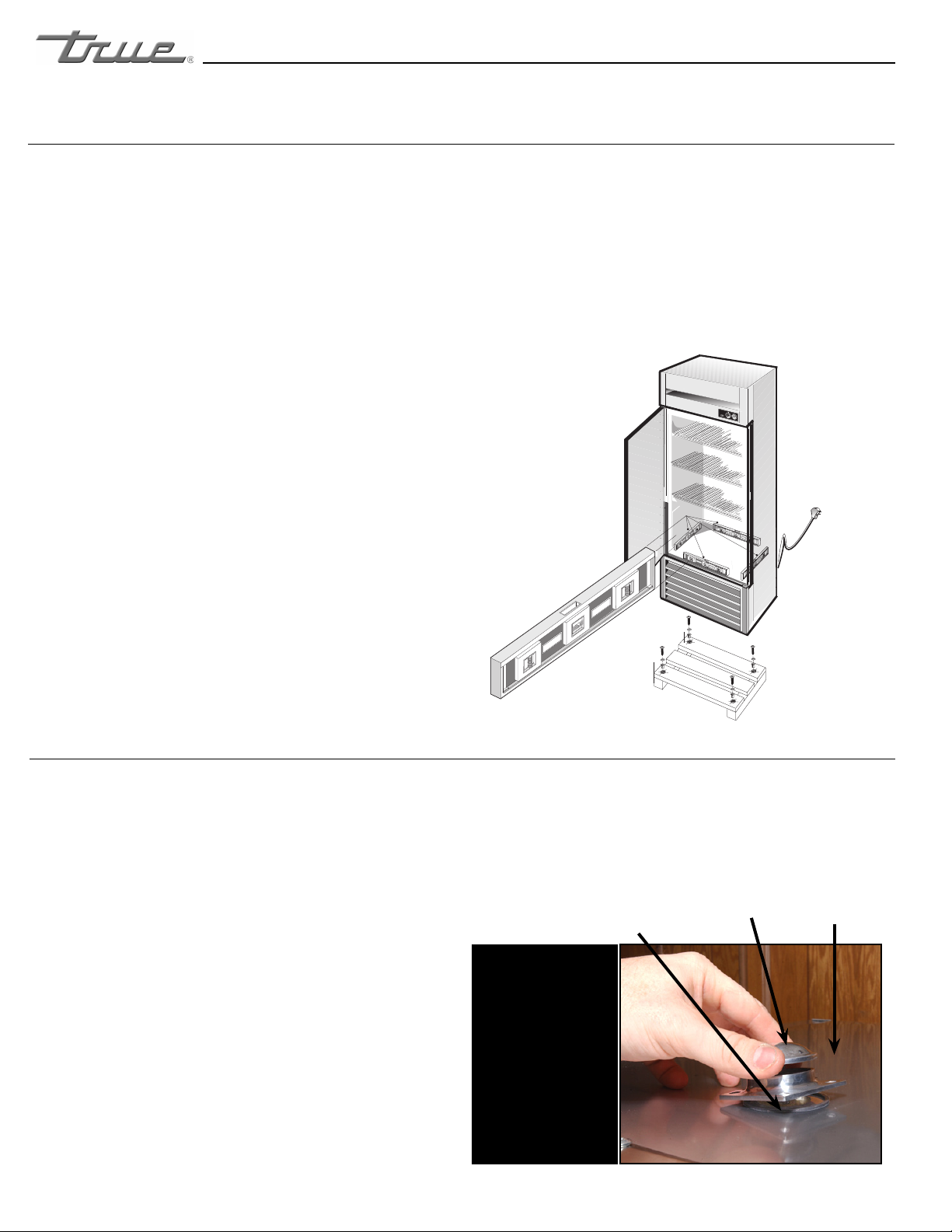

To reference wiring diagram - Remove lower rear grill.

Wiring diagram is positioned on the inside cabinet wall.

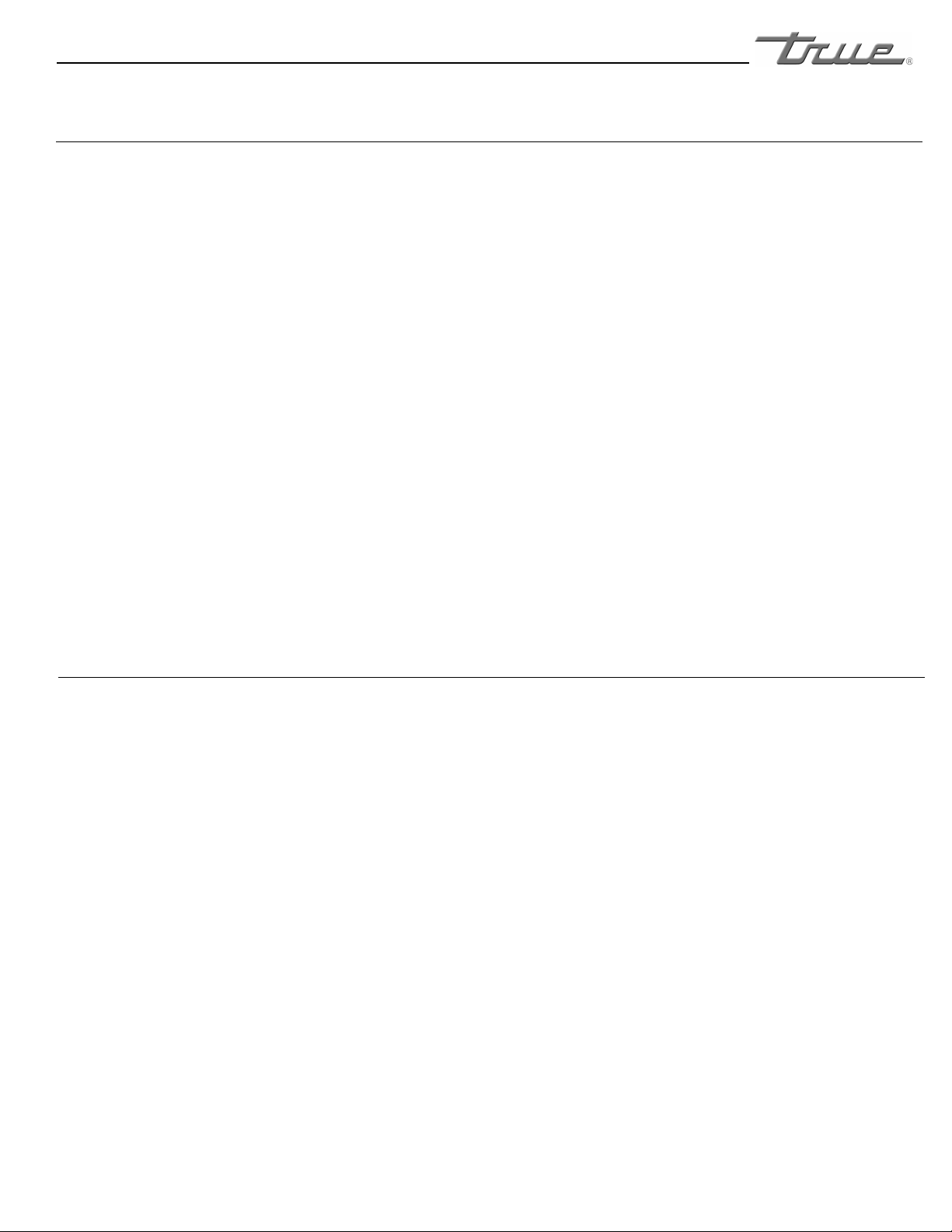

NEMA plugs

TRUE uses these types of

plugs. If you do not have

the right outlet have a

certied electrician install

the correct power source.